热轧马氏体和贝氏体双相钢扩孔性能及机理

陈继平1,董玉庆1,钱健清1,康永林2

(1. 安徽工业大学 冶金工程学院,安徽 马鞍山,243002;

2. 北京科技大学 材料科学与工程学院,北京,100083)

摘要:对热轧马氏体双相钢和贝氏体双相钢进行扩孔试验,利用金相显微镜和扫描电镜对2种双相钢扩孔裂纹和断面组织进行分析,研究2种双相钢的扩孔开裂机理,并分析预制孔为冲孔时的扩孔率小于预制孔为钻孔时的原因。研究结果表明:热轧贝氏体双相钢断口微观形态的主要特征是韧窝,开裂类型属于穿晶延性断裂。热轧马氏体双相钢断口微观形态的主要特征是舌状花样,开裂类型属于沿晶脆性断裂。预制孔为冲孔时扩孔率较低的主要原因是扩孔过程在圆孔边部产生加工硬化层和毛刺,且加工硬化层起着主导作用,如在扩孔前用砂纸或锉刀去除2 mm厚加工硬化层和毛刺,或采用钻孔等方法加工中心孔,其扩孔率将大幅提高。

关键词:热轧双相钢;扩孔;加工硬化;扩孔机理

中图分类号:TG31 文献标志码:A 文章编号:1672-7207(2014)02-0395-06

Hole expansion property and mechanism of ferrite+martensite and ferrite+bainite hot-rolled dual phase steels

CHEN Jiping1, DONG Yuqing1, QIAN Jianqing1, KANG Yonglin2

(1. School of Metallurgical Engineering, Anhui University of Technology, Maanshan 243002, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Hole expansion tests were conducted for hot-rolled ferrite+martensite dual phase steel and ferrite+bainite dual phase steel. Metallographic microscope and scanning electron microscope were used to observe the expansion crack and sectional microstructure to analyze the cracking mechanism. The causes of lower hole expansion property of the preformed hole produced by piercing than that of drilled hole for hot-rolled dual phase steels were also studied. The results show that the ferrite+bainite dual phase steel exhibits transgranular ductile fracture with dimples. The ferrite+martensite dual phase steel displays fracture features of tongue pattern and intergranular brittle fracture. Lower hole expansion value for pierced hole samples is caused by work hardening layer and burr. The work hardening layer plays a dominant role. If the burr and work hardening layer about 2 mm away from the hole edge are removed by sandpaper or file, or the hole is preformed by drilling, the hole expansion performance will be improved greatly.

Key words: hot-rolled dual phase steel; hole expansion; work hardening; cracking mechanism

近年来,随着汽车向轻量化、节能减排和高安全性方向发展,高性能热轧双相钢以其强度高、屈强比低、初始加工硬化率高、低的屈强比以及连续屈服等优良的冲压和成形性能,被广泛地应用于汽车的保险杠、车门、车轮以及车体的纵向横梁等各种安全零部件中[1-7]。许多学者对扩孔过程中裂纹形成及扩展机理进行研究。丁昊等[8]认为铁素体贝氏体双相钢中的裂纹扩展主要是以微孔聚集机制进行,裂纹会通过铁素体贝氏体相界面并剪断铁素体进行扩展。王卫卫等[9]认为扩孔裂纹的扩展与试验钢成分、微观组织和裂纹尖端形貌有关,扩孔裂纹扩展机制为微孔聚集模式。李秀华等[10]分析铁素体贝氏体双相钢的断裂类型及断裂机理,认为铁素体贝氏体双相钢在扩孔过程中的断裂类型为韧性断裂,断裂机理为微孔聚集断裂机制。Fang等[11]阐明了预制圆孔的孔缘是扩孔成形的变形危险区,当该处的伸长变形超过材料的成形极限时,就会导致局部集中变形而产生裂纹或破裂。文献中主要分析了铁素体贝氏体双相钢的断裂机理,对马氏体双相钢的裂纹扩展和断裂机理以及预制孔加工方法对马氏体双相钢和贝氏体双相钢扩孔性能的影响则没有相关报道。本文作者通过对扩孔后的热轧贝氏体双相钢和马氏体双相钢试样断口进行金相显微镜和扫描电镜分析,研究热轧双相钢裂纹开裂位置和扩展路径,并分析了预制孔为冲孔时比钻孔时扩孔率高的原因。

1 试验材料和方法

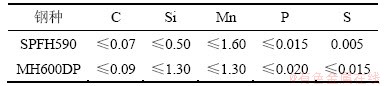

采用NHB-30A多功能板料成形机对热轧贝氏体双相钢SPFH590(约25%贝氏体+75%铁素体,质量分数)和马氏体双相钢MH600DP(约15%马氏体+85%铁素体,质量分数)进行扩孔试验,试验用热轧贝氏体双相钢SPFH590和马氏体双相钢MH600DP的化学成分和力学性能分别如表1和表2所示。

表1 试验用双相钢的化学成分(质量分数)

Table 1 Chemical compositions of dual phase steels %

表2 试验用双相钢的力学性能

Table 2 Mechanical properties of dual phase steels

2 扩孔机理

采用金相显微镜和扫描电镜从微观角度对扩孔机理进行了研究,并分析了预制孔为冲孔时扩孔性能较差的原因。

2.1 扩孔断口分析

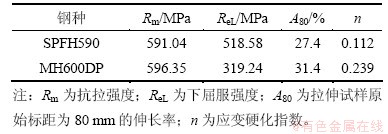

在扩孔试样开裂位置附近(包含断口)切取长×宽为10 mm×10 mm的小试样,用酒精进行清洗。采用JSM-6490LV扫描电镜对裂纹正面进行扫描分析,分析热轧贝氏体双相钢和热轧马氏体双相钢的裂纹走向。热轧贝氏体双相钢和热轧马氏体双相钢扩孔后裂纹处的SEM照片如图1所示,预制孔为冲孔,凸模为锥模。

由图1可见:热轧贝氏体双相钢裂纹尾部长度短于热轧马氏体双相钢的裂纹尾部长度,且热轧贝氏体双相钢裂纹尾部较曲折,热轧马氏体双相钢较平直。热轧贝氏体双相钢主裂纹上易滋生二次裂纹,热轧马氏体双相钢上滋生的二次裂纹较少,同时,热轧贝氏体双相钢裂纹起源处圆角较大,热轧马氏体双相钢裂纹起源处较尖。

2.2 金相分析

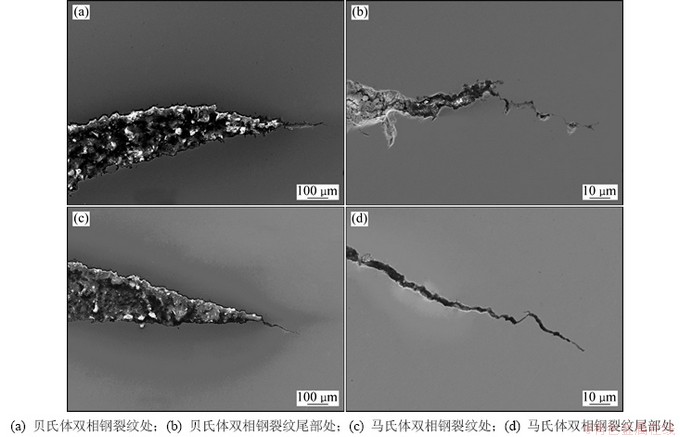

在扩孔试样开裂位置附近(包含断口)切取长×宽为10 mm×10 mm的小试样,镶嵌磨制抛光后用4%硝酸酒精进行腐蚀,采用Leica Axiovert 40MAT金相显微镜观察扩孔裂纹走向。热轧贝氏体双相钢和热轧马氏体双相钢裂纹尾部处组织如图2所示。

扩孔试验结果表明,热轧双相钢组织对板料的扩孔性能影响较大。在凸模为锥模、毛刺朝上的条件下,热轧贝氏体双相钢的平均扩孔率为70.82%,热轧马氏体双相钢的平均扩孔率为22.42%,热轧贝氏体双相钢的平均扩孔率大于热轧马氏体双相钢的扩孔率。

热轧马氏体双相钢中的铁素体和马氏体两相之间的力学性能和理化性能的差异较热轧贝氏体双相钢中铁素体和贝氏体两相性能差异大,这种差异导致晶界之间结合力减弱,同时两相变形抗力不等,在挤压力作用下,因变形程度不同产生附加应力导致产生裂纹,这种裂纹常常发生在两相界面处。热轧贝氏体双相钢两相之间在力学性能和理化性能上的差异没有马氏体双相钢明显,有助于改善硬相的韧性,使两相在塑性变形阶段表现出一定的相容性,变形较为协调,当铁素体产生较大塑性变形时,贝氏体也可能产生屈服,减少了两相界面产生孔洞或微裂纹的几率。另外,由于铁素体是软相,当孔洞或微裂纹产生在铁素体内时,强度较低的铁素体在应力场的作用下产生较大的塑性变形,减弱了裂纹附近的局部应力集中,从而阻止裂纹扩展,改善了钢材的塑性及抗裂纹扩展性能,扩孔裂纹常常穿过铁素体基体或两相[12-13]。因此,热轧马氏体双相钢比热轧贝氏体双相钢容易开裂,热轧马氏体双相钢的扩孔性能不如热轧贝氏体双相钢。

图1 热轧双相钢裂纹处和裂纹尾部SEM图

Fig. 1 SEM micrographs of crack and crack tail of hot-rolled dual phase steels

图2 热轧双相钢裂纹尾部处组织图

Fig. 2 Microstructures of crack tail of hot-rolled dual phase steels

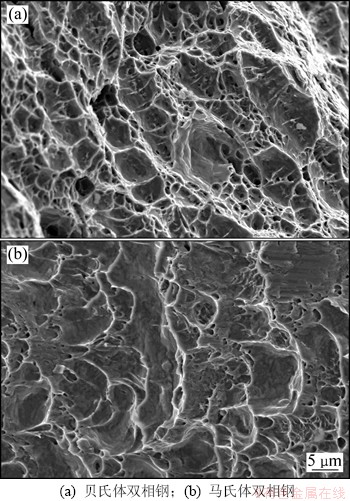

2.3 断口SEM分析

对热轧贝氏体双相钢和马氏体双相钢扩孔试样的断口进行扫描电镜观察,分析热轧马氏体双相钢和热轧贝氏体双相钢的扩孔开裂类型。热轧贝氏体双相钢和马氏体双相钢扩孔试样的断口形貌如图3所示。由图3可见:热轧贝氏体双相钢的开裂类型属于穿晶延性断裂,断口微观形态的主要特征是韧窝。韧窝是由一些大小不等的圆形或椭圆形的凹坑组成,它是材料微区塑性变形产生的显微空隙聚集长大,以至毗邻,材料断裂在断口表面上留下的痕迹。显微空隙是由于第二相粒子与基体的弹性和塑性性能的差异,塑性变形不一致或第二相粒子本身断裂而形成的。在晶界、二次相界面、亚晶界夹杂物以及位错堆积区等应变不连续的地方,当整体或局部过载时,均可生成大量的显微空隙[14-16]。热轧马氏体双相钢的开裂是非微孔聚合型的断裂,开裂类型属于沿晶脆性断裂,断口微观形态的主要特征是舌状花样。晶界面上一般相当平滑,整个断面上多面体感很强。

2.4 预制孔的加工方法对扩孔性能影响

选择热轧贝氏体双相钢来考察预制孔为冲孔和钻孔时对扩孔率的影响,热轧贝氏体双相钢的扩孔性能如表3所示。预制孔为冲孔(左)和钻孔(右)时的扩孔情况如图4所示。

图3 热轧双相钢断口形貌

Fig. 3 Fracture morphology of hot-rolled dual phase steels

表3 热轧贝氏体双相钢的扩孔性能

Table 3 Hole expansion property of hot-rolled ferrite+bainite dual phase steels

由表3可知:在凸模同为锥模的条件下,预制孔为钻孔时的平均扩孔率为197.72%,其扩孔率远大于预制孔为冲孔时的平均扩孔率69.92%。

在热轧贝氏体双相钢和热轧马氏体双相钢试样上进行冲孔,通过观察孔缘和远离孔缘内部组织的差异变化来分析预制孔为冲孔时其扩孔性能较差的原因。2种双相钢孔缘处和内部的金相组织如图5所示。由图5可以看出,试样孔缘处晶粒被拉长,呈现一定的方向性。而远离孔缘处,晶粒呈现等轴状。冲裁加工使得孔缘处晶粒发生了明显的改变,产生了加工硬化层、表面凸凹不平乃至微小裂纹,这些原因使得试样伸长变形能力大幅下降。

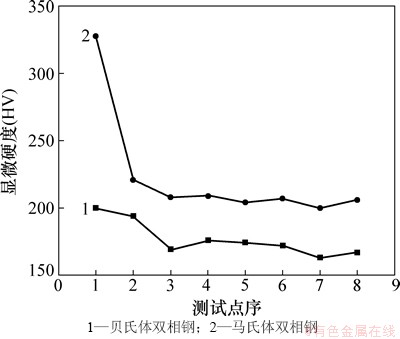

采用HV-1000 Microhardness Tester显微维氏硬度计对扩孔试样进行显微硬度测定,取扩孔试样的1/4进行试验,由中心孔圆弧面垂直向内每间隔1 mm打一点。维氏硬度测定载荷为0.2 kg,载荷持续作用时间为15 s。热轧贝氏体双相钢和马氏体双相钢冲孔试样显微硬度如图6所示。

图4 预制孔为冲孔(左)和钻孔(右)时的扩孔试样

Fig. 4 Hole expansion samples for pierced hole (left) and drilled hole(right)

图5 热轧双相钢孔缘处和内部组织

Fig. 5 Microstructures of hot-rolled dual phase steels

从图6可以看出:热轧贝氏体双相钢的显微硬度值变化相对较小,热轧马氏体双相钢显微硬度变化较大。产生此硬度的变化,正是源自冲孔后发生的加工硬化。此外,通过硬度测试还能发现,冲孔试样的加工硬化区域大概在距圆孔约2 mm之内。

图6 热轧贝氏体双相钢和马氏体双相钢冲孔试样显微硬度曲线

Fig. 6 Microhardness curves of pierced samples for hot-rolled ferrite+bainite and ferrite+martensite dual phase steels

3 结论

(1) 热轧贝氏体双相钢的扩孔率比热轧马氏体双相钢高,原因是热轧马氏体双相钢裂纹扩展相对容易,属于脆性断裂,而热轧贝氏体双相钢属于韧性断裂。

(2) 热轧贝氏体双相钢断口微观形态的主要特征是韧窝,开裂类型属于穿晶延性断裂;热轧马氏体双相钢断口微观形态的主要特征是舌状花样,开裂类型属于沿晶脆性断裂。

(3) 预制孔为冲孔时扩孔率低的最主要原因是冲孔过程在圆孔边缘产生加工硬化层和毛刺,且加工硬化层起到主导作用。若在扩孔前去除2 mm厚加工硬化层和毛刺,或者采用钻孔等方法加工中心孔则扩孔率将大幅提高。

参考文献:

[1] 康永林. 现代汽车板工艺及成形理论与技术[M]. 北京: 冶金工业出版社, 2009: 130-145.

KANG Yonglin. Theory and technology of processing and forming for advanced automobile steel sheets[M]. Beijing: Metallurgical Industry Press, 2009: 130-145.

[2] Takahashi M. Development of high strength steels for automobiles[J]. Nippon Steel Technical Report, 2003(88): 8-12.

[3] Yan B. 用于汽车车身面板的新型双相钢[J]. 世界钢铁, 2003(5): 32-38.

Yan B. New type dual phase steels for autobody panel[J]. World Iron & Steel, 2003(5): 32-38.

[4] Hyun D I, Oak S M, Kang S S, et al. Estimation of hole flangeability for high strength steel plates[J]. Journal of Materials Processing Technology, 2002, 130/131: 9-13.

[5] 郑芳, 郑磊. 成分对经济型热轧双相钢性能的影响研究[J]. 宝钢技术, 2007(2): 30-34.

ZHENG Fang, ZHENG Lei. Effect of chemical composition on economical hot-rolled DP steel’s properties[J]. Baosteel Technology, 2007(2): 30-34.

[6] 董瑞峰, 孙丽钢, 刘哲, 等. 汽车结构用590 MPa级热轧双相钢的开发[J]. 轧钢, 2008, 25(1): 9-12.

DONG Ruifeng, SUN Ligang, LIU Zhe, et al. Development of 590 MPa dual-phase hot strip steel for automobile structure[J]. Steel Rolling, 2008, 25(1): 9-12.

[7] 黄群飞, 何燕霖, 李麟. 高性能双相钢的研究进展[J]. 热处理技术与装备, 2007, 28(3): 11-14.

HUANG Qunfei, HE Yanlin, LI Lin. Study progress of high property DP steel[J]. Heat Treatment Technology and Equipment, 2007, 28(3): 11-14.

[8] 丁昊, 丁桦, 唐正友, 等. 热轧FB扩孔钢的组织性能研究[J]. 轧钢, 2008, 25(3): 16-21.

DING Hao, DING Hua, TANG Zhengyou, et al. Study on microstructure and mechanical properties of a hot rolled hole flanging FB steel[J]. Steel Rolling, 2008, 25(3): 16-21.

[9] 王卫卫, 丁桦, 唐正友, 等. 铁素体贝氏体钢的扩孔性能[J]. 钢铁研究学报, 2009, 21(6): 48-52.

WANG Weiwei, DING Hua, TANG Zhengyou, et al. Stretch-flangeability of ferrite-bainite steel[J]. Journal of Iron and Steel Research, 2009, 21(6): 48-52.

[10] 李秀华, 吕伟, 张凌云. 对扩孔试验用凹模圆角半径的探讨[J]. 辽宁工程技术大学学报, 2007, 26(1): 123-124.

LIU Xiuhua, L Wei, ZHANG Lingyun. Research on central angle of female die in hole expanding test[J]. Journal of Liaoning Technical University, 2007, 26(1): 123-124.

Wei, ZHANG Lingyun. Research on central angle of female die in hole expanding test[J]. Journal of Liaoning Technical University, 2007, 26(1): 123-124.

[11] Fang X, Fan Z, Ralph B, et al. Effects of tempering temperature on tensile and hole expansion properties of a C-Mn steel[J]. Journal of Materials Processing Technology, 2003, 132(1/2/3): 215-218.

[12] 蔡明晖, 丁桦, 张建苏, 等. 经济型铁素体/贝氏体高扩孔钢的组织与性能[J]. 钢铁, 2008, 43(8): 77-80.

CAI Minghui, DING Hua, ZHANG Jiansu, et al. Microstructures and properties of ferrite/bainite dual-phase steels with high hole-expanding ratio[J]. Iron and Steel, 2008, 43(8): 77-80.

[13] 蔡明晖, 丁桦, 张建苏, 等. 铁素体/贝氏体双相钢的变形和断裂特性[J]. 材料研究学报, 2009, 23(1): 83-88.

CAI Minghui, DING Hua, ZHANG Jiansu, et al. Deformation and fracture characteristics of ferrite/bainite dual-phase steels[J]. Chinese Journal of Materials Research, 2009, 23(1): 83-88.

[14] 蔡明晖. 高延伸凸缘型铁素体/贝氏体钢的组织演变及力学行为[D]. 沈阳: 东北大学材料与冶金学院, 2009: 98-113.

CAI Minghui. Microstructural evolution and mechanical behavior of ferrite/bainite steels with high stretch- flangeability[D]. Shenyang: Northeastern University, School of Materials and Metallurgy, 2009: 98-113.

[15] Narayanasamy R, Narayanan C S, Padmanabhan P, et al. Effect of mechanical and fractographic properties on hole expandability of various automobile steels during hole expansion test[J]. The International Journal of Advanced Manufacturing Technology, 2010, 47(1/2/3/4): 365-380.

[16] 钟群朋, 赵子华. 断口学[M]. 北京: 高等教育出版社, 2005: 131-240.

ZHONG Qunpeng, ZHAO Zihua. Fractography[M]. Beijing: Higher Education Press, 2005: 131-240.

(编辑 赵俊)

收稿日期:2013-05-05;修回日期:2013-09-10

基金项目:“十一五”国家科技支撑计划项目(2006BAE03A13)

通信作者:陈继平(1975-),男,安徽肥东人,博士,讲师,从事汽车钢板研究;电话:0555-2311571;E-mail:leavejames944316@aliyun.com