DOI: 10.11817/j.issn.1672-7207.2015.12.002

含硫铝酸钠溶液中铁质量浓度的变化规律

牛飞,李小斌,周秋生,齐天贵,刘桂华,彭志宏

(中南大学 冶金与环境学院,难冶有色金属资源高效利用国家工程实验室,湖南 长沙,410083)

摘要:在260 ℃高压溶出黄铁矿制备高硫高铁的铝酸钠溶液,研究溶液温度、保温时间、苛性比(αk)以及Na2CO3,Na2SO4和Na2C2O4等杂质对溶出液中铁质量浓度的影响。研究结果表明:溶液温度为50 ℃和60 ℃时,随着保温时间的延长,溶液中铁质量浓度略有降低;苛性比为3.0左右时,随着Na2CO3质量浓度的升高,溶液中铁质量浓度略有升高,而Na2SO4和Na2C2O4质量浓度的升高则能显著提高溶液中的铁质量浓度;随着溶液苛性比的升高,溶液中铁质量浓度在苛性比为 2.0~2.5之间有1个急剧升高的区间,然后逐渐趋于稳定。

关键词:黄铁矿;铝酸钠溶液;铁质量浓度;高压溶出

中图分类号:TF821 文献标志码:A 文章编号:1672-7207(2015)12-4398-06

Variation of mass concentration of iron in sulfur sodium aluminate solution

NIU Fei, LI Xiaobin, ZHOU Qiusheng, QI Tiangui, LIU Guihua, PENG Zhihong

(National Engineering Laboratory for Efficient Utilization of Refractory Non-ferrous Metals Resources,

School of Metallurgy and Environment, Central South University, Changsha 410083, Hunan)

Abstract: The sodium aluminate solution with high iron and sulfur content was prepared by the high-pressure digestion of pyrite at 260 ℃. The influences of temperature, residence time, caustic ratio αk and the content of Na2CO3, Na2SO4 and Na2C2O4 on the mass concentration of iron in sodium aluminate solution were investigated. The results show that the mass concentration of iron decreases slightly with the increase of residence time when the solution temperatures are 50 ℃ and 60 ℃. When αk is approximately 3.0, the mass concentration of iron increases slightly with the increase of Na2CO3 mass concentration and obviously with the increase of Na2SO4 and Na2C2O4 concentration. The mass concentration of iron increases rapidly with αk from 2.0 to 2.5 and then enters a relatively stable state with the continuous increase of αk.

Key words: pyrite; sodium aluminate solution; mass concentration of iron; high-pressure digestion

随着我国优质铝土矿资源的日渐匮乏,高硫铝土矿的充分利用问题引起人们极大关注。采用拜耳法处理高硫铝土矿生产氧化铝时,矿石中的硫(特别是S2-)会在生产过程中积累,并产生一系列不良后果[1],不仅增加碱耗,腐蚀设备,结疤严重,而且会造成循环母液溶出液颜色变深甚至变黑[2],最终得到铁含量超标的绿色甚至墨绿色的氢氧化铝产品。高硫铝土矿中危害最大的含硫矿物是黄铁矿,其会在高温溶出过程中反应,进而造成危害。Ciminelli等[3-4]研究了黄铁矿在低温碱性体系的表面氧化行为,但是没有涉及硫和铁在高温条件下的反应。李小斌等[5-6]研究了黄铁矿在拜耳法高温溶出条件下的反应,认为生成的S2-与铁反应生成的硫铁络合物是导致产品污染的主要因素,明确了铁可与S2-反应生成硫代铁酸钠等物质,并可达到除去溶液中S2-的目的。Abikenova等[7]研究了氧化铝生产中硫化合物的影响,认为绝大部分低价硫在蒸发单元被氧化成硫酸盐,但并未提出新的除硫思路。目前研究较多的除硫方法包括焙烧除硫、浮选脱硫等矿石脱硫技术[8-10],添加铝酸钡[11]等钡盐来除SO42-、加入氧化剂或者ZnO等[2]除去S2-等溶液脱硫技术,这些技术虽可降低进入氧化铝生产系统的硫,但成本较高,脱硫后残留的少量硫进入溶液经循环积累后仍可达到较高水平,不能解决溶液和产品中铁含量高的问题,也难以解决高硫铝土矿的高效经济利用问题。研究铁和硫在铝酸钠溶液中的反应行为,对解决高硫铝土矿生产氧化铝过程中存在的问题具有重要的意义。刘桂华等[12]认为各种铁矿物在含硫循环母液中经高压溶出铁都可进入溶出液中,溶液中杂质对溶出液中铁质量浓度有一定影响。陈文汨等[13]研究认为,进入含硫碱液中的铁以胶体形态存在,延长稀释矿浆的停留时间,可降低拜耳液中的铁。宋超等[14]研究了黄铁矿在铝酸钠溶液中的反应行为研究,认为在预脱硅条件下黄铁矿大量反应,高温溶出条件下黄铁矿几乎全部反应。在此,本文作者研究了含硫碱性溶液(苛碱或铝酸钠溶液)中铁质量浓度的变化规律,采用含Na2S的NaOH溶液高温溶出黄铁矿,再加入Al(OH)3调节溶液苛性比(简称αk,即溶液中Na2O和Al2O3的摩尔比),得到高硫高铁铝酸钠溶液,研究不同保温时间、保温温度、杂质条件下,铝酸钠溶液中铁质量浓度的变化,以期找出高硫铝酸钠溶液中铁质量浓度的变化规律,为经济利用高硫铝土矿提供参考。

1 实验

1.1 实验原料

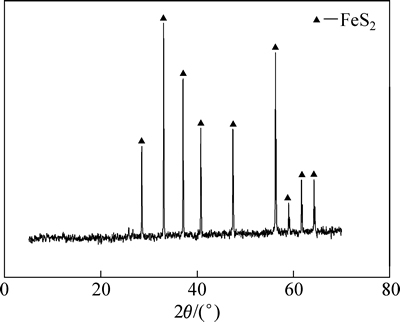

实验用Al(OH)3和NaOH均为工业纯,Na2S·9H2O为分析纯试剂。黄铁矿来自铜陵矿产品有限公司,经细磨后过孔径为125 μm筛,其XRD图谱结果如图1所示。从图1可知:该黄铁矿中杂质含量较少,主要元素为铁和硫,纯度较高。对该黄铁矿进行化学分析可知:Fe和S质量分数分别为51%和46%。

1.2 实验仪器与设备

实验所用黄铁矿采用D/MAX2500X型X线衍射分析仪(日本理学公司)进行分析;高压溶出实验在自制的XYF-Φ44×6钢弹型溶出设备中进行,钢弹容积为150 mL,加热介质为熔盐,控温精度为±1℃;吸光度采用752型紫外可见光分光光度计(上海光谱仪器有限公司)检测;溶液保温在自制恒温玻璃水浴沉降槽和恒温油浴锅中进行;溶液的红外光谱数据采用Nicolet 6700傅里叶变换红外光谱仪(美国尼高力公司)进行采集。

图1 黄铁矿的XRD图谱

Fig. 1 XRD pattern of pyrite

1.3 溶出液成分分析

本文中涉及的铝酸钠溶液中苛碱、氧化铝以及铁质量浓度(文中如未特别指出,铁质量浓度均指以Fe2O3计的质量浓度)采用文献[15]中所述的方法进行分析,其中苛碱和氧化铝浓度采用容量法测定;溶出液中铁质量浓度采用邻二氮菲比色法测定。

1.4 实验步骤

称取3 g黄铁矿和7.5 g Na2S·9H2O(S2-质量浓度为10 g/L),放进钢弹(体积为150 mL)中,并移入100 mL一定浓度的NaOH溶液,放入直径分别为20 mm和10 mm的钢球各2颗以加强搅拌,加盖后拧紧密封。将钢弹放入260 ℃的高压釜中搅拌,反应1 h后取出,快速冷却至100 ℃左右时打开高压钢弹,加入一定质量的Al(OH)3,然后将钢弹重新拧紧放回高压釜反应10 min,确保Al(OH)3能完全溶解到溶液中。再取出钢弹,冷却至100 ℃左右,打开,即可制得高硫高铁的铝酸钠溶液。将其倒入沉降管中,在一定温度的水浴槽中保温,取上清液在100 ℃保温过滤,然后分析溶液中的Na2Ok,Al2O3和Fe2O3浓度,并对部分样品进行了红外光谱分析。

2 实验结果与讨论

2.1 溶液温度和保温时间对铁质量浓度的影响

研究表明,温度对溶液中铁质量浓度的影响很大。为了通过降低溶液温度和延长保温时间,进而降低铝酸钠溶液中铁的质量浓度,研究了不同温度和不同保温时间下的铝酸钠溶液中的铁质量浓度的变化。

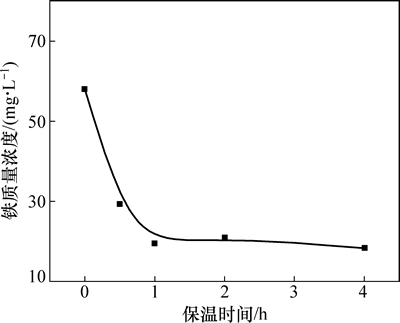

氢氧化钠溶液质量浓度(以Na2Ok计)为226 g/L, S2-质量浓度为10 g/L,溶出温度为260 ℃,溶出时间1 h,冷却后加入Al(OH)3,测得调后溶液αk为2.9,将溶出液置于沉降管中在100 ℃油浴中保温一定时间,不同保温时间对溶出液中铁质量浓度的影响如图2所示。

图2 保温时间对溶出液中铁质量浓度的影响

Fig. 2 Effect of holding time on mass concentration of iron in digestion solution

由图2可以看出:当保温时间从0增加到30 min时,溶液中的铁质量浓度从60 mg/L急剧下降至30 mg/L以下,时间延长到1 h时,铁质量浓度从30 mg/L左右降至20 mg/L左右,而且随着时间的延长,铁质量浓度基本保持稳定。铁和硫在铝酸钠溶液中以配合物形式存在[6],溶液中存在有微小的铁胶体[13]和未溶解的固体颗粒,在保温的过程中,这些细小颗粒可能充当了晶种的作用,溶液中的铁硫配合物沉降析出,使得铁质量浓度降低,当铁质量浓度低至20 mg/L时又进入一个稳定状态,保持稳定。溶液温度降低时会有固体析出,溶液的颜色也从黄色变为黑色。溶液温度是影响铁质量浓度的敏感因素。

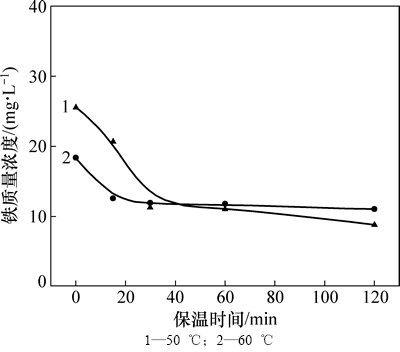

拜耳法生产氧化铝的晶种分解过程的温度范围为75~45 ℃,在温度降低的过程中,氢氧化铝结晶析出,铝酸钠溶液的αk升高。生产实践表明,溶出液中所含的铁会在晶种分解过程中析出,进入到氢氧化铝产品中,造成污染。已有研究表明:苛碱浓度增加会使得溶液中的铁质量浓度增加[12],而且本文作者在研究自配不同αk溶液对铁质量浓度的影响时发现,低αk时溶液中的铁质量浓度很低,为了使得研究体系中铁质量浓度处在一个较高的水平,选取较高的苛碱浓度和αk溶液体系为研究对象,研究了溶液温度分别为50 ℃和60 ℃时,溶液中铁质量浓度的变化。溶出液为NaOH溶液,质量浓度(以Na2Ok计)为232 g/L,S2-质量浓度10 g/L,260 ℃溶出1 h,然后加Al(OH)3调节αk至3.0,溶液温度分别为50 ℃和60 ℃下保温时间对铁质量浓度的影响如图3所示。

图3 50 ℃和60 ℃下保温时间对溶出液中铁质量浓度的影响

Fig. 3 Effect of holding time on mass concentration of iron in digestion solution at 50 ℃ and 60 ℃

从图3可以看出:随着保温时间的延长,溶液中的铁质量浓度有逐渐减少的趋势,从开始的25 mg/L减少到10 mg/L左右并保持稳定,铁质量浓度变化的区间不大,这是因为在低温时,溶解度降低,溶液中的铁会析出,留在清液中的铁减少。当保温时间为0~40 min时,50 ℃时溶液中铁质量浓度反而比60 ℃时的略高,这可能与溶液的黏度有关,成琼文等[16]研究了温度、αk等因素对铝酸钠溶液黏度的影响,结果表明:碱浓度一定时,温度越低,溶液的黏度越大,这会导致溶液中的铁析出和沉降的速度减缓,所以溶液温度较低时,溶液中的铁质量浓度反而略大;随着保温时间的延长,由于溶解度的关系,60 ℃时溶液中的铁质量浓度比50 ℃时的略高。

2.2 杂质对铁质量浓度的影响

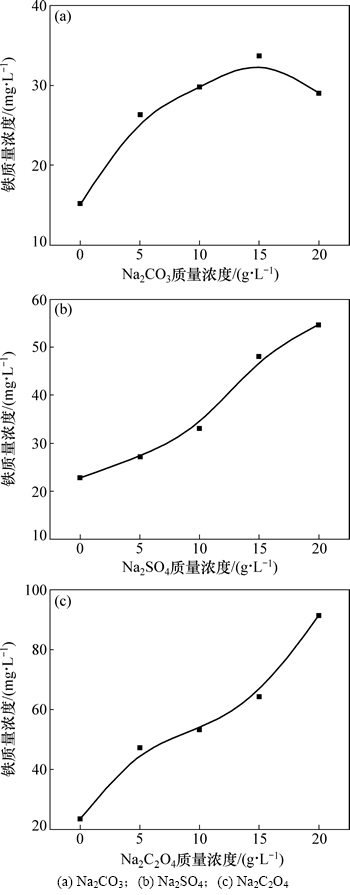

在氧化铝生产过程中,由于铝土矿和石灰中含有的碳酸盐、硫酸盐以及有机物等杂质会在溶出过程中进入溶液,因此在循环母液中往往会积累一定浓度的Na2CO3,Na2SO4和有机物等杂质,因此,在溶出过程之前,往钢弹中添加一定质量的Na2CO3,Na2SO4和有机物(Na2C2O4),以探讨这些杂质对于溶出后溶液中铁质量浓度的影响规律。溶出液为NaOH溶液,其质量浓度(Na2Ok计)为232 g/L,S2-质量浓度为10 g/L,260 ℃溶出1 h,然后加入Al(OH)3调节铝酸钠溶液的αk至3.0,保温温度为100 ℃,保温时间为30 min。不同杂质对溶出液中的铁质量浓度影响如图4所示。

由图4可以看出:随着Na2CO3质量浓度的增加,溶液中的铁质量浓度增加,当Na2CO3的加入量达到10 g/L时,再增加Na2CO3的加入量,溶液中的铁质量浓度基本上处于稳定状态。而随着Na2SO4和Na2C2O4 质量浓度的增加,溶出液的铁质量浓度升高的趋势比较明显,其中Na2SO4和Na2C2O4对铁质量浓度升高的促进作用要比Na2CO3的大,尤其是Na2C2O4,当Na2C2O4的加入量达到20 g/L时,溶液中的铁质量浓度能够达到90 mg/L左右。原因可能是高αk时,溶液的黏度较小,加入杂质后,增大了溶液体系的黏度[12],使体系中的离子运动减弱,不利于溶液中的铁析出,从而使溶液中的铁质量浓度随着杂质浓度的增加而逐渐增大。

图4 杂质对溶出液中铁质量浓度的影响

Fig. 4 Effect of impurities on mass concentration of iron in digestion solution

2.3 苛性比对铁质量浓度的影响

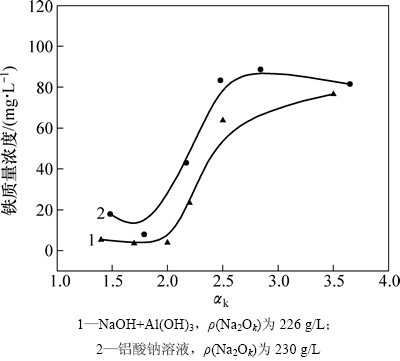

苛性比(αk)是氧化铝生产过程中的一个重要指标,在拜耳法流程中,随着矿石溶出过程的进行,溶液αk由大变小;在分解过程中,伴随着溶液中氢氧化铝的析出,溶液的αk由小变大。分别采用不同αk的铝酸钠溶液直接溶出黄铁矿和用NaOH溶液先溶出黄铁矿,然后再加入Al(OH)3调节以达到预期αk,铝酸钠溶液的苛碱质量浓度为230 g/L,氢氧化钠溶液的苛碱(以Na2O计)质量浓度为226 g/L,260 ℃溶出1 h,100 ℃保温30 min。在2种体系中,不同苛性比对溶出液中铁质量浓度的影响如图5所示。

图5 溶液苛性比对溶出液中铁质量浓度的影响

Fig. 5 Effect of caustic ratio on mass concentration of iron in desgestion solution

从图5可以看出:铁质量浓度在2个体系的溶液中的变化趋势基本上是一致的,都是低αk段(αk<2.0),铁的浓度很低,而且随着αk的增加,铁质量浓度增加不明显;当2.0<αk<2.5时,铁质量浓度急剧升高,铝酸钠溶液体系的铁质量浓度从20 mg/L左右增加到80 mg/L以上,NaOH溶液体系从10 mg/L以下增加到60 mg/L左右;当αk>2.5时,αk再增加,溶液中铁质量浓度趋于稳定。

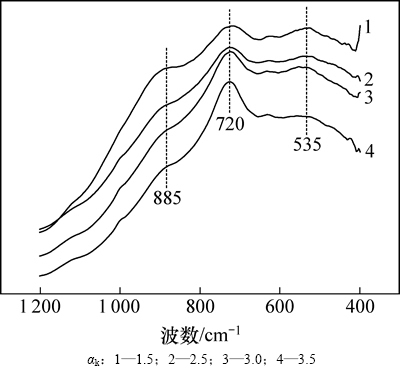

对保温过滤的不同苛性比的滤液进行了红外分析,铝酸钠溶液结构的变化如图6所示。文献[17]指出,720 cm-1处为Al—OH反对称伸缩振动带,代表的是Al(OH)4-;530 cm-1处为Al—O—Al振动带,代表的是Al2O(OH)62-;885 cm-1处为AlO4中Al—O的伸缩振动带,代表的是二聚铝酸根离子[Al2(OH)8(H2O)2]2-。由图6可以看出:有3个比较明显的峰分别位于885 cm-1处、720 cm-1处和530 cm-1处,最明显的峰位于720 cm-1处,此处对应的是Al(OH)4-,885 cm-1处和530 cm-1处对应的均为聚合铝酸根离子,随着苛性比的升高,720 cm-1处峰强度越大,885 cm-1处和530 cm-1处越来越弱,说明聚合离子转变简单的Al(OH)4-,使得溶液中的Al(OH)4-增多。随着αk的升高,铝酸钠溶液中的游离碱浓度升高,溶液结构和性质发生了变化:低αk时,以聚合的铝酸根离子为主,溶液中游离碱浓度低;高αk时以简单的Al(OH)4-为主,溶液中游离碱浓度高。

图6 不同苛性比的铝酸钠溶液的红外光谱

Fig. 6 IR absorption spectra of aluminate solution at different caustic ratios

铁质量浓度的变化与铝酸钠溶液性质有关。在低αk段(αk<2.0),溶液中的游离碱浓度低,铝酸根以聚合离子为主,有学者认为铁和硫在铝酸钠溶液中生成可溶的羟基硫代铁酸钠(Na2[FeS2(OH)2]·2H2O)[6],过低的游离碱浓度不利于其形成,所以反应平衡时,铁在溶液中的质量浓度较小;当2.0<αk<2.5时,随着αk增大,溶液中的聚合铝酸钠根离子逐渐转变为简单的Al(OH)4-,溶液的游离碱浓度逐渐升高,加剧了羟基硫代铁酸钠的生成反应,溶液中的铁质量浓度急剧升高;当αk>2.5时,溶液中以简单的Al(OH)4-为主,游离碱浓度很高,羟基硫代铁酸钠的生成反应达到平衡,铁在溶液中的质量浓度趋于稳定。由此可见,实验结果和理论分析相吻合。而在工厂用拜耳法处理高硫铝土矿生产氧化铝的过程中,铁在溶出液中的质量浓度能达到100 mg/L以上,在降温晶种分解的过程中,铁析出污染Al(OH)3产品,这与实验结果不相符,在本研究的实验条件下,低αk时,铁在含硫铝酸钠溶液的质量浓度约为20 mg/L,故影响铁在含硫铝酸钠溶液中质量浓度升高的因素还需要进一步研究。

3 结论

1) 铝酸钠溶液的温度在40~60 ℃之间变化时,溶液中铁质量浓度随保温时间延长略有降低,溶液温度对铁质量浓度影响并不明显。

2) 铝酸钠溶液中铁质量浓度与溶液中的杂质浓度有关。随着Na2SO4和Na2C2O4质量浓度的升高,溶液中铁质量浓度显著增加,而Na2CO3质量浓度的升高对溶液中铁质量浓度增加的促进作用不明显。

3) 铝酸钠溶液的苛性比对溶出液中铁质量浓度的影响较大。当1.4<αk<2.0时,铁质量浓度保持在一个比较低的水平;当2.0<αk<2.5时,铁质量浓度急剧升高;而当αk>2.5时,铁质量浓度的增加不明显,逐渐趋于稳定。

参考文献:

[1] YIN Jianguo, XIA Wentang, HAN Mingrong. Resource utilization of high-sulfur bauxite of low-median grade in Chongqing China [C]//TMS 2011 Annual Meeting. San Diego, California: Wiley, 2011: 19-22.

[2] 彭欣, 金立业. 高硫铝土矿生产氧化铝的开发与应用[J]. 轻金属, 2010(11): 14-17.

PENG Xin, JIN Liye. Development and application of bauxite containing high sulfur[J]. Light Metals, 2010(11): 14-17.

[3] Ciminelli V S T, Osseo-Asare K. Kinetics of pyrite oxidation in sodium hydroxide solutions[J]. Metallurgical and Materials Transactions B. 1995, 26(4): 677-685.

[4] Ahlberg E, Forssberg K, Wang X. The surface oxidation of pyrite in alkaline solution[J]. Journal of Applied Electrochemistry, 1990, 20(6): 1033-1039.

[5] 李小斌, 李重洋, 齐天贵, 等. 拜耳法高温溶出条件下黄铁矿的反应行为[J]. 中国有色金属学报, 2013, 23(3): 829-835.

LI Xiaobin, LI Chongyang, QI Tiangui, et al. Reaction behavior of pyrite during Bayer digestion at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 829-835.

[6] LI Xiaobin, LI Chongyang, PENG Zhihong, et al. Interaction of sulfur with iron compounds in sodium aluminate solutions[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 608-614.

[7] Abikenova G K, Kovzalenko V A, Ambarnikova G A, et al. Investigation of the effect and behavior of sulfur compounds on the technological cycle of alumina production[J]. Russian Journal of Non-Ferrous Metals, 2008, 49(2): 91-96.

[8] YIN Zhonglin, WU Guobao, LI Xinhua, et al. Reaction behavior of sulphur existed in diasporic bauxite in Bayer digestion professor[J]. TMS 2009 Annual Meeting. San Francisco: Wiley, 2009: 69-73.

[9] 吕国志, 张廷安, 鲍丽, 等. 高硫铝土矿的焙烧预处理及焙烧矿的溶出性能[J]. 中国有色金属学报, 2009, 19(9): 1684-1689.

L Guozhi, ZHANG Tingan, BAO Li, et al. Roasting pretreatment of high-sulfur bauxite and digestion performance of roasted ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1684-1689.

Guozhi, ZHANG Tingan, BAO Li, et al. Roasting pretreatment of high-sulfur bauxite and digestion performance of roasted ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1684-1689.

[10] 王晓民, 张廷安, 吕国志, 等. 丁黄药用作高硫铝土矿浮选除硫的捕收剂[J]. 过程工程学报, 2009, 9(3): 498-502.

WANG Xiaomin, ZHANG Tingan, L Guozhi, et al. Flotation desulfurization of high-sulfur bauxite with butyl xanthate as collector[J]. The Chinese Journal of Process Engineering, 2009, 9(3): 498-502.

Guozhi, et al. Flotation desulfurization of high-sulfur bauxite with butyl xanthate as collector[J]. The Chinese Journal of Process Engineering, 2009, 9(3): 498-502.

[11] 黎志英, 张念炳, 何润德. 用高品位高硫铝土矿生产氧化铝时的除硫新方法研究[J]. 贵州工业大学学报(自然科学版), 2007, 36(2): 29-32.

LI Zhiying, ZHANG Nianbing, HE Runde. Research on the new method of desulphurizing in producing alumina with exploitable sulfur-containing and high grade bauxite[J]. Journal of Guizhou University of Technology (Nature Science Edition), 2007, 36(2): 29-32.

[12] 刘桂华, 高君丽, 李小斌, 等. 拜耳法高压溶出液中铁质量浓度变化规律的研究[J]. 矿冶工程, 2007, 27(5): 38-40.

LIU Guihua, GAO Junli, LI Xiaobin, et al. Study on variation rule of iron in the aluminate solution after digestion process at high temperature by Bayer process[J]. Mining and Metallurgical Engineering, 2007, 27(5): 38-40.

[13] 陈文汨, 陈学刚, 郭金权, 等. 拜耳液中铁的行为研究[J]. 轻金属, 2008(4): 14-18.

CHEN Wenmi, CHEN Xuegang, GUO Jinquan, et al. Research on the behavior of iron in Bayer liquor[J]. Light Metals, 2008(4): 14-18.

[14] 宋超, 彭志宏, 魏欣欣, 等. 黄铁矿在拜耳法溶出过程中的反应行为研究[J]. 有色金属科学与工程, 2011, 2(5): 1-5.

SONG Chao, PENG Zhihong, WEI Xinxin, et al. The reaction behavior of pyrite in process of Bayer digestion[J]. Nonferrous Metals Science and Engineering, 2011, 2(5): 1-5.

[15] 联合法生产氧化铝编写组. 联合法生产氧化铝生产控制分析[M]. 北京: 冶金工业出版社, 1975: 153-161, 167-168.

The Compilatory Staffs of the Alumina Production by Combining Process. The alumina production by combining process[M]. Beijing: Metallurgical Industry Press, 1975: 153-161, 167-168.

[16] 成琼文, 李小斌, 彭志宏, 等. 铝酸钠溶液的粘度[J]. 中南大学学报(自然科学版), 2005, 36(2): 229-233.

CHENG Qiongwen, LI Xiaobin, PENG Zhihong, et al. Viscosity of sodium aluminate solution[J]. Journal of Central South University (Science and Technology), 2005, 36(2): 229-233.

[17] LI Xiaobin, WANG Danqin, ZHOU Qiusheng, et al. Concentration variation of aluminate ions during the seeded precipitation process of gibbsite from sodium aluminate solution[J]. Hydrometallurgy, 2011, 106(1): 93-98.

(编辑 赵俊)

收稿日期:2015-01-05;修回日期:2015-03-20

基金项目(Foundation item):国家自然科学基金资助项目(51374239);中南大学创新驱动计划(2015CX001)(Project (51374239) supported by the National Natural Science Foundation of China; Project (2015CX001) supported by the Innovation-driven Plan in Central South University)

通信作者:齐天贵,博士,从事碱法提取冶金过程研究;E-mail:qitiangui@csu.edu.cn