Trans. Nonferrous Met. Soc. China 20(2010) s968-s972

Effects of casting factors of cooling slope on semisolid condition

T. HAGA1, R. NAKAMURA1, R. TAGO1, H. WATARI2

1. Department of Mechanical Engineering, Osaka Institute of Technology, 5-16-1 Omiya Asahi-ku,

Osaka City 535-8585, Japan;

2. Department of Production Science and Technology, Gunma University, Tenjin-cho,

Kiryu City 376-8515, Japan

Received 13 May 2010; accepted 25 June 2010

Abstract:The effects of the casting factors such as nozzle size to pour the melt, nozzle height, tilt of the slope and slope length, of the cooling slope on the process to make semisolid slurry were investigated. The results show that these factors affect the behaviors of the semisolid slurry on the cooling slope. The tilt of the slope is the factor that has major influence on the behavior of the semisolid slurry. The cooling roll is developed from the result of the research of the cooling slope. The rotating cooling roll can improve the sticking of the semisolid slurry on the substrate and it is suitable for making the semisolid slurry.

Key words: casting factors; cooling roll; semisolid slurry; cooling slope

1 Introduction

A cooling slope was one of the simplest equipment to cast the semisolid slurry for thixocasting and rheocasting. Low equipment cost and simplicity of the operation are the advantages of the cooling slope. However, the cooling slope has some disadvantages, such as the adhesion of the metal. The relationship between the casting factors and the adhesion has not been investigated precisely. In the present study, the influences of the casting factors on the adhesion of the metal at the cooling slope were investigated. The casting factors were nozzle size to pour the melt, distance between the nozzle and cooling slope, tilt of the cooling slope, and cooling distance of the melt on the slope. The spread of the melt was concerned to the adhesion of the metal. The spread of the melt was observed.

The cooling roll was devised from the result of the investigation of the cooling slope. The curvature of cooling roll was suitable to prevent the adhesion of the metal. When the roll was rotated, the peeling of the metal from the cooling roll became better.

In this work, the effects of the casting factors on the adhesion of the metal, and the behavior of the spread of the melt on the cooling slope was investigated. Moreover, the cooling roll devised in this study was introduced.

2 Experimental

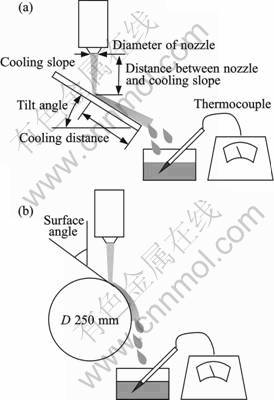

The schematic illustration of the cooling slope and the colling roll are shown in Fig.1[1-5]. The cooling slope was made from mild steel. The thermal conductivity of the mild steel is less than that of the copper. The mild steel was suitable for the cooling slope. When the thermal conductivity was too large, the adhesion occurred easily. Therefore, the mild steel was chosen for the cooling slope. The cooling slope was cooled from the inside by water. BN was sprayed on the cooling slope to prevent the adhesion of the metal. The tilt angles of the cooling slope were 15?, 30?, 45? and 60?. The cooling distances were 30, 50, 100, 200 and 300 mm. The melt was poured from the nozzle to the cooling slope. The diameters of the nozzles were 3, 5, and 10 mm. The distance from the nozzle to the slope affected the speed of the melt. The distances were 30, 100, 200, 400 and 600 mm. A356 aluminum alloy was used and the melt temperature was 620 ?C.

The cooling roll was made from the mild steel. The BN was sprayed on the surface. The melt-flow angles against roll-surface were 15?, 30?, 45 and 60?. The roll speeds were 5 and 10 m/min. The nozzle diameters were 5 and 10 mm. A356 aluminum alloy was used and the melt temperature was 620 ?C, too. The experiment was recorded by the video camera. The temperature of the metal after going through the cooling slope or the cooling roll was measured by the thermo-couple.

Fig.1 Schematic illustration of cooling slope (a) and cooling roll (b)

3 Results and discussion

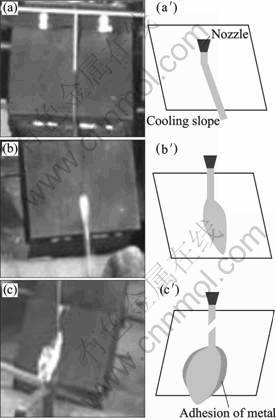

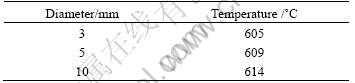

The flow speed of the melt increases as the distance between the nozzle and the cooling slope enlarges. The effect of the distance between the nozzle and the cooling slope on the behavior of poured melt on the cooling slope is shown in Fig.2. The diameter of the nozzle is 3 mm, and the tilt angle of the cooling slope is 60?. It can be seen that the spread of the melt is affected by the distance between the nozzle and the cooling slope. When the distance is 50 mm, the melt does not spread on the cooling slope. The flow of the melt looks like jump when the melt collides with the cooling slope. The melt might not be cooled by the cooling slope, and the melt might not be cooled by the cooling slope. When the distance between the nozzle and the cooling slope is 200 mm, the melt disperses on the cooling slope. The adhesion of the melt to the slope does not occur. When the distance is 600 mm, the spread area of the melt becomes wider and the adhesion of the melt on the cooling slope occurs.

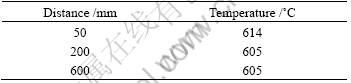

The effect of the distance between the nozzle and cooling slope on the temperature of the melt after going through the cooling slope is listed in Table 1. The cooling distance shown in Fig.1 is 30 mm. Therefore, the melt is cooled only when the melt collides with the cooling slope. When the distance between the nozzle and cooling slope is 50 mm, the melt is only decreased by 6 ?C. When the distances are 200 mm and 600 mm, the melt temperature are decreased by 15 ?C. The difference of the melt temperature after going through the cooling slope is caused by the difference of the force of the collision. The force of the collision becomes greater as the distance between the nozzle and the cooling slope increases. The wetting condition between the melt and the cooling slope becomes better as the force of the collision becomes greater. As the result, heat transfer between the melt and the cooling slope becomes larger. Therefore, the melt is cooled better.

Fig.2 Photographs ((a), (b), (c)) and schematic illustrations ((a'), (b'), (c')) showing effect of distance between nozzle and cooling slope on behavior of poured melt on cooling slope: (a), (a') Distance of 50 mm; (b), (b') Distance of 200 mm; (c), (c') Distance of 600 mm

Table 1 Effect of distance between nozzle and cooling slope on temperature of melt after going through cooling slope at cooling distance of 30 mm and nozzle diameter of 3 mm

The effect of the diameter of the nozzle on the spread of the melt on the cooling slope is shown in Fig.3. The diameters of the nozzle are 5 mm and 10 mm. The distance between the nozzle and the cooling slope is 200 mm. The tilt of the cooling slope is 60?. The cooling distance is 30 mm. When the diameter of the nozzle is 10 mm, the spread of the melt is larger than that using the 5 mm-diameter nozzle. The adhesion of the solidified metal on the cooling slope does not occur. Table 2 shows the relationship between the nozzle diameter and the temperature of the melt went through the slope. The temperatures of the metal went through the cooling slope are 609 ?C at 5mm-diameter nozzle and 614 ?C at 10 mm-diameter nozzle. When the diameter of the nozzle is 3 mm, the temperature of the metal went through the cooling slope is 605 ?C. The metal can be cooled until lower temperature as the nozzle-size becomes smaller. The thickness of the melt dispersed on the cooling slope might becomes thicker as the diameter of the melt flow ejected from nozzle becomes thicker. As a result, the metal could be cooled better when the nozzle-diameter is thinner.

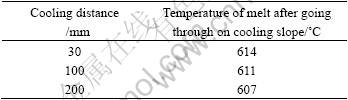

The cooling distance affects the adhesion of the solidified metal, and the temperature of the metal went through the cooling slope. Fig.4 shows the behavior of the metal on the cooling slope when the cooling distance is 300 mm. In Fig.4, the nozzle diameter was 10 mm, and the tilt angle was 60?. The metal solidified and adhered on the cooling slope. When the cooling distance was longer than limitation distance, the adhesion of the solidified metal occurred. The limitation of the cooling distance became longer as the nozzle became thicker. The distance between the nozzle and the cooling slope affected the limitation of the cooling distance. The limitation distance became shorter as the distance between the nozzle and the cooling slope became longer. Table 3 shows the relationship between the cooling distance and the temperature of the melt went through on the cooling slope. The temperature of the metal became lower as the cooling distance became longer. The cooling of the metal may be classified into the two stages. One is collision of the melt against the slope, and the other is flow down of the melt on the cooling slope.

Fig.3 Photographs showing effect of diameter of nozzle on spread of melt on cooling slope: (a) Diameter of 5 mm; (b) Diameter of 10 mm

Table 2 Effect of nozzle diameter on temperature of melt after going through on cooling slope at cooling distance of 30 mm, distance between nozzle and cooling slope of 200 mm

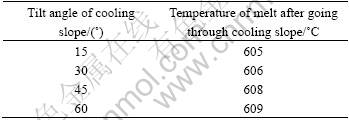

The tilt angle of the cooling slope affects the spread of the metal on the cooling slope. It is clear from comparison between Fig.2(b) and Fig.5 that the spread of the melt becomes wider as the tilt angle of the cooling slope becomes smaller. The adhesion of the solidified metal increases as the tilt angle becomes smaller. The effect of the tilt angle of the cooling slope on the adhesion of the solidified metal is the greatest in the conditions investigated in the present study. Table 4 shows the relationship between the tilt angle of the cooling slope and the temperature of the metal went through the cooling slope. The temperature of the metal decreases as the tilt angle decreases. The vertical force of the melt against the cooling slope becomes larger as the tilt angle of the cooling slope becomes smaller. Therefore, the contact condition between the melt and cooling slope becomes better, and the heat transfer between the melt and the cooling slope becomes larger. The speed of the melt on the cooling slope becomes slower as the tilt angle becomes smaller. Therefore, the cooling time becomes longer as the tilt angle becomes smaller. In this way, the influence of the factors, which decreases the temperature of the metal, becomes greater as the tilt angle becomes smaller.

Fig.4 Photograph of adhesion of solidified metal on cooling slope at nozzle size of 5 mm, tilt angle of 60?, cooling distance of 300 mm.

Table 3 Effect of cooling distance on temperature of melt after going through cooling slope at distance between nozzle and cooling slope of 200 mm, tilt of cooling slope of 60?, nozzle-diameter of 10 mm

Fig.5 Photograph of adhesion of solidified metal on cooling slope at nozzle size of 5 mm, tilt angle of 15?, cooling distance of 30 mm and distance between nozzle and cooling slope of 200 mm

Table 4 Effect of cooling distance on temperature of melt after going through cooling slope at distance between nozzle and cooling slope of 200 mm, cooling distance of 30 mm, and nozzle diameter of 5 mm

It is not easy to decide the proper tilt angle and cooling distance in order to cool the melt without the adhesion of the solidified metal. A cooling roll was devised and tested to realize the sound cooling and prevention of the adhesion of the metal [6-10].

The results of the experiment of the cooling roll are shown in Fig.6. In Figs.6(a) and (b), the roll speeds are 5 m/min and 10 m/min, respectively. In Fig.6(a), the metal solidifies on the roll and the solidified metal sticks to the roll. When the roll speed increases from 5 m/min to 10 m/min, the adhesion of the metal is eliminated. The metal is released from the roll before the solidification. The roll speed is useful to prevent the adhesion of the metal on the roll-surface. The difference between Figs.6(b) and (c) is only the surface angle (see Fig.1(b)). In Figs.6(b) and (c), the surface angles are 30? and 15?, respectively. Adhesion of the solidified metal occurs in Fig.6(c). When the surface angle is 15?, the roll speed must be set higher to prevent the adhesion. In Figs.6(d) and (f), the roll is not rotated and the surface angles are 45? and 60?, respectively. The adhesion of the metal occurs at both of Figs.6(d) and (f). The surface angle becomes larger as the metal flew on the surface of the roll at the cooling roll. It is thought that the increase of the surface angle solves the problem of the adhesion of the solidified metal. The increase of the surface angle improves the adhesion of the metal, and the improvement is not complete. In Figs.6(e) and (f), the roll rotates at 5 m/min, and the adhesion is decreased. When the surface angles are 45? and 60?, the roll speed must be set higher than 5 m/min. The temperature of the metal in Fig.6(b) is cooled down to 610 ?C, and the temperature of the metal in Fig.6(e) is cooled down to 607 ?C. It becomes clear that the cooling roll is useful to improve the adhesion of the solidified metal.

Fig.6 Photographs of semisolid casting using cooling roll(distance between nozzle and roll of 200 mm): (a) Roll speed of 5 m/min, surface angle of 30?, Nozzle diameter of 5 mm; (b) Roll speed of 10 m/min, surface angle of 30?, nozzle diameter of 5 mm; (c) Roll speed of 10 m/min, surface angle of 15?, nozzle diameter of 5 mm; (d) Roll speed of 0 m/min, surface angle of 45?, nozzle diameter of 10 mm; (e) Roll speed of 5 m/min, surface angle of 45?, nozzle diameter of 10 mm; (f) Roll speed of 0 m/min, surface angle of 60?, nozzle diameter of 10 mm; (g) Roll speed of 5 m/min, surface angle of 60?, nozzle diameter of 10 mm

4 Conclusions

1) The distance between the nozzle and the cooling slope affects the cooling of the melt and adhesion of the metal. The cooling of the metal increases as the distance becomes longer. The adhesion of the metal becomes harder as the distance becomes longer.

2) The nozzle size affects the cooling of the melt. The temperature of the melt becomes lower as the nozzle becomes thinner. This means that the cooling of the melt becomes better as the poured melt ratio becomes smaller.

3) The cooling distance affects the cooling of the melt and the adhesion of the solidified metal. The melt temperature becomes lower as the distance becomes longer. The adhesion of the solidified metal occurs when the cooling distance becomes longer than the suitable distance.

4) The tilt angle of the cooling slope affects the cooling of the melt and the adhesion of the solidified metal. The cooling of the melt increases as the tilt angle becomes smaller. The adhesion of the solidified metal becomes harder as the tilt angle becomes smaller. The effect of the tilt angle on the adhesion of the metal is the largest in the casting factors investigated in this study.

5) A cooling roll is devised in this study. The cooling roll is useful to prevent the adhesion of the solidified metal. The adhesion of the metal decreases as the roll speed increases.

References

[1] HAGA T, ASAI T, WATARI H, KUMAI S. Casting of aluminum alloy bar by semisolid roll casting [J]. Solid State Phenomena, 2008, 141/142/143: 295-300.

[2] HAGA T, SUZUKI S. Casting of aluminum alloy ingot for thixoforming using a cooling slope [J]. Journal of Materials Processing and Technology, 2001, 118: 169-172.

[3] HAGA T,. KAPRANOS P. Billetless simple thixoforming process [J]. Journal of Materials Processing and Technology, 2002, 130: 581-586.

[4] HAGA T, KAPRANOS P. Simple rheocasting process [J]. Journal of Materials processing and Technology, 2002, 130: 594-598.

[5] MOTEGI M, OGAWA N, KONDO K, LIU C, AOYAMA S. Continuous casting semisolid Al-Si Mg alloy [C]// Proceeding of the ICAA-6. 1998: 297-326.

[6] HAGA T, INUI H, WATARI H, KUMAI S. Semisolid casting of aluminum alloy strip and its properties [J]. Solid State Phenomena, 2006,116/117: 379-382.

[7] HAGA T, SAKAGUCHI H, INUI H, WATARI H, KUMAI S. Aluminum alloy semisolid strip casting using an unequal diameter twin roll caster [J]. Journal of Achievements in Materials and Manufacturing Engineering, 2006, 14:157-162.

[8] HAGA T, SUZUKI S. A downward melt drag single roll caster for casting semisolid slurry[J]. Journal of Materials Processing and Technology, 2004, 157: 695-700.

[9] HAGA T, TAKAHASHI K, WATARI H. Semisolid strip casting using a vertical type twin roll caster[J]. Materials Science Forum, 2003, 426: 477-482.

[10] HAGA T, SUZUKI S. Semisolid strip casting using a twin roll caster equipped with a cooling slope[J]. Journal of Materials Processing and Technology, 2002, 130: 558-561.

[11] HAGA T. Semi-solid roll casting of aluminum alloy strip by melt drag twin roll caster[J]. Journal of Materials Processing and Technology, 2001, 111: 64-68.

(Edited by LONG Huai-zhong)

Corresponding author: T. HAGA; Tel: +81-6-69544888; E-mail: haga@med.oit.ac.jp