DOI: 10.11817/j.ysxb.1004.0609.2021-37956

铅阳极泥真空氧化-气化挥发脱除砷锑碲的研究

伊家飞1, 2,程珂珂1, 2,查国正1, 2,范 凯1, 2,孔祥峰1, 2, 3,杨 斌1, 2, 3,刘大春1, 2, 3,徐宝强1, 2, 3

(1. 昆明理工大学 真空冶金国家工程实验室,昆明 650093;

2. 昆明理工大学 冶金与能源工程学院,昆明 650093;

3. 昆明理工大学 省部共建复杂有色金属资源清洁利用国家重点实验室,昆明 650093)

摘 要:铅阳极泥中含大量有害元素As、Sb和Te,为绿色高效脱除这三种元素,本研究提出“铅阳极泥真空氧化-气化挥发脱砷锑碲”创新工艺。以废铅膏碳酸化脱硫产物450 ℃温度下煅烧9 h所得Pb3O4为氧化剂,对铅阳极泥进行真空氧化-气化挥发脱砷锑碲实验,考察真空氧化温度、氧化时间、真空气化温度、气化时间对铅阳极泥中砷锑碲脱除效果的影响。在铅阳极泥与氧化剂质量比为 1:1、炉内压强5~10 Pa、升温速率为 30 K/min、真空氧化温度为748 K、氧化时间为90 min、真空气化温度为1123 K、气化时间90 min的实验条件下,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%。元素As、Sb和Te以单质和低价氧化物形式进入挥发物中,贵金属Ag、Au在该过程中无损失,实现了砷锑碲的高效脱除。

关键词:铅阳极泥;砷锑碲;选择性氧化;脱除;绿色高效

文章编号:1004-0609(2021)-xx-- 中图分类号:TF813 文献标志码:A

引文格式:伊家飞,程珂珂,查国正, 等. 铅阳极泥真空氧化-气化挥发脱除砷锑碲的研究[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37956

YI Jia-fei, CHENG Ke-ke, ZHA Guo-zheng, et al. Arsenic, antimony and tellurium removal from lead anode slime by vacuum oxidation-gasification volatilization[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37956

铅阳极泥是粗铅电解精炼过程中产生的副产物,其产量约占粗铅产量的 1.2%~1.8%,除富含Au、Ag等有价金属外,还含有大量As、Sb、Te等有害元素[1-2]。元素As 分散在铅阳极泥处理的多个环节中,使生产过程变得繁复[3-4];Sb 的电极电势与金属Bi相近,电解提Bi时,Sb与Bi易在阴极共同析出[5-7];Te 在铅阳极泥还原-氧化精炼时进行脱除,不仅要加入固体氧化剂如硝石(NaNO3)来强化氧化过程,还需加入纯碱减少TeO2的挥发,大幅增加物耗[8-9]。铅阳极泥中As、Sb、Te不仅给生产带来很大困难,更重要的是会造成环境污染,影响生态和人类健康[10-11]。为此,生态环境部将铅阳极泥列入《国家危险废物名录(2021年版)》(废物代码321-019-48,危险特性T)[12],对其贮存和处理进行严格管理[13-15]。

目前,铅阳极泥脱As、Sb、Te主要有火法工艺和湿法工艺两种。其中火法工艺对铅阳极泥原料适应性强,不受氧化程度、干湿程度和稀贵金属品位的限制,在国内外许多企业得到应用[16-22]。铅阳极泥脱As、Sb、Te火法工艺首先将铅阳极泥在反射炉或回转炉中进行还原熔炼得到贵铅,然后在转炉中进行氧化熔炼,控制800~900 ℃的温度,通入压缩空气,使As、Sb氧化挥发进入烟气中,并产生As、Sb、Pb的氧化浮渣;待As、Sb基本氧化挥发后,使炉温升至1000~1100 ℃再继续吹风使残余As、Sb和Pb氧化造渣;吹风氧化精炼很难使Te完全氧化,需加入硝石(NaNO3),为使Te完全进入渣中,还需加入纯碱,形成亚碲酸钠苏打渣[14, 23]。该工艺渣中Ag和Au夹杂高、Te分散[24-26]等问题突出,制约着Ag、Au、Te的高效提取;工艺过程繁琐、能源和资源消耗高,产生大量的高As烟尘和重金属废渣、废水,环境问题突出,制约着铅冶炼行业绿色发展[14-15, 23]。

湿法工艺脱As、Sb、Te的主要原理是利用铅阳极泥中金属元素氧化还原性和氧化产物溶解性的差异,分离杂质金属[27]。如控电浸出法,利用铅阳极泥中元素氧化还原电位的差异,在“HCl+ NaCl+氧化剂”体系中,以氯气、氯酸钠为氧化剂并控制350~500 mV的电位对铅阳极泥进行选择性浸出,浸出后As、Sb、Te等金属进入溶液,贵金属富集于氯化渣中。浸出液中的Te采用二氧化硫还原,As用蒸馏结晶法脱除,蒸馏残液中的Sb采用水解法回收;浸出渣可采用氢氧化钠中和、火法熔铸、电解精炼得到纯金银[1,28]。此外,根据氧化剂和浸出剂的不同,湿法工艺还包括酸性浸出法(氯盐、硅氟酸)和碱-酸浸出法(氢氧化钠-盐酸联合)[29]。湿法工艺避免了高砷烟尘的产生,直接的环境影响较低,但产出大量危险废渣、废液,环境隐患高;反复的氧化、浸出、还原对金属元素赋存形态的转化要求高,难以有效控制化学反应的动力学过程[14-16]。

本文针对铅阳极泥传统处理工艺中有害元素As、Sb、Te高效分离困难、环境问题突出等难题,借鉴选择性氧化的成功经验,利用真空气化的独特技术[30-31],探索研究采用真空气化法处理铅阳极泥,先将金属间化合物中的As、Sb、Te选择氧化,再在真空条件下使铅阳极泥中易挥发的As、Sb、Te等元素气化进入挥发物中,Au、Ag、Cu等不易挥发的金属则保留在残留物中,实现铅阳极泥中As、Sb、Te与Au、Ag、Cu等的高效分离。

1 实验部分

1.1 实验原料

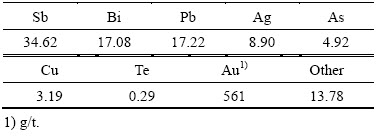

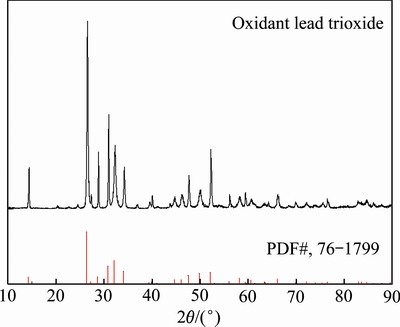

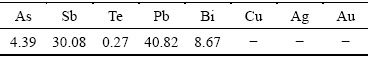

实验所用铅阳极泥来自某铅冶炼厂的粗铅电解精炼车间。铅阳极泥经热水洗涤后烘干、磨碎,用孔径 0.25 mm 的筛子除去其中的大颗粒夹杂物。铅阳极泥粒径大小采用激光粒度分析仪(LA-960, HORIBA, Japan)进行分析,其平均粒径只有7.0474 μm。铅阳极泥成分采用化学滴定和原子吸收光谱法进行测定(AAS, WFX-320, Beijing Beifen-Ruili, China),主要化学成分如表1所示。由于铅阳极泥中Au的含量较低,其含量采用电感耦合等离子体原子发射光谱法(ICP-AES, OPTIMA 8000, PerkinElmer, America)进行分析。由表1 可知,铅阳极泥为高锑(Sb含量为34.62%)高银(Ag含量为8.90%)高金(Au含量为561 (g/t))型铅阳极泥,具有很高的综合回收价值。

铅阳极泥物相采用X射线衍射仪(XRD, D-MAX/2600, Rigaku, Japan)进行测定,射线源 Cu Kα,管电压 40 kV,电流 150 mA,扫描速率 5 (°)/min,扫描范围10°~90°,利用MDI Jade 6 软件对铅阳极泥物相进行分析,物相分析结果见表2。铅阳极泥中的砷主要以三氧化二砷和铜砷金属间化合物的形式存在;锑主要以单质锑、五氧化二锑和三氧化二锑、锑化银的形式存在;铅和铋除以单质形式存在外,两者还形成复合盐;银和铜元素性质稳定较难氧化,但在铅阳极泥中和砷锑形成了金属间化合物。

表1 铅阳极泥主要化学成分

Table 1 Main chemical composition of lead anode slime (mass fraction, %)

表2 铅阳极泥物相组成

Table 2 Phase compounds in lead anode slime

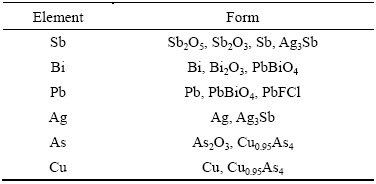

1.2 真空氧化-气化分离砷锑碲工艺流程

铅阳极泥真空氧化-气化挥发脱除砷锑碲的工艺流程如图1所示。

图 1 真空氧化-气化挥发处理铅阳极泥的工艺流程图

Fig. 1 Process flowchart for vacuum oxidation- gasification volatilization of lead anode slime

1.2.1 真空氧化-气化挥发实验设备及方法

实验所用设备为立式真空炉。真空炉主体由坩埚、冷凝罩、冷凝盘组成。将一定质量的实验原料放入坩埚内,装好炉,抽真空至10 Pa 以下,升温至预设的氧化温度保温一定时间,再升温至气化温度后保温一定时间,高挥发性的金属及氧化物先气化并最终冷凝,低挥发性的金属则留在坩埚中,最终实现砷锑碲有害元素的脱除。气化过程结束后,结束加热使炉体降温,待炉体降温至室温后打开炉门,收集冷凝盘上的挥发冷凝物和坩埚中的残留物进行称重及化学成分分析,并进行物料平衡计算。铅阳极泥真空氧化-气化所得挥发物使用扫描电子显微镜(SEM, SU-5000, Hitachi, Japan)进行微观形态分析。

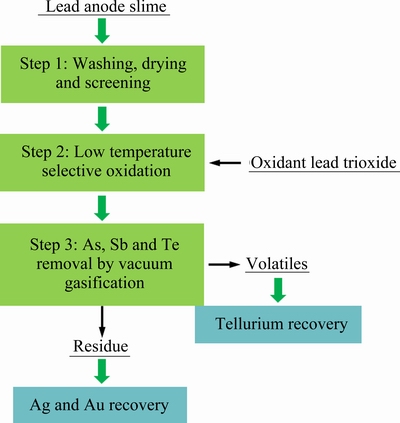

1.2.2 氧化剂Pb3O4的制备

氧化剂Pb3O4的加入是为了将铅阳极泥中与银铜等形成金属间化合物的元素As、Sb和Te选择性氧化,以提高铅阳极泥中元素As、Sb和Te的脱除率。本研究中Pb3O4的制备以废铅酸电池铅膏为原料,(NH4)2CO3作为脱硫剂,首先在碳酸铵浓度0.720 mol/L,反应温度60 ℃,液固比5:1,反应时间为60 min,搅拌速率为500 r/min的实验条件下进行脱硫,然后将脱硫产物在450 ℃温度下煅烧9 h后得到四氧化三铅(Pb3O4)。所得氧化剂经原子吸收光谱及X射线衍射分析,其为晶型完整纯度很高(Pb含量为90.62%)的Pb3O4,如图2所示。

图2 氧化剂Pb3O4的XRD谱

Fig. 2 XRD pattern of the oxidant lead trioxide

1.2.3 实验数据处理

实验数据按下式计算物料挥发率,砷锑碲脱除率及贵金属回收率:

挥发率=

(1)

(1)

脱除率=

(2)

(2)

直收率=

(3)

(3)

式中:m0 为物料(铅阳极泥与氧化剂)总质量;m1为真空气化所得挥发物质量;m2为真空气化所得残留物质量;w0为物料中元素As、Sb、Te的含量(%);w1为挥发物中元素As、Sb、Te的含量(%);w2为物料中元素Ag(%),Au(g/t)的含量;w3为残留物中元素Ag(%),Au(g/t)的含量。

2 真空氧化-气化挥发热力学分析

2.1 铅阳极泥中各纯物质饱和蒸气压

众所周知,任何固态或液态的物质都具有挥发成为气态的趋势,其气态亦有凝华为固态或凝聚成相应液态的趋势。比较不同物质饱和蒸气压高低可以判断出其蒸发速率的大小,通常认为,具有较高饱和蒸气压的物质具有较大的挥发性。蒸气压与温度及物质分子脱离液体或固体的趋势有关。饱和蒸汽压 p*常与温度 T 呈非线性的关系,可由克劳修斯-克拉佩龙方程(Clausius-Clapeyron Relation)进行推导,经推导得到金属饱和蒸气压随温度变化的关系式[32]:

(4)

(4)

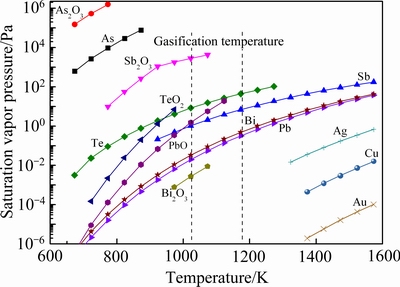

式中:p*为纯物质的饱和蒸汽压,A、B、C、D 被称作蒸发常数,其具体数值可由文献[32]查得,计算铅阳极泥中各纯物质的p*值,将计算所得数据绘制成 T-p*图,如图3所示。

图3 温度与p*关系

Fig. 3 Relationship between temperature and p*

由图 3 可知,As2O3、As、Sb2O3 即使在较低温度时饱和蒸汽压值亦远大于其它金属及氧化物,在蒸馏温度1073 K至1173 K温度范围内,其它金属及氧化物的饱和蒸汽压值大小顺序依次是PAs*>PSb2O3*> PTeO2*>PTe*>PPbO*>PSb*>PBi*>PPb*>PBi2O3*>PAg*>PCu*>PAu*,铅阳极泥中各物质的相应挥发性即可确定为 As2O3>As>Sb2O3>TeO2>Te>PbO>Sb>Bi>Pb>Bi2O3>Ag>Cu>Au。控制适当的蒸馏温度可使As2O3、Sb2O3、As、Te、TeO2、Sb在蒸馏过程中较 Au、Cu、Ag更易于挥发进入气相,进而实现有害元素As、Sb、Te的真空脱除。

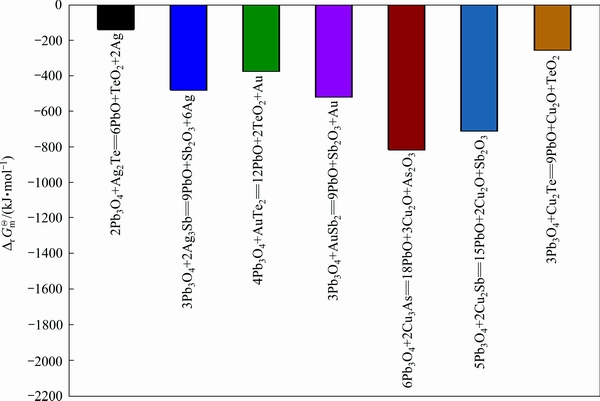

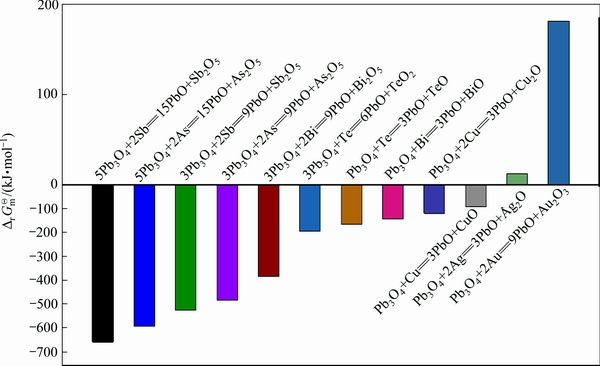

2.2 Pb3O4选择性氧化铅阳极泥热力学判据

选择Pb3O4在密闭低压系统中强化氧化与银、金、铜形成金属间化合物的元素As、Sb、Te,最大限度脱除有害元素As、Sb、Te。为判断在氧化温度748 K下Pb3O4选择性氧化铅阳极泥中与银、金、铜形成金属间化合物的As、Sb、Te的可行性,可通过计算反应:

(5)

(5)

的 值来进行判断[33-34]。Pb3O4氧化As、Sb、Te与银、金形成的金属间化合物时的

值来进行判断[33-34]。Pb3O4氧化As、Sb、Te与银、金形成的金属间化合物时的 值,如图4所示;图5所示为Pb3O4氧化单质As、Sb、Te时的

值,如图4所示;图5所示为Pb3O4氧化单质As、Sb、Te时的 值。

值。

由图4可知,Pb3O4氧化As、Sb、Te与Ag、Au、Cu形成的金属间化合物(Ag2Te、Ag3Sb、AuTe2、AuSb2、Cu3As、Cu2Sb、Cu2Te)的反应 值均小于0,即Pb3O4可将Ag2Te、Ag3Sb、AuTe2、AuSb2、Cu3As、Cu2Sb、Cu2Te中的As、Sb、Te氧化成低价易挥发氧化物As2O3、Sb2O3、TeO2。同时,由图5可知,Pb3O4 氧化单质As、Sb、Te的

值均小于0,即Pb3O4可将Ag2Te、Ag3Sb、AuTe2、AuSb2、Cu3As、Cu2Sb、Cu2Te中的As、Sb、Te氧化成低价易挥发氧化物As2O3、Sb2O3、TeO2。同时,由图5可知,Pb3O4 氧化单质As、Sb、Te的 值亦小于0,Pb3O4 氧化单质Ag、Au的

值亦小于0,Pb3O4 氧化单质Ag、Au的 值大于0,表明Pb3O4 可氧化As、Sb、Te单质,但单质状态的Ag、Au 无法被氧化,仍以原单质状态存在。

值大于0,表明Pb3O4 可氧化As、Sb、Te单质,但单质状态的Ag、Au 无法被氧化,仍以原单质状态存在。

3 结果与讨论

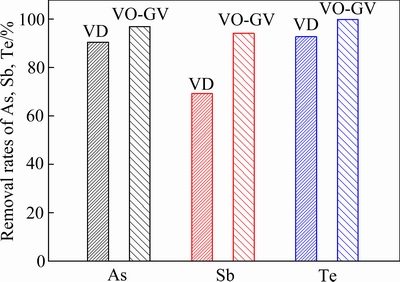

3.1 对比实验

为研究与分析真空氧化-气化挥发(VO-GV)脱除铅阳极泥中As、Sb、Te的效果,还对铅阳极泥进行了直接真空气化挥发(VD)实验。直接真空气化挥发实验铅阳极泥用量为100 g,真空气化温度为1123 K,保温90 min;真空氧化-气化挥发实验铅阳极泥用量同样为100 g,氧化剂用量为100 g,真空氧化温度为748 K,氧化时间为90 min,真空气化温度和保温时间与直接真空气化挥发实验相同。对比实验结果如图6所示。

铅阳极泥直接真空气化(VD)挥发实验中,As、Sb和Te的脱除率分别为90.46%、69.18% 和92.71%;铅阳极泥真空氧化-气化挥发(VO-GV)实验中,As、Sb和Te的脱除率分别为96.84%、94.21% 和99.93%,脱除率均高于90%。铅阳极泥真空氧化-气化挥发法相比于直接真空气化挥发法,As、Sb 和 Te 的脱除率显著提高,尤其是Sb,提高了25.03%,实现了对As、Sb和Te的高效脱除。

图4 Pb3O4氧化金属间化合物反应的 值

值

Fig. 4  values for oxidation reactions of intermetallic compounds by Pb3O4

values for oxidation reactions of intermetallic compounds by Pb3O4

图 5 Pb3O4氧化各单质反应的 值

值

Fig. 5  values for oxidation reactions of different elements by Pb3O4

values for oxidation reactions of different elements by Pb3O4

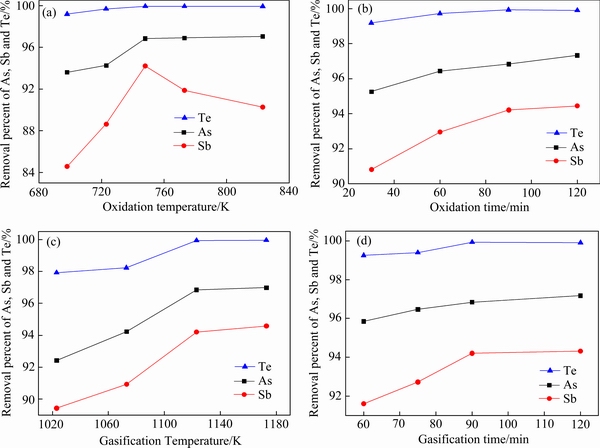

3.2 单因素实验

在铅阳极泥质量为 100 g、铅阳极泥与氧化剂质量比为 1:1、炉内压强5~10 Pa、升温速率为 30 K/min的条件下,分别对真空氧化温度、氧化时间、真空气化温度、气化保温时间对铅阳极泥的脱砷锑碲效果进行了研究,实验结果如图 7 所示。

3.2.1 真空氧化温度对砷锑碲脱除的影响

真空氧化时间为 90 min,真空气化温度1123 K,真空气化保温时间为90 min,真空氧化温度分别为 698 K、723 K、748 K、773 K、823 K,元素砷锑碲的脱除率如图7(a)所示。

图6 对比实验结果

Fig. 6 Results of contrast experiments

氧化温度从698 K逐渐增加至823 K,As脱除率从93.61%增至97.04%;在698 K至748 K氧化温度区间内,As脱除率从93.61%增至96.84%,增加了3.23%,增幅较大;在748 K至823 K氧化温度区间内,As脱除率增加较小。在748 K至823 K氧化温度区间内,Te脱除率从99.18%提高至99.91%,但从氧化温度723 K开始,Te脱除率无显著变化。氧化温度从698 K增加至748 K,Sb脱除率从84.57%增至94.21%,增值较大;氧化温度从748 K逐渐增加至823 K,Sb脱除率从94.21%降至90.27%;计算反应吉布斯自由能,在温度高于689.25 K时,Pb3O4开始分解产生PbO和氧气,Sb脱除率下降正是由于氧化温度过高氧化剂Pb3O4分解,氧化作用减弱导致。为保证砷锑碲较高的脱除率,选择748 K作为氧化温度。

3.2.2 真空氧化时间对砷锑碲脱除的影响

真空氧化温度为748 K,真空气化温度1123 K,真空气化保温时间为90 min,真空氧化时间分别为30 min、60 min、90 min、120 min,元素砷锑碲的脱除率如图7(b)所示。

图7 氧化温度、氧化温度、气化温度和气化时间对砷锑碲脱除的影响

Fig. 7 Effects of oxidation temperature(a), oxidation time(b), gasification temperature(c) and gasification time(d) on As, Sb and Te removal

氧化时间从30 min逐渐增加至120 min,As、Sb和Te的脱除率都呈增加趋势。As脱除率从95.26%增加至97.33%,增幅为2.06%;Sb脱除率从90.81%增加至94.45%,提高了3.61%,增幅较大;Te脱除率从99.19%增加至99.91%,已脱除得较为彻底。在氧化时间为90 min条件下,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%,说明氧化时间已较为充裕,进一步增加氧化时间,As、Sb和Te的脱除率提高较小,且会延长铅阳极泥处理周期,故90 min的铅阳极泥氧化时间较为适宜。

3.2.3 真空气化温度对砷锑碲脱除的影响

真空氧化温度为748 K,真空氧化时间为 90 min,真空气化保温时间为90 min,真空气化温度分别为 1023 K、1073 K、1123 K、1173 K,探究气化温度对元素砷锑碲脱除的影响。

如图7(c)所示,气化温度从1023 K逐渐增加至1173 K,As脱除率从92.42%增加至96.98%,提高了4.56%;Sb脱除率从89.44%提高至94.45%,增幅为5.51%,变化较大;Te脱除率从97.92%增加至99.95%,提高了2.03%。在气化温度为1123 K时,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%,若继续提高气化温度,As、Sb和Te的脱除率虽略有增加,但会造成少量Ag等贵金属进入挥发物中,降低贵金属直收率,且会增加铅阳极泥处理能耗,故选择1123 K作为铅阳极泥气化温度。

3.2.4 真空气化保温时间对砷锑碲脱除的影响

真空氧化温度为 748 K,真空氧化时间为 90 min,真空气化温度为1123 K,真空气化保温时间分别为 60 min、75 min、90 min、120 min,探究气化时间对元素砷锑碲脱除的影响。

如图7(d)所示,在气化时间60 min至120 min 范围内,As、Sb和Te的脱除率均在90%以上;As脱除率从95.85%增加至97.18%,提高了1.33%;Sb脱除率从91.61%提高至94.32%,增幅为2.71%;Te脱除率从99.25%增加至99.91%,提高了0.66%。在气化时间为90 min时,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%,三者已得到较好脱除:若气化时间从90 min增加至120 min,As和Sb的脱除率分别只提高0.34%和0.11%,Te脱除率几变化,所以选择90 min的铅阳极泥气化时长较为适宜。

3.3 铅阳极泥真空氧化-气化挥发物

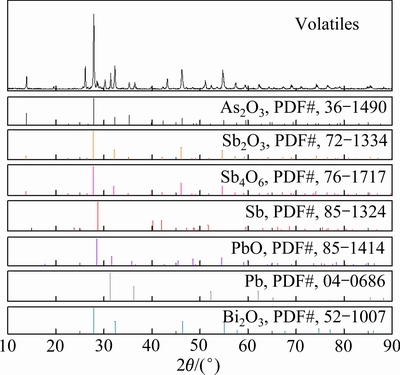

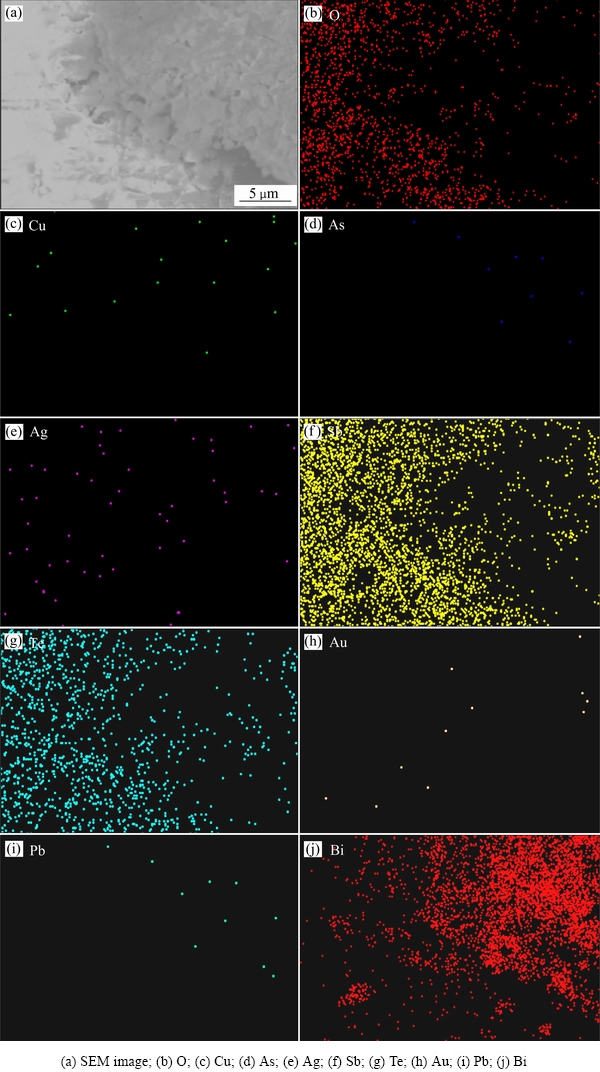

在铅阳极泥与氧化剂质量比为 1:1、炉内压强5~10 Pa、升温速率为 30 K/min、真空氧化温度为748 K、氧化时间为90 min、真空气化温度为1123 K、气化保温时间90 min的实验条件下,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%,并得到富含砷锑碲的挥发物,成分见表3。挥发物X射线衍射(XRD)物相分析及X射线能谱(EDS)元素分布结果分别如图8、9所示。

表3 最优实验条件下挥发物主要化学成分

Table 3 Main chemical composition of volatiles under optimized conditions (mass fraction, %)

图8 最优实验条件下挥发物的XRD谱

Fig. 8 XRD pattern of the volatiles under optimized conditions

图9 最优实验条件下挥发物的SEM像

Fig. 9 SEM images of volatiles under optimized conditions

由表3可知,挥发物中主要元素为As、Sb、Te、Pb 和Bi,贵金属Ag和Au则留在残留物中,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%,即实现了元素As、Sb 和Te的高效脱除。如图8所示,挥发物中主要物相为As2O3、Sb2O3、Sb4O6、Sb、Bi2O3、PbO 和Pb,说明铅阳极泥原料中的Ag3Sb、Cu0.95As4等金属间化合物被选择氧化,以致As、Sb和Te有较高的脱除率。挥发物中元素Cu、Ag和 Au含量较低;As、Te两元素分布与元素O分布重合,主要以氧化物形式进入气相;Sb、Pb 、Bi三元素分布与O元素分布部分重合,Sb、Pb 和Bi可以单质和低价氧化物两种形式气化挥发,如图9所示。

4 结论

1) 通过计算铅阳极泥中各纯物质饱和蒸气压及Pb3O4选择性氧化Ag、Au、Cu 与As、Sb、Te金属间化合物的反应吉布斯自由能,结合铅阳极泥直接真空气化挥发对比实验,论证了铅阳极泥真空氧化-气化挥发脱砷锑碲的可行性。

2) 利用单因素实验法,考察了真空氧化-气化挥发过程中各因素对砷锑碲脱除效果的影响,确定了铅阳极泥脱砷锑碲的最佳工艺条件:在铅阳极泥与氧化剂质量比为 1:1、炉内压强5~10 Pa、升温速率为 30 K/min、真空氧化温度为748 K、氧化时间为90 min、真空气化温度为1123 K、气化保温时间90 min的实验条件下,As、Sb和Te的脱除率分别为96.84%、94.21%和99.93%。

3) 元素As、Sb和Te在铅阳极泥真空氧化-气化过程所得挥发物中,以单质和低价氧化物形式存在,便于后续对三种元素进一步回收处理;贵金属Ag、Au在该过程中无损失,直收率高;铅阳极泥真空氧化-气化挥发法脱砷锑碲具有流程短、砷锑碲脱除效率高、无污染、能耗低等优点。

REFERENCES

[1] 李 阔, 徐瑞东, 何世伟, 等. 采用碱性加压氧化浸出从高铋铅阳极泥中脱除砷锑[J]. 中国有色金属学报, 2015, 25(5): 1394-1402.

LI Kuo, XU Rui-dong, HE Shi-wei, et al. Arsenic and antimony removal from bismuth-rich lead anode slime by alkaline pressure oxidation leaching[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1394-1402.

[2] 刘伟锋, 杨天足, 刘又年, 等. 脱除铅阳极泥中贱金属的预处理工艺选择[J]. 中国有色金属学报, 2013, 23(2): 549-558.

LIU Wei-feng, YANG Tian-zu, LIU You-nian, et al. Selection of pretreatment process for removing base metals from lead anode slime[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 549-558.

[3] 杨天足, 王 安, 刘伟锋, 等. 控制电位氧化法铅阳极泥脱砷[J]. 中南大学学报(自然科学版), 2012, 43(7): 2482-2488.

YANG Tian-zu, WANG An. LIU Wei-feng, et al. Removing arsenic from lead anode slime by oxidation under potential control[J]. Journal of Central South University (Science and Technology), 2012, 43(7): 2482-2488.

[4] 吴俊升, 陆跃华, 周杨霁, 等. 高砷铅阳极泥水蒸气焙烧脱砷实验研究[J]. 贵金属, 2003(4): 26-31.

WU Jun-sheng, LU Yue-hua, ZHOU Yang-ji, et al. Experimental study on arsenic removal from arsenic-rich lead anode slime by volatilization roasting in steam condition[J]. Precious Metals, 2003(4): 26-31.

[5] LIN De-qiang, QIU Ke-qiang. Removal of arsenic and antimony from anode slime by vacuum dynamic flash reduction.[J]. Environmental Science & Technology, 2011, 45(8): 3361-3366.

[6] LIN De-qiang, QIU Ke-qiang. Removing arsenic from anode slime by vacuum dynamic evaporation and vacuum dynamic flash reduction[J]. Vacuum, 2012, 86(8): 1155-1160.

[7] 李 磊, 张仁杰, 廖 彬, 等. 砷锑烟尘中砷与锑的选择性氧化分离[J]. 过程工程学报, 2014, 14(1): 71-77.

LI Lei, ZHANG Ren-jie, LIAO Bin, et al. Separation of As from As and Sb contained smoke dust by selective oxidation[J]. The Chinese Journal of Process Engineering, 2014, 14(1): 71-77.

[8] 李利丽. 铜铅阳极泥中碲的综回回收利用工艺研究[J]. 世界有色金属, 2018(12): 17-19.

LI Li-li. Study on recycling process of tellurium in copper lead anode slime[J]. World Nonferrous Metals, 2018(12): 17-19.

[9] 刘秀庆, 吴文花. 提高铅阳极泥中Te回收率的实验研究[J]. 稀有金属与硬质合金, 2016, 44(6): 22-25, 38.

LIU Xiu-qing, WU Wen-hua. Experimental study on improvement of tellurium recovery from lead anode slime[J]. Rare Metals and Cemented Carbides, 2016, 44(6): 22-25, 38.

[10] LIU Tian-tian, QIU Ke-qiang. Removing antimony from waste lead storage batteries alloy by vacuum displacement reaction technology[J]. Journal of Hazardous Materials, 2018, 347(5). 334-340.

[11] CHOOG T, CHUAH T G, ROBIAH Y, et al. Arsenic toxicity, health hazards and removal techniques from water: An overview[J]. Desalination, 2007, 217(1/3): 139-166.

[12] 中华人民共和国生态环境部. 国家危险废物名录(2021年版)[EB/OL]. [2021-03-21]. http://mee.gov.cn/xxgk2018/ xxgk/xxgk02/202011/t20201127_810202.html.

Ministry of Ecology and Environment of People’s Republic of China. National Hazardous Wastes List (2021) [EB/OL]. [2021-03-21]. http://www.mee.gov.cn/gkml/hbb/bl/201606/ t20160621 354852.htm.

[13] GB 18597—2001. 危险废物贮存污染控制标准[S]. 中华人民共和国生态环境部, 2013.

[14] GB 18597—2001. Pollution control standard for hazardous waste storage[S]. Ministry of Ecology and Environment of People’s Republic of China, 2013.

[15] 彭容秋. 铅冶金[M]. 长沙: 中南大学出版社, 2004.

PENG Rong-qiu. Lead metallurgy[M]. Changsha: Central South University Press, 2004.

[16] 张乐如. 现代铅冶金[M]. 长沙: 中南大学出版社, 2013.

ZHANG Yue-ru. Modern lead metallurgy[M]. Changsha: Central South University Press, 2004.

[17] 李卫锋, 张晓国, 郭学益, 等. 阳极泥火法处理技术新进展[J]. 稀有金属与硬质合金, 2010, 38(3): 63-67.

LI Wei-feng, ZHANG Xiao-guo, GUO Xue-yi, et al. The latest development of pyrometallurgical technology for processing anode slime[J]. Rare Metals and Cemented Carbides, 2010, 38(3): 63-67.

[18] 王光忠. 铅阳极泥富氧底吹还原熔炼-氧化精炼新工艺的生产实践[D]. 长沙: 中南大学, 2011.

WANG Guang-zhong. Production practice of oxygen enriched bottom blowing reduction smelting oxidation refining process for lead anode slime[D]. Changsha: Central South University, 2011.

[19] 方红生, 李慧颖, 王晓阳, 等. 高砷高锡铅阳极泥脱砷与综合回收工业试验[J]. 矿冶, 2020, 29(4): 111-115, 136.

FANG Hong-sheng, LI Hui-ying, WANG Xiao-yang, et al. Pilot test of arsenic removal and comprehensive recovery from high As, Sn and Pb bearing anode slime[J]. Mining & Metallurgy, 2020, 29(4): 111-115, 136.

[20] HE Yun-long, XU Rui-dong, HE Shi-we, et al. Alkaline pressure oxidative leaching of bismuth-rich and arsenic-rich lead anode slime[J]. International Journal of Minerals, Metallurgy, and Materials, 2019, 26(6): 689-700.

[21] SHU Yan-xiang, CAO Hua-zhen, WU Lian-kui, et al. The comprehensive utilization of oxidative hydrochloric acid leaching of anode slime bearing fluorine, arsenic and antimony[J]. Hydrometallurgy, 2019, 183: 106-111.

[22] HE Yun-long, XU Rui-dong, HE Shi-wei, et al. φ-pH diagram of As-N-Na-H2O system for arsenic removal during alkaline pressure oxidation leaching of lead anode slime[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(3): 676-685.

[23] CAO Hua-zhen, CHEN Jin-zhong, YUAN Hai-jun, et al. Preparation of pure SbCl3 from lead anode slime bearing high antimony and low silver[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(12): 2397-2403.

[24] 周连碧, 祝怡斌, 邵立南. 有色金属工业废物综合利用[M]. 北京: 化学工业出版社, 2018.

ZHOU Lian-bi, ZHU Yi-bin, SHAO li-nan. Comprehensive utilization of nonferrous metal industrial waste[M]. Beijing: Chemical Industry Press, 2018.

[25] MAKUEI F M, SENANAYAKE G. Extraction of tellurium from lead and copper bearing feed materials and interim metallurgical products—A short review[J]. Minerals Engineering, 2018, 115: 79-87.

[26] XU Zhi-peng, GUO Xue-yi, LI Dong, et al. Optimization of tellurium and antimony extraction from residue generated in alkaline sulfide leaching of tellurium-bearing alkaline skimming slag using central composite design[J]. Mining, Metallurgy & Exploration 2020, 37(2): 493-505.

[27] 张殿彬. 从碲碱渣中回收碲的工艺研究[D]. 昆明: 昆明理工大学, 2012.

ZHANG Dian-bin. Recovery of tellurium from tellurium alkali residue[D]. Kunming: Kunming University of Science and Technology, 2012.

[28] 郑国渠, 黄荣斌, 潘 勇. 含氟三氯化锑溶液中和水解产物的物相[J]. 中国有色金属学报, 2005, 15(8): 1278-1282.

ZHENG Guo-qu, HUANG Rong-bin, PAN Yong. Phases of antimony trichloride solution containing fluorine neutralization[1]hydrolysis products[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1278-1282.

[29] 刘伟锋, 刘好男, 孙百奇, 等. 富贵锑控电位氯化浸出选择性分离贱金属[J]. 中国有色金属学报, 2019, 29(2): 396-403.

LIU Wei-feng, LIU Hao-nan, SUN Bai-qi, et al. Selectively separating base metals from noble antimony by chlorination leaching with controlling potential[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 396-403.

[30] 郑国渠, 支 波, 陈进中. 五氯化锑的水解过程[J]. 中国有色金属学报, 2006, 16(9): 1628-1633.

ZHENG Guo-qu, ZHI Bo, CHEN Jin-zhong. Hydrolysis process of antimony pentachloride[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1628-1633.

[31] 戴永年, 杨 斌. 有色金属材料的真空冶金[M]. 北京: 冶金工业出版社, 2000.

DAI Yong-nian, YANG Bin. Vacuum metallurgy of nonferrous materials[M]. Beijing: Metallurgical Industry Press, 2000.

[32] 伊家飞. 真空法处理含砷锑复杂铜合金的研究[D]. 昆明: 昆明理工大学, 2015.

YI Jia-fei. Vacuum distillation of complex copper alloy containing arsenic and antimony[D]. Kunming: Kunming University of Science and Technology, 2015.

[33] 戴永年, 杨 斌. 有色金属真空冶金[M]. 北京: 冶金工业出版社, 2009.

DAI Yong-nian, YANG Bin. Vacuum metallurgy of nonferrous metals[M]. Beijing: Metallurgical Industry Press, 2009.

[34] 郭汉杰. 冶金物理化学[M]. 北京: 冶金工业出版社, 2006.

GUO Han-jie. Physical Chemistry of Metallurgy[M]. Beijing: Metallurgical Industry Press, 2006.

[35] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 北京, 冶金工业出版社, 2002.

YE Da-lun, HU Jian-hua. Handbook of practical inorganic thermodynamic data[M]. Beijing: Metallurgical Industry Press, 2002.

Arsenic, antimony and tellurium removal from lead anode slime by vacuum oxidation-gasification volatilization

YI Jia-fei1, 2, CHENG Ke-ke1, 2, ZHA Guo-zheng1, 2, FAN Kai1, 2, KONG Xiang-feng1, 2, 3, YANG Bin1, 2, 3, LIU Da-chun1, 2, 3, XU Bao-qiang1, 2, 3

(1. National Engineering Laboratory of Vacuum Metallurgy, Kunming University of Science and Technology, Kunming 650093, China

2. Faulty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China

3. State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: Lead anode slime (LAS) contains amount of harmful elements As, Sb, and Te. In order to remove these three elements green and efficiently, an innovative process of “vacuum oxidation-gasification volatilization arsenic antimony tellurium” was proposed. Lead trioxide (Pb3O4) obtained by calcination of waste lead paste carbonation desulfurization product at 450 ℃ for 9 h was used as oxidant to remove As, Sb, and Te from LAS. The effects of vacuum oxidation temperature, oxidation time, gasification temperature and gasification time on the removal of As, Sb, and Te from LAS were investigated. The results show that the removal rates of As, Sb and Te were 96.84%, 94.21% and 99.93% respectively under the following conditions: mass ratio of lead anode slime to oxidant was 1:1, system pressure was 5-10 Pa, heating rate was 30 K/min, vacuum oxidation temperature was 748 K, oxidation time was 90 min, vacuum gasification temperature was 1123 K and gasification holding time was 90 min. The elements As, Sb and Te enter the volatiles in the form of elemental and low valent oxides, and the precious metals Ag and Au do not lose in this process, which realizes the efficient removal of As, Sb and Te.

Key words: lead anode slime; As, Sb and Te; selective oxidation; removal; green and efficient process

Foundation item: Project(52004115) supported by the National Natural Science Foundation of China; Project (202001AU070045) supported by the Basic Research Plan of Yunnan Province, China; Project(2020J0069) supported by the Scientific Research Foundation of Yunnan Province, China; Project(KKZ7201952006) supported by the construction of high-level talents of Kunming University of Science and Technology, China; Projects(2020T20180050, 2020P20191102020, 2020M20192228015) supported by the Analysis and Testing Foundation of Kunming University of Science and Technology, China

Received date: 2021-03-29; Accepted date: 2021-07-14

Corresponding authors: KONG Xiang-feng; Tel: +86-13648833231; E-mail: xfkong@kust.edu.cn

YANG Bin; Tel: +86-13888113129; E-mail: kgyb2005@126.com

(编辑 )

基金项目:国家自然科学基金资助项目(52004115);云南省基础研究计划项目(202001AU070045);云南省科学研究基金资助项目(2020J0069);昆明理工大学高层次人才建设项目(KKZ7201952006);昆明理工大学分析测试基金项目(2020T20180050,2020P20191102020,2020M20192228015)

收稿日期:2021-03-29;修订日期:2021-07-14

通信作者:孔祥峰,副教授,博士;电话:13648833231;E-mail:xfkong@kust.edu.cn

杨 斌,教授,博士;电话:13888113129;E-mail:kgyb2005@126.com