磨削淬硬温度场数值模拟与试验研究

马占龙1,韩正铜2

(1. 中国科学院 长春光学精密机械与物理研究所 应用光学国家重点实验室,吉林 长春,130033;

2. 中国矿业大学 机电工程学院,江苏 徐州,221008)

摘要:磨削温度作为影响磨削淬硬工艺的重要因素,直接关系着工件的表面质量。为研究其在磨削淬硬过程的分布情况,确定磨削淬硬机理,建立磨削温度场的数学模型,并采用ANSYS软件对其进行有限元仿真研究,通过对磨削温度场的分布以及变化情况的分析验证磨削淬硬的机理,并根据仿真结果对淬硬层深度进行预测。最后进行磨削淬硬试验,对工件显微硬度进行测量,将预测结果和试验结果进行比较,验证仿真结果的有效性,表明可以通过仿真来对其进行研究。

关键词:磨削淬硬;温度场;数值模拟;淬硬层深度

中图分类号:TG156.33;TG580.63 文献标志码:A 文章编号:1672-7207(2012)03-0960-06

Numerical simulation of temperature field and experiment of grind-hardening

MA Zhan-long1,HAN Zheng-tong2

(1. The State Key Laboratory of Applied Optics, Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Science, Changchun 130033, China;

2. College of Mechanical and Electrical Engineering, China University of Mining and Technology,Xuzhou 221008, China)

Abstract: Grinding temperature which is the most important factor of the grind-hardening technology affects the surface quality of the workpiece directly. In order to study the temperature distribution and the mechanism of the technology, the mathematical model of the grinding temperature field was established, and the FEA simulation was conducted by using ANSYS software, and the mechanism of grind-hardening was proved through the analysis of the distribution and changing of the grinding temperature field, and then the hardened depth was predicted with the simulation result. At last, the grinding experiment was carried out, and the prediction result was proved consistent with the analysis of the hardness distribution of the workpiece, which indicates that the simulation results are available and feasible to study grind-hardening by means of FEA simulation.

Key words: grind-hardening; temperature filed; numerical simulation; hardened depth

磨削淬硬工艺[1]是利用磨削加工过程中产生的热量使工件表层温度短时间内升高到奥氏体化温度,然后通过基体的高导热率快速冷却使其发生马氏体相变,从而提高工件表面硬度。该工艺实现了磨削加工与表面淬火的集成,缩短了生产周期,降低了生产成本,减少了能源消耗和环境污染,具有显著的经济效益和社会效益。目前,国内外学者[2-6]对磨削淬硬的研究主要以试验为主,并且试验材料基本是高淬透性的合金钢,对常用工程材料涉及较少,这无疑将直接影响该项工艺研究的理论价值和实际应用价值。因此,本文作者将采用仿真与试验相结合的方式对45钢进行磨削淬硬工艺研究,根据三角形移动热源理论采用有限元法对其主要影响因素磨削温度场进行数值模拟,研究磨削过程中温度场的分布状况以及温度随时间变化情况,并对淬硬层深度进行预测,最后通过试验研究对仿真结果进行验证。

1 磨削温度场的数学模型

磨削温度场是一个三维瞬态热传导问题,其场变量 在直角坐标中应满足如下微分方程[7]:

在直角坐标中应满足如下微分方程[7]:

(在Ω内) (1)

边界条件:

(在Γ1边界上) (2)

(在Γ1边界上) (2)

(在Γ2边界上) (3)

(在Γ3边界上) (4)

式中:ρ为材料密度;c为材料比热容;t为时间;kx,ky和kz分别为材料沿x,y和z方向的热传导系数;Q=Q(x, y, z, t)为物体内部的热源密度;nx,ny和nz为边界外法线的方向余弦; 为Γ1边界上的给定温度;

为Γ1边界上的给定温度; 为Γ2边界上的给定热流量;h为放热系数;

为Γ2边界上的给定热流量;h为放热系数; 在自然对流条件下,

在自然对流条件下, 为外界环境温度;在强迫对流条件下,

为外界环境温度;在强迫对流条件下, 为边界的绝热壁温度。边界应满足

为边界的绝热壁温度。边界应满足 ,其中Γ为Ω域的全部边界。

,其中Γ为Ω域的全部边界。

2 仿真条件确定

2.1 试验条件

工件材料选用调质态45钢,作为机械工程中常用的碳素结构钢,适用于制造高强度的运动零件,通常在调质或正火状态下使用,可代替渗碳钢,用以制造表面耐磨的零件。试验在M7130H型卧轴矩台平面磨床上进行。砂轮型号WA46L8V,直径350 mm,磨削用量选取如表1所示,磨削方式选用单程平面磨削,冷却条件为空气自然冷却。

表1 磨削用量参数

Table 1 Grinding parameters

2.2 热源强度

传入工件的热源强度qm可按下式计算[8]:

(5)

(5)

式中:ls为接触弧长;Ft为切向磨削力;Rw为热量分配比;vs为砂轮速度;b为磨削宽度。

接触弧长

(6)

(6)

式中:ds为砂轮直径;ap为磨削深度。

平面磨削条件下切向磨削力[9-10]:

(7)

(7)

式中:k为与工件材料有关的系数;ω平均磨粒间隔;ε为影响系数;vw为进给速度;Rs为砂轮半径。

平面干磨条件下热量分配比[8]:

(8)

(8)

式中: 为与砂轮有关的参数;

为与砂轮有关的参数; 为与工件有关的参数;λ为热传导率。

为与工件有关的参数;λ为热传导率。

2.3 仿真条件

选取表1中的4号试验进行有限元仿真,由磨削加工参数和相应公式可以得到其仿真初始条件,如表2所示。

表2 仿真初始条件

Table 2 Initial conditions of simulation

由于磨削时间较短,并且空气是热的不良导体,所以认为工件的表面是绝热的。工件发生相变的表层深度很浅,相变潜热引起的热量变化同磨削热量相比较小,所以可以忽略相变潜热的影响。工件的初始温度取当时试验的室温20 ℃。

3 有限元模型建立

3.1 材料性能参数

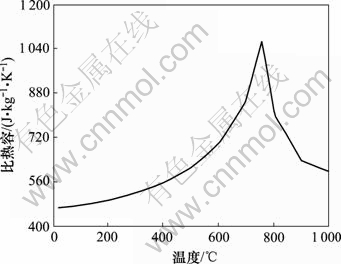

由于只考虑工件本身的热传导,而不考虑与空气的对流换热,因此只需设置材料的密度、热传导率以及比热容等参数。45钢密度为7 824 kg/m3,热传导率和比热容均同温度呈非线性关系[11],其变化曲线分别如图1和2所示。

图1 45钢热传导率的变化

Fig.1 Thermal conductivity variation of 45 steel

图2 45钢比热容的变化

Fig.2 Specific heat variation of 45 steel

3.2 模型创建及热源加载

创建长为3倍磨削弧长、宽和高均为10 mm的实体模型并进行网格划分[12-13],单元类型选用三维8节点六面体单元,即Solid70单元。由于工件表面的温度梯度较大,为相变发生区域,对精度要求较高,所以在划分网格时实体模型表面层的网格划分得更细密一些,随着深度的增加,网格越稀疏,这样既能保证对工件表层进行精确的计算分析,又可以节约计算量,减少系统的数据存储空间。网格划分结果如图3所示。

图3 网格划分结果

Fig.3 Meshing result

三角形移动热源的加载模式[14]如图4所示,已知热源强度的分布长度为lc,移动速度v=vw。设在零时刻起,该热载荷的前沿到达工件的某点O,需要求解的是t=lc/vw时刻工件上的温度分布,这时热载荷的前沿到达工件上的点A, 。在有限单元法结构离散时,若将

。在有限单元法结构离散时,若将 划分为n段,可以将0至t的时间段也划分为n段,从t=0时刻起,01段上有热源强度斜率为2q/lc的斜坡载荷作用;从t=lc/(nvw)时刻起,12段上作用有同样斜率的斜坡载荷作用;依此类推,从t=(n-1)lc/(nvw)时刻起,(n-1)n段上作用有同样斜率的斜坡载荷作用。依据求解时间步,将三角形分布热源载荷等效到节点上,依次求解各个载荷步,即可求得t=lc/Vw时刻工件上得温度分布。

划分为n段,可以将0至t的时间段也划分为n段,从t=0时刻起,01段上有热源强度斜率为2q/lc的斜坡载荷作用;从t=lc/(nvw)时刻起,12段上作用有同样斜率的斜坡载荷作用;依此类推,从t=(n-1)lc/(nvw)时刻起,(n-1)n段上作用有同样斜率的斜坡载荷作用。依据求解时间步,将三角形分布热源载荷等效到节点上,依次求解各个载荷步,即可求得t=lc/Vw时刻工件上得温度分布。

图4 三角形移动热源加载模式

Fig.4 Loading mode of triangle moving heat resource

4 仿真结果分析及淬硬层深度预测

4.1 仿真结果分析

图5所示为温度场分布等值线图。从图5可以看出:工件表面温度最高达到966.767 ℃,并且在一定深度处都达到了表面淬火的温度要求,随着深度的增加温度逐渐降低。

图5 温度场分布等值线图

Fig.5 Temperature field distribution isoline

图6所示为工件表面单点温度的变化。从图6可以看出:当热源移动到该位置时,温度迅速上升并达到966.767 ℃,随着热源的离开,温度又迅速下降到300 ℃以下,整个过程在2 s左右完成,具有加热温度高、保温时间短和下降迅速的特点,满足表面淬火的要求。

图6 工件表面单点温度的变化

Fig.6 Temperature variation of one-point on workpiece surface

图7所示为工件表面沿长度方向各点温度的变化。从图7可以看出:各点均经历了相似的温度变化过程,而且变化规律基本相同,中间和切出区最高温度非常接近,而切入区由于热源强度和热源积累时间较短,使得该区域温度偏低。

图7 工件表面沿长度方向各点温度的变化

Fig.7 Temperature variation of points along length direction on workpiece surface

4.2 淬硬层深度预测

当45钢加热温度在Ac3=805 ℃ [15]以上时基体转变为奥氏体组织,随着温度迅速下降奥氏体转变为马氏体,因此,可以将加热温度位于Ac3以上的区域近似看作磨削淬硬区域,进而对淬硬层深度进行预测。图8所示为4号工件温度随深度的变化。从图8可以得到磨削淬硬层深度预测值约为0.24 mm。

图8 工件温度随深度的变化

Fig.8 Temperature variation with depth

5 磨削淬硬试验

以表1中磨削用量进行多组磨削淬硬试验研究,磨削完成后将工件沿淬硬层深度方向进行线切割,取下宽为8 mm、厚为3 mm的材料试样,经镶嵌后研磨抛光,用4%硝酸酒精溶液腐蚀,制成试样,采用HXD-1000TM/LCD数字式显微硬度计测量其显微硬度,加载载荷为4.904 N,保荷时间为15 s。

图9所示为磨削淬硬试样显微硬度的分布。从图9可以看出:除3号试样外均取得了一定的淬硬效果,并且具有相似的硬度分布规律:完全淬硬层主要由马氏体组成,硬度平均在HV 650(HRC 58)左右,最高硬度达到HV 728.4(HRC 61);过渡层随着马氏体含量的减少和铁素体含量的增加,硬度急剧下降;基体硬度集中在HV 200(HBS 190)左右。

45钢经表面淬火后硬度要求一般为HRC 40~50,认为硬度大于HRC 40(HV 392)时即为淬硬。图10所示为4号试样显微硬度的分布。在图上画一条显微硬度为HV 392的水平直线,该直线同硬度分布曲线交点H的横坐标即为淬硬层深度,由此可以得到工件的磨削淬硬层深度试验值约为0.26 mm。将仿真值同试验值进行比较得到其误差为7.69%,精度较高,预测结果有效可靠,说明利用有限元法对磨削温度场进行数值仿真及对淬硬层深度进行预测是可行的,对磨削淬硬的试验研究具有指导意义。

图9 试样显微硬度分布曲线

Fig.9 Microhardness distribution curves of grind-hardening samples

图10 4号试样显微硬度的分布

Fig.10 Microhardness distribution of sample No.4

6 结论

(1) 通过对磨削淬硬温度场的有限元仿真,可以得到工件表面温度场的分布及变化,工件表层在一定深度处均达到了表面淬火的温度要求,并且工件表面上各点均经历了先快速加热后又迅速冷却的过程,从而验证了磨削淬硬产生的机理。

(2) 在磨削用量选择合适的情况下可以采用磨削淬硬工艺对45钢进行表面淬火,并且表面最高硬度可以达到HV 728.4 HV(HRC 61)。

(3) 通过对磨削淬硬层深度的预测及试验验证,表明仿真结果的有效性,从而可以借助仿真研究为工艺参数的选取及优化提供一定的指导。

参考文献:

[1] Brinksmeier E, Brockhoff T. Randschicht-W?rmebehandlung durch Schleifen[J]. HTM, 1994, 49(5): 327-330.

[2] Brinksmeier E, Brockhoff T. Utilization of grinding heat as a new heat treatment process[J]. Annals of the CIRP, 1996, 45(1): 283-286.

[3] Zarudi I, Zhang L C. Mechanical property improvement of quenchable steel by grinding[J]. Journal of Materials Science, 2002, 37(18): 3935-3943.

[4] 韩正铜, 张宁菊, 高顶. 40Cr调质钢磨削淬硬表面强化的实验研究[J]. 材料工程, 2007(12): 35-38.

HAN Zheng-tong, ZHANG Ning-ju, GAO Ding. Experimental research on grinding hardening for quenched and tempered 40Cr steel[J]. Materials Engineering, 2007(12): 35-38.

[5] 韩正铜, 杨刚, 杜长龙, 等. 外圆磨削表面淬硬试验研究与动态仿真[J]. 中国机械工程, 2008, 20(23): 2800-2803.

HAN Zheng-tong, YANG Gang, DU Chang-long, et al. Experiments and dynamic simulation of external grind- hardening[J]. Chinese Mechanical Engineering, 2008, 20(23): 2800-2803.

[6] 马占龙, 韩正铜, 杨刚, 等. 基于BP神经网络的外圆磨削淬硬试验研究[J]. 工具技术, 2009, 43(3): 29-31.

MA Zhan-long, HAN Zheng-tong, YANG Gang, et al. Study on external grind hardening base on BP neural network[J]. Tool Technology, 2009, 43(3): 29-31.

[7] 王勖成, 邵敏. 有限单元法基本原理和数值方法[M]. 北京: 清华大学出版社, 1997: 421-423.

WANG Xu-cheng, SHAO Min. The principle and numerical method of finite element[M]. Beijing: Tsinghua University Press, 1997: 421-423.

[8] 任敬心, 华定安. 磨削原理[M]. 西安: 西北工业大学出版社, 1988: 64-78.

REN Jing-xing, HUA Ding-an. Principle of grinding and cutting[M]. Xi’an: Northwest Industrial University Press, 1988: 64-78.

[9] 臼井英治. 切削磨削加工学[M]. 高希正, 译. 北京: 机械工业出版社, 1982: 46-50.

臼井英治. Technology of cutting and grinding[M]. GAO Xi-zheng, trans. Beijing: China Machine Press, 1982: 46-50.

[10] 王龙山, 李国发. 磨削过程模型的建立及其计算机仿真[J]. 中国机械工程, 2002, 13(1): 1-4.

WANG Long-shan, LI Guo-fa. Modeling and computer simulation for grinding process[J]. Chinese Mechanical Engineering, 2002, 13(1): 1-4.

[11] 谭真, 郭文广. 工程合金热物性[M]. 北京: 冶金工业出版社, 1991: 52-53.

TAN Zhen, GUO Wen-guang. Thermal physical property of the engineering alloy[M]. Beijing: Metallurgical Industry Press, 1991: 52-53.

[12] 张磊, 葛培琪, 张建华, 等. 40Cr钢磨削强化的试验与数值仿真[J]. 机械工程学报, 2006, 42(8): 60-64.

ZHANG Lei, GE Pei-qi, ZHANG Jian-hua, et al. Simulation of 40Cr steel in grind-hardening[J]. Chinese Journal of Mechanical Engineering, 2006, 42(8): 60-64.

[13] 张磊. 单程平面磨削淬硬技术的理论分析与试验研究[D]. 济南: 山东大学机械工程学院, 2006: 78-81.

ZHANG Lei. Study on mechanism and experiment of single- pass surface grind-hardening technology[D]. Jinan: Shandong University. College of Mechanical Engineering, 2006: 78-81.

[14] 张文丽. 基于ANSYS的磨削热分析中移动热源加载技巧[J]. 现代制造工程, 2007(3): 88-90.

ZHANG Wen-li. The loading skill of moving heat resource based on ANSYS in grinding heat analysis[J]. Modern Manufacturing Engineering, 2007(3): 88-90.

[15] 樊东黎. 热处理工程师手册[M]. 北京: 机械工业出版社, 1999: 259-261.

FAN Dong-li. Handbook of heat treatment engineer[M]. Beijing: China Machine Press, 1999: 259-261.

(编辑 陈爱华)

收稿日期:2011-04-19;修回日期:2011-06-30

基金项目:高等学校博士学科点专项科研基金资助项目(200802900513);中国矿业大学科技基金资助项目(2006B009)

通信作者:马占龙(1983-),男,河北唐山人,硕士,助理研究员,从事超精密加工技术研究;电话:15948797594,E-mail: mzlcumt@126.com