粉末活性炭/超滤组合工艺处理微污染含藻水效果

刘永旺1,李星1,杨艳玲1,梁爽2,刘玲1,任家炜1

(1. 北京工业大学 建筑工程学院,北京,100124;

2. 北京市规划委员会东城分局,北京,100013)

摘要:采用粉末活性炭/超滤(PAC/UF)和单独UF处理微污染含藻水,分析2种工艺对水中污染物和微囊藻毒素(MC-LR)的去除效果以及PAC对膜污染控制效果。研究结果表明:2种工艺均能有效去除含藻水中的叶绿素a。反应器内亚硝化菌成熟时间为15 d左右,硝化菌的成熟时间为20 d左右,硝化菌成熟明显滞后于亚硝化菌。单独UF工艺对UV254和溶解性有机物(DOC)的平均去除率分别为11.5%和15.0%,PAC/UF工艺对UV254和DOC的平均去除率分别为32.7%和23.8%,PAC明显提高了超滤工艺对有机物去除效果,将MC-LR平均去除效果从18.5%提高至43.0%,同时,PAC有效减少了含藻水超滤过程膜污染。生物粉末活性炭与超滤联用成为一种经济、高效的MC-LR控制技术。

关键词:粉末活性炭;超滤;微囊藻毒素

中图分类号:TU991.2 文献标志码:A 文章编号:1672-7207(2014)08-2928-06

Treatment of micro-polluted alga-rich water with PAC and ultrafiltration integrated process

LIU Yongwang1, LI Xing1, YANG Yanling1, LIANG Shuang2, LIU Ling1, REN Jiawei1

(1. College of Architecture and Civil Engineering, Beijing University of Technology, Beijing 100124, China;

2. Beijing Dongcheng Municipal Commission of Urban Planning, Beijing 100013, China)

Abstract: An integrated process of powdered activated carbon (PAC) and ultrafiltration (UF) and the independent UF were conducted to treat a micro-polluted alga-rich water. Effects of the two treatments on pollutant and microcystin-LR removal, as well as fouling control of PAC, were investigated. The results indicate that both of the two processes can remove the chlorophyll-a effectively. The maturities of nitrosomonas group and nitrobacteria are about 15 d and 20 d, respectively. The removal efficiencies of DOC and UV254 for the PAC/UF are 32.7% and 23.8%, and those of the independent UF process are 11.5% and 15.0%. Therefore, PAC can effectively enhance the organic removal and the MC-LR removal increases from 18.5% to 43.0% with the PAC addition, Moreover, PAC can mitigate the membrane fouling of UF process of alga-rich water. The integrated process of biological powdered activated carbon and UF tends to be a both economical and efficient technology for the treatment of MC-LR.

Key words: powered activated carbon; ultrafiltration; MC-LR

以湖泊、水库为水源的自来水厂在夏秋季节经常遭遇藻类爆发问题,对饮用水水质造成了巨大威胁,因此,如何高效去除藻类和藻毒素已成为人们关注的热点。常规水处理工艺对含藻类及其分泌物(如藻毒素)去除效果较差[1],因此,需要研发新型、高效的含藻水处理工艺。以超滤为核心的膜分离工艺以出水水质稳定、占地面积小、无二次污染、易于自动控制等优点备受瞩目[2],被称作第三代城市饮用水净化工艺核心技术[3]。研究表明,粉末活性碳炭(powdered activated carbon,PAC)能有效地吸附水中溶解性有机物(dissolved organics,DOC),将PAC与超滤联用不仅能够提高有机物去除效果,同时可以延缓膜污染[4-6]。谢良杰等[7]经研究发现粉末活性炭与超滤联用工艺在PAC投加量为20 mg/L时,产水中未检测出微囊藻毒素(MC-LR)。由于PAC价格较高且无法重复利用,不适应于长期使用,有必要探索更加经济、高效的藻毒素处理方法。膜生物反应器是将生物作用与膜滤作用置于同一个反应器内完成, 不仅能有效截留颗粒物, 而且能通过生物降解与膜滤联合去除有机物,具有占地面积小、出水水质优良等特点[8]。对于一次性投加PAC/UF生物反应器,其有机物去除过程经历了以粉末炭吸附为主、粉末炭吸附与生物降解相结合、以生物降解为主3个阶段[8]。而生物反应器启动阶段对MC-LR的去除效果还未见报道。在此,本文作者将粉末活性炭(PAC)和浸没式超滤膜(UF)置于同一反应器中,通过连续运行而形成生物反应器,考察该过程PAC/UF处理微污染含藻水时的除污染特性,尤其是对MC-LR的去除效能和机理,以便为微污染含藻水处理提供一种新途径。

1 材料与方法

1.1 试验原水与材料

试验中将自来水和生活污水按体积比50:1混合,并加入铜绿微囊藻和鱼腥藻,维持藻细胞浓度107个/L作为试验原水,原水配制后静置稳定24 h后供反应器使用。根据实验要求添加一定量的MC-LR标准样品。试验期间原水水质参数如表1所示。

试验中选用某公司生产的聚偏氟乙烯(PVDF)材质的中空纤维膜,标称孔径为0.01 μm,截留相对分子质量为1×105,膜面积为0.02 m2。试验中采用的椰壳基粉末活性炭,粒径为75 μm,比表面积为642.49 m2/g,以中孔为主;pH为7.28,水分质量分数为10.4%,灰分质量分数为39.6%,碘吸附值为473.8 mg/g。

表1 原水水质参数

Table 1 Characteristics of source water

试验中所用铜绿微囊藻和鱼腥藻购自中科院水生生物研究所,并且按照间歇光照法[1]培养14 d后稀释使用;MC-LR标准样品为美国Alexis公司生产,纯度≥96%;甲醇色谱纯为美国Fisher公司生产,高效液相色谱流动相溶液均采用Millipore Milli-Q (Billerica,MA)超纯水配制。

1.2 试验装置

采用2组UF装置进行对比研究,向其中一组UF中投加4 g/L的PAC(以UF反应器有效体积计),具体试验装置如图1所示,原水经恒位水箱进入UF(有效体积为300 mL),出水通过蠕动泵抽吸排出。将压力传感器置于抽吸泵和UF反应器之间以监测跨膜压差(TMP)的变化情况。曝气头置于反应器底部进行连续曝气,使PAC保持悬浮状态,同时为微生物生长繁殖提供溶解氧,气水体积比为12:1。实验装置以恒通量20 L/(m2·h)连续运行,膜池内水力停留时间为45 min左右,试验期间膜池内不进行反洗和排泥。

图1 膜装置示意图

Fig. 1 Schematic diagram of membrane device

1.3 MC-LR检测

(1) MC-LR的富集。400 mL水样经GF/C玻璃纤维滤膜(Whatman,England)过滤,再用预先活化过的C18固相萃取小柱(500 mg,6 mL,Agilent,USA)进行富集。水样富集后用淋洗液(10 mL超纯水,10 mL 10%甲醇)淋洗萃取小柱,最后使用10 mL甲醇将MC-LR洗脱下来。最后,将收集到的洗脱液用氮气吹干定容至1 mL,经孔径为0.45 μm的针头过滤器过滤,装入密封样品瓶中待测。

(2) MC-LR的测定。采用带紫外检测器的1260高效液相色谱(Agilent,USA)对MC-LR进行测定。操作条件如下:色谱柱(Zorbax 300 Stable Bond SB-C18色谱柱:250×4.6 mm,5 μm,Agilent,USA);检测波长为238 nm;流动相为0.05%三氟乙酸水溶液和100%甲醇,其体积比为40:60;流速为1.0 mL/min;检测温度为40 ℃;进样量为40 μL[9]。

1.4 检测方法

试验对水样浊度、UV254及DOC、叶绿素a、NH3-N和NO2--N等污染物指标的质量浓度测定。浊度采用HACH2100N散射光浊度仪测定;采用UV2600紫外可见分光光度计在254 nm处测定紫外吸光度(UV254),ρ(DOC)采用Element Vario TOC测定,水样测定UV254和ρ(DOC)前均用孔径为0.45 μm微滤膜过滤;叶绿素a、NH3-N 以及NO2--N的质量浓度按标准方法进行测定。跨膜压差采用压力传感器采集数据,由PLC系统自动记录。

2 结果与讨论

2.1 生物作用启动特性

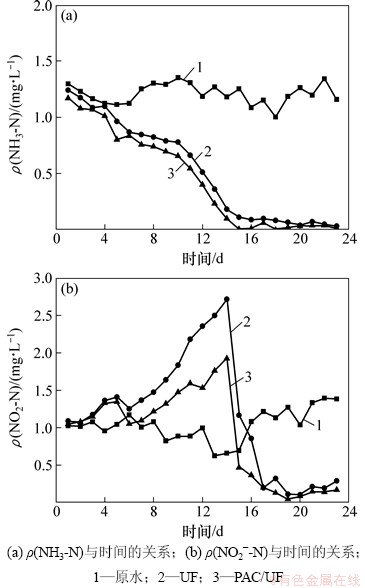

2种工艺对NH3-N(a)和NO2--N(b)的去除特性如图2所示。从图 2(a)可以看出,工艺运行初始阶段NH3-N去除效果不明显。随着反应器内污泥停留时间增加,出水中ρ(NH3-N)逐渐下降,在第10~15天下降速度明显加快,说明UF中以NH3-N为营养的亚硝化细菌群落逐渐开始形成;从第15天开始去除效果趋于稳定,去除率可以达到85%以上,出水中NH3-N质量浓度低于0.1 mg/L。

如图2(b)所示,在运行初始阶段,出水中NO2--N的质量浓度和原水的相比几乎没有变化;从第4天开始,由于亚硝化菌作用而导致出水中NO2--N质量浓度逐渐增加,而硝化细菌的生长世代时间长,菌落成熟期要滞后于亚硝化细菌,因而反应器中的NO2--N逐渐增加,质量浓度最高达到2.7 mg/L;从第15天开始逐渐下降,降到1 mg/L以下,说明反应器中硝化细菌群落已开始形成,到20 d后基本成熟,NO2--N质量浓度稳定在0.5 mg/L以下。反应器内亚硝化菌成熟时间为15 d左右,硝化菌的成熟时间为20 d左右,硝化菌成熟明显滞后于亚硝化菌。这与田家宇等[8]的研究结论基本一致,他们在研究中发现硝化细菌的成熟较亚硝化菌滞后了6 d。

图2 2种工艺对NH3-N和NO2--N的去除特性

Fig. 2 Removal characteristics of NH3-N and NO2--N during operation of two processes

2.2 启动过程污染物去除效果

2.2.1 浊度以及叶绿素a去除效果

试验期间超滤膜出水浊度均能保持在0.100 NTU以下,且基本不受原水浊度波动的影响,浊度远低于《生活饮用水卫生标准》对浊度1.000 NTU的要求。由于超滤膜孔径为0.01 μm,因此其具有良好的胶体和颗粒物去除效果,良好的浊度控制效果是超滤工艺的突出特点。

叶绿素a是评价藻细胞浓度的重要指标。2种工艺对叶绿素a的去除特性如图3所示。从图3可知,原水中叶绿素的质量浓度在4~5.5 μg/L之间波动,平均质量浓度为4.67 μg/L;经过UF工艺后叶绿素a质量浓度降低至(0.33±0.29) μg/L,去除率为93.02%,超滤膜孔径远小于铜绿微囊藻细胞(直径3~7 μm)和鱼腥藻细胞(丝状)直径,因此,超滤工艺能够有效控制出水中藻细胞数,降低水中叶绿素a含量。但死亡藻细胞及个别破碎藻细胞导致叶绿素a外泄,叶绿素a相对分子质量为893.51,远小于超滤膜的截留分子量而无法被超滤膜截留。而经过PAC/UF工艺后,叶绿素a质量浓度降低至(0.33±0.15) μg/L,平均去除率为95.67%,效果优于单独UF工艺,这是因为PAC的吸附能力有效强化了膜池内外泄叶绿素a的去除。

图3 2种工艺对叶绿素a的去除特性

Fig. 3 Removal characteristics of chlorophyll-a during operation of two processes

2.2.2 DOC和UV254去除效果

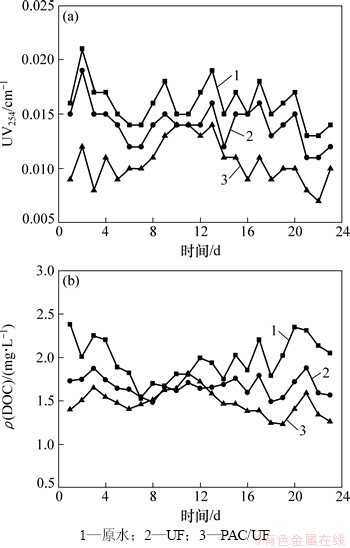

水中总有机污染物大体可分为颗粒性有机物和溶解性有机物,颗粒性有机物基本可以通过常规处理工艺(混凝、沉淀、过滤)分离去除,但溶解性有机物难以去除,是饮用水处理过程中关注的焦点。试验采用ρ(DOC)和UV254 2个有机物指标考察生物作用启动过程中2种工艺对有机物去除效果。

由图4可知,对于PAC/UF工艺,反应器启动前6 d以及14 d以后,UV254和DOC去除效果较好。经分析认为:初期PAC具有较强的吸附能力,强化了超滤工艺对溶解性有机物的去除效果,而反应器运行后期,硝化菌以及亚硝化菌的生物作用保证了溶解性有机物良好的去除效果。在试验运行第10天左右,有机物去除效果较差,经分析认为PAC已基本吸附饱和、微生物作用尚不成熟是造成有机物去除效果较差的主要原因。试验期间,UF对UV254和DOC的平均去除率分别为11.5%和15.0%,PAC/UF对UV254和DOC的去除率分别为32.7%和23.8%,PAC明显提高了超滤工艺对溶解性有机物去除效果,PAC与UF联用成为很有前景的溶解性有机物处理技术。

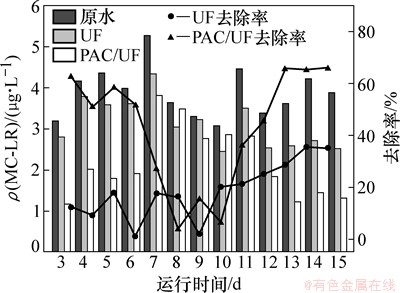

2.2.3 MC-LR去除效果

为研究生物作用启动阶段对于MC-LR的控制效果,试验考察了第3~15天2种工艺对MC-LR的去除效果。2种工艺对MC-LR的去除特性如图6所示。从图6可以看出,单独UF对MC-LR的去除效果较差,基本维持在11.5%左右,从第11天起,随着反应器中异养菌的生长和成熟,对MC-LR的去除率逐渐升高,平均去除率稳定在35%左右。MC-LR相对分子质量为1 000左右,远小于超滤膜截留相对分子质量1×105,超滤膜对MC-LR去除主要是通过超滤膜自身吸附作用以及膜表面形成泥饼层的截留作用[10]。

图4 2种工艺对UV254和DOC的去除特性

Fig. 4 Removal characteristics of UV254 and DOC during operation of two processes

图6 2种工艺对MC-LR的去除特性

Fig. 6 Removal characteristics of MC-LR during operation of two processes

试验阶段PAC/UF工艺对MC-LR的平均去除率为43.0%,明显高于单独UF工艺平均去除率18.5%,PAC/UF工艺可以有效降低出水中MC-LR的含量,这与Campinas等[6, 11]的研究结论一致。在运行初始阶段,PAC/UF对MC-LR的去除率可达到57.1%±5.0%,明显高于单独UF工艺,这主要是PAC强大的吸附能力所致。随着运行时间增加,PAC/UF对MC-LR的去除效果逐渐下降,在运行第7~10天,对MC-LR的去除率与单独UF工艺基本相同,这是由于PAC逐渐吸附饱和,而此时生物作用并不明显。从第11天开始,MC-LR去除效果逐渐增加,到第15天时,平均去除率稳定在65.8%左右,经分析认为水中异养菌逐渐成熟,最终在45 min停留时间内将水中大部分MC-LR降解和去除,因此,生物作用可以有效降解水中MC-LR,其降解效率与粉末活性炭初期吸附效果相当,而生物作用成本明显低于粉末活性炭吸附成本,因此,生物作用是一种经济、高效的MC-LR去除技术,生物粉末活性炭与超滤联用成为一种有效控制MC-LR的组合工艺。

2.3 PAC对超滤工艺膜污染控制效果

试验采用恒通量运行,跨膜压差的变化可以反映超滤工艺过程中膜污染情况[12]。2种工艺中跨膜压差增长特性如图7所示。从图7可以看出,单独UF工艺中的跨膜压差增加速率明显高于PAC/UF工艺,反应器运行前9 d,跨膜压差分别增加42.0 kPa和16.9 kPa,向反应器内投加PAC有效降低了跨膜压差增加速率,减轻了超滤膜污染,这与Zhang等[1]采用PAC/UF工艺处理含藻水的结论相一致。在PAC/UF工艺中,PAC夹杂在形成的泥饼层中,利用其孔隙度有效改善了泥饼层结构,增加了其透水性而减轻了膜污染阻力[13-14]。在第10天,分别对2个反应器中的超滤膜进行了物理清洗,从图7可以看出:经物理清洗后跨膜压差明显降低,单独UF和PAC/UF工艺跨膜压差分别降低至17.4 kPa和10.0 kPa,物理清洗时主要通过擦洗膜表面以去除被膜表面截留的泥饼层,因此,泥饼层是造成含藻水膜污染的主要因素,这与Lin等[15]的研究结论一致。因此,有效降低泥饼层造成的膜污染是未来研究的重点。

图7 2种工艺中跨膜压差增长特性

Fig. 7 Comparison of transmembrance pressure development during operation of two processes

3 结论

(1) 反应器内亚硝化菌成熟时间为15 d左右,硝化菌的成熟时间为20 d左右,硝化菌成熟明显滞后于亚硝化菌。

(2) 在试验阶段,PAC/UF出水中的MC-LR的平均去除率为43.0%,明显高于单独UF工艺平均去除率18.5%,PAC/UF工艺可以有效提高水中MC-LR的去除效果。生物粉末活性炭与超滤联用成为一种经济、高效的MC-LR控制技术。

(3) PAC能够有效缓解超滤工艺处理含藻水膜污染,泥饼层的形成是造成超滤膜膜污染的主要原因。

参考文献:

[1] ZHANG Yan, TIAN Jiayu, NAN Jun, et al. Effect of PAC addition on immersed ultrafiltration for the treatment of algal-rich water[J]. Journal of Hazardous Materials, 2011, 186(2/3): 1415-1424

[2] XIA Shengji, LIU Yanan, LI Xing, et al. Drinking water production by ultrafiltration of Songhuajiang River[J]. Journal of Environmental Sciences, 2007, 19: 536-539.

[3] 李圭白, 杨艳玲. 超滤—第三代城市饮用水净化工艺的核心技术[J]. 供水技术, 2007, 1(1): 1-3.

LI Guibai, YANG Yanling. Ultrafiltration—The 3rd generation key water purification technology for city[J]. Water Technology, 2007, 1(1): 1-3.

[4] Campinas M, Rosa M J. Assessing PAC contribution to the NOM fouling control in PAC/UF systems[J]. Water Research, 2010, 44: 1636-1644.

[5] Kim J, Cai Z, Benjamin M M. NOM fouling mechanisms in a hybrid adsorption/membrane system[J]. Journal of Membrane Science, 2010, 349(1/2): 35-43.

[6] Campinas M, Rosa M J. Removal of microcystins by PAC/UF[J]. Separation and Purification Technology, 2010, 71(1): 114-120.

[7] 谢良杰, 李伟英, 陈杰, 等. 粉末活性炭-超滤膜联用工艺去除水体藻毒素的特性研究[J]. 水处理技术, 2010, 36(7): 92-95.

XIE Liangjun, LI Weiying, CHEN Jie, et al. Study on removal characteristic of PAC-UF intergrated process of MCs[J]. Technology of Water Treatment, 2010, 36(7): 92-99.

[8] 田家宇, 杨艳玲, 南军, 等. 膜生物反应器用于饮用水处理的启动特性[J]. 北京工业大学学报, 2009, 35(12): 1680-1684.

TIAN Jiayu, YANG Yanling, NAN Jun, et al. Start-up characteristics of membrane bioreactor (MBR) for drinking water treatment[J]. Journal of Beijing University of Technology, 2009, 35(12): 1680-1684.

[9] Sangolkar L N, Maske S S, Chakrabarti T. Methods for determining microcystins (Peptide Hepatotoxins) and microcystin-producing cyanobacteria[J]. Water Research, 2006, 40(19): 3485-3496.

[10] Lee J, Walker H W. Mechanisms and factors influencing the removal of microcystin-Lr by ultrafiltration membranes[J]. Journal of Membrane Science, 2008, 320(1): 240-247.

[11] Dixon M B, Richard Y, Ho L, et al. A Coagulation-powdered activated carbon-ultrafiltration: Multiple barrier approach for removing toxins from two australian cyanobacterial blooms[J]. Journal of Hazardous Materials, 2011, 186(2/3): 1553-1559.

[12] GAO Wei, LIANG Heng, MA Jun, et al. Membrane fouling control in ultrafiltration technology for drinking water production: A review[J]. Desalination, 2011, 272(1/3): 1-8.

[13] LIN Hongjun, WANG Fangyuan, DING Linxian, et al. Enhanced performance of a submerged membrane bioreactor with powdered activated carbon addition for municipal secondary effluent treatment[J]. Journal of Hazardous Materials, 2011, 192(3): 1509-1514.

[14] Fabris R, Lee E K, Chow C W K, et al. Pre-treatments to reduce fouling of low pressure micro-filtration (Mf) membranes[J]. Journal of Membrane Science, 2007, 289(1/2): 231-240.

[15] Lin H, Xie K, Mahendran B, et al. Sludge properties and their effects on membrane fouling in submerged anaerobic membrane bioreactors (Sanmbrs)[J]. Water Research, 2009, 43(15): 3827-3837.

(编辑 赵俊)

收稿日期:2013-07-25;修回日期:2013-10-18

基金项目:国家水体污染控制与治理科技重大专项(2012ZX07404-003)

通信作者:李星(1963-),男,黑龙江哈尔滨人,研究员,博士生导师,从事饮用水安全保障技术研究;电话:010-67391726;E-mail:lixing@bjut.edu.cn