文章编号:1004-0609(2015)-09-2510-07

丝粉同步送进激光沉积制备铝基复合材料的显微组织

李福泉,张 阳,陈彦宾,高振增

(哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001)

摘 要:采用旁轴送进铝丝结合同轴送给WC陶瓷粉末的工艺,在铝基体表面进行激光沉积,以获得铝合金表面的复合材料层。通过优化工艺参数,得到较好的表面沉积层。采用XRD、SEM、EDAX等方法对沉积层进行显微组织分析。结果表明:沉积层中WC陶瓷颗粒在铝基体中发生溶解,在WC陶瓷颗粒周围生成大量杆状和簇状的Al4W、细小颗粒状的W2C以及针状的Al4C3。与基体相比,激光沉积复合材料层的硬度明显提高。

关键词:铝基复合材料;激光沉积;丝粉同步;显微组织

中图分类号:TG174.453 文献标志码:A

Microstructure of Al matrix compound fabricated by coincident wire-powder feeding in laser deposition

LI Fu-quan, ZHANG Yang, CHEN Yan-bin, GAO Zhen-zeng

(State Key Laboratory of Advanced Welding and Joining,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: Through coaxial ceramic powder feeding and wire feeding simultaneously, aluminum matrix compounds layer was fabricated on the aluminum alloy by laser deposition. Ideal metal matrix compounds (MMC) layer was produced by optimized parameters. XRD, SEM, and EDAX were conducted to analyze the microstructure of the aluminum matrix compounds. The results show that WC particle dissolves into aluminum matrix, leading to the formation of a large number of rod-shaped and tufted Al4W, tiny granule-shaped W2C and needle-shaped Al4C3. Compared with aluminum substrate, the microhardness of MMC layer is improved significantly.

Key words: Al matrix compound; laser deposition; coincident wire-powder feeding; microstructure

颗粒增强铝基复合材料拥有高比强度、比刚度、耐疲劳和耐磨等优良的性能[1-5]。现有的颗粒增强铝基复合材料制备方法包括粉末冶金法、铸造法和喷射沉积法等[6-9]。然而,制备整体复合材料造价昂贵,难于焊接和加工,并且大多数材料的失效发生在表面,因此制备表面复合材料层成为一种更加经济、可行的方法。激光沉积作为一种先进的加工与制造技术,具有成形结构复杂、空间可达性好、适用材料广泛、可实现梯度功能、生产周期短等优点[10-12]。MAN等[13]将Ti、C、W及WC混合粉末预置在铝合金表面进行激光沉积,得到的沉积层硬度和耐磨性都得到较大提高。JENDRZEJEWSKI等[14]采用同步送进SiC、WC混合粉末的方法在铝合金表面进行激光沉积,得到的增强相在沉积层中呈梯度分布,很好地将陶瓷颗粒的耐蚀性与基体的塑韧性结合起来。

送粉式、送丝式是材料表面激光沉积的两种主要材料添加方式:送粉式激光沉积容易实现自动化控制,激光能量吸收率高,但粉的利用率低,易造成粉尘污染;送丝式激光沉积制备的表面层致密度好,丝材利用率高,成本低,制备的表面具有较高的厚度[15-20]。

丝粉同步添加激光沉积综合了两种技术的优势[21]。FARAYIBI等[22]采用旁轴送进Ti-6Al-4V焊丝与WC粉末的方法,在Ti-6Al-4V基材表面进行激光沉积,并对多道搭接进行探索,得到的沉积层中WC颗粒分布均匀,起到很好的强化作用。

本文作者采用同轴送粉结合旁轴送丝的方法在铝基体表面进行激光沉积实现复合材料的制备。丝的加入可以控制沉积层尺寸;粉的添加提供增强相,并通过调节送粉量,实现对复合材料中增强相体积分数的调节。通过工艺实验获得成型较好的沉积层,并研究沉积层的显微组织,在此基础上采用优化后的工艺参数对叠层沉积进行探索。

1 实验

激光沉积试验采用4 mm厚1060铝板,并采用4047铝焊丝,其成分如表1所列。激光沉积试验采用不规则型态的单晶WC颗粒,其显微形貌如图1所示。其相组成为WC和W2C。

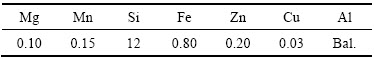

表1 4047铝合金焊丝的化学成分

Table 1 Chemical composition of 4047 aluminum alloy wire(mass fraction, %)

图1 WC颗粒的显微形貌

Fig. 1 Morphology of WC particles

实验中采用的主要仪器包括:德国IPG公司生产的YLS-10000型光纤激光器,光纤传输;德国GTV公司生产的MF-PF2/2型双筒送粉器,送粉精度可以达到0.1 g/min;德国PECTIEC公司生产的YC52型同轴熔覆头;德国KUKA公司生产的六轴联动机器人;福尼斯公司生产的KD4010型送丝机。实验中WC粉末是通过载气从送粉器送出,铝丝由送丝机送入熔池。

首先,将铝板经砂纸打磨后用丙酮清洗,在40~60 ℃温度下用6%~10%(质量分数)NaOH水溶液碱洗10 min;放入30%(质量分数)HNO3溶液中酸洗5 min。将铝板和WC粉末放入烘干机中,在120 ℃下烘干1.5 h备用。激光沉积工艺示意图如图2所示。实验过程中通过熔覆头进行同轴送粉,同时在旁轴送进铝合金焊丝。激光束在到达基体表面前先与WC粉末束流作用,而后作用于铝合金焊丝及铝表面层,形成熔池,并在机器人的带动下向前运动。

对激光沉积而言,主要的几个工艺参数如下:激光功率、送丝速度、送粉速率、扫描速度等。当激光功率过大时,大量的WC粉末将会被烧损;当激光功率较小时,沉积层边缘容易出现未熔合等缺陷;送丝速度会影响沉积层的尺寸及沉积层与基体的结合效果;当送粉率过大时,沉积层成型差,并且与基体的冶金结合较差,应在成型良好的前提下尽量提高送粉率;扫描速度则影响沉积层的尺寸及WC含量。

图2 激光沉积工艺示意图

Fig. 2 Schematic diagram of laser deposition process

制备金相试样的过程中采用抛光盘外圈长时间抛光,得到光洁的金相试样。抛光后采用1%HF+1.5%HNO3+97.5%H2O(体积分数)腐蚀剂腐蚀。通过D/MAX-RB 12KW型X射线衍射仪分析沉积层的相组成。通过Hitachi-S3400扫描电子显微镜观察沉积层,利用点能谱和线能谱对结构及界面反应进行探究。采用宏观硬度计对沉积层进行硬度测试,由沉积层表面开始每隔0.2 mm打点测量硬度,测试载荷为2 N,加载时间为10 s。对比沉积层与基体的硬度,分析注入WC对沉积层性能的影响。

2 结果与分析

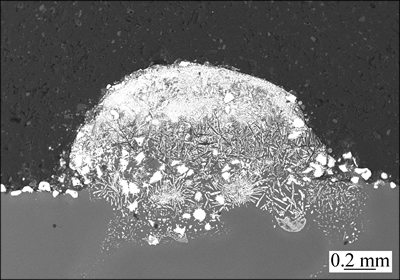

实验中优化后的工艺参数如下:激光功率2.2 kW,扫描速度0.005 m/s,送丝速度40 cm/min,送粉率164 mg/s。得到的沉积层截面组织如图3所示。其他工艺参数为:激光束光斑直径2.2 mm,熔覆头倾角为10°,送丝角度为10°,送粉载气流量5 L/min,保护气流量为10 L/min。

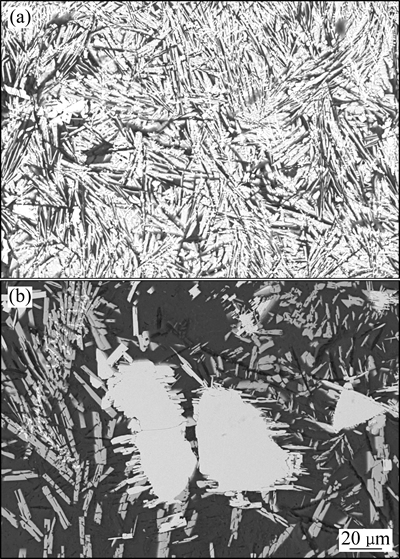

沉积层不同位置处的SEM像如图4所示。沉积层上部WC几乎全部溶解(见图4(a)),生成大量杆状及簇状W、Al化合物,均匀分布在铝合金基体中,对基体起到一定的增强作用。由于WC颗粒与铝基体性能差异明显,若两者不能形成良好的冶金结合,则在摩擦作用下硬质WC颗粒易发生脱落,影响复合材料的使用性能。沉积层下部区域的WC颗粒较好地保持原始形态(见图4(b)),并且由颗粒向周围基体生长出许多杆状W、Al化合物,表明WC颗粒能够实现对铝基体的增强作用。

图3 激光沉积复合材料层的截面形态

Fig. 3 Cross-section structure of MMC layer produced by laser deposition

图4 复合材料沉积层上部和下部的SEM像

Fig. 4 SEM images of MMC layer at location of upper part (a) and bottom part (b)

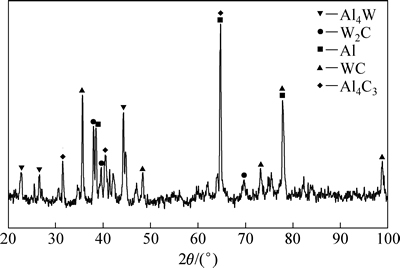

复合材料层的XRD谱如图5所示。由图5可知,沉积层中包含Al4W、AL4C3、WC、W2C、Al相。由此推测, WC在沉积过程中部分熔化, 分解产生W及C的局部富集区及贫乏区。富集的C原子与Al结合形成Al4C3;而贫C区的存在促进了W2C的析出。

图5 复合材料层的XRD谱

Fig. 5 XRD spectra of MMC layer

复合材料层的陶瓷颗粒增强相的分布及其形态是影响表面层性能的主要因素,图6所示为复合材料层中WC颗粒的形态。由图6可见,WC陶瓷颗粒仍然保持原始的棱角形态,同时颗粒与基体形成了明显的冶金反应层。沉积层中主要由Al基体、WC颗粒、白色块状相、灰色杆状相、黑色针状相以及亮白色细小颗粒状相等组成。相应区域的EDX分析结果如表2所列。

图6中A处灰白色杆状相的能谱结果显示,该相中只含有W和Al元素,且Al与W摩尔比为4:1,结合XRD结果判断其为Al4W。该相呈簇状广泛分布于基体中,可以增大基体的硬度,对基体产生很好的强化作用。B处及C处的能谱结果显示,这些相中主要含有W和C元素。结合背散射电子像分析可知,WC颗粒与白色块状物颜色一致,初步判断B区域块状物也是WC。由于铝合金沸点为2327℃,而WC颗粒的熔点为2870 ℃,因此WC颗粒在熔池中不会因为高温而熔化。WC颗粒在添加过程中由于受到激光的辐照而导致表面熔化,进入到液态熔池以后,熔化后的WC将以W原子和C原子的形式存在于复合材料层中[23]。随后在凝固的过程中重新结晶形成块状物质。进一步推测激光沉积过程中WC与Al反应机制如下:一部分WC颗粒在送入熔池之前受激光束加热全部熔化,在进入熔池后受到铝熔池的粘滞阻力,留在沉积层中上部,与铝基体发生反应;另一部分WC表面熔化,未熔化的内部颗粒以及其表面由于张力而附着的少量液态WC进入熔池后下沉到中下部,与基体发生发应。

图6 复合材料层中WC颗粒及基体形态

Fig. 6 Morphologies of WC particles and matrix in MMC layer

表2 图6中不同位置处的EDX分析结果

Table 2 EDX analysis results at zones A, B, C and D shown in Fig. 6

D区域黑色针状相由Al和C原子组成,结合XRD结果判定为脆性相Al4C3。从图6(b)可以看出,针状的Al4C3在生长过程中贯穿基体和Al4W化合物,并且与基体结合较差。观察发现,在沉积层中均存在大量针状脆性相Al4C3。抑制Al4C3的过度生成是改善复合材料层性能的基本要求。参考文献[24],可以通过在激光沉积形成熔池中添加Ti-90Al合金来抑制Al4C3的生成,这是本文作者后续将要开展的研究。

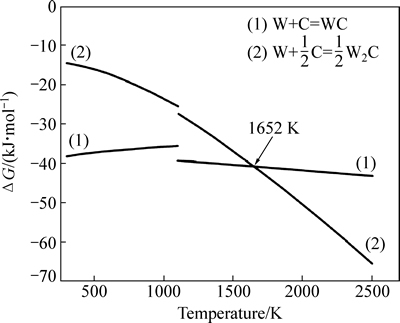

根据背散射图片原子序数越大颜色越亮的特点及XRD分析结果,可以确定图6(a)中E区域存在的亮白色细小颗粒为W2C。由图7中W与C反应的ΔG-T曲线[25]可知,在高温时由于生成W2C的自由能比WC的自由能低,表明在熔池的高温条件下W2C会优先析出。可以认为其反应过程如下:WC颗粒熔化后进入熔池,分解出W和C原子,参与熔池反应;C原子扩散快,部分进入基体与Al反应生成Al4C3;W原子扩散慢,在原位形成富W区,与Al反应生成Al4W。并且在高温下生成W2C的自由能较低,因此会在富W区析出W2C相。

图7 W与C反应的ΔG-T 曲线[25]

Fig. 7 ΔG-T curves for W reacting with C[25]

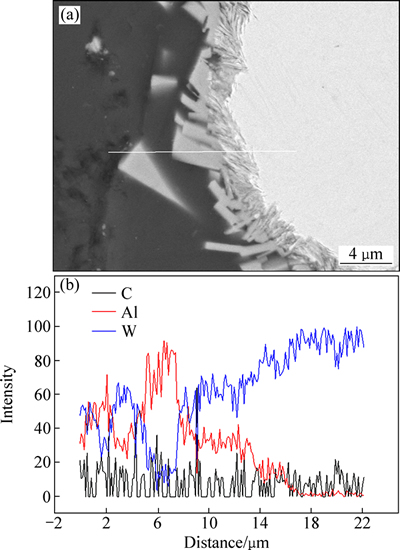

Al/WC结合界面的形貌和线扫描结果如图8所示。从铝基体进入WC颗粒内部的直线上,忽略C元素的干扰,Al元素含量整体趋于减小,W元素含量趋于增加。而在灰色Al4W中Al和W含量保持不变。形成此反应界面的机理有两种可能:WC颗粒表面在受热分解过程中,当外界提供的热量不足时,只有W2C溶解,未分解的WC呈枝晶状分布在颗粒表面[26];WC枝晶外侧有灰色Al4W生成,而在结合面并未发现Al4C3,推测是WC颗粒外部熔化,其中的W原子与Al生成Al4W,而C原子并未参与反应,导致颗粒外层贫W区的形成。在随后的冷却过程中只能以WC的形式重新结晶形成细小枝晶。由以上分析可见,Al/WC界面为枝晶状WC外侧包围着Al4W,表明WC颗粒与铝基体结合良好,便于载荷的传递,有利于避免因性能差异过大导致的组织开裂或在磨损过程中发生的WC颗粒脱落。

图8 WC颗粒与Al基体反应界面形貌及元素线扫描曲线

Fig. 8 SEM image of interface between WC and Al matrix (a) and element line scanning curves of line (b) shown in Fig. (a)

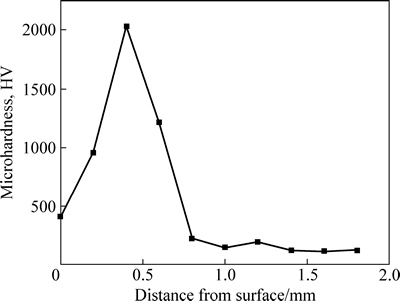

为了研究沉积层硬度与显微组织的关系,试验采用显微硬度计对沉积层进行硬度分析,图9所示为沉积层显微硬度分析结果。由图9可以看出,沉积层的平均硬度为1000HV左右,较基体的硬度(250HV)有显著提高。结合上述组织分析结果,沉积层中Al4W附近的硬度为1000HV左右;WC颗粒所在区域的硬度较高,可达2000HV。虽然增强相WC与铝基体之间的硬度差较大,但由于WC颗粒外围包裹着Al4W,因此硬度呈梯度下降,有利于避免因硬度差过大导致的开裂。

图9 复合材料层的显微硬度

Fig. 9 Microhardness of MMC layer

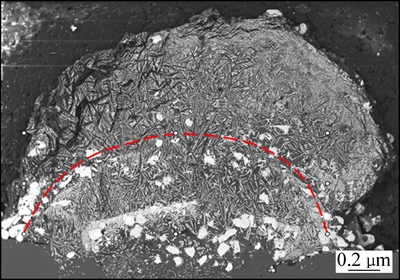

图10 叠层沉积截面SEM像

Fig. 10 Cross-section SEM image of laminated MMC

采用上述优化后的工艺参数进行叠层沉积,获得的叠层沉积层的截面SEM像如图10所示。由图10可以看出,沉积层成型良好,与单道沉积相比,叠层沉积层尺寸明显增加。由于第一层MMC中WC颗粒处于组织中下层,经过第二层的激光沉积的重熔作用,对第一层MMC中WC颗粒的形态及其分布影响不大。第二层MMC中WC颗粒有明显下沉现象,WC颗粒在接近两层的熔合处下沉聚集。在叠层沉积时,可以认为各沉积层会成为下层激光沉积的基体,上述研究表明采用丝粉同步叠层沉积方法能够制备铝基复合材料结构。

3 结论

1) 采用同轴送粉结合旁轴送丝激光沉积制备表面复合材料层,试验的工艺参数如下:激光功率2.2 kW,扫描速度0.005 m/s,送丝速度40 cm/min,送粉率164 mg/s。

2) 对复合材料层显微组织的XRD分析发现,复合材料中包含Al4W、AL4C3、WC和W2C相。部分WC颗粒在送入熔池之前受激光加热全部熔化,在进入熔池后受到铝熔池的粘滞阻力,留在沉积层中上部,与铝基体发生剧烈反应,形成大量杆状和簇状Al4W、细小颗粒状W2C以及针状Al4C3等;另一部分WC表面熔化,未熔化的内部颗粒以及表面由于张力附着的少量液态WC进入熔池后下沉到中下部,与基体发生轻微发应,在WC/Al反应界面形成枝晶状WC以及外围的Al4W。

3) 对沉积层的硬度分析表明,注入WC的沉积层硬度得到明显提高。叠层沉积时第二层的激光重熔对第一层内部增强相颗粒的形态及分布并无明显影响。表明采用丝粉同步叠层沉积方法能够制备铝基复合材料结构。

REFERENCES

[1] SPOWART J E, MIRACLE J B. The influence of reinforcement morphology on the tensile response of 6061/SiC/25p discontinuously-reinforced aluminum[J]. Materials Science and Engineering, 2003, 357: 111-123.

[2] TANAKA K, AKINIWA Y, SHIMIZU K, KIMURA H, ADACHI S. Fatigue thresholds of discontinuously reinforced aluminum alloy correlated to tensile strength[J]. International Journal of Fatigue, 2000, 22: 431-439.

[3] IRFAN M A,PRAKASH V. Dynamic deformation and fracture behavior of novel damage tolerant discontinuously reinforced aluminum composites[J]. International Journal of Solids and Structures, 2000, 37: 4477-4507.

[4] MIRACLE D B,PANDEY A B,MAJUMDAR B S. Laminated particulate-reinforced aluminum composites with improved toughness[J]. Acta Materialia, 2001, 49: 405-417.

[5] 赵龙志, 杨 敏. 颗粒增强铝基复合材料的研究[J]. 材料热处理技术, 2011, 40: 107-115.

ZHAO Zhi-long, YANG Min. Research on particle reinforced aluminum matrix composite[J]. Material & Heat Treatment, 2011, 40: 107-115.

[6] LIOYD D J. Particle reinforced aluminium and magnesium matrix composites[J]. Inter Mater Rev, 1994, 39: 1-9.

[7] SHIONO T, NODA K. Fabrication of ceramic composites consisting of powders with different specific gravity by the slip-casting technique[J]. J Mater Sci, 1997, 32: 2665-2678.

[8] WATANABE Y, NAKAMURA T. Microstructure and wear resistance of hybrid Al-(Al3Ti+Al3Ni) FGMs fabricated by a centrifugal method[J]. Intermetallics, 2001, 9(1): 33-43.

[9] 王双喜, 刘雪敬, 孙家森. 铝基复合材料的制备工艺[J]. 热加工工艺, 2006, 35(1): 65-69.

WANG Shuang-xi, LIU Xue-jing, SUN Jia-sen. Preparation technologies for aluminum matrix composites[J]. Casting & Forging, 2006, 35(1): 65-69.

[10] THIVILLON L, BERTRAND P H, LAGET B. Potential of direct metal deposition technology for manufacturing thick functionally graded coatings and parts for reactors components[J]. Journal of Nuclear Materials, 2009, 385: 236-241.

[11] SCHWENDNER K I, BANERJEE R, COLLINS P C. Direct laser deposition of alloys from elemental powder blends[J]. Scripta Materialia, 2001, 45(19): 1123-1129.

[12] ATWOOD C L, GRIFFITH M L, SCHLIENGER M E. Laser engineered net shaping(LENSTM): A tool for direct fabrication of metal parts[C]//Processing of the Laser Materials Processing Conference Section A 1998. Orlando: Laser Institute of America, 1998: E-1.

[13] MAN H C, YANG Y Q, LEE W B. Laser induced reaction synthesis of TiC+WC reinforced metal matrix composites coatings on Al 6061[J]. Surface & Coatings Technology, 2004, 185(1): 74-80.

[14] JENDRZEJEWSKI R, VANACKER K, VANHOYWEGHEN D, SLIWINSKI G. Metal matrix composite production by means of laser dispersing of SiC and WC powder in Al alloy[J]. Applied Surface Science, 2009, 255: 5584-5587.

[15] SYED W U H, PINKERTON A J, LI L. A comparative study of wire feeding and powder feeding in direct diode laser deposition for rapid prototyping[J]. Applied Surface Science, 2005, 247: 268-276.

[16] SYEDA W U H, PINKERTON A J, LIU A, LI L. Coincident wire and powder deposition by laser to form compositionally graded material[J]. Surface & Coatings Technology, 2007, 201(16/17): 7083-7091.

[17] HUSSEIN N I S, SEGAL J, MCCARTNEY D G, PASHBY I R. Microstructure formation in Waspaloy multilayer builds following direct metal deposition with laser and wire[J]. Materials Science and Engineering A, 2008, 497(1/2): 260-269.

[18] SYED W U H, PINKERTON A J, LI L. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects)[J]. International Journal of Machine Tools and Manufacture, 2004, 44(6): 573-584.

[19] PINKERTON A J,LI L,LAU W S. Effects of powder geometry and composition in coaxial laser deposition of 316L steel for rapid prototyping[J]. CIRP Annals-Manufacturing Technology, 2003, 52: 181-184.

[20] MARTUKANITZ R P, MICHALERIS P, LIU Z K, HEO T K. Toward an integrated computational system for describing the additive manufacturing process for metallic materials[J]. Additive Manufacturing, 2014, 4: 52-63.

[21] SYED W U H, PINKERTON A J, LI L. Combining wire and coaxial powder feeding in laser direct metal deposition for rapid prototyping[J]. Applied Surface Science, 2006, 252(13): 4803-4808.

[22] FARAYIBI P K,MURRAY J W,HUANG L,BOUD F, KINNELL P K,CLARE A T. Erosion resistance of laser clad Ti-6Al-4V/WC composite for water jet tooling[J]. Journal of Materials Processing Technology, 2014, 214(3): 710-721.

[23] 姚建华. 激光表面改性技术及其应用[M]. 北京: 国防工业出版社, 2012: 171.

YAO Jian-hua. Laser surface modification technology and application[M]. Beijing: Defense Industry Press, 2012: 171.

[24] 雷玉成, 邵奇栋, 张 振, 聂加俊. Ti-Al合金对SiCp/6061Al 复合材料等离子弧焊焊缝组织的影响[J]. 中国有色金属学报, 2009, 19(2): 241-246.

LEI Yu-cheng, SHAO Qi-dong, ZHANG Zhen, NIE Jia-jun. Effect of Ti-Al alloy on microstructures of weld in plasma ‘in-situ’ welding of SiCp/6061Al MMCs[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(2): 241-246.

[25] 迟 静, 李惠琪, 王淑峰, 李 敏, 李建楠, 王 梅, 高旭杰. 直流电弧原位冶制备粗晶碳化钨块体复合材料[J]. 中国有色金属学报, 2013, 23(5): 35-37.

CHI Jing, LI Hui-qi, WANG Shu-feng, LI Min, LI Jian-nan, WANG Mei, GAO Xu-jie. Coarse-grain bulk WC composites prepared by direct current arc in-situ metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 35-37.

[26] 黄汝清, 李祖来, 山 泉, 蒋业华, 周 荣, 隋育栋. 钢铁基复合材料中铸造碳化颗粒的分解过程[J]. 特种铸造及有色金属, 2012, 32(2): 76-78.

HUANG Ru-qing, LI Zu-lai, SHAN Quan, JIANG Ye-hua, ZHOU Rong, SUI Yu-dong. Decomposition process of casting tungsten carbide particle in steel/iron substrate[J]. Special Casting & Nonferrous Alloys, 2012, 32(2): 76-78.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51175114);黑龙江省博士后科研启动资助项目(LBH-Q13065)

收稿日期:2014-12-09;修订日期:2015-05-28

通信作者:李福泉,副教授,博士;电话:0451-86415506;E-mail:lifuquan@hit.edu.cn