文章编号: 1004-0609(2006)02-0213-06

激光熔覆-激光氮化复合法制取TiNi-TiN梯度材料

杨永强, 张翠红

(华南理工大学 机械工程学院, 广州 510641)

摘 要: 将激光熔覆与激光表面氮化技术相结合制取TiNi-TiN梯度材料。 采用先进的六孔同轴送粉喷嘴系统, 分别将纯Ti、 Ni粉末按一定比例送入激光熔化区, 在粉末熔化过程中发生Ti、 Ni间高温合成反应, 原位合成一定厚度的TiNi金属间化合物熔覆层, 然后将原位合成的熔覆层在富氮气氛中进行激光氮化处理, 表面形成一层金黄色的TiN。 利用光学显微镜和扫描电镜观察了熔覆层组织, 并测量了熔覆层及氮化层的厚度 。 对不同工艺参数获得的熔覆层用X射线衍射仪进行了物相鉴定, 并对氮化试样的熔覆层进行了显微硬度分布测试, 得出了较好的制取TiNi-TiN梯度材料的工艺参数为: 激光功率600 W, 扫描速度0.5m/min, 钛送粉量2.5g/min; 镍送粉量3.2g/min。

关键词: TiN-TiNi梯度材料; 激光熔覆; 原位合成; 激光氮化

中图分类号: TG113 文献标识码: A

Synthesis of TiNi-TiN gradient coating by hybrid method of

laser cladding and laser nitriding

YANG Yong-qiang, ZHANG Cui-hong

(Institute of Mechanical Engineering,

South China University of Technology, Guangzhou 510641, China)

Abstract: Laser cladding, together with laser nitriding was used to in-situ synthesize TiNi-TiN gradient coating on the pure nickel substrate. During the cladding process, Ti and Ni powders react with each other and in-situ synthesized a cladding layer composed of Ti, Ni intermetallic compounds. Then, laser nitrding was carried out in nitrogen-rich atmosphere. A golden yellow TiN layer forms on the cladding surface. Microscopy and scaning electron microscopy were used to investigate the microstructure of the cladding layer. The thickness of TiN layer and the clad layer were measured respectively. X-ray diffractometry was used for phase identification. Also the microhardness profile of the cladding layer was tested with Vicker hardness tester. The optimum process parameters were obtained: laser power 600W; scanning velocity 0.5m/min; Ti powder feeding rate 2.5g/min; Ni powder feeding rate 3.2g/min.

Key words: TiN-TiNi gradient material; laser cladding; in-situ synthesis; laser nitriding layer

等摩尔比的钛镍合金具有优异的形状记忆、 超弹性和高阻尼性能, 目前已经广泛的应用于航天航空业的各种零部件以及机械行业的各种特殊器件。 此外, 钛镍合金无磁无毒, 具有良好的生物相容性及较低的生物蜕变性, 使其成为一种理想的生物医学材料[1-3]。 科研人员一直在探索新的制备钛镍合金的方法, 以期在提高硬度增加表面耐磨性、 耐蚀性的同时保持钛镍合金其它的优异性能[4-6]。 激光熔覆是一种新颖的表面处理技术, 在激光熔覆过程中, 激光作为热源熔化金属粉末并诱发化学反应, 原位形成一层熔覆层。 由于加热及冷却速度都非常快, 可以克服平衡热力学结晶所带来的缺陷从而改善材料性能[7-10]。 利用激光熔覆方法原位合成钛镍合金目前还未见有所报道。 激光表面氮化处理也是一种近年来出现的材料表面改性技术, 它可以提高材料表面的耐磨和耐腐蚀性。 在一些钛镍合金制作的医用器件表面形成一层TiN还能有效的防止金属离子的扩散[11]。 本文作者拟将激光表面氮化技术与激光熔覆技术相复合, 先利用激光熔覆原位合成TiNi金属间化合物熔覆层, 随后进行激光氮化处理以获得TiNi-TiN梯度材料, 达到改善材料表面性能的目的, 同时也为合成钛镍合金提供一种新的工艺方法。

1 实验

1.1 激光熔覆过程

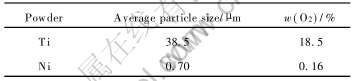

熔覆过程中所使用的激光器是3kW HAAS Nd: YAG连续激光器, 激光波长为1.064μm。 六孔同轴送粉装置系统外观如图1所示。 它由1个双筒送粉器、 2个粉末分离器和一个六孔同轴喷嘴组成。 实验用基板为5mm厚的纯Ni板, 实验前经去油及清洁处理, 基板放在数控工作台上, 可以沿3个方向移动, 按实验要求调节。 实验中所使用的钛镍粉末技术指标列于表1。

图1 六孔同轴喷嘴系统

Fig.1 Powder feeding system with six-hole coaxial nozzle

表1 Ti和Ni粉末的规格

Table 1 Specification of titanium and nickel powder

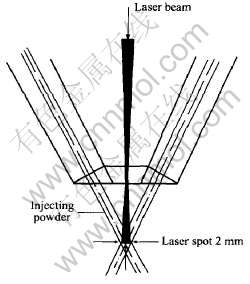

激光熔覆时, Ti、 Ni粉末由双筒送粉器分别按一定比例送出, 再经分离器由两路分成六路, 交错排列吹入同轴喷嘴进行混合, 混合粉末以锥状喷出进入激光作用区, 在激光作用下混合粉末熔化形成熔池, 在此期间Ti、 Ni粉末发生燃烧合成反应原位生成钛镍金属间化合物。 为提高粉末的利用率, 调整喷嘴的高度, 使喷出的锥状粉末的锥顶恰好与激光的作用光斑重合, 光斑大小为2mm, 如图2中的示意图所示。 通过调整送粉气体的流量及同轴保护气体, 该送粉系统可以稳定、 连续、 以一定的送粉率准确的将粉末送进熔池。 熔覆道之间的搭接率为50%。 表2所列为实验采用的工艺参数。 实验中选取了几组工艺参数, 以便于对不同工艺条件下熔覆层的组织结构和性能进行比较, 获得较为理想的熔覆层组织及较好的熔覆工艺。 工艺 A、 B、 C中Ni的摩尔分数分别为50%、 65%和76%。

图2 激光与粉末作用示意图

Fig.2 Schematic diagram of interaction between laser and powders

1.2 激光氮化处理

激光氮化处理时, 仍然使用同样的激光器和六孔同轴喷嘴送粉系统, 实验过程中氮气经同轴喷嘴吹入激光作用区, 构成富氮气氛。 氮化处理时采用的激光功率为1.5kW, 作用光斑直径2mm, 激光扫描速度为0.5m/s。 为保证氮化层质量及均匀程度, 每道激光扫描线间的搭接率为80%。

1.3 试样测试

利用线切割法将试样沿与激光作用方向平行的方向切割加工成金相试件, 经适当腐蚀之后通过光

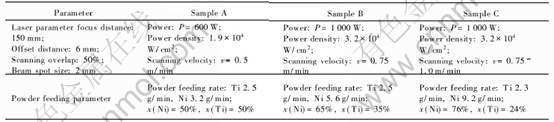

表2 相关工艺参数

Table 2 Ralevant process parameters

学显微镜观察其断面熔覆层的显微组织及熔覆层的厚度。 使用Philips X Pert MPD型X射线衍射仪对熔覆层进行X射线衍射(XRD)分析确定产物的物相组成, 采用铜靶、 Kα辐射, 扫描速度为2(°)/min, 扫描范围为10°~90°。 通过将衍射峰的d值与JCPDS卡片 查对的方法进行物相鉴定。 利用维氏硬度机测试试样熔覆层的硬度, 载荷0.98N, 作用时间15s。 利用LEO1530VP型场发射扫描电镜进一步观测试样显微组织结构及氮化试样TiN层的形貌及厚度, 并用其附带的INCA300型能量色散谱仪分析产物的微区成分。

2 结果与分析

2.1 熔覆层的显微组织

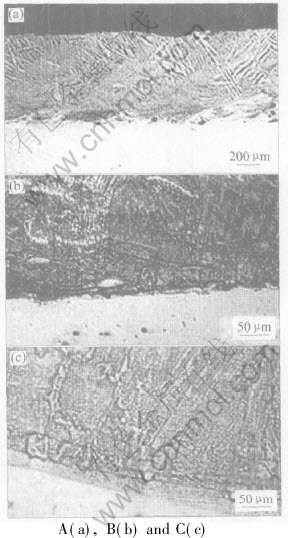

图3所示为试样横截面熔覆层的显微组织。 可以看到, 熔覆层与基体的结合较为理想, 为冶金结合。 在激光熔覆成形时, 熔覆层主要通过基体与激光扫描过后熔覆层的上表面来散热, 由于激光能量密度极高, 熔覆层和基体间形成较大的温度梯度, 凝固过程中晶核以树枝晶的形态沿热流的负方向呈外延方式生长。 其中以试样A中树枝晶的生长最为明显。 经测量试样A熔覆层的厚度约为0.65~0.95mm。 试样B、 C熔覆层厚度约为1.0~1.2mm。

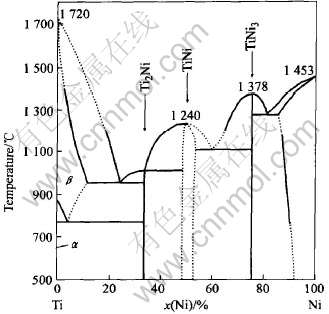

根据Ti-Ni合金二元相图(图5)[12]可知,Ti、 Ni共有3种金属间化合物, 分别为Ti2Ni、 TiN和TiNi3。 图4所示为试样A、 B、 C熔覆层的X射线衍射谱。

图3 不同试样熔覆层的显微组织

Fig.3 Microsructures of cladding layers of sample

X射线衍射结果表明, 熔覆层中有Ti、 Ni金属间化合物峰, 纯Ni峰, 没有纯Ti峰。 这表明在熔覆过程中Ti粉末已经完全与Ni粉反应, 显微组织表明熔覆层组织均匀致密, 无明显冶金缺陷。 由于混粉和熔覆过程是在很短的时间内完成的, 在试样的熔覆层中会有混粉不匀的现象, 出现Ti、 Ni成分的波动。

X射线分析结果表明(图4(a)), 试样A的熔覆层中主要相是B2相(奥氏体态的TiNi金属化合物相), 其它相为B19′相(马氏体态的TiNi金属化合物相)、 TiNi3相和纯Ni相。 在熔覆过程中送入的Ti粉与Ni粉发生了充分的反应原位合成TiNi金属化合物, 由于冷却速度快, 大部分TiNi相以B2相的状态保留了下来, 结合钛镍合金相图(图5)及其显微组织可知(图3(a)), 白色粗大针状组织应

图4 不同试样熔覆层的X射线衍射谱

Fig.4 XRD patterns of cladding layers of samples

图5 Ti-Ni二元合金相图

Fig.5 Phase diagram of Ti-Ni alloy

为原生的TiNi金属化合物相(B2相), 白色针状体之间灰黑色部分为TiNi3、 纯Ni和少量的马氏体B19′。 TiNi3相的形成是由于某些局部地区富Ni而生成的。

试样B的熔覆层中以TiNi金属化合物相(B2相)和纯Ni相为主要相, 如X射线衍射结果所示(图4(b))。 其它相有Ti2Ni和TiNi3相。 根据熔覆工艺, Ni的摩尔分数为65%, 结合钛镍合金二元相图(图5)及其显微组织(图3(b)), 试样B的相结构应为: 灰黑色呈枝状的部分为TiNi(B2)+TiNi3的共晶体, 期间夹杂着纯Ni相。 在混粉不匀的富Ti区合成了Ti2Ni相, 其周围应为纯Ni相。 同时由于扫描激光功率较高, 熔覆过程的温度相应会高一些, 高温下Ni原子扩散迅速, 也会形成Ni原子的偏聚, 使得熔覆层中Ni相含量较高。

根据X射线衍射分析结果, 试样C熔覆层中的主要相为TiNi金属化合物(呈B2相的形态)及纯Ni相。 试样C中Ni的摩尔分数高达76%, 激光功率和扫描速度均有所提高, 根据熔覆条件并结合钛镍合金二元相图(图5)及显微组织(图3(c)), 组织中有TiNi(B2)+TiNi3的共晶体, 原位合成的TiNi金属间化合物(呈B2相), 在钛镍金属间化合物的周围及其枝晶间是经历熔化结晶的纯Ni相。

由图3可见, 熔覆层中有一些圆形气孔的存在。 这是由于快速冷却气体来不及逸出所致[13]。 通过这几组熔覆工艺结果可以看出, 在激光熔覆过程中, 在激光能量的诱导下, 尽管送粉量变化较大, 但Ti、 Ni粉末之间发生了充分的化学反应, 并且原位合成了不同的Ti、 Ni系金属间化合物。 由于Ti、 Ni间的反应都是放热反应, 反应放出的热量可以用于维持反应发生所需热量, 所以并不需要太大的激光能量输入。 事实表明, 过高的激光功率会导致裂纹的出现。 激光扫描速度与激光功率适当配合是保证熔覆层质量的关键。 X射线衍射分析结果表明, 在不同成分的熔覆层中都有纯Ni相的存在, 纯Ni相的存在使得熔覆层与基体Ni过渡自然, 同时不会有除钛镍间金属化合物以外的杂相的存在, 熔覆层与基体之间形成良好的冶金结合。

2.2 氮化层的显微形貌

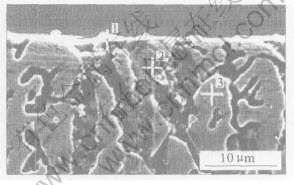

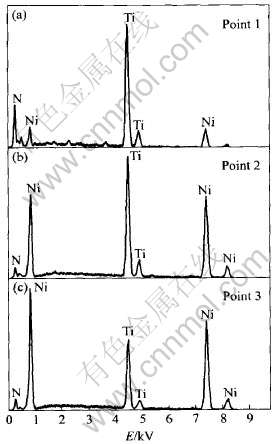

试样A经激光熔覆后熔覆层的主要相为等摩尔比的TiNi金属间化合物, 具有该成分的钛镍合金性能比较优异, 将该试样在富氮气氛下利用激光进行氮化处理, 在试样的表面形成了一层金黄色的TiN, 厚度约为0.4~0.65μm, 构成了TiNi-TiN梯度材料, 如图6所示。 图中表面白亮带为TiN层。 为进一步确定相组成, 进行了点能谱分析, 结果如图7所示。

图6 试样A的TiN-TiNi梯度层的SEM形貌

Fig.6 SEM morphology of TiNi-TiN gradient layer of sample A

图7 试样A中图6所示的点1、 2、 3的能谱分析

Fig.7 Energy spectrum patterns of points 1, 2 and 3 shown in Fig.6 of sample A

点1由N、 Ti、 Ni元素组成, 根据其位置和元素含量, 主要相为TiN, 其余为TiNi, TiNi3和Ni。 TiN的形成是由于Ti与N的结合力远远大于Ni与N的结合力, Ti与N原子更容易结合发生反应[14, 15]。 点2和点3的能谱分析结果表明, 熔覆层的相组成为TiNi、 Ni和TiNi3, 与X射线衍射结果相符。 由于点2和点3距离表面较近, 在氮化过程中, N原子向内扩散, 所以在点2和点3的能谱分析中都有微弱的N元素峰。

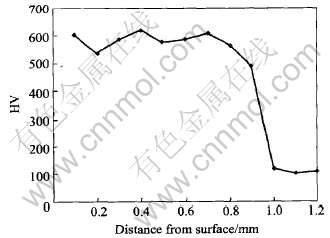

2.3 试样A熔覆层的显微硬度分布

形成梯度材料的试样硬度分布如图8所示。 熔覆层平均硬度为HV550。 而根据文献[8], 奥氏体B2相的硬度为HV200~350, 马氏体B19′的硬度仅为HV180~200, 说明熔覆层的硬度得到了很大的提高, 而且硬度分布相对来说较为均匀, 在整个熔覆层中硬度分布在HV490~610范围内。 熔覆层的高硬度应归功于以下两个原因: 一方面熔覆层中保留了大量的奥氏体B2相, 奥氏体B2相硬度较高。 由于Ti的化学性质较为活泼, 在熔覆中会有损失, 从而使得Ni的含量在熔覆层中偏高, 降低了奥氏体B2向马氏体B19′转变的温度, 室温下主要相是高温相B2; 另一方面由于冷却速度快, 有较多 Ni原子固溶在了奥氏体B2中形成过饱和奥氏体, 从而使熔覆层组织硬度提高。 一般来说, 材料的硬度高, 其耐磨性相应地就要好一些, 所以该熔覆层的耐磨性会有很大改善。 表面形成的TiN不仅提高了表面的耐蚀性, 同时也可提高表面的耐磨性。 相关实验还在进行中。

图8 试样A熔覆层显微硬度的分布

Fig.8 Microhardness profile of cladding layer of sample A

3 结论

1) 通过调整工艺, 可以获得近等摩尔比的TiNi(B2)金属间化合物的熔覆层, 最佳工艺参数为: P=600W; v=0.5m/min; 送粉量: Ti 2.5g/min, Ni 3.2g/min; 镍的摩尔分数为50%。

2) 熔覆层硬度较高, 提高了其耐磨性。 在激光熔覆过程中, 通过调整送粉量, 可以获得不同成分的Ti、 Ni系金属间化合物并可通过调整送粉量而对所合成的化合物的含量和种类进行控制, 为改善熔覆层性能提供指导。

3) 激光氮化处理在熔覆层的表面获得了一层金黄色的TiN, 分布均匀, 与熔覆层结合牢固组成了TiNi-TiN梯度材料, 不仅可以提高表面耐蚀性还可提高表面耐蚀性。

REFERENCES

[1]Mori J C, Serra P, Martinez E, et al. Surface treatment of titanium by Nd: YAGlaser irradiation in the presence of nitrogen[J]. Appl Phys A, 1999, 69(S): S699-S702.

[2]Carpene E, Shinn M, Schaaf P. Synthesis of highly oriented TiNx coatings by free-electron laser processing of titanium in nitrogen gas[J]. Appl Phys A, 2004, 10: 1007/s3399-004-3113-0.

[3]孙世清, 郭志猛, 殷声. TiNi形状记忆合金致密体、 薄膜和多孔体的制备[J]. 热加工工艺, 2001(3): 41-46.

SUN Shi-qing, GUO Zhi-meng, YIN Sheng. Fabrication processes of dense-article, thin-film and porosint of TiNi shape memory alloy[J]. Technique of Heat Treatment, 2001(3): 41-46.

[4]Bendahan M, Seguin J L, Lollman D, at el. New type of schottky barriers using NiTi shape memory alloy films[J]. Thin Solid Films, 1997, 294(1-2): 61-66.

[5]Jardine A P, Field Y, Herman H, at el. Processing and properties of arc-sprayed shape memory effect NiTi[J]. Scripta Metallurgica et Materialsia, 1990, 24(12): 2391-2396.

[6]Richman R H, Rao A S, Kung D. Cavitation erosion of NiTi explosively welded to steel[J]. Wear, 1995, 181-183: 80-85.

[7]Chol J, Choudhuri S K, Mazumder J. Role of preheating and specific energy input on the evolution of microstructure and wear properties of laser clad Fe-Cr-C-W alloys[J]. Journal of Materials Science, 2000, 35: 3213-3219.

[8]杨杰, 吴月华. 形状记忆合金及其应用[M]. 合肥: 中国科学技术大学出版社, 1993.

YANG Jie, WU Yue-hua. Shape Memory Alloy and Its Application[M]. Hefei: Press of University of Science and Technology of China, 1993.

[9]胡项, 陈振华, 朱蓓蒂, 等. 同步送粉激光熔覆的粉末分布密度[J]. 中国有色金属学报, 1991, 7(2): 136-139.

HU Xiang, CHEN Zhen-hua, ZHU Bei-di, et al. Average density in laser cladding processing with a powder injector[J]. The Chinese Journal of Nonferrous Metals, 1991, 7(2): 136-139.

[10]尚丽娟, 贺春林, 才庆魁, 等. 应用稀土及激光熔覆工艺制备钴基合金梯度涂层[J]. 中国有色金属学报, 2002, 12(4): 653-657.

SHANG Li-juan, HE Chun-lin, CAI Qing-kui, et al. Formation of gradient coating of Cobased alloy with rare earth by laser cladding[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(4): 653-657..

[11]Gyorgy E, Pino A P D, Serra P, et al. Depth profiling characterization of the surface layer obtained by pulsed Nd: YAG laser irradiation of titanium in nitrogen[J]. Surface and Coatings Technology, 2003, 173: 265-270.

[12]Kaieda Y. Fabrication of composition-controlled TiNi shape memory wire using combustion synthesis process and the influence of Ni content on phase transformation behavior[J]. Science and Technology of Advanced Materials, 2003, 4: 239-246.

[13]Yang Y Q, Man H C. Microstructure evolution of laser clad layers of W-C-Co alloy powders[J]. Surface and Coatings Technology, 2000, 132: 130-136.

[14]Wu S K, Lin H C, Lee C Y. Gas nitriding of an equiatomic TiNi shape-memory alloy(part Ⅰ): Nitriding parameters and microstructure characterization[J]. Surface and Coatings Technology, 1999, 113: 17-24.

[15]Wu S K, Lin H C, Lee C Y. Gas nitriding of an equiatomic TiNi shape memory alloy Ⅱ: Hardness, wear and shape memory ability[J]. Surface and Coatings Technology, 1999, 113: 13-16.

(编辑陈爱华)

基金项目: 广东省自然科学基金资助项目(031448); 教育部留学回国人员科研启动基金资助项目

收稿日期: 2005-07-06; 修订日期: 2005-09-25

作者简介: 杨永强(1961-), 男, 教授, 博士

通讯作者: 杨永强, 教授; 电话: 13430256374; E-mail: meyqyang@scut.edu.cn