文章编号:1004-0609(2009)12-2204-06

TiO2薄膜对金刚石磨削性能的影响

刘小磐1, 2,万 隆1,胡伟达1,汪 洋1

( 1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 湘潭大学 低维材料及其应用教育部重点实验室,湘潭 411105)

摘 要:采用溶胶-凝胶法在金刚石表面涂覆TiO2薄膜。利用扫描电镜、能谱以及红外光谱等手段对涂膜后金刚石磨料表面形貌、结构和成键情况进行分析,研究在不同进刀量时TiO2薄膜对金刚石磨削性能的影响。结果表明:磨料表面的TiO2薄膜可以保护金刚石磨料在烧结过程中不受结合剂中碱金属氧化物的侵蚀,提高结合剂对金刚石的润湿性;在进刀量为5 μm/s时,与未涂膜金刚石砂轮相比,涂膜金刚石砂轮对硬质合金(WC,6%(质量分数)Co)的磨耗比提高121%。

关键词:TiO2薄膜;金刚石;陶瓷结合剂;溶胶-凝胶法;磨削性能

中图分类号:TG74 文献标识码: A

Influence of TiO2 films on wear performance of diamond

LIU Xiao-pan1, 2, WAN Long1, HU Wei-da1, WANG Yang1

(1. College of Materials Science and Technology, Hunan University, Changsha 410082, China;

2. The Key Laboratory of Low Dimensional Materials and Application Technology, Ministry of Education,

Xiangtan University, Xiangtan 411105, China)

Abstract: TiO2 films were prepared on the surface of diamond through sol-gel method. The surface morphologies, structures and chemical bond of TiO2 film/C were studied through SEM, EDS and FTIR. The effect of TiO2 film on the diamond wear performance under different cut depths was discussed. The results show that the compact TiO2 film coated on the diamond surface by sol-gel method can protect the diamond from reacting with the metal oxides in matrix and increase the bonding strength between the matrix and diamond. When the depth of cut is 5 μm/s and work piece is carbide (WC, 6%-Co), the grinding ratio of the vitrified bonded wheel prepared by Ti-film-coated diamond is increased by 121% when compared with the wheel prepared by general diamond.

Key words: TiO2 film; diamond; vitrified bond; sol-gel method; wear performance

陶瓷结合剂金刚石砂轮具有硬度高、化学性质稳定、耐水、耐热、耐酸、自锐性强且成本低等特点,在工业应用上具有不可替代的优势[1-4]。但与常用的树脂结合剂和金属结合剂金刚石砂轮相比,以往的陶瓷结合剂金刚石砂轮的耐用度偏低,这主要是因为陶瓷结合剂对金刚石磨料润湿性较差,结合剂对磨料的把持力小,磨削过程中磨料易于脱落。同时,金刚石磨料的高温稳定性差,在700 ℃以上时会与陶瓷结合剂中的氧化物反应产生气体,影响磨具的强度[5]。

目前,通用的提高陶瓷结合剂与金刚石磨料的界面结合强度的方法如下:利用电镀法在金刚石磨料表面物理镀覆一层金属薄膜,常见的镀膜金属有Ni、Cr、Ti、Cu和Al等[6-7]。但使用该方法在金刚石表面镀膜时对环境污染严重,镀膜过程中需要消耗大量电能,同时电镀的金属薄膜在陶瓷磨具烧结过程中极易与陶瓷结合剂反应,使得结合剂与金刚石磨料的结合强度提高不大,所以到目前为止,对于陶瓷结合剂用金刚石磨料,还未找到一种效果理想的表面改性方式。

本文作者采用溶胶-凝胶工艺,以钛酸丁酯为有机前驱体在金刚石磨料表面涂覆TiO2薄膜。并通过扫描电镜、能谱分析、红外光谱分析和磨削试验等手段对涂膜后的磨料表面形貌、结构和磨削性能进行表征,探讨表面涂覆TiO2薄膜对金刚石磨料磨削性能的影响,期望能够研发出一种可显著提高陶瓷结合剂对金刚石磨料把持力、无环境污染的新型金刚石表面改性方法。

1 实验

1.1 样品的制备

以钛酸丁酯(Ti(OC4H9)4,CP)、无水乙醇(AR)、去离子水和二乙醇胺(HN(OC2H5)2)为原料制备TiO2溶胶,TiO2溶胶的化学组成为Ti(OC4H9)4、C2H5OH、H2O及HN(OC2H5)2,各组分的摩尔比为1?26.5?1?1。其制备方法如下:在搅拌下,将钛酸丁酯溶于无水乙醇中,接着加入二乙醇胺,待溶液混合均匀后,再滴加体积比为V(H2O)?V(C2H5OH)=1?10的乙醇水溶液,继续搅拌1 h,室温下陈化24 h,获得浅黄色溶胶。

实验镀覆TiO2薄膜时,首先将洁净的工业基体浸泡于TiO2溶胶中,静置1 min后用铜网捞出,所得金刚石基体置于80 ℃烘箱中干燥5 min后再冷却,重复浸渍涂膜3次。涂膜完成后,对金刚石进行如下的后期热处理:先在马弗炉内缓慢升至100 ℃下保温30 min,然后将炉温以5 ℃/min的升温速度升至650 ℃,保温1 h后在炉内自然冷却,制得表面涂覆纳米TiO2薄膜的金刚石磨料。

1.2 TiO2纳米薄膜的表征

分别用日本电子株式会社生产的JSM-6700F型扫描电镜对金刚石表面薄膜形貌观察;用EDAX公司生产的GENESIS 60S型能谱仪对试样的指定点进行元素分析;用SPECTRUM one红外光谱仪检测TiO2薄膜成键情况。

1.3 磨削性能测试

将未涂膜的金刚石磨料和涂膜后的金刚石磨料与实验室自制陶瓷结合剂按质量比7?3混合,在60 MPa的压力下冷压成型,砂轮规格为d150 mm×10 mm×40 mm。

成型好的金刚石砂轮在Ar保护下于700 ℃烧结1.5 h随炉冷却。采用“针盘式”测试方法,在TACHIKAWA,TP100-P磨削试验机上测试了不同磨料制备的陶瓷结合剂金刚石砂轮的摩擦因数。测试用针为硬质合金(WC,6%Co)圆柱体,d8 mm。摩擦盘为金刚石砂轮,金刚石磨盘转速为3 600 r/min,硬质合金圆柱体的加载载荷为1.8 N,磨削时间20 min,磨削过程中冷却液为水。

将制备的砂轮装配在CNC PSG-52DXNC数控磨床上,砂轮转速为60 m/s,工件为(WC,6%Co)圆柱体,d 20 mm,转速为18 m/s。磨削过程中冷却液为水,测量不同进刀量下工件的表面粗糙度,磨削完成后用硬质合金的质量损失与金刚石砂轮的质量损失之比计为磨耗比G。

2 结果与讨论

2.1 金刚石表面TiO2薄膜的结构

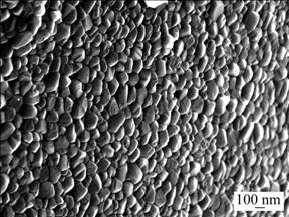

图1所示为金刚石磨料表面经热处理后TiO2薄膜的SEM像。由图1可知,金刚石磨料表面的TiO2薄膜由70~230 nm的TiO2球形颗粒组成,颗粒间排列致密,薄膜中未发现气孔。这说明采用溶胶-凝胶法可以在金刚石磨料表面涂覆一层致密的TiO2薄膜。

图1 金刚石磨料表面TiO2薄膜的SEM像

Fig.1 SEM image of TiO2 film on diamond surface

图2所示为不同条件下TiO2薄膜的红外光谱。图2中3 080~3 415 cm-1处的吸收峰是由表面吸附水产生的─OH基团伸缩振动引起的,1 639 cm-1处为H─O─H的弯曲振动峰,峰与结构水有关;1 450 cm-1处的吸收峰为CO32-中C─O的振动峰[8]。图2(a)中 2 862~2 922 cm-1处的吸收峰是由亚甲基─CH2─的弯曲振动所产生的,图2(b)和(c)中未出现此峰,这是因为样品经650 ℃热处理后该有机基团被排除。图2(a)中1 075 cm-1处的吸收峰代表Ti─O─C化学键的特征振动,该基团是TiO2与其表面有机团中游离的C在室温时反应形成的[9]。当热处理温度上升到650 ℃时,TiO2中绝大部分游离C在热处理条件下被氧化排除,该特征峰消失(见图2中曲线(b))。图2中曲线(c)中,在1 086 cm-1处出现较强吸收峰,根据实验情况应为 Ti─O─C基团的特征振动。试样经过650 ℃的热处理后,TiO2薄膜中不可能存在游离C,因此,曲线(c)中Ti─O─C基团中的C为基底金刚石中的C,其峰值比曲线(a)中的峰值后移10 cm-1,可解释为基底金刚石中的C的化学环境与曲线(a)中TiO2表面有机团中游离的C不同,造成Ti─O─C化学键的特征振动频率改变。

图2 不同条件下TiO2薄膜的红外光谱

Fig.2 FTIR spectra of TiO2 films under different conditions: (a) on diamond surface before heat treatment; (b) on diamond surface after 650 ℃ heat treatment; (c) on diamond surface after 650 ℃ heat treatment

2.2 TiO2薄膜对金刚石与陶瓷结合剂界面结合的影响

分别将普通金刚石和表面涂有TiO2薄膜的金刚石磨料制备成陶瓷结合剂金刚石砂轮,其显微结构如图3所示。由图3可看出,由两种磨料制备的金刚石砂轮在700 ℃保温1.5 h后,磨料之间的结合剂桥烧结均很充分,不存在烧结颈(见图3(b))。对于普通金刚石磨料,结合剂与磨料之间的界面很明显,说明结合剂对磨料的润湿性较差,同时在烧结体中存在着大量的气孔。由于金刚石的热稳定性较差,陶瓷结合剂金刚石砂轮的烧结一般都控制在800 ℃以下。为了降低烧结温度,实验所用陶瓷结合剂中加入了大量碱金属氧化物,在烧结温度下碱金属氧化物中的氧原子具有相当大的活性会缓慢氧化金刚石磨料,从而在烧结体中留下大量气孔[10]。涂膜磨料制备的砂轮显微结构显示,结合剂将金刚石磨料完全包裹,结合剂与磨料的界面不明显,润湿性较普通金刚石磨料有很大提高。同时,烧结体中未出现大量气孔,说明金刚石表面涂覆的TiO2薄膜能够在烧结温度下保护金刚石磨料不受结合剂中的碱金属氧化物氧化,抑制烧结体中气孔的产生。

图3 不同磨料制备的陶瓷结合剂金刚石砂轮的SEM像

Fig.3 SEM images of vitrified bond wheels made by different diamond abrasives: (a) General diamond; (b) TiO2-film- coated diamond

对涂膜的金刚石磨料制备的砂轮在A和B两点处进行能谱分析(见图4)。A点位于烧结体中裸露的磨料表面,能谱分析显示在烧结后磨料的表面依然存在TiO2薄膜(见表1);B点位于靠近与磨料界面的结合剂处,能谱分析显示B点处存在的O、Na、Al、Si和Ca元素均为结合剂组成元素,但结合剂中不含Ti元素(见表2)。B点处检测出的Ti元素说明在烧结过程中,金刚石表面的TiO2薄膜会溶解于结合剂中,如果TiO2薄膜的溶解速率较快,那么在烧结过程中,金刚石磨料会被碱金属氧化物氧化,在烧结体中产生气孔(见图3),烧结体中未产生大量气孔,说明烧结过程中金刚石表面的TiO2薄膜是通过扩散而缓慢溶解于结合剂中,TiO2薄膜对金刚石的保护作用可以维持较长时间。同时,TiO2薄膜向结合剂中的溶解能在金刚石与结合剂的界面处形成过渡层,可能有利于提高结合剂对金刚石的把持力[11]。

图4 涂膜金刚石制备的砂轮的SEM像

Fig.4 SEM image of wheel made by TiO2-film-coated diamond

表1 图4中A点处的能谱分析

Table 1 EDS analysis of point A shown in Fig.4

表2 图4中B点处的能谱分析

Table 2 EDS analysis of point B shown in Fig.4

2.3 涂膜后金刚石的磨削性能

采用“针盘式”测试方法,在磨削试验机上测试了不同磨料制备的陶瓷结合剂金刚石砂轮的摩擦因 数[12]。

图5所示为硬质合金圆柱体砂轮与金刚石砂轮的摩擦因数测试结果。由图5可知,普通金刚石磨料制备的砂轮的摩擦因数平均值为0.46,涂膜金刚石砂轮的摩擦因数平均值为0.49。在整个测试过程中,未涂膜磨料制备的砂轮摩擦因数基本没有波动,而涂膜的磨料制备的砂轮随测试时间的延长摩擦因数缓慢降低。通过对不同金刚石磨料制备的砂轮磨削表面的观察发现(见图6),普通金刚石制备的砂轮的磨削面存在大量晶型完整的金刚石,说明在磨削过程中由于结合剂对金刚石的把持力不牢,金刚石的脱粒为整粒脱落。对于涂膜金刚石制备的砂轮,磨削面处的金刚石均已破碎,结合剂对金刚石的把持力较高,磨削过程中金刚石以破碎方式脱粒。因为普通金刚石与结合剂的把持力较低,在磨削过程中金刚石容易脱粒,所以磨削过程中摩擦因数较小[13]。对于涂膜金刚石制备的砂轮,在磨削过程中金刚石为破碎脱粒,随着磨削时间的延长,磨削面起伏变小,因此,摩擦因数随磨削时间的延长而下降。

图5 硬质合金圆柱体与金刚石砂轮的摩擦因数

Fig.5 Fiction coefficient of different diamond grinding wheels: (a) Diamond wheel made by general diamond abrasive; (b) Diamond wheel made by TiO2 film coated diamond abrasive

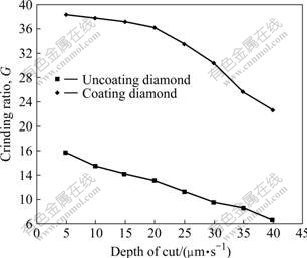

砂轮进刀量与砂轮对硬质合金的磨耗比的关系如图7所示。由图7可看出,在相同的进刀量时,涂膜金刚石制备的砂轮磨耗比远高于普通金刚石砂轮的,这证明在磨削过程中,涂膜后的金刚石磨料脱落更加缓慢,金刚石磨料利用率较高,所以磨耗比提高。同时随着进刀量的加大,两种磨料制备的砂轮的磨耗比都呈下降趋势。在磨削过程中,砂轮在法向上承受的为压应力,进刀量越大,压应力越大。陶瓷结合剂为脆性材料,在应力的诱发下结合剂与磨料的界面处,很容易断裂破碎,造成金刚石磨料脱落,降低砂轮磨耗比[14]。对于普通金刚石磨料制备的砂轮,陶瓷结合剂对磨料的把持力较低,随着进刀量加大,金刚石磨料与结合剂界面处的应力变大,金刚石脱粒速度加快,砂轮磨耗比迅速降低。对于涂膜磨料制备的砂轮,当进刀量低于20 ?m/s时,砂轮磨耗比降低幅度很小,这是由于金刚石表面存在TiO2薄膜时,结合剂对磨料的把持力有所提高,结合剂与磨料的界面能够承受一定的压应力而不被破坏,所以,磨料脱落的速率并不会随着应力的提高而明显加快。当进刀量大于20 ?m/s时,此时金刚石与结合剂界面的应力大于它们的结合强度,界面被迅速破坏,造成金刚石快速脱落,所以随着进刀量加大,砂轮磨耗比大幅降低。

图6 不同金刚石磨料制备砂轮磨削面表面的SEM像

Fig.6 SEM images of grinding surface of different diamond wheels: (a) General diamond abrasive; (b) TiO2 film coated diamond abrasive

图7 砂轮进刀量对金刚石砂轮磨耗比的影响

Fig.7 Influence of depth of cut on grinding ratio of diamond

进刀量对加工工件表面粗糙度的影响如图8所示。由图8可知,对于普通磨料的金刚石砂轮,进刀量对其磨削出的工件的表面粗糙度影响不大,随进刀量增大,工件轮廓算术平均偏差(Ra)波动很小,不平度十点高度(Rz)呈缓慢递增趋势。对于涂膜磨料制备的金刚石砂轮,在进刀量较小时,加工工件的表面质量优于未涂膜磨料加工的工件;随着进刀量增加,工件Ra和Rz数值均迅速增加;当进刀量达到30 μm/s时,两种工件Ra值相等为1.25 μm;继续增加砂轮进刀量时,工件表面粗糙度波动较小。

图8 进刀量对工件表面粗糙度的影响

Fig.8 Influence of depth of cut on surface roughness of samples

磨削过程中,工件的表面粗糙度取决于磨料刺入工件的深度[15]。对于未涂膜的金刚石磨料,其失效方式以整颗脱粒为主,工件的粗糙度主要由磨料的粒度决定[16],所以进刀量对工件的表面粗糙度影响不大。对于涂膜后的磨料,当进刀量较小时,磨料的是失效方式以破碎为主,工作面上磨料的露出高度较低,因此加工出的工件的表面粗糙度优于未涂膜金刚石磨料;当进刀量较大时,涂膜磨料的失效方式也以脱粒为主,此时工件的表面粗糙度由磨料粒度决定,两种磨料加工出的工件表面粗糙度大致相当。

3 结论

1) 利用溶胶-凝胶法可以在金刚石磨料表面涂覆一层致密的TiO2薄膜,TiO2薄膜由70~230 nm的球形TiO2颗粒组成。

2) 金刚石磨料表面涂覆TiO2薄膜后,TiO2薄膜可以保护金刚石磨料在烧结过程中不受碱金属氧化物侵蚀,提高结合剂对金刚石的润湿性和把持力。

3) 用涂膜磨料制备的陶瓷结合剂金刚石砂轮,在进刀量为5 μm/s时,其对硬质合金的磨耗比较未涂膜磨料制备的砂轮提高121%,工件表面粗糙度Ra为0.47 μm,未涂膜磨料加工工件的表面粗糙度Ra为1.18 μm。

REFERENCES

[1] JACTION M J, MILLS B. Microscale wear of vitrified abrasive materials[J]. Journal of Materials Science, 2004, 39(2): 2131-2143.

[2] TANAKA T, IKAWA N, UENO N. A ceramic aspect of vitrified bond for diamond grinding wheel[J]. Bull Jpn Soc Prec Eng, 1985, 19(3): 221-223.

[3] GUO Chang-sheng. Energy partition and cooling during grinding [J]. Journal of Manufacture Processes, 2005, 4(3): 151-157.

[4] GAO Tao, PEN Wei, YAO Chun-yan. Application and progress of diamond surface treatment[J]. Diamond & Abrasives Engineering, 2004(3): 6-9.

[5] VIEIRA A A, LAGES M P. On the temperature field during superficial grinding: an experimental study[J]. Manufacture Technology, 2008, 17(1): 1442-1451.

[6] WANG Ming-zhi, WANG Yan-hui, GUAN Chang-bing. Influence of Ti, Mo and W coating and interface reaction on oxidation resistance of diamond[J]. Material Composite Sinica, 1996(2): 48-52.

[7] WANG Qin-sheng, WANG Xiao-jun. Effect mechanism of diamond surface coating in diamond tools[J]. Diamond & Abrasive Engineering, 2006, 13(5): 5-9.

[8] CHRISTOPHE J. Sol-gel synthesis of potassium titanyl phosphate: Solution chemistry and gelation[J]. Sol-Gel Science and Technology, 1997, 9(5): 183-199.

[9] CUI Ting, TANG Shao-qiu, WAN Long. Study on preparation and property of nanometer titania thin films[J]. Bulletin of Chinese Ceramic Society, 2006, 25(2): 121-124.

[10] KUANG Hong, LIN, Shih FENG Pen. Sintering parameters and wear performance of vitrified bond diamond wheels[J]. International Journal of Refractory Metals and Hard Materials, 2007, 32(2): 25-31.

[11] LIU Xiao-pan, WAN Long. Effect of Na2O content on properties of wheel vitrified bond for diamond grinding[J]. Diamond & Abrasive Engineering, 2007, 14(5): 71-74..

[12] TELLEZ L. Synthesis of inorganic-organic hybrid materials from TEOS, TBT and PDMS[J]. Materials Science, 2003, 38(4): 1773-1780.

[13] KUROSHIMA Y, KONDO Y, OKADA S. Development of Vitrified diamond grinding wheel for engineering ceramics[J]. J Ceram Soc Jpn, 1985, 93(9): 587-589.

[14] JACTION M J, BARLOW N, MILLS B. The effect of bond composition on the strength of partially bonded vitrified ceramic abrasives[J]. J Mater Sci Lett, 1994, 13(5): 1287-1289.

[15] LIU X F, LI Y Z .The microanalysis of the bonding condition between coated diamond and matrix[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21(3): 119-123.

[16] XU Xi-peng, JIN Cun. Friction studies on surface grinding of granite with a vitrified CBN wheel[J]. Surface and Interface Analysis, 2008, 40(1): 863-866.

基金项目:国家科技支撑计划资助项目(2006BAF02A21);湘潭大学低维材料及其应用技术教育部重点实验室开放基金资助项目(KF200605);湖南省科技计划资助项目(2007FJ3063)

收稿日期:2008-11-10;修订日期:2009-07-15

通信作者:刘小磐,讲师,博士;E-mail: liuxiaopanjj@126.com

(编辑 龙怀中)