复合铸造制备稻壳灰增强AA6061铝合金及表征

来源期刊:中国有色金属学报(英文版)2015年第3期

论文作者:J. ALLWYN KINGSLY GLADSTON N. MOHAMED SHERIFF I. DINAHARAN J. DAVID RAJA SELVAM

文章页码:683 - 691

关键词:6061铝合金;铝基复合材料;复合铸造;稻壳灰;显微组织

Key words:6061 Al alloy; aluminum matrix composite; compocasting; rice husk ash; microstructure

摘 要:稻壳灰(RHA)是一种有潜力的廉价铝基复合材料的增强颗粒。采用复合铸造方法制备不同稻壳灰含量(0,2%,4%,8%,质量分数)增强的AA6061铝合金复合材料。采用X射线衍射和扫描电镜对所制备复合材料进行表征。X射线衍射谱表明AA6061/RHA铝基复合材料中除RHA颗粒外未形成其他金属间化合物。扫描电镜图片表明RHA颗粒均匀分布在铝基体中。RHA基本分布在晶粒内部。此外,RHA颗粒与铝基体结合良好并形成清晰的界面。RHA颗粒的添加能提高铝基复合材料的显微硬度和抗拉强度。铝基复合材料的拉伸行为与其微观组织密切相关。

Abstract: Rice husk ash (RHA) is a potential particulate reinforcement to produce aluminum matrix composites (AMCs) economically. Compocasting method was applied to produce aluminum alloy AA6061 reinforced with various amounts (0, 2%, 4%, 6% and 8%, mass fraction) of RHA particles. The prepared composites were characterized using X-ray diffraction and scanning electron microscopy. X-ray diffraction patterns of AA6061/RHA AMCs revealed the presence of RHA particles without the formation of any other intermetallic compounds. The scanning electron micrographs showed a homogeneous distribution of RHA particles all over the aluminum matrix. Intragranular distribution of RHA particles was observed. Further, RHA particles were bonded well with the aluminum matrix and a clear interface existed. The reinforcement of RHA particles enhanced the microhardness and ultimate tensile strength (UTS) of the AMCs. The tensile behavior is correlated to the microstructure of the AMCs.

Trans. Nonferrous Met. Soc. China 25(2015) 683-691

J. ALLWYN KINGSLY GLADSTON1, N. MOHAMED SHERIFF2, I. DINAHARAN3, J. DAVID RAJA SELVAM4

1. Department of Mechanical Engineering, SCAD College of Engineering and Technology, Cheranmahadevi 627414, Tamil Nadu, India;

2. Department of Mechanical Engineering, PET Engineering College, Vallioor 627117, Tamil Nadu, India;

3. Department of Mechanical Engineering Science, University of Johannesburg, Auckland Park Kingsway Campus, Johannesburg 2006, South Africa;

4. Centre for Research in Metallurgy (CRM), School of Mechanical Sciences, Karunya University, Coimbatore 641114, Tamil Nadu, India

Received 13 May 2014; accepted 7 December 2014

Abstract: Rice husk ash (RHA) is a potential particulate reinforcement to produce aluminum matrix composites (AMCs) economically. Compocasting method was applied to produce aluminum alloy AA6061 reinforced with various amounts (0, 2%, 4%, 6% and 8%, mass fraction) of RHA particles. The prepared composites were characterized using X-ray diffraction and scanning electron microscopy. X-ray diffraction patterns of AA6061/RHA AMCs revealed the presence of RHA particles without the formation of any other intermetallic compounds. The scanning electron micrographs showed a homogeneous distribution of RHA particles all over the aluminum matrix. Intragranular distribution of RHA particles was observed. Further, RHA particles were bonded well with the aluminum matrix and a clear interface existed. The reinforcement of RHA particles enhanced the microhardness and ultimate tensile strength (UTS) of the AMCs. The tensile behavior is correlated to the microstructure of the AMCs.

Key words: 6061 Al alloy; aluminum matrix composite; compocasting; rice husk ash; microstructure

1 Introduction

The development of aluminum matrix composites (AMCs) is one of the significant milestones in the history of materials. AMCs were developed to improve the performance of conventional aluminum alloys which cannot meet the requirement of modern engineering products. AMCs exhibit high strength, high elastic modulus and good wear resistance compared to the unreinforced aluminum alloys. AMCs are increasingly used to produce several components in aerospace, automotive, marine and nuclear industries [1-3]. The cost of AMCs remains high which limits its applications. The use of inexpensive reinforcements and natural materials will reduce the cost of AMCs and increases its application [4].

Rice husk ash (RHA) is a cheaper reinforcement material compared to traditionally used ceramic particles such as SiC, Al2O3, B4C and TiC. RHA is an abundantly available agricultural waste worldwide. A major portion of milled paddy consists of rice and bran and the rest is husk. Rice mills utilize this husk as fuel to generate steam for the parboiling process. During burning, the volatile matter in the husk disappears and the remaining husk is converted into ash which is known as RHA [5,6]. A million tons of RHA are produced every year across the world. Dumping of RHA pollutes the land and the surrounding area. On the other hand, the effective utilization of this agriculture waste will protect the environment.

AMCs are presently produced by employing several conventional and patented methods. The properties of AMCs are governed by the processing method. Liquid method of processing is widely preferred owing to its simplicity, ease of adoption and applicability to mass production [7]. Stir casting is one of the liquid methods which is being extensively used to prepare AMCs [8].

The entire aluminum matrix is melted and the ceramic particles are gradually introduced into the molten aluminum. A vortex is commonly created using a mechanical stirrer to facilitate incorporation. The limitation of stir casting is the wettability between the molten aluminum matrix and the ceramic particle. Several methods were proposed to enhance the wettability including the addition of wettability agent [9] and fluxes [10], preheating [11], oxidation [12] and coating [13] of ceramic particles. Those techniques to improve the wettability increase the overall production cost. Another technique to enhance the wettability economically is to lower the casting temperature and add the ceramic particles when the aluminum is in a semi solid state. This modified stir casting method is known as compocasting or slurry casting [14]. Several investigators obtained enhanced wettability and proper distribution of ceramic particles in the AMCs produced using compocasting compared to stir casting [15-17].

Some studies on AMCs reinforced with RHA particles were reported in the literature [18-23]. PRASAD and KRISHNA [18] produced A356/RHA AMCs using stir casting method. The preheated RHA particles were incorporated into a vortex to form the AMCs. The mechanical properties such as hardness and tensile strength improved with an increase in RHA content. PRASAD and KRISHNA [19] reported the dry sliding wear behavior of A356/RHA AMCs. RHA particles were found to increase the wear resistance of the AMCs. SARAVANAN and KUMAR [20] developed AlSi10Mg/RHA using liquid metallurgy method and studied the effect of RHA content on the mechanical properties of the AMCs. SARAVANAN et al [21] prepared AlSi10Mg/RHA AMCs using liquid metallurgy method and analyzed the effect of RHA particle size on the tribological behavior of the AMCs. ALANEME et al [22] compared the mechanical properties of AA6060/ Al2O3 AMC and AA6060/(Al2O3+RHA) hybrid AMC fabricated using two-step stir casting. They reported that the addition of RHA enhanced the mechanical properties of the hybrid composite compared to that of Al2O3 reinforced AMC. ALANEME and OLUBAMBI [23] showed that the corrosion resistance of AA6060/Al2O3 AMC is superior to that of AA6060/(Al2O3+RHA) hybrid AMC.

In the present work, an attempt is made to produce aluminum alloy AA6061 reinforced with RHA particles by compocasting method and analyze the effect of microstructure on mechanical properties of AA6061/ RHA AMCs.

2 Experimental

AA6061 rods were placed in a graphite crucible and heated using an electrical furnace. The crucible was coated inside to avoid contamination. The chemical composition of AA6061 aluminum alloy is presented in Table 1. The RHA particles were collected from a rice mill in southern India. The rice mill produces 0.25 t of RHA per day with an average composition furnished in Table 2. The SEM micrograph and XRD pattern of the RHA particles are shown in Fig. 1. Most of the RHA particles exhibit solid spherical shapes. The average size was estimated to be 2-3 μm. The XRD pattern clearly indicates that the peaks of the major constituent belongs to SiO2. The temperature of the furnace was maintained at 600 °C. Measured quantity of RHA particles was incorporated into the semi solid aluminum alloy. Concurrent stirring of the semi solid aluminum alloy was carried out using a mechanical stirrer driven by an electric motor. Stirring was continued till all the RHA particles were incorporated into the semi solid aluminum alloy. The semi solid composite melt was then poured into a permanent die at room temperature. The pouring temperature was kept slightly above the casting temperature to enhance fluidity. The castings were taken with various amounts of RHA particles (0, 2%, 4%, 6% and 8%, mass fraction).

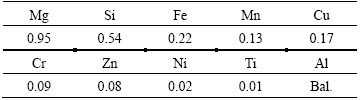

Table 1 Chemical composition of AA6061 aluminum alloy (mass fraction, %)

Table 2 Chemical composition of rice husk ash (mass fraction, %)

Specimens were prepared from the castings to carry out microstructural and mechanical characterization. All the specimens were polished using standard metallographic technique and etched with Keller’s reagent. The etched specimens were observed using a scanning electron microscope (SEM). X-ray diffraction patterns (XRD) were recorded using an X-ray diffractometer. The microhardness was measured using a microhardness tester at 500 g load applied for 15 s. The tensile specimens were prepared as per ASTM E8 standard having a gauge length of 40 mm, a gauge width of 7 mm and a thickness of 6 mm. The ultimate tensile strength (UTS) was estimated using a computerized universal testing machine. The fracture surfaces of the failed tensile specimens were observed using SEM.

Fig. 1 Lower magnification (a) and higher magnification (b) SEM micrographs of RHA particles and XRD pattern of RHA particles (c)

3 Results and discussion

Aluminum alloy AA6061 reinforced with RHA particulate was successfully produced using compocasting. The microstructure and mechanical characterization of the fabricated AA6061/RHA AMCs are discussed below.

3.1 X-ray diffraction analysis of AA6061/RHA AMCs

The XRD patterns of the produced composites are depicted in Fig. 2. The diffraction peaks of SiO2 which is the major constituent of RHA particle are clearly seen. The intensity of SiO2 peaks increases as RHA content in the AMC increases. It is noticeable in Fig. 2 that the aluminum peaks in the composites are somewhat shifted to higher 2θ compared to unreinforced aluminum alloy. The shifting occurs due to the incorporation of RHA particles into the aluminum to produce the AMC. Peaks of any other elements except Al and SiO2 were not detectable in Fig. 2. This result indicates that the integrity of RHA particles is preserved during the formation of the composite. RHA particles behave thermodynamically stable under the casting conditions employed in this work. RHA particle neither decompose nor interact with aluminum to form any sort of intermetallic compounds. This confirms that the interface between the aluminum matrix and RHA particle tends to be clean. Otherwise, the reaction products usually accumulate at the interface and inhibit load transfer mechanism to operate during tensile loading [24]. PRASAD and KRISHNA [25] produced A356/RHA AMCs using stir casting and observed the decomposition of RHA into Al2O3 and Si. They noticed the presence of primary silicon single crystals in the vicinity of rice husk ash. The absence of such reactions in the prepared composites can be attributed to the following two factors. The processing temperature of compocasting is significantly lower compared to stir casting. It is observed from existing literatures that the interfacial reaction occurs if the casting temperature exceeds 750 °C [26]. Secondly, the semi solid composite melt was poured within a shorter duration after the completion of RHA particle incorporation. The holding time, i.e., the time between incorporation and pouring is not sufficiently long enough to cause interfacial reactions.

Fig. 2 XRD patterns of AA6061/RHA AMCs with various amount of RHA

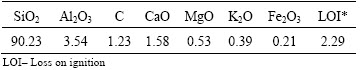

Fig. 3 SEM micrographs of AA6061/RHA AMCs containing various amount of RHA

3.2 Microstructure of AA6061/ RHA AMCs

The SEM micrographs of the produced AA6061/ RHA AMCs at various RHA content are shown in Fig. 3. Figure 3(a) represents the SEM micrographs of cast aluminum alloy AA6061. The microstructure consists of a typical dendritic structure induced by rapid solidification. The cooling rate is very high, known as super cooling, which forms the dendritic structure. The dendritic structure is characterized with elongated primary α(Al) dendritic arms which have high aspect ratios. The average spacing between dendritic arms is measured to be 40-50 μm. The alloying elements of the aluminum alloy AA6061 such as Mg and Si are present at a level which is higher than their solubility limit. As a result, the intermetallic phase Mg2Si is formed around the dendrites during casting.

The SEM micrographs (Figs. 3(b)-(e)) of the AA6061/RHA AMCs exhibit no casting defects, including porosity, shrinkages or slag inclusion. The absence of those defects demonstrates the good casting quality. This can be attributed to the set of process parameters employed for the production of castings. The dendritic shape is not present in the micrographs of the AMCs. A grain structure is formed in the AMCs. The incorporation of RHA particles alters the dendritic structure of the aluminum matrix. The solidification pattern of the AMCs is influenced by the presence of RHA particles. It is evident from the micrographs that the RHA particles act as effective grain refiners. The average grain size decreases with the increase in RHA content. The grain refinement takes place due to the following possible factors [27]. RHA particles act as grain nucleation sites and the aluminum grains solidify on it. The constitution under cooling zone in front of the RHA particles may cause it to act as a grain nucleation site. The dispersion of RHA particles in the aluminum matrix restricts the growth of α(Al) grains during solidification. The higher the content of RHA particle, the more the grain nucleation sites are created as well as the more the resistance is offered to the freely growing α(Al) grains. Therefore, the grains are further refined.

The distribution of second phase particles in AMCs is significantly influenced by the production method. The SEM micrographs (Figs. 3(b)-(e)) of the AA6061/RHA AMCs reveal the distribution of RHA particles in the aluminum matrix. The distribution of RHA particles is nearly homogenous in the aluminum matrix. A homogenous distribution of second phase particles is desirable to achieve higher mechanical properties. The particle distribution is influenced during several stages of casting: 1) distribution in the semi solid melt as a result of mixing, 2) distribution in the semi solid melt after mixing and during pouring, and 3) redistribution as a result of solidification. The SEM micrographs confirm that the stirring was adequate to disperse RHA particles throughout the aluminum matrix. The change in distribution after mixing and during pouring is trivial due to shorter holding time and rapid transfer of semi solid melt from the crucible to the mold. The solidification pattern dictates the final distribution of RHA particles within the aluminum matrix. The density gradient between the aluminum matrix and the RHA particles is a key factor during solidification. If the density of the particles is lower compared to that of aluminum, the particle will float or otherwise it will sink. Therefore, retaining the suspension of RHA particles in the composite melt for a longer duration is essential to homogeneously disperse the particle. Compocasting offers another added advantage to obtain homogenous distribution. The RHA particles were added to the semi solid aluminum alloy. Compared to conventional stir casting, the movements of particles within the semi solid melt subsequent to mechanical stirring are minimized. The high viscosity of the semi solid melt restricts the motion of particles and inhibits particle settling as well as floating [26,28]. During stirring, particles mix with the semi solid melt. The wetting of particles by the semi solid melt begins. The wetting action resists the free movement of RHA particles. The above discussed factors lead to homogeneous distribution of RHA particles in the aluminum matrix.

It can be observed from Fig. 3 that most of the RHA particles are dispersed within the grains. The distribution of RHA particles is intragranular. The intragranular distribution of particles is desirable compared to intergranular distribution in AMCs to obtain better mechanical and tribological properties. Several factors influence the distribution of RHA particles in the semi solid melt such as convection current, movement of the solidification front against particles and buoyant motion of particles [29]. The velocity of the solidification front plays a crucial role which governs the distribution to be either intra granular or intergranular. If the velocity of the solidification front is higher than the critical velocity, the solidification front will grow around the particles and engulf them, leading to intragranular distribution and vice versa. The particle size and the temperature gradient influence the value of critical velocity. The intragranular distribution of RHA particles reveals that the particles were engulfed by the solidification front.

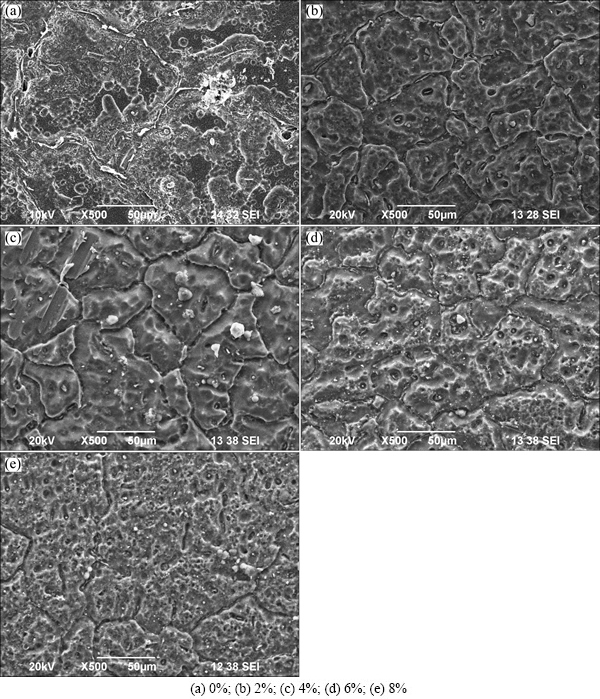

The SEM micrographs of AA6061/RHA AMCs at higher magnification are shown in Fig. 4. The details of the interface between the aluminum matrix and the RHA particle are revealed. A clear interface is observed between the aluminum matrix and the RHA particles.

Fig. 4 SEM micrographs of AA6061/RHA AMCs with different amount of RHA at higher magnification

The interface is free from any kind of reaction products. The shape of the particle is similar to the original shape in Fig. 1. There is no interfacial reaction or decomposition of RHA particles during compocasting. The interfacial reaction has a tendency to affect the metallurgy of the matrix alloy. Some investigators observed reaction products around the ceramic particles in AMCs produced by stir casting [30,31]. The ceramic particles tend to react with the aluminum matrix or decompose at elevated temperature to form new brittle compounds. If reaction products surround particles, the load will not be effectively transferred to the particle. The load bearing capacity of the interface will be reduced. A clean interface enhances the load bearing capacity. Further, the particles are not surrounded by pores or voids or micro cracks. RHA particles are completely wetted by the semi solid aluminum. They can be considered to be well bonded with the matrix. This in turn reduces the possibility of the pullout of RHA particles during tensile loading.

3.3 Mechanical properties of AA6061/ RHA AMCs

The effect of mass fraction of RHA particles on microhardness and UTS of the AA6061/RHA AMCs is depicted in Fig. 5. It is evident from Fig. 5 that the reinforcement of RHA particles significantly improves the microhardness and UTS of the AMCs. AA6061/8% RHA (mass fraction) AMC exhibits 167.27% higher microhardness and 57.42% higher UTS compared to unreinforced AA6061 alloy. The results clearly indicate that RHA particles strengthens the AMCs. Similar findings were reported by SARAVANAN and KUMAR [20]. It is well known that when the motion of dislocations is hindered or delayed, the strengthening takes place. The strengthening of AA6061/RHA AMCs is elaborated as follows. The value of coefficient of thermal expansion of aluminum alloy and RHA particles is different. The variation in coefficient of thermal expansion sets up strain fields around RHA particles during solidification. These strain fields hinder the motion of dislocations during tensile loading. Higher applied load is required to pass the dislocations around the strain fields. It is discussed earlier that the RHA particles refine the grains of the aluminum alloy. According to Hall-Patch relationship, the grain size is inversely proportional to tensile strength. As grains are refined, the area to resist the external force and the number of boundaries increase. The motion of dislocation is retarded due to frequent change in orientation of dislocations at grain boundaries. The good bonding and clear interface delay the detachment of RHA particles from the aluminum matrix during tensile loading. The applied tensile load is effectively transferred to the RHA particle. Further, the dispersion of RHA particles all over the matrix provides Orowan strengthening [32]. The dislocations bow around the particle and the motion is retarded. Therefore, the microhardness and UTS of AA6061/AMCs are improved by RHA particles. As the mass fraction of RHA particles increases, the effect of the above discussed factors goes up which further increases the mechanical properties.

Fig. 5 Effect of RHA content on microhardness (a) and ultimate tensile strength (b) of AA6061/RHA AMCs

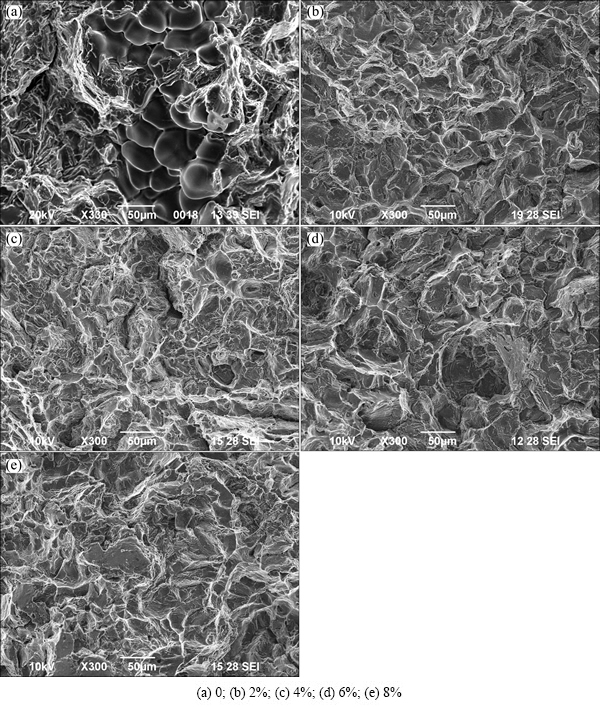

Fig. 6 Fracture morphologies of AA6061/RHA AMCs containing different amount of RHA

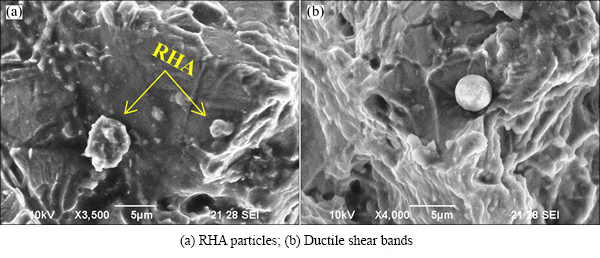

The effect of RHA content on the fracture morphology of the tensile tested specimens of AA6061/RHA AMCs is presented in Fig. 6. Uniformly distributed and bigger size voids are visible in the fracture morphology (Fig. 6(a)) of aluminum matrix AA6061. The fracture mode is ductile. Smaller size voids are present in the fracture morphology of AA6061/RHA AMCs. The grain refinement in the AMCs causes the voids to shrink in size. Plastic flow of aluminum matrix is evident from the micrographs of AA6061/RHA AMCs, which confirm a ductile fracture. Some flat regions are observed in the fracture morphology of AA6061/8% RHA AMC which indicates mixed mode of fracture. The fracture is macroscopically brittle and microscopically ductile. The fracture morphology of AA6061/8% RHA AMC at higher magnification is presented in Fig. 7. The ductile shear bands in the fracture morphology (Fig. 7(b)) indicate that some amount of ductility is retained by the AMC. RHA particles remain intact in several places which gives evidence for the existence of good interfacial bonding between the aluminum matrix and RHA particles.

4 Conclusions

1) AA6061/RHA AMCs were successfully produced using the compocasting method. The RHA particles were homogeneously distributed in the aluminum matrix. The distribution was predominantly intragranular.

2) The RHA particles refined the grains of the aluminum matrix.

3) The RHA particles were thermodynamically stable at the compocasting temperature. There was no interfacial reaction between the RHA particle and the aluminum matrix. The interface between the aluminum matrix and the RHA particle was clear and the RHA particles were bonded well with the aluminum matrix.

4) The reinforcement of RHA particles enhanced the mechanical properties of the AMCs. AA6061/8% RHA AMC exhibited 167.27% higher microhardness and 57.42% higher UTS compared to the unreinforced AA6061 alloy.

5) The fracture mode of the produced AMCs was observed to be ductile fracture.

Fig. 7 Fracture morphologies of AA6061/8% RHA AMCs at higher magnification

Acknowledgements

The authors are grateful to the Centre for Research in Metallurgy (CRM), School of Mechanical Sciences, Karunya University, Coimbatore, India for providing the facilities. The authors are also thankful to Mr. A. RAJA, Mr. I. Deva MANOHARAN and Mr. C. John KENNEDY for their assistance offered to execute the above work.

References

[1] ITSKOS G, ROHATGI P K, MOUTSATSOU A, DEFOUW J D, KOUKOUZAS N, VASILATOS C, SCHULTZ B F. Synthesis of A356 Al–high-Ca fly ash composites by pressure infiltration technique and their characterization [J]. Journal of Materials Science, 2012, 47: 4042-4052.

[2] ROHATGI P K. Metal matrix composites [J]. Defence Science Journal, 2013, 43: 323-349.

[3] ZAHI S, DAUD A R. Fly ash characterization and application in Al-based Mg alloys [J]. Materials and Design, 2011, 32: 1337-1346.

[4] MARIN E, LEKKA M, ANDREATTA F, FEDRIZZI L, ITSKOS G, MOUTSATSOU A, KOUKOUZAS N, KOULOUMBI N. Electrochemical study of aluminum-fly ash composites obtained by powder metallurgy [J]. Materials Characterization, 2012, 69: 16-30.

[5] SARANGI M, NAYAK P, TIWARI T N. Effect of temperature on nano-crystalline silica and carbon composites obtained from rice-husk ash [J]. Composites: Part B, 2011, 42: 1994-1998.

[6] AYSWARYA E P, FRANCIS K F V, RENJU V S, THACHIL E T. Rice husk ash—A valuable reinforcement for high density polyethylene [J]. Materials and Design, 2012, 41: 1-7.

[7] HASHIM J, LOONEY L, HASHMI M S J. Metal matrix composites: Production by the stir casting method [J]. Journal of Materials Processing Technology, 1999, 92-93: 1-7.

[8] SCHULTZ B F, FERGUSON J B, ROHATGI P K. Microstructure and hardness of Al2O3 nanoparticle reinforced Al-Mg composites fabricated by reactive wetting and stir mixing [J]. Materials Science and Engineering A, 2011, 530: 87-97.

[9] ASHOK KUMAR B, MURUGAN N. Metallurgical and mechanical characterization of stir cast AA6061-T6–AlNp composite [J]. Materials and Design, 2012, 40: 52-58.

[10] KALAISELVAN K, MURUGAN N, PARAMESWARAN S. Production and characterization of AA6061-B4C stir cast composite [J]. Materials and Design, 2011, 32: 4004-4009.

[11] SAHIN Y. Preparation and some properties of SiC particle reinforced aluminum alloy composites [J]. Materials and Design, 2003, 24: 671-679.

[12] URENA A, MARTINEZ E E, RODRIGO P, GIL L. Oxidation treatments for SiC particles used as reinforcement in aluminium matrix composites [J]. Composites Science and Technology, 2004, 64: 1843-1854.

[13] RAMESHA C S, KESHAVAMURTHY R, CHANNABASAPPA B H, AHMED A. Microstructure and mechanical properties of Ni-P coated Si3N4 reinforced Al6061 composites [J]. Materials Science and Engineering A, 2009, 502: 99-106.

[14] CESCHINI L, MINAK G, MORRI A. Tensile and fatigue properties of the AA6061/20 vol.% Al2O3p and AA7005/10 vol.% Al2O3p composites [J]. Composites Science and Technology, 2006, 66: 333-342.

[15] AMIRKHANLOU S, REZAEI M R, NIROUMAND B, TOROGHINEJAD M R. High-strength and highly-uniform composites produced by compocasting and cold rolling processes [J]. Materials and Design, 2011, 32: 2085-2090.

[16] SAJJADI S A, EZATPOUR H R, PARIZI M T. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes [J]. Materials and Design, 2012, 34: 106-111.

[17] AMIRKHANLOU S, NIROUMAND B. Fabrication and characterization of Al356/SiCp semisolid composites by injecting SiCp containing composite powders [J]. Journal of Materials Processing Technology, 2012, 212: 841-847.

[18] PRASAD D S, KRISHNA A R. Production and mechanical properties of A356.2 /RHA composites [J]. International Journal of Advanced Science and Technology, 2011, 33: 51-57.

[19] PRASAD D S, KRISHNA A R. Tribological properties of A356.2/RHA composites [J]. Journal of Materials Science and Technology, 2012, 28: 367-372.

[20] SARAVANAN S D, SENTHILKUMAR M. Effect of mechanical properties on rice husk ash reinforced aluminum alloy (AlSi10Mg) matrix composites [J]. Procedia Engineering, 2013, 64: 1505-1513.

[21] SARAVANAN S D, SENTHILKUMAR M, SHANKAR S. Effect of particle size on tribological behavior of rice husk ash–reinforced aluminum alloy (AlSi10Mg) matrix composites [J]. Tribology Transactions, 2013, 56: 1156-1167.

[22] ALANEME K K, AKINTUNDE I B, OLUBAMBI P A, ADEWALE T M. Fabrication characteristics and mechanical behaviour of rice husk ash-alumina reinforced Al-Mg-Si alloy matrix hybrid composites [J]. Journal of Materials Research and Technology, 2013, 2: 60-67.

[23] ALANEME K K, OLUBAMBI P A. Corrosion and wear behavior of rice husk ash-Alumina reinforced Al-Mg-Si alloy matrix hybrid composites [J]. Journal of Materials Research and Technology, 2013, 2: 188-194.

[24] RAJAN T P D, PILLAI R M, PAI B C, SATYANARAYANA K G, ROHATGI P K. Fabrication and characterisation of Al-7Si-0.35Mg/fly ash metal matrix composites processed by different stir casting routes [J]. Composites Science and Technology, 2007, 67: 3369-3377.

[25] PRASAD D S, KRISHNA A R. Fabrication and characterization of A356.2-rice husk ash composite using stir casting technique [J]. International Journal of Engineering Science and Technology, 2010, 2: 7603-7608.

[26] LLOYD J. Particle reinforced aluminium and magnesium matrix composites [J]. International Materials Reviews, 1994, 39: 1-23.

[27] HAN Y, LIU X, BIAN X. In situ TiB2 particulate reinforced near eutectic Al-Si alloy composites [J]. Composites: Part A, 2002, 33: 439-444.

[28] AKHLAGHI F, LAJEVARDI A, MAGHANAKI H M. Effects of casting temperature on the microstructure and wear resistance of compocast A356/SiCp composites: A comparison between SS and SL routes [J]. Journal of Materials Processing Technology, 2004, 155-156: 1874-1880.

[29] BAURI R, YADAV D, SUHAS G. Effect of friction stir processing (FSP) on microstructure and properties of Al-TiC in situ composite [J]. Materials Science and Engineering A, 2011, 528: 4732-4739.

[30] DAVIDSON A M, REGENER D. A comparison of aluminium-based metal-matrix composites reinforced with coated and uncoated particulate silicon carbide [J]. Composites Science and Technology, 2000, 60: 865-869.

[31] TOPTAN F, KILICARSLAN A, KARAASLAN A, CIGDEM M, KERTI I. Processing and microstructural characterisation of AA 1070 and AA 6063 matrix B4Cp reinforced composites [J]. Materials and Design, 2009, 31: S87-S91.

[32] ZHANG Z, CHEN D L. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites [J]. Materials Science and Engineering A, 2008, 483-484: 148-152.

J. ALLWYN KINGSLY GLADSTON1, N. MOHAMED SHERIFF2,

I. DINAHARAN3, J. DAVID RAJA SELVAM4

1. Department of Mechanical Engineering, SCAD College of Engineering and Technology, Cheranmahadevi 627414, Tamil Nadu, India;

2. Department of Mechanical Engineering, PET Engineering College, Vallioor 627117, Tamil Nadu, India;

3. Department of Mechanical Engineering, V V College of Engineering, Tisaiyanvilai 627657, Tamil Nadu, India;

4. Centre for Research in Metallurgy (CRM), School of Mechanical Sciences, Karunya University, Coimbatore 641114, Tamil Nadu, India

摘 要:稻壳灰(RHA)是一种有潜力的廉价铝基复合材料的增强颗粒。采用复合铸造方法制备不同稻壳灰含量(0,2%,4%,8%,质量分数)增强的AA6061铝合金复合材料。采用X射线衍射和扫描电镜对所制备复合材料进行表征。X射线衍射谱表明AA6061/RHA铝基复合材料中除RHA颗粒外未形成其他金属间化合物。扫描电镜图片表明RHA颗粒均匀分布在铝基体中。RHA基本分布在晶粒内部。此外,RHA颗粒与铝基体结合良好并形成清晰的界面。RHA颗粒的添加能提高铝基复合材料的显微硬度和抗拉强度。铝基复合材料的拉伸行为与其微观组织密切相关。

关键词:6061铝合金;铝基复合材料;复合铸造;稻壳灰;显微组织

(Edited by Yun-bin HE)

Corresponding author: J. ALLWYN KINGSLY GLADSTON; Fax: 091-0462- 2501007; Email: akgaavin@gmail.com

DOI: 10.1016/S1003-6326(15)63653-6