DOI: 10.11817/j.issn.1672-7207.2018.10.019

基于环管实验的膏体流变特性及影响因素

王少勇,吴爱祥,阮竹恩,陈顺满

(北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083)

摘要:为研究膏体的流变特性与影响因素,自主设计研发小型膏体环管实验平台,测试不同工况条件下膏体管道输送的τw-dv/dr流动曲线,并采用Hershel-Bulkey模型(简称H-B模型)进行回归分析,获得膏体管道输送的流变参数,分析水泥掺量、尾砂颗粒粒径及料浆质量分数对膏体屈服应力τ0、塑性黏度μ的影响。研究结果表明:膏体流变模型属于n<1,τ0>0屈服伪塑性体,用H-B模型描述更为精确,其屈服应力τ0和塑性黏度μ都随着膏体料浆的质量分数增加呈指数增加,随着水泥掺量的增加先增大后降低;膏体料浆质量分数一定的情况下,构成膏体的尾砂粒径越细,屈服应力越大,与尾砂的比表面积呈幂指数关系。

关键词:环管实验;膏体;流变特性;屈服伪塑性体

中图分类号:O373;TD926;TQ177.6 文献标志码:A 文章编号:1672-7207(2018)10-2519-07

Rheological properties of paste slurry and influence factors based on pipe loop test

WANG Shaoyong, WU Aixiang, RUAN Zhuen, CHEN Shunman

(Key Laboratory of High-Efficient Mining and Safety of Metal, Ministry of Education,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To study the rheological properties of paste slurry and influence factors, the mini pipe loop experiment platform was designed. τw-dv/dr rheological characteristic curves were drawn under different working conditions. The Hershel-Bulkey model (H-B model) was used for regression analysis, and the rheological parameters of the paste were obtained. The influences of the cement content and particle size of tailings and mass fraction of paste slurry on the yield stress τ0, plastic viscosity μ of the paste slurry were investigated. The results show that the rheological model of paste slurry is pseudo plastic fluid with n<1, τ0>0, and H-B model describes more precisely. The yield stress and plastic viscosity exponential function increase with the increase of mass fraction of paste slurry. With the increase of cement dosage, the yield stress and plastic viscosity first rise and then drop. Keeping constant mass fraction of paste slurry, the diameter of the tailings of the paste is smaller and the yield stress is greater, and the yield stress power exponent increase with the increase of specific surface area of tailings.

Key words: pipe loop test; paste slurry; rheological properties; pseudo plastic fluid

尾矿是矿产资源开采产生的主要固体废弃物,我国目前累计堆存尾矿146亿t以上,且年排放量达到了15亿t以上[1],建设的尾矿库达8 869座,基础薄弱、安全保障能力偏低的四、五等尾矿库仍占88.9%,尾矿库溃坝隐患大[2]。同时,地下矿开采产生大量采空区,易诱发井下岩石冒落和地表塌陷。尾矿库和采空区是金属矿山的两大危险源,处理不当将给安全生产和生态环境带来巨大的威胁。将浮选尾矿浆进行浓密后添加水泥制成高浓度的膏体充填到井下,一方面可以减少尾矿的地表排放,降低尾矿库溃坝的安全隐患;另一方面可以消除采空区安全风险,有效地控制地压,提高回采作业的安全性,具有“一废治两害”的优势[3]。膏体是指将选厂排放的全尾砂经深锥浓密机浓密后,添加适量水泥,制备成牙膏状的不分层、不离析、不脱水的流体,较传统的充填方式具有尾砂利用率高、充填体质量好,充填综合成本低的优点,是我国矿业发展的一个重要方向,具有广阔的应用前景[4]。但是膏体料浆质量分数高,屈服应力和塑性黏度大,管道输送难度较大。因此,精确测量膏体料浆的流变参数并研究其影响因素,对管道输送参数设计与泵送设备的选型具有重要现实意义。目前普遍将膏体视为塑性流体,用Bingham模型回归分析其流变参数,可由屈服应力和塑性黏度两参数来表示[5],许多研究人员直接利用R/S型四叶桨式旋转流变仪直接测试膏体的屈服应力和黏度[6-10]。但是,膏体料浆在管道输送过程中发生管壁剪切、壁面滑移等现象[11],其流变特性与室内实验相差很大。L管法考虑了料浆管道流动状态,通过测料浆流量、流速及流动结束后静止状态下竖直管中料浆柱的高度,基于Bingham模型计算料浆的屈服应力和塑性黏度[12],但L型管道中料浆的流速范围较小,拟合后的流变参数与实际偏离较大。而环管实验法克服了L管实验的缺陷,最符合工程实际,测量膏体料浆流变特性最为准确。但由于系统较笨重,建设成本高,需要时间长,在很大程度上限制了其发展与应用。为此,本文作者基于自行设计的室内小型环管实验系统,测试膏体的流变参数,分析膏体料浆的流变模型,研究粒径、膏体质量分数、水泥掺量等因素对膏体屈服应力、塑性黏度的影响。

1 实验

1.1 样品性质

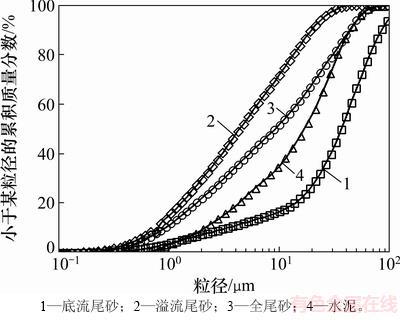

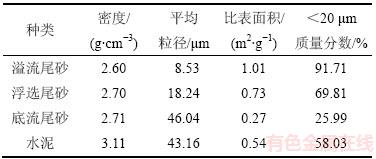

实验样品取自某金矿的浮选尾砂,通过水力旋流器进行分级后形成溢流尾砂,底流尾砂,其粒径组成见图1,物理参数见表1。

由表1可见:尾砂小于20 μm的质量分数都超过15%,符合膏体料浆制备条件[13-14]。但是,小于20 μm的尾砂质量分数也不宜太多,因为小于20 μm的尾砂质量分数过高,料浆黏度增大,管输阻力也大。按平均粒径来分,溢流尾砂最细,其次是浮选尾砂,再次是水泥,最大的是底流尾砂。比表面积正好相反,溢流尾砂最大,约为底流尾砂的5倍。

图1 实验样品级配曲线

Fig. 1 Particle size distribution of test materials

表1 实验材料物理性质

Table 1 Physical properties of experiment material

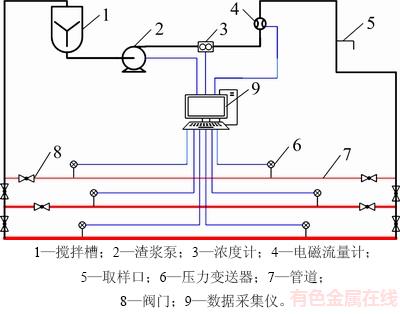

1.2 实验装置

自行设计小型膏体料浆环管实验平台,如图2所示。其中料浆在搅拌槽(1)中进行均质化搅拌,由浓度计(3)测量实时监测料浆的质量分数;通过渣浆泵(2)输送到不同管径的管道,并通过控制系统(9)设置泵送频率;管道输送系统包括DN80、DN100和DN125这3种常用的钢管,根据实验要求选择测试管道,且管道上布置取样口(5);实验过程中的数据由控制系统(9)和管道上的压力变送器(6)、电磁流量计(4)和浓度计(3)完成,采集频率达到每秒记录1次。

图2 膏体料浆流变特性环管实验测试系统示意图

Fig. 2 Schematic diagram of pipe loop test system for paste slurry rheological parameters

1.3 实验步骤

为了保证实验精度,尽量充分利用同一种物料,从高质量分数向低质量分数进行测量。高质量分数w1的全尾砂膏体通过加水得到较低质量分数w2的料浆,计算需要加的水量见下式。

(1)

(1)

式中:mw为需要加水质量,kg;w1为原料浆质量分数,%;w2为目标料浆质量分数,%;m为料浆总质量,kg。

具体是实验过程如下:

1) 首先连接好实验管道;

2) 加入清水,对整个系统进行调试,确保压力变送器、流量计、数据记录仪工作正常;

3) 逐渐加入干尾砂至搅拌罐中,待料浆具有一定的流动性后,启动渣浆泵,低速运行排除气泡,使料浆开始在管道中循环;

4) 调节泵送频率,使料浆首先在最大流速vmax(此时压力变送器达到量程的80%~90%)下运行,然后再逐渐降低频率,每个频率持续测试20 s,直到管道中的料浆停止移动,然后逐渐提高频率,再次达到最大流速vmax。控制系统记录此过程中的料浆质量分数w和管道压力p和流量Q;

5) 测试顺序从最高质量分数向最低质量分数进行,通过计算向搅拌罐中加入一定量的水稀释料浆,得到较低质量分数料浆,加完水后需要泵送在较高频率下运行5 min,使料浆混合均匀,然后开始低质量分数的测试。重复实验步骤4),直到测试完成实验设计的料浆质量分数;

6) 清洗系统,重复实验步骤3)~5),对另一种的料浆进行测试。

2 流变理论

对于浆体,在剪切力作用下,其剪切力与切变率之间存在一定的关系,称为流型。如果在浆体上施加剪切应力为τ,浆体以某一个速率dv/dr发生应变,这个速率即为剪切速率,其绝对值为剪切应力τ和产生的剪切速率dv/dr之间存在一定的关系[15],典型的非牛顿流体流变力学数学模型的通用表达式为[16]

(2)

(2)

式中:τ为剪切应力,Pa;dv/dr为剪切速率,s-1;τ0为屈服应力,Pa;μ为塑性黏度,Pa·s;v为料浆流速,m/s;n为流变特性指数。τ0,μ和n统称为浆体的流变参数。

若切变率与剪切力关系表现为通过坐标轴原点的线性特点的浆体为牛顿流体(τ0=0,n=1),例如水。若流型不通过坐标轴原点或表现出为非线性关系的均为非牛顿体(τ0>0,n>0),常见的非牛顿体有塑性体、膨胀体、宾汉体等,图3所示为非牛顿体各种流型的流变曲线图[16]。

图3 不同流型的流变曲线

Fig. 3 Rheological curves of different models

3 结果与分析

3.1 流变参数

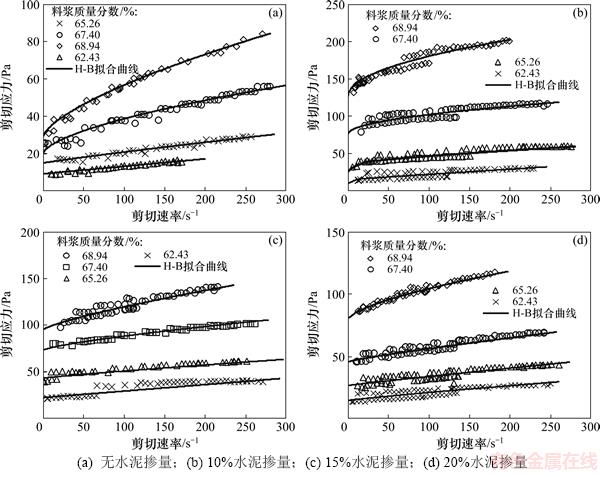

对底流尾砂添加水泥掺量(水泥质量/固体总质量)为0,10%,15%和20%时制备质量分数分别为62.43%,65.26%,67.40%和68.94%的膏体,回归分析的τw-dv/dr流变曲线见图4。

由图4可以看出:在不同水泥掺量下,4种质量分数的膏体料浆在管道输送过程中的流变曲线具有相似的变化趋势,符合图3(a)所示的宾汉塑性体与3(c)所示的屈服伪塑性体的流变曲线。在较低质量分数时,流变特性指数n约等于1,膏体料浆为宾汉塑性体,随着质量分数的升高,流变特性指数n小于1,越符合屈服伪塑性体,因此,采用τ0,μ和n这3个参数表示的Hershel-Bulkey模型(简称H-B模型)描述更为精确,即:

(3)

(3)

式中:τw为膏体在管道流动时的管壁切应力,Pa。

计算公式如下[17]:

(4)

(4)

(5)

(5)

式中:△p为压力差,Pa;D为管道直径,m;l为两压力计之间的距离,m。

根据上述数据分析方法,对所采集的数据进行处理,绘制τw-dv/dr流变特性曲线,采用式(3)对剪切速率与剪切应力进行拟合回归,得到不同配比下的膏体流变参数,见表2。

3.2 屈服应力的影响因素

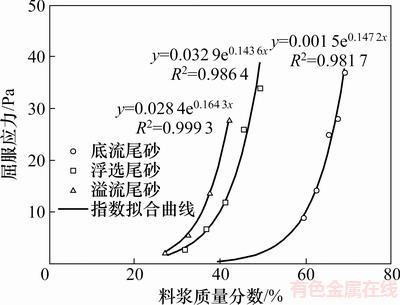

屈服应力由浆体内各颗粒之间的附着力和摩擦力产生,是阻止浆体塑性变形的最大应力[18]。膏体屈服应力的影响因素众多,有尾砂颗粒粒径、料浆质量分数、水泥掺量及尾砂浆的离子种类等。同一选矿厂的尾砂,离子种类和质量分数基本接近。为此,本文将研究尾砂颗粒粒径、料浆质量分数和水泥掺量对膏体屈服应力的影响。图5所示为3种不同粒径尾砂制成的膏体在不同质量分数下的屈服应力变化曲线。从图5可见:膏体料浆的屈服应力随质量分数的增加呈现较为典型的指数增加趋势。质量分数增加,颗粒与颗粒间的作用力迅速增加,浆体颗粒间的相对滑动较难。

图4 不同水泥掺量的料浆流变曲线

Fig. 4 Rheological properties curves of paste slurry in different cement dosages

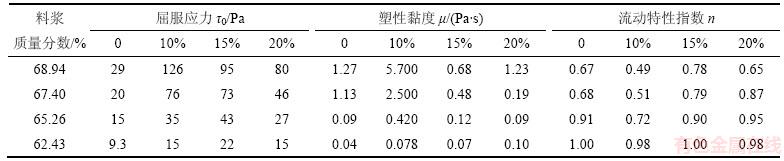

表2 不同水泥掺量的膏体料浆流变特性参数

Table 2 Rheological parameters for paste slurry with different cement dosages

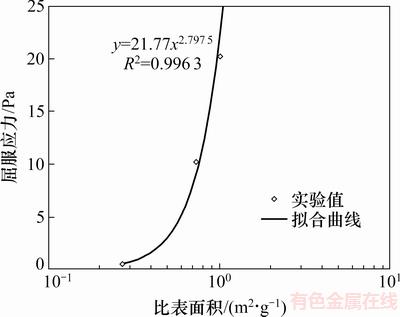

由图6可见:膏体屈服应力随着组成尾砂表面积的增加成幂指数增加趋势。从表1可知:溢流尾砂的比表面积(1.01 m2/g)>浮选尾砂比表面积(0.73 m2/g)>底流尾砂比表面积(0.27 m2/g)。粒度越小,比表面积越大,料浆与管道壁接触面积越大,摩擦阻力越大。同样从图5可以看出:在相同质量分数下,构成膏体的尾砂粒径越小,屈服应力越大,这说明尾砂颗粒越细,达到膏体时的质量分数越低。

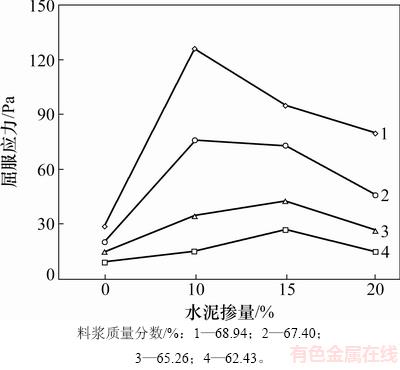

图7所示为4种不同质量分数下,水泥掺量对膏体屈服应力影响的变化曲线。从图7可以看出:在相同质量分数下,屈服应力随水泥掺量增加呈现先增加后降低趋势;质量分数越高水泥掺量对膏体屈服应力的影响越明显。屈服应力产生的原因是黏性细颗粒形成絮网结构而引起的,是阻止浆体塑性变形的最大应力[18]。水泥添加初期,黏结作用使浆体的絮网机构更加结实,屈服应力增加,水泥继续添加,细颗粒比例增加,提高润滑效果,屈服应力降低,但是比不添加水泥是的底流尾砂屈服应力要高。

图5 料浆质量分数与屈服应力的关系

Fig. 5 Relationship between of mass fraction and yield stress

图6 比表面积与屈服应力的关系(料浆质量分数为40%)

Fig. 6 Relationship between of specific surface area and yield stress

图7 水泥掺量对膏体屈服应力的影响

Fig. 7 Effect of cement dosage on yield stress of paste slurry

3.3 塑性黏度的影响因素

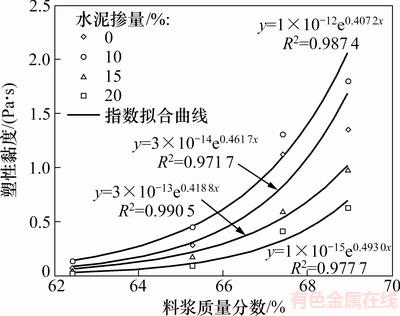

塑性黏度是膏体内部结构阻碍流动的性能。图8所示为一定的水泥掺量下膏体塑性黏度随料浆质量分数的变化曲线。从图8可以看出:塑性黏度随着料浆质量分数的增加呈指数增加的趋势,这与屈服应力表现规律一致,宏观表现为料浆的流动性变差。

图8 料浆质量分数与塑性黏度的关系曲线

Fig. 8 Relationship between mass fraction and plastic viscosity of paste slurry

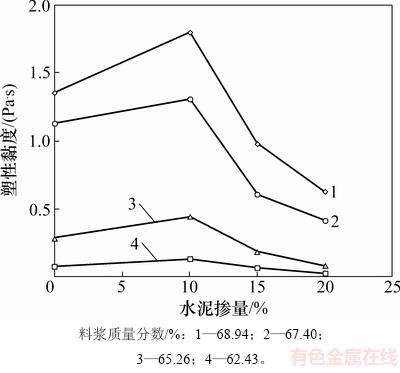

图9所示为一定质量分数的分级尾砂膏体添加水泥后,塑性黏度随水泥掺量的变化规律。从图9可见:尾砂浆添加水泥后塑性黏度显著增加,随着水泥掺量的继续增大(>10%时),料浆的塑性黏度又随着水泥掺量的增加而降低,与屈服应力的表现规律一致。分析原因主要为:一是水泥为黏性材料,添加后将使尾砂浆颗粒间的黏聚力增加;二是水泥比底流尾砂颗粒细,起初掺入水泥后,水泥比表面积的增加将使活性增强,水化速度加快,从而导致塑性黏度升高。当水泥掺量大于10%时,料浆呈现均质性、稳定性好,有利于浆体颗粒间的相对滑动,料浆的塑性黏度开始降低。

图9 水泥掺量与塑性黏度的关系曲线

Fig. 9 Relationship between cement dosage and plastic viscosity of paste slurry

4 结论

1) 设计了室内小型环管实验系统,流变参数测量更为合理,更符合工程实际。且测量结果表明质量分数较高的膏体流动指数n<1,屈服应力τ0>0,为典型的屈服伪塑性体,用H-B模型描述更为精确。

2) 膏体质量分数对其流变参数影响最为明显,膏体料浆的屈服应力、塑性黏度随着膏体料浆的质量分数增加呈指数增加。

3) 尾砂粒径也是影响膏体流变特性的重要因素,在膏体质量分数一定的情况下,尾砂颗粒越小,其表面积越大,屈服应力随着物料比表面积的增加呈显著的幂指数增加,相同质量分数的情况下,细粒尾砂膏体屈服应力与塑性黏度较高。

4) 保持膏体料浆的质量分数恒定,膏体料浆的屈服应力与塑性黏度受水泥添加量的影响,表现为随着水泥掺量的增加先增大后降低。

参考文献:

[1] 孟凡君. 中国矿产资源节约与综合利用报告(2015)[EB/OL]. [2016-03-01]. http://www.cinn.cn/xw/chanj/353847.shtm.

MENG Fanjun. The report of mineral resources conservation and comprehensive utilization in China (2015) [EB/OL]. [2016-03-01]. http://www.cinn.cn/xw/chanj/353847.shtm.

[2] 国家安全生产监管总局,安监总局部署尾矿库安全生产工作会议[EB/OL]. [2016-06-17]. http://www.lc123.net/xw/tp/ 2016-06-17/400132.html.

The state administration of work safety, Guidance on further strengthening supervision and administration work of the tailings[EB/OL]. [2016-06-17]. http://www.lc123.net/xw/ tp/2016-06-17/400132.html.

[3] 吴爱祥. 膏体充填与尾矿处置技术研究进展[J]. 矿业装备, 2011(4): 32-35.

WU Aixiang. The overview of the paste backfill and tailings disposal technology research[J]. Mining Equipment, 2011(4): 32-35.

[4] 吴爱祥, 王洪江. 金属矿膏体充填理论与技术[M]. 北京: 科学出版社, 2015: 11-13.

WU Aixiang, WANG Hongjiang. Theory and technology of paste backfill in metal mine[M]. Beijing: Science Press, 2015: 11-13.

[5] 段鸿杰, 孙恒虎. 高浓度浆体流变参数测定的新方法[J]. 中国矿业大学学报, 2001, 30(4): 371-374.

DUAN Hongjie, SUN Henghu. New method of measuring rheologic parameters of high-density slurry[J]. Journal of China University of Mining & Technology, 2001, 30(4): 371-374.

[6] 吴爱祥, 焦华喆, 王洪江, 等. 膏体尾矿屈服应力检测及其优化[J]. 中南大学学报(自然科学版), 2013, 44(8): 3371-3376.

WU Aixiang, JIAO Huazhe, WANG Hongjiang, et al. Yield stress measurements and optimization of paste tailings[J]. Journal of Central South University (Science and Technology), 2013, 44(8): 3371-3376.

[7] BOGER D V. Rheology and the resource industries[J]. Chemical Engineering Science, 2009, 64(22): 4525-4536.

[8] WALLEVIK J E. Relationship between the Bingham parameters and slump[J]. Cement and Concrete Research, 2006(36): 2214-1221.

[9] 刘同友. 金川全尾砂膏体物料流变特性的研究[J]. 中国矿业, 2001, 10(1): 14-21.

LIU Tongyou. Rheological characteristic of high density tailings slurry used for stowing in Jinchuan mine[J]. China Mining Magazine, 2001, 10(1): 14-21.

[10] 沈慧明, 吴爱祥, 姜立春, 等. 全尾砂膏体小型圆柱塌落度检测[J]. 中南大学学报(自然科学版), 2016, 47(1): 204-209.

SHEN Huiming, WU Aixiang, JIANG Lichun, et al. Small cylindrical slump test for unclassified tailings paste[J]. Journal of Central South University (Science and Technology), 2016, 47(1): 204-209.

[11] 吴爱祥, 程海勇, 王贻明, 等. 考虑管壁滑移效应膏体管道的输送阻力特性[J]. 中国有色金属学报, 2016, 26(1): 180-187.

WU Aixiang, CHENG Haiyong, WANG Yiming, et al. Gravity transport law of paste based on inclined pipe experiment[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 180-187.

[12] 李公成, 王洪江, 吴爱祥, 等.基于倾斜管实验的膏体自流输送规律[J]. 中国有色金属学报, 2014, 24(12): 3162-3167.

LI Gongcheng, WANG Hongjiang, WU Aixiang, et al. Gravity transport law of paste based on inclined pipe experiment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3162-3167.

[13] AMINUL I L, SUDIP T. Rheological behavior of high performance concrete with mineral admixtures and their blending[J]. Construct Build Mater, 2008, 22(12): 2345-2354.

[14] CORINALDSI V, MORRICONI G. The role of industrial by-products in self-compacting concrete[J]. Construct Build Mater, 2011, 25(8): 3181-3186.

[15] 胡华, 孙恒虎, 黄玉诚, 等. 似膏体粘弹塑性流变模型与流变方程研究[J]. 中国矿业大学学报, 2003, 32(2): 119-122.

HU Hua, SUN Henghu, HUANG Yucheng, et al. Rheological model and equation of viscoelastic-plasticity of paste-like backfill pulp[J]. Journal of China University of Mining & Technology, 2003, 32(2): 119-122.

[16] KWAK M, JAMES D F, KLEIN K A. Flow behaviour of tailings paste for surface disposal[J]. International Journal of Mineral Processing, 2005, 77(3): 139-153.

[17] 王少勇, 吴爱祥, 尹升华, 等. 膏体料浆管道输送压力损失的影响因素[J]. 工程科学学报, 2015, 37(1): 7-12.

WANG Shaoyong, WU Aixiang, YIN Shenghua, et al. Simulation and experiment of pipeline influence factors of pressure loss in pipeline transportation of paste slurry[J]. Chinese Journal of Engineering, 2015, 37(1): 7-12.

[18] BELEM T, BENZAAZOUA M. Design and application of underground mine paste backfill technology[J]. Geotechnical and Geological Engineering, 2008, 26(2): 147-174.

(编辑 杨幼平)

收稿日期:2017-10-22;修回日期:2017-12-11

基金项目(Foundation item):国家重点研发计划项目(2017YFC0602903)(Project(2017YFC0602903) supported by the National Key Research and Development Program of China)

通信作者:吴爱祥,博士,教授,从事膏体充填理论与技术研究;E-mail:wuaixiang@126.com