文章编号:1004-0609(2015)-01-0043-06

7075/5A06异种铝合金TIG焊接头的显微组织和力学性能

廖传清1,宿国友1,高艳芳2,宋 伟1,鲍宏伟1,高嘉爽1

(1. 上海航天设备制造总厂,上海 200245;

2. 上海锅炉厂有限公司,上海 200245 )

摘 要:采用BJ380A和ER4043铝合金焊丝进行7075/5A06异种铝合金TIG焊对接试验,并对接头的显微组织和力学性能进行分析。结果表明:焊缝无裂纹,但存在分散的气孔;7075母材一侧热影响区晶粒长大较5A06母材一侧的明显,且采用BJ380A焊丝获得的焊缝晶粒较采用ER4043焊丝获得的焊缝晶粒粗大。采用两种焊丝获得的接头抗拉强度均为220 MPa左右,约为5A06铝合金母材的70%,且接头均断裂于焊缝处。显微硬度测试时,7075母材一侧热影响区出现软化现象,而5A06母材一侧热影响区出现硬化现象。另外,采用ER4043焊丝获得的焊缝硬度大于采用BJ380A焊丝获得的焊缝硬度。

关键词:异种铝合金;钨极氩弧焊;显微组织;抗拉强度;显微硬度

中图分类号:TG444 文献标志码:A

Microstructure and mechanical properties of 7075/5A06 dissimilar aluminum alloy joints made by TIG welding

LIAO Chuan-qing1, SU Guo-you1, GAO Yan-fang2, SONG Wei1, BAO Hong-wei1, GAO Jia-shuang1

(1. Shanghai Aerospace Equipments Manufacturer, Shanghai 200245, China;

2. Shanghai Boller Works Corporation Limited, Shanghai 200245, China)

Abstract: The butt joining of 7075 aluminum alloy to 5A06 aluminum alloy was conducted by TIG welding with BJ380A and ER4043 aluminum alloy filler wires, and the microstructure and mechanical properties of the joints were analyzed. The results show that the dispersive pores without cracks are observed in welds. The grain growth in the heat-affected zones (HAZ) near 7075 base metal is more obvious than that near 5A06 base metal (BM), and the grain is coarser in the weld made with BJ380A filler wire than that in the weld made with ER4043 filler wire. The tensile strength of joints is about 220MPa, 70% of that of the 5A06 aluminum alloy base metal, and the fracture occurs in the welds during tensile test. The microhardness results reveal that softening appears in the heat-affected zones near 7075 base metal, but hardening exists in the heat-affected zones near 5A06 base metal. Moreover, the microhardness in the weld made with ER4043 filler wire is higher than that in the weld made with BJ380A filler wire.

Key words: dissimilar aluminum alloy; TIG welding; microstructure; tensile strength; microhardness

铝及铝合金具有密度低、比强度高、比刚度高和耐腐蚀能力强等特点,被广泛应用于航空、航天、船舰和车辆等制造领域[1-2],是目前应用最广泛的轻金属之一。在铝合金结构中,不可避免地出现异种铝合金之间的焊接。目前,异种铝合金焊接技术主要包括搅拌摩擦焊、激光焊和氩弧焊等。PEEL等[3-4]和PARK 等[5]分别进行了AA5083/AA6082和5052/6061异种铝合金搅拌摩擦焊研究,并分析了焊接工艺参数,如搅拌头旋转速度、搅拌头下压量、焊接速度等,对接头组织和性能的影响。李宏伟等[6]进行了ZL114A/5A06异种铝合金激光焊试验,结果表明,接头的抗拉强度可达265 MPa,为ZL114A母材抗拉强度的80%以上,且接头具有很好的抗疲劳性能;拉伸测试时,接头断裂于ZL114A 母材一侧的熔合线附近。马立彩等[7]和吕世雄等[8]分别进行了2519/5A06和ZL101A/5A06异种铝合金的氩弧焊研究,发现通过添加活性剂、增加焊缝背面氩气保护和母材背面开坡口的方法均可改善焊缝的成形能力,提高接头的抗拉强度。

7075铝合金强度高,可用作主要承力结构;5A06铝合金具有良好的焊接性和耐蚀性,是最常用的铝合金之一。在铝合金焊接结构中,主要承力部分采用7075铝合金,而辅助支撑部分采用5A06铝合金,这样既可保证整体结构的强度,又可节约生产成本。国内外对7075和5A06同种铝合金接头进行了广泛的研究[1, 9-12],然而,对7075/5A06异种铝合金接头的研究还鲜见报道。

TIG焊(钨极氩弧焊)具有焊接工艺性能好、成本低和易操作等优点,是最常用的熔焊方法之一。在此,本文作者选用BJ380A和ER4043铝合金焊丝进行7075/5A06异种铝合金TIG焊对接试验,并对接头组织和性能进行分析,以期对7075/5A06异种铝合金TIG焊接头的推广应用提供理论参考。

1 实验

1.1 试验材料及规格

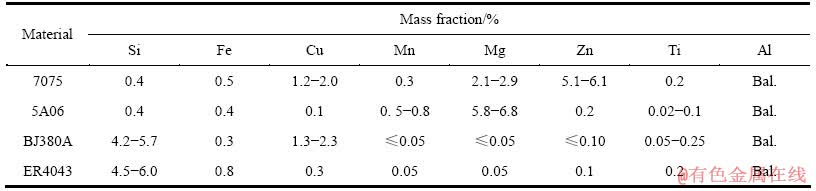

本试验中所选用的焊接母材为200 mm×100 mm×12 mm的7075和5A06铝合金板。其中,5A06母材为O状态,抗拉强度约为315 MPa;7075母材为T6状态,抗拉强度约为515 MPa。焊丝选用d 3.0 mm的BJ380A和ER4043铝合金焊丝。表1列出了焊接母材和焊丝的主要化学成分。

1.2 试验方法及过程

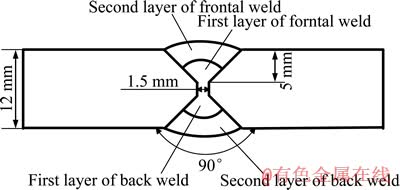

焊前,对待焊母材及焊丝表面进行化学清洗,然后用不锈钢丝刷打磨待焊区域及周围宽25 mm区域的氧化膜直至呈光亮金属光泽。接头形式为对接,双面开5 mm、45°的“V”坡口,中间留2 mm钝边,对接间隙为1.5 mm,如图1所示。采用手工TIG焊正反两面各焊两层(见图1),焊接电流和保护气体流量分别为250 A和15 L/min,电流种类和钨极直径分别为交流和4.0 mm。焊后,对焊缝进行X射线测试,以表征焊缝中焊接缺陷的分布情况。然后,采用金相显微镜进行接头显微组织的观察,采用扫描电镜对拉伸试样的断口形貌进行观察,接头抗拉强度和显微硬度分别采用万能试验机和显微硬度机进行表征。接头的抗拉强度取3个拉伸试样抗拉强度的平均值,拉伸试样按GB2651-89标准制备。显微硬度测试时,测试位置均为正面第二层焊缝,加载载荷和承载时间分别为1.96 N和20 s。

图1 焊接坡口尺寸和焊接顺序示意图

Fig. 1 Schematic diagram of welding groove dimensions and welding sequence

2 结果与讨论

2.1 焊缝的X射线检测

表1 焊接母材及焊丝的主要化学成分

Table 1 Chemical composition of base metals and filler wires

焊后对焊缝进行X射线检测,发现两种焊丝所获得的焊缝均无裂纹,但有分散的气孔存在,且最大气孔直径约为1 mm。焊缝中气孔出现的原因可能包括以下几个方面。

1) 母材及焊丝表面残留的氧化物会吸收空气中的水分,水分在高温下分解出氢气残留于焊缝形成氢气孔。

2) 保护气体不当,使空气进入熔池,并残存下来成为气孔。

3) 焊缝中低熔点高蒸气压的Mg和Zn等元素的蒸发形成气泡,气泡来不及逸出焊缝而成为气孔[13]。

2.2 接头的显微组织分析

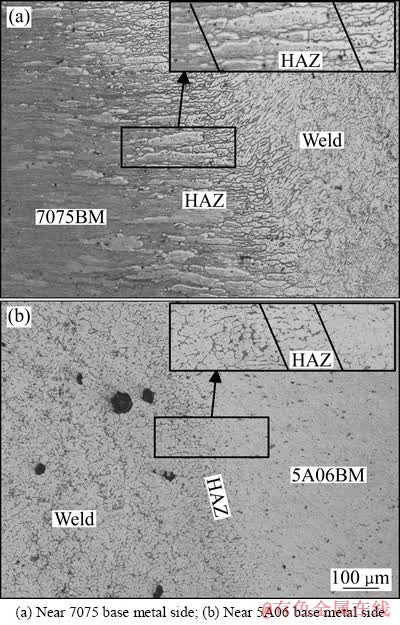

图2所示为采用BJ380A焊丝获得的7075/5A06接头的显微组织。从图2可知,接头主要分为焊缝、热影响区和母材3个部分。靠近7075母材一侧的热影响区的晶粒呈明显的长大现象,且热影响区的平均宽度约为250 μm(见图2(a))。另外,该热影响区的晶粒为柱状晶,沿母材方向生长。一方面,受焊接热循环的作用,热影响区晶粒将长大;另一方面,垂直于母材方向的晶粒在长大过程中会相互挤压,抑制晶粒垂直于母材方向长大。然而,靠近5A06母材一侧的热影响区晶粒无明显长大,且热影响区的平均宽度约为80 μm,如图2(b)所示。对于采用ER4043焊丝获得的接头,7075母材一侧热影响区的晶粒也明显长大,而5A06母材一侧热影响区的晶粒也无明显长大,且两侧热影响区的平均宽度与采用BJ380A焊丝获得的接头基本一致,如图3所示。

图2 采用BJ380A焊丝获得的接头显微组织

Fig. 2 Microstructures of joint made with BJ380A wire

图3 采用ER4043焊丝获得的接头显微组织

Fig. 3 Microstructures of joint made with ER4043 wire

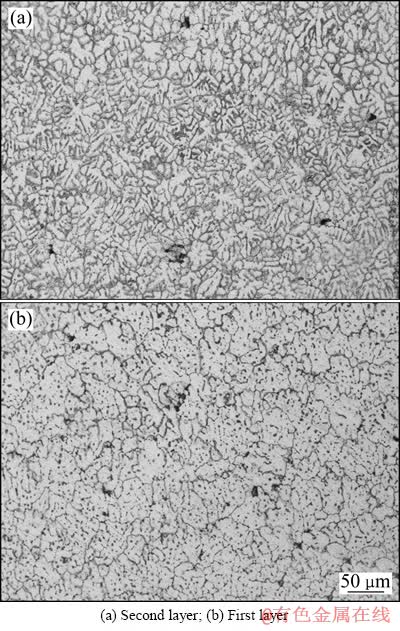

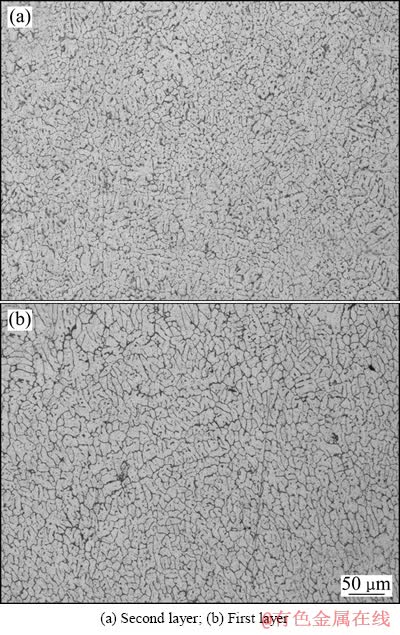

采用BJ380A焊丝获得的接头中焊缝的显微组织如图4所示。从图4可知,焊缝为等轴晶组织,由晶内的α(Al)和分布于晶界的共晶组织组成。比较图4(a)和(b)可知,正面第一层焊缝的晶粒较第二层焊缝的粗大。第二层焊接过程可对第一层焊缝进行加热,促使第一层焊缝晶粒的长大,该过程类似于热影响区的晶粒长大。正面第一层焊缝晶粒较第二层焊缝粗大的现象同样出现于采用ER4043焊丝获得的焊缝中,如图5(a)和(b)所示。另外,比较图4和5可以发现,对于同一层焊缝,采用ER4043焊丝获得焊缝的晶粒尺寸较采用BJ380A焊丝获得焊缝的小。由表1可知,BJ380A焊丝中Cu元素的含量是ER4043焊丝的4倍以上,这使得BJ380A焊丝的固相线温度较ER4043焊丝的低,导致在相同的焊接参数下,输入到采用BJ380A焊丝获得的焊缝中的热量较多,促进焊缝晶 粒长大。

2.3 接头的力学性能分析

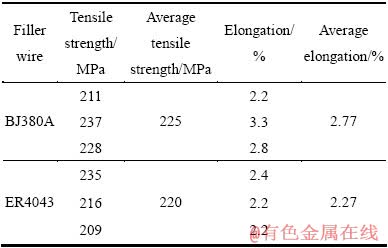

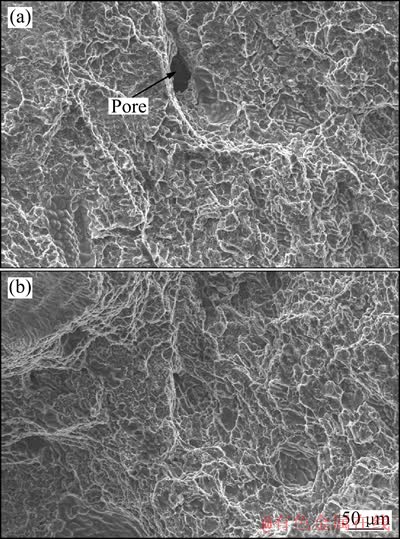

接头抗拉强度及断后伸长率如表2所列。从表2可知,采用两种焊丝获得的接头抗拉强度差异较小,接头平均抗拉强度均为220 MPa左右,约为5A06铝合金母材的70%;接头断后伸长率较小,均为2.5%左右。拉伸测试时,采用两种焊丝获得的接头均断裂于焊缝处,如图6所示。PASTOR等[14]将铝合金焊缝中直径大于200 μm的气孔称为宏观气孔,并认为这种气孔的存在将严重恶化接头的力学性能。如前所述焊缝中存在直径约为1 mm的气孔,这些气孔的存在将减小拉伸测试时焊缝的受力面积并造成应力集中,从而导致接头断裂于焊缝。然而,这些气孔可通过母材焊前的深入清理、改进焊接气体保护和优化焊接参数等方法进行消除[15],今后将对这一方面进行深入研究。进一步对断口进行扫描电镜分析可知,两接头断口形貌均为韧性断裂,如图7所示;另外,断口处存在明显的气孔(见图7(a))。

图4 采用BJ380A焊丝获得正面焊缝的显微组织

Fig. 4 Microstructures of frontal weld made with BJ380A wire

图5 采用ER4043焊丝获得正面焊缝的显微组织

Fig. 5 Microstructures of frontal weld made with ER4043 wire

表2 接头抗拉强度及断后伸长率

Table 2 Tensile strength and elongation of joints

图6 接头断裂位置示意图

Fig. 6 Fracture positions in joints made with BJ380A wire (a) and ER4043 wire (b)

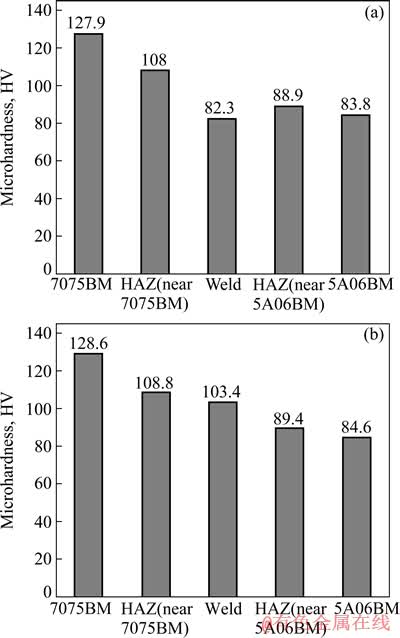

图8所示为接头的显微硬度分布,其中每个区域硬度值为该区域5点硬度的平均值。由图8可知,7075母材一侧热影响区的硬度小于7075铝合金母材的,而5A06母材一侧热影响区的硬度值大于5A06铝合金母材的。换句话说,7075母材一侧热影响区出现软化,而5A06母材一侧热影响区出现硬化。7075母材一侧热影响区晶粒在焊接热循环过程中的长大是造成软化的根本原因。焊接过程中,焊缝金属中Si元素将往5A06母材一侧热影响区扩散,进而导致硬化现象 [16]。另外,比较图8(a)和(b)可知,采用BJ380A焊丝获得的焊缝硬度低于采用ER4043焊丝获得的焊缝硬度。由焊缝显微组织分析可知,采用BJ380A焊丝获得的焊缝晶粒较采用ER4043焊丝获得的焊缝粗大,晶粒尺寸越大,硬度值越低。

图7 采用BJ380A焊丝获得的接头断口SEM像

Fig. 7 SEM images of fracture surfaces made with BJ380A wire (a) and ER4043 wire (b)

图8 采用BJ380A焊丝和ER4043焊丝获得的接头显微硬度分布

Fig. 8 Microhardness distribution in joints made with BJ380A wire (a) and ER4043 wire (b)

3 结论

1) 采用两种焊丝获得的接头中, 7075母材一侧热影响区的平均宽度约为250 μm,且有明显的晶粒长大现象,而5A06母材一侧热影响区的平均宽度约为80 μm,晶粒长大现象并不明显。焊缝均为等轴晶组织,第二层焊缝焊接过程可对第一层焊缝进行加热,导致第一层焊缝的晶粒尺寸大于第二层焊缝的。

2) 两种焊丝获得的接头抗拉强度均为220 MPa左右,约为5A06铝合金母材的70%。拉伸测试时,接头均断裂于焊缝处,断口形貌为韧性断裂。焊缝中存在的宏观气孔减小了焊缝拉伸测试时的受力面积,导致接头断裂于焊缝处。

3) 热影响区晶粒在焊接热循环过程中的长大造成7075母材一侧热影响区出现软化现象,而焊接过程中焊缝金属中的Si元素往5A06母材一侧热影响区的扩散导致5A06母材一侧热影响区出现硬化现象。采用BJ380A焊丝获得的焊缝晶粒较采用ER4043焊丝获得的焊缝晶粒粗大,导致前者的焊缝硬度低于后者的焊缝硬度。

REFERENCES

[1] 从保强, 齐铂金, 周兴国, 罗 军. 复合脉冲方波电流频率对5A06铝合金焊缝组织和性能的影响[J]. 焊接学报, 2010, 31(1): 89-92.

CONG Bao-qiang, QI Bo-jin, ZHOU Xin-guo, LUO Jun. Effect of hybrid-pulse square-wave current frequency on microstructure and mechanical properties of 5A06 aluminum alloy welds[J]. Transactions of the China Welding Institution, 2010, 31(1): 89-92.

[2] 刘克文, 邢 丽, 柯黎明. LY12 铝合金摩擦点焊接头组织及性能[J]. 中国有色金属学报, 2008, 18(2): 288-293.

LIU Ke-wen, XING Li, KE Li-ming. Microstructures and properties of friction stir spot welding joints for LY12 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 288-293.

[3] PEEL M J, STEUWER A, WITHERS P J, DICKERSON T, SHI Q, SHERCLIFF H. Dissimilar friction stir welds in AA5083-AA6082. Part I: Process parameter effects on thermal history and weld properties[J]. Metallurgical and Materials Transactions A, 2006, 37: 2183-2193.

[4] PEEL M J, STEUWER A, WITHERS P J. Dissimilar friction stir welds in AA5083-AA6082. Part Ⅱ: Process parameter effects on microstructure[J]. Metallurgical and Materials Transactions A, 2006, 37: 2195-2206.

[5] PARK J C, HAN M S, JANG S K, KIM S J. Optimum traveling and rotation speeds in friction stir welding for dissimilar Al alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 1486-1490.

[6] 李宏伟, 姚 为, 王志敏, 陈绍勇, 果建文. 激光焊接ZL114A/5A06异种铝合金接头组织及性能[J]. 宇航材料工艺, 2010, 6: 70-73.

LI Hong-wei, YAO Wei, WANG Zhi-ming, CHEN Shao-yong, GUO Jian-wen. Microstructure and properties of dissimilar aluminum alloys ZL114A/5A06 joints by laser welding[J]. Aerospace Materials & Technology, 2010, 6: 70-73.

[7] 马立彩, 孙燕洁, 王 锋, 胡 赟. 2519/5A06 异种铝合金熔焊焊接接头性能试验研究[J]. 航天制造技术, 2010, 7: 26-28.

MA Li-cai, SUN Yan-jie, WANG Feng, HU Yun. Experimental study on performance of 2519/5A06 welded joint[J]. Aerospace Manufacturing Technology, 2010, 7: 26-28.

[8] 吕世雄, 李俐群, 石经纬, 柳 燕. ZL101A和LF6 异种铝合金的脉冲交流TIG焊工艺[J]. 焊接, 2007, 9: 42-45.

L Shi-xiong, LI Li-qun, SHI Jing-wei, LIU Yan. AC pulsed gas tungsten arc welding technology for dissimilar aluminum alloys ZL101A and LF6[J]. Welding & joining, 2007, 9: 42-45.

Shi-xiong, LI Li-qun, SHI Jing-wei, LIU Yan. AC pulsed gas tungsten arc welding technology for dissimilar aluminum alloys ZL101A and LF6[J]. Welding & joining, 2007, 9: 42-45.

[9] 杨新岐, 栾国红, 许海生, 柴 鹏. 铝合金搅拌摩擦与MIG焊接接头疲劳性能对比试验[J]. 焊接学报, 2006, 27(4): 1-4.

YANG Xin-qi, LUAN Guo-hong, XU Hai-sheng, CHAI Peng. Experimental comparison of fatigue properties for 5A06 aluminium alloy friction stir and metal inert gas welded joints[J]. Transactions of the China Welding Institution, 2006, 27(4): 1-4.

[10] 张红霞, 吴广贺, 闫志锋, 裴飞飞, 李晋永, 王文先, 李永莲. 5A06铝合金及其焊接接头的疲劳断裂行为[J]. 中国有色金属学报, 2013, 23(2): 327-335.

ZHANG Hong-xia, WU Guang-he, YAN Zhi-feng, PEI Fei-fei, LI Jin-yong, WANG Wen-xian, LI Yong-lian. Fatigue fracture behavior of 5A06 aluminum alloy and its welded joint[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 327-335.

[11] BALASUBRAMANIAN V, RAVISANKAR V, REDDY G M. Effect of pulsed current welding on mechanical properties of high strength aluminum alloy[J]. The International Journal of Advanced Manufacturing Technology, 2008, 36: 254-262.

[12] 王希靖, 孙桂苹, 张 杰, 徐 成, 李树伟, 牛 勇. 焊后热处理对高强铝合金搅拌摩擦焊接头的影响[J]. 中国有色金属学报, 2009, 19(3): 484-489.

WANG Xi-jing, SUN Gui-ping, ZHANG Jie, XU Cheng, LI Shu-wei, NIU Yong. Effects of heat treatment after welding on friction stir welding joints of high-strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 484-489.

[13] CAO X, WALLACE W, POON C, IMMARIGEON J P. Research and progress in laser welding of wrought aluminum alloys-part I: Laser welding processes[J]. Materials and Manufacturing Processes, 2003, 18: 1-22.

[14] PASTOR M, ZHAO H. Porosity, underfill and magnesium loss during continuous wave Nd:YAG laser welding of thin plates of aluminum alloys 5182 and 5754[J]. Welding Journal, 1999, 78(6): 207s-216s.

[15] DONG H G, LIAO C Q, YANG L Q. Microstructure and mechanical properties of AZ31B magnesium alloy gas metal arc weld[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1336-1341.

[16] DONG H G, LIAO C Q, CHEN G Q, DONG C. Butt joining of aluminium to steel by arc brazing process[J]. Materials and Manufacturing Processes, 2012, 27(12): 1392-1396.

(编辑 龙怀中)

基金项目:国家国际合作项目(2013DFR504xx)

收稿日期:2014-05-10;修订日期:2014-11-05

通信作者:廖传清,工程师;电话:021-24187443;E-mail:chuanqingliao@163.com