1文章编号:1004-0609(2015)-07-1953-08

某铅锌尾矿浓密机溢流的工艺矿物学分析

成 岚1, 2,李茂林1, 2, 3,黄光耀3

(1. 武汉科技大学 资源与环境工程学院,武汉 430081;

2. 武汉科技大学 冶金矿产资源高效利用与造块湖北省重点实验室,武汉 430081;

3. 长沙矿冶研究院有限责任公司,长沙 410012)

摘 要:运用矿物参数自动分析和传统的工艺矿物学研究技术相结合的方式对某铅锌尾矿浓密机溢流进行了工艺矿物学研究,研究了该溢流的化学成分、矿物组成、主要金属硫化物的产出形式及解离度。分析结果表明:样品中金属矿物主要是黄铁矿(占溢流样品质量的46.30%),其次为方铅矿和闪锌矿,3种主要矿物的粒度大多小于0.03 mm。MLA的统计结果表明:3种主要矿物呈单体产出的比例分别为黄铁矿94.93%、方铅矿85.48%和闪锌矿89.34%。黄铁矿含量高,解离程度好,预计通过分选可获得较高品位的硫精矿。基于上述工艺矿物学分析,推荐将浓密机溢流通过高压水力旋流器分级脱泥,旋流器沉砂与原回收高硫精矿的给矿混合进入原回收高硫精矿的生产流程,可实现在较低的工业改造投资条件下,获得较大的收益。

关键词:铅锌尾矿;浓密机溢流;工艺矿物学;矿物参数自动分析;水力旋流器;硫精矿

中图分类号:TD952 文献标志码:A

Process mineralogy analysis of certain lead-zinc tailings thickener overflow

CHENG Lan1, 2, LI Mao-lin1, 2, 3, HUANG Guang-yao3

(1. School of Resources and Environmental Engineering,

Wuhan University of Science and Technology, Wuhan 430081, China;

2. Key Laboratory of Efficient Utilization of Metallurgical Mineral Resources and

Agglomeration of Hubei Province, Wuhan University of Science and Technology, Wuhan 430081, China;

3. Changsha Research Institute of Mining and Metallurgy Co., Ltd., Changsha 410012, China)

Abstract: The valuable elements of a certain lead-zinc tailing thickener overflow have recyclable value. Process mineralogy research of this overflow was implemented using mineral automated quantitative mineralogy (MLA), and the chemical composition, mineral composition, the output form of main metal sulfide and the dissociation degree were investigated by traditional process mineralogy methods. Statistical results show that pyrite is the main metal mineral followed by galena and sphalerite, the mass fraction of pyrite is 46.30%, and most size of the three minerals is under 0.03 mm. The monomer dissociation degrees of pyrite, galena and sphalerite are 94.93%, 85.48% and 89.34%, respectively. The separation of high-grade sulfur concentrate is good due to the high pyrite content and dissociation degree of the sample. Based on the process mineralogy analysis, the desilting of the high-pressure hydrocyclone was mixed with the feed of original production as a new feed to produce high grade sulfur concentrate. The process can achieve larger benefit with few industrial transformation investments.

Key words: lead-zinc tailing; thickener overflow; process mineralogy; mineral automated quantitative mineralogy; hydrocyclone; sulfur concentrate

二次资源的有效利用,早已成为世界性的热点问题。矿山尾矿作为重要的二次资源,无论对社会经济的发展,还是对矿山企业的可持续发展,都具有重要的再利用价值[1-2]。由于矿产资源属不可再生资源,国内采出矿石已逐步趋于贫、细、杂化,尾矿再利用可以在保障国民经济建设需要的前提下延缓资源品质下滑速度。而从尾矿中对有用矿物的再次选别,是尾矿再利用的重要方向之一,从尾矿中回收有用组分既不会对生态环境产生新的破坏,又使尾矿堆积造成的环境污染程度得以减小[3-4]。

无论是对原生矿石还是矿山尾矿的选别利用,矿石的矿物学特点研究,均是选别方式选择、工艺流程制定的重要前提[5-7]。近年来,工艺矿物学的研究手段、研究对象和研究领域不断拓展,国内外工艺矿物学研究手段主要有人工显微镜检测、X射线衍射分析、X射线荧光分析以及扫描电子显微镜能谱分析[8]。由澳大利亚昆士兰大学JK矿物学研究中心开发研制的矿物参数自动分析(MLA)是目前世界上最先进的工艺矿物学参数自动定量分析测试仪器[9-11]。近十年来,以矿物参数自动分析(MLA)为代表的工艺矿物学参数自动检测技术不仅可以快速准确地测定几乎所有工艺矿物学参数,而且能对样品中的所有矿物进行统计分析,使工艺矿物学研究得到阶段性的发展[12]。

硫精矿在部分有色金属矿山作为副产品产出,它是硫酸工业的重要原料,高品位硫精矿烧成的硫酸渣也可以直接制备铁精矿[13-14]。某铅锌矿选厂铅锌浮选尾矿浓密机底流用于回收单一高品位硫精矿效果显著,年生产直接经济效益达到了6000多万元。然而,占尾矿总量13%的极细粒级矿物从浓密机溢流中流失,这部分矿泥中硫品位约为22%,相当于9万t左右的标准硫,潜在的经济价值约为2000万元,对这部分硫的回收值得作进一步探索。本文作者利用MLA 矿物自动分析系统并结合传统工艺矿物学研究方法,对该铅锌浮选尾矿的浓密机溢流进行了详细的工艺矿物学研究,为该溢流中极细粒级硫资源的回收利用提供了重要的理论指导。

1 实验

用于测试的试样取自某铅锌尾矿浓密机溢流,首先对试样进行化学成分分析,利用7700ICP-MS电感耦合等离子体质谱仪进行半定量分析,采用SpectrAA220FS /Z 型原子吸收光谱仪进行化学定量分析。利用XRD确定了试样的物相组成。利用XPL-900 型透反射偏光显微镜进行光片和薄片鉴定,确定主要矿物的组成及嵌布特性[15-16]。利用MLA工艺矿物学参数自动分析系统地研究溢流的矿物组成、解离特征、有价元素赋存状态、典型矿物颗粒图像等工艺矿物学参数。

2 试样元素与物相分析

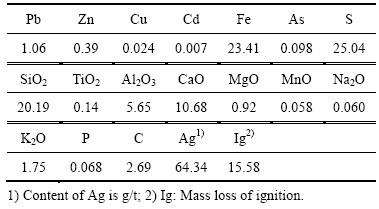

试样多元素化学成分分析及主要矿物物相分析结果如表1~4所示。从测定结果可知。

1) 试样中可供选矿富集回收的主要元素是硫,其品位为25.04%;铅和锌的品位分别为1.06%、0.39%;银的含量为64.34 g/t,可综合利用。

2) 为达到富集有用矿物的目的,需要选矿排除的脉石组分主要是SiO2,其次为Al2O3、CaO和K2O,四者合计含量为38.27%(质量分数)。

表1 样品的化学多元素分析结果

Table 1 Chemical analysis result of sample (mass fraction, %)

表2 样品中铅的化学物相分析结果

Table 2 Phase analysis results of lead in sample

表3 样品中锌的化学物相分析结果

Table 3 Phase analysis results of zinc in sample

表4 样品中硫的化学物相分析结果

Table 4 Phase analysis results for sulfur of sample

3) 试样中铅主要以方铅矿和硫酸铅的形式存在,二者分布率分别为74.53%和16.98%,前者即为采用浮选作业分选样品中铅矿物时铅的最大理论回收率。

4) 试样中锌的赋存形式较为简单,呈闪锌矿产出的硫化锌占89.74%,可见与铅相比,样品中锌矿物的氧化程度相对较低。

5) 试样中硫的赋存状态亦较为单一,存在于金属硫化物中的硫分布率高达97.24%,而硫酸盐和元素硫所占比例均较低。

综合化学成分特点,通过选矿可望获得较高品位的硫精矿。

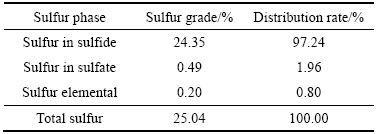

3 矿物镜下显微分析

将鉴定样品经切割、磨片、抛光后制成的显微镜观察的光片和薄片,用 XPL-900 型透反射偏光显微镜进行镜下观察、显微图片采集以及粒度统计。确定试样中硫、铅和锌各主要矿物的组成。矿物的镜下显微照片如图1所示。

图1 主要金属硫化物的显微照片(反光)

Fig. 1 Microscopic photographs of main metal sulfide (reflection) (Gn: Galena; Sp: sphalerite; Py: Pyrite; G: Gangue)

镜下分析结果照片分别显示,形态规则的单体粒状方铅矿(Gn),黄白色微粒为黄铁矿反光(见图1(a)), 闪锌矿(Sp)与方铅矿(中部白色)连生体,黄白色微粒为黄铁矿反光(见图1(b)),单体粒状闪锌矿(Sp),黄白色微粒为黄铁矿,脉石(G)反光(见图1(c)),闪锌矿(Sp)内部包裹微粒黄铁矿(黄白色)反光(见图1(d)),微细的自形粒状黄铁矿(黄白色)包裹在脉石(G)中反光(见图1(e)),黄白色微粒为黄铁矿反光(见图1(f))。

分析表明,黄铁矿为样品中最主要的金属硫化物。呈自形、半自形粒状,部分呈不规则状,个别粗颗粒粒径可达50 μm左右,一般小于30 μm。方铅矿为样品中铅的主要赋存矿物,亦是选矿富集回收铅的主要目的矿物,但显微镜下未发现方铅矿的蚀变产物-铅矾。除少数形态较规则以外,样品中方铅矿大多为不规则粒状,粒度通常在20 μm以下,部分甚至小于5 μm。闪锌矿为样品中锌的主要赋存矿物,出现的频率明显较方铅矿的广泛。半自形粒状居多,部分为不规则状,个别颗粒粒径可达50 μm左右,一般小于30 μm。

4 MLA工艺矿物学参数自动分析

MLA 工艺矿物学参数自动测试系统与传统的显微镜下鉴定统计相比具有自动、快速、数据准确及重现性高等特性[17-18]。因此,这一技术手段越来越成为了选矿工艺矿物学研究的最佳选择。本研究中采用的MLA 系统由一台Quanta 250 扫描电镜、一台EDAXGENESIS 能谱仪和JKTech工艺矿物学自动测试软件构成,主要利用背散射电子图像,结合图像分析技术进行数据计算和处理,可得到测试样品的矿物组成、解离特性、有价元素赋存状态、典型矿物颗粒图像等工艺矿物学参数。一方面其结果可与化学和光学显微镜分析结果相互印证;另一方面,可确定各主要矿物的嵌布粒度及特征,为该矿物的高效回收利用工艺流程制定提供理论指导。

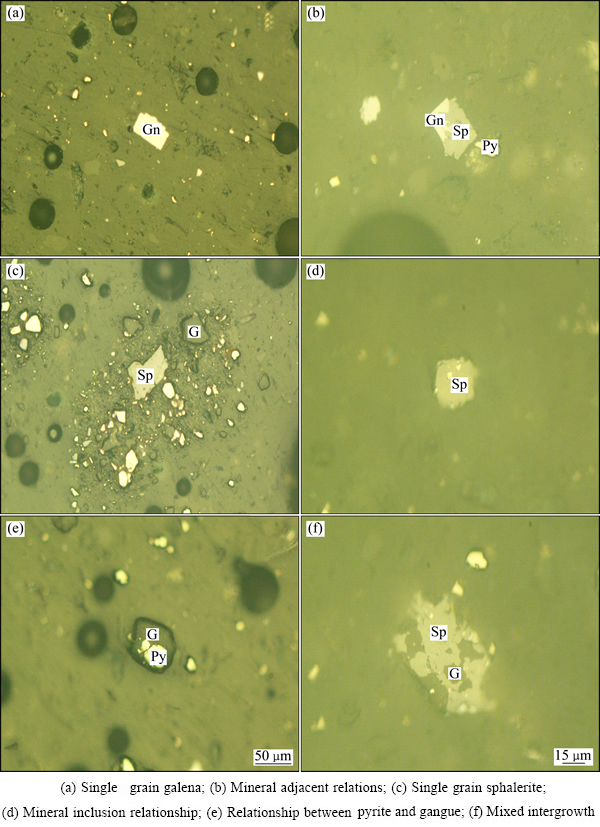

4.1 矿物组成及相对含量

样品肉眼下为粒度极为细小均匀的黑色粉状,样品的X射线衍射分析结果见图2。采用MLA统计了样品中主要矿物的含量,其结果列于表5。

图2 样品的XRD谱

Fig. 2 XRD pattern of sample

经镜下鉴定、X射线衍射分析、扫描电镜分析和MLA测定综合分析结果表明,样品的组成矿物种类相对较为简单,金属矿物主要是黄铁矿(含量达到了46.30%),其次为方铅矿和闪锌矿,偶见黄铜矿、毒砂、磁黄铁矿和铅矾;脉石矿物以石英、方解石和绢云母为主,其次是白云石和绿泥石,其他微量矿物尚见长石、褐铁矿、菱铁矿、磷灰石、金红石、石榴石、重晶石、石膏、锆石等。

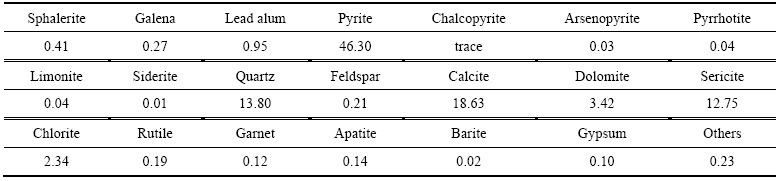

4.2 主要矿物的解离特征及连生关系分析

在明确试样主要矿物粒度组成的基础上,进一步研究各有价矿物的解离度及连生关系等嵌布特性,对预测该选矿理论回收率有重要意义。矿样中主要矿物黄铁矿、方铅矿及闪锌矿的MLA彩图分别如图3所示。根据MLA分析结果可统计,主要矿物的解离度及相互连生关系情况。

表5 样品中主要矿物的含量

Table 5 Composition and contents of main minerals for sample (mass fraction, %)

4.2.1 矿物解离度分析

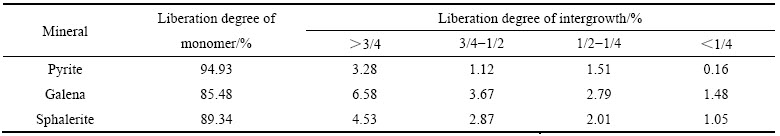

根据MLA分析统计,矿样中主要金属硫化物的解离度分析结果如表6所示。样品中黄铁矿、方铅矿和闪锌矿的粒度大多在0.03mm以下,呈单体产出者分别占94.93%、85.48%和89.34%。

4.2.2 主要矿物连生关系

根据MLA分析统计,矿样中主要矿物的连生关系分析结果结如表7~9所示,其背散射电子图像如图4所示。

据MLA统计,样品中呈单体产出的黄铁矿所占比例高达94.93%,明显高于方铅矿和闪锌矿,其余部分虽呈连生体产出。但与方铅矿和闪锌矿不同的是,和黄铁矿连生的矿物主要是石英、方解石和绢云母等脉石,而与方铅矿、闪锌矿及铅矾镶嵌者合计仅占23.46%。由于样品中黄铁矿含量高、解离程度较好,预计通过分选可获得较高品位的硫精矿。

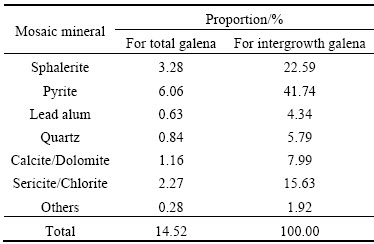

样品中呈单体产出的方铅矿占85.48%,其余部分主要沿其他金属硫化物或脉石边缘嵌布,或表现出穿插、包裹交生的复杂镶嵌类型,与方铅矿连生的矿物主要是闪锌矿和黄铁矿,其次为绢云母、绿泥石和方解石,显然与闪锌矿和黄铁矿连生的方铅矿分选过程中部分将进入锌精矿或硫精矿。

图3 不同矿物MLA彩图

Fig. 3 MLA color maps of different ores

表6 样品中主要金属硫化物的解离度

Table 6 Liberation degree of main metal sulfide

表7 黄铁矿连生体与嵌连矿物的比例

Table 7 Proportion of pyrite intergrowth and mosaic mineral

表8 方铅矿连生体与嵌连矿物的比例

Table 8 Proportion of galena intergrowth and mosaic mineral

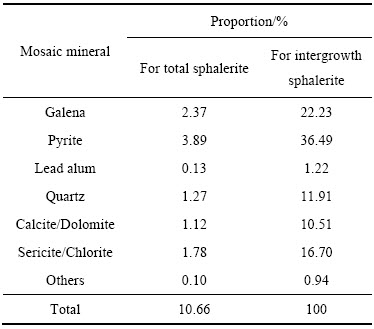

表9 闪锌矿连生体与嵌连矿物的比例

Table 9 Proportion of sphalerite intergrowth and mosaic mineral

样品中呈单体产出的闪锌矿占89.34%,而呈连生体出现者主要与方铅矿和黄铁矿镶嵌,连生方式以毗连型为主,其次是包裹型连生体,与其连生的矿物除方铅矿和黄铁矿以外,亦常见其与石英、方解石、绢云母或绿泥石紧密交生。根据嵌连关系推断,分选过程中随同脉石排入尾矿的闪锌矿所占比例可能略高于方铅矿。

图4 矿样BES背散射电子像

Fig. 4 Back scattering electron images of samples (Gn: Galena; Sp: Sphalerite; Py: Pyrite; B: Sericite; Q: Quartz)

5 混合矿与单一矿的浮选效果比较

浓密机溢流中主要可回收矿物是黄铁矿,研究发现矿物中黄铁矿粒度分布极细,直接浮选回收必然要增加工艺改造和设备投资。因此,推荐将底流先用高压水力旋流器脱除部分粒径小于5 μm的颗粒,尽管从表面上看会直接损失一些回收率,但是带来的好处也是非常明显的:1) 微细粒的脱除一定会提高可浮性;2) 在脱除细颗粒的同时,提高了物料的浓度,入选的体积量将大为减少;

试验选用GMAX-100水力旋流器,旋流器溢流口直径为d0=22 mm,旋流器沉砂口直径du=14 mm,旋流器给矿压力p=0.3 MPa,将浓密机溢流进行分级,分级后沉砂产品与原高硫给矿按质量比1:4混合进行浮选粗选探索试验。浮选设备为1.5LXFD单槽浮选机,浮选条件为硫酸7 kg/t,乙黄药150 g/t,2号油10 g/t,原给矿已经加入了硫酸活化剂,因此混合矿只需要按沉砂干矿质量加入相应硫酸即可,其试验结果如表10所示。试验结果显示,原单一给矿和混合矿回收的硫精矿品位和回收率基本接近。因此,可以认为,混合矿浮选不会因为沉砂的加入恶化选矿指标。由此可判断,将沉砂与高硫给矿混合浮选在工业生产上据有可行性。

表10 两种给矿的浮选结果

Table 10 Flotation results of two feeding

6 结论

1) 试样中可供选矿富集回收的主要元素是硫、铅和锌;需要选矿排除的脉石组分以SiO2为主,其次为Al2O3、CaO和K2O。金属矿物主要是黄铁矿,其次为方铅矿和闪锌矿;脉石矿物以石英、方解石和绢云母为主,其次是白云石和绿泥石。黄铁矿、方铅矿和闪锌矿的粒度大多小于30 μm,呈单体产出者分别占94.93%、85.48%和89.34%。呈连生体产出的上述金属硫化物中,与方铅矿和闪锌矿嵌连关系最密切的是黄铁矿,与黄铁矿连生的矿物则以脉石矿物居多。如能将黄铁矿、方铅矿和闪锌矿全部回收,可获得的理论选矿指标:硫精矿产率46.30%、硫回收率97.24%;铅精矿产率0.27%、铅回收率74.53%;锌精矿产率0.41%、锌回收率89.74%。

2) 通过对某铅锌尾矿浓密机溢流的MLA 工艺矿物学研究,提供了能高效低投资条件下回收分选高硫精矿的工艺方案。将浓密机溢流用GMAX-100水力旋流器分级,沉砂产品与原高硫给矿按干矿质量比1:4混合浮选方案,探索试验结果显示,混合矿与单一矿粗选效果相近,具有工业可行性。此方案对于工业生产具有投资小、风险少的特点。对于其他二次资源的回收利用,也具有一定的参考价值。

REFERENCES

[1] 何锦龙, 陈 建, 吴启明, 何桂春, 应平.某选铜尾矿工艺矿物学研究[J]. 中国矿业, 2014, 23(10): 121-124.

HE Jin-long, CHEN Jian, WU Qi-ming, HE Gui-chun, YING Ping. Study on process mineralogy of a certain copper tailing[J]. China Mining Magazine, 2014, 23(10): 121-124.

[2] 王成彦, 邱定蕃, 徐盛明. 金属二次资源循环利用意义、现状及亟需关注的几个领域[J]. 中国有色金属学报, 2008, 18(S1): s360-s366.

WANG Cheng-yan, QIU Ding-fan, XU Sheng-ming. Significance, status and important issues for recycling utilization of metal secondary resource in China[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(S1): s360-s366.

[3] 李 瑾, 倪 文, 范郭城, 李 媛, 伏程红. 齐大山铁尾矿工艺矿物学研究[J]. 金属矿山, 2014, 451(1): 158-162.

LI Jin, NI Wen, FAN Guo-cheng, LI Yuan, FU Chen-hong. Process mineralogy research on iron tailing from Qidashan [J]. Metal Mine, 2014, 451(1): 158-162.

[4] 肖军辉, 冯启明, 樊珊萍, 徐龙华, 王 振. 玻利维亚铜、钨、锡多金属尾矿的综合利用[J]. 中国有色金属学报, 2013, 23(10): 2949-2951.

XIAO Jun-hui, FENG Qi-ming, FAN Shan-ping, XU Long-hua, WANG Zhen. Comprehensive utilization of copper, tungsten and tin polymetallic tailings in Bolivia[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2949-2951.

[5] LI Mi, PENG Bing, CHAI Li-yuan, PENG Ning, XIE Xian-de, YAN Huan. Technological mineralogy and environmental activity of zinc leaching residue from zinc hydrometallurgical process[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1480-1488.

[6] 库建刚, 刘 羽, 刘文元, 刘树林, 何 逵. 河南卢氏花岗伟晶岩的矿物学特征及综合利用[J]. 中国有色金属学报, 2014, 24(2): 491-498.

KU Jian-gang, LIU Yu, LIU Wen-yuan, LIU Shu-lin, HE Kui. Mineralogical characteristics and comprehensive utilization of pegmatite tourmaline in Lushi, Henan Province[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 491-498.

[7] XU Yang-bao, QIN Wen-qing, LIU Hui. Mineralogical characterization of tin-polymetallic ore occurred in Mengzi, Yunnan Province, China[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 725-730.

[8] 谢海云, 叶群杰, 周 平, 高利坤, 庄故章, 童 雄. 云南思茅地区铜锌硫化矿工艺矿物学分析[J].岩矿测试, 2012, 33(3): 345-352.

XIE Hai-yun, YE Qun-jie, ZHOU Ping, GAO Li-kun, ZHUANG Gu-zhang, TONG Xiong. Process mineralogy analysis of copper-zinc sulfide ore from the Simao[J]. Rock and Mineral Analysis, 2012, 33(3): 345-352.

[9] 李艳军, 王艳玲, 刘 杰, 朱一民. 羚羊铁矿石工艺矿物学[J]. 东北大学学报(自然科学版), 2011, 32(10): 1484-1487.

LI Yan-jun, WANG Yan-ling, LIU Jie, ZHU Yi-min, Mineralogy process of Lingyang iron ore[J]. Journal of Northeastern University (Natural Science), 2011, 32(10): 1484-1487.

[10] CAO Yi-jun, GUI Xia-hui, MA Zi-long, YU Xiao-xia, CHEN Xiao-dong, ZHANG Xiu-pin. Process mineralogy of copper-nickel sulphide flotation by a cyclonic-static micro-bubble flotation column[J]. Mining Science and Technology, 2009, 19: 784-787.

[11] 葛英勇, 查 辉, 余永富, 朱鹏程. 还原焙烧铁矿磁选精矿的工艺矿物学及反浮选机理研究[J]. 中国矿业大学学报, 2012, 43(3): 514-520.

GE Ying-yong, CHA Hui, YU Yong-fu, ZHU Peng-cheng. Studies of process mineralogy and reverse flotation mechanism on magnetic separation iron concentrates reducing roasting[J]. Journal of China University of Mining & Technology, 2012, 43(3): 514-520.

[12] 刘婷婷, 袁 威, 张 超, 金自钦. 加拿大某钒钛磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2012(3): 51-54.

LIU Ting-ting, YUAN Wei, ZHANG Chao, JIN Zi-qin. Mineralogical characterization of the vanadium titano magnetite in Canada[J]. Multipurpose Utilization of Mineral Resources, 2012(3): 51-54.

[13] 罗 骏, 李光辉, 饶明军, 张吉清, 郭宇峰, 姜 涛. 煤系硫铁矿浮选尾矿热化学活化脱硅制备铝精矿[J]. 中国有色金属学报, 2013, 23(12): 3470-3477.

LUO Jun, LI Guang-hui, RAO Ming-jun, ZHANG Ji-qing, GUO Yu-feng, JIANG Tao. Desilication of coal-derived pyrite flotation tailing for preparing alumina concentrate by thermochemical activation process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3470-3477.

[14] 李茂林, 颜亚梅. 重浮联合分选高品位硫精矿试验研究[J]. 矿冶工程, 2014, 34(2): 31-34.

LI Mao-lin, YAN Ya-mei. Beneficiation of high-grade sulfur concentrate by the combined flow sheet of gravity separation and flotation[J]. Mining and Metallurgical Engineering, 2014, 34(2): 31-34.

[15] 杨洪英, 李雪娇, 佟玲玲, 陈国宝. 高铅铜阳极泥的工艺矿物学[J]. 中国有色金属学报, 2014, 24(1): 269-278.

YANG Hong-ying, LI Xue-jiao, TONG Ling-ling, CHEN Guo-bao. Process mineralogy of high lead copper anode slime[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 269-278.

[16] 罗立群, 李金良, 曹佳宏. 哈密铜镍矿工艺矿物学特性与影响选矿的因素[J]. 中国有色金属学报, 2014, 24(7): 1846-1854.

LUO Li-qun, LI Jing-liang, CAO Jia-hong. Process mineralogy and factors affecting mineral processing for copper-nickel ore in Hami[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1846-1854.

[17] 方明山, 肖依武, 童捷矢. MLA在铅锌氧化矿物解离度及粒度测定中的应用[J]. 有色金属(选矿部分), 2012(3): 1-3.

FANG Ming-shan, XIAO Yi-wu, TONG Jie-shi. Application of MLA on determining liberation degree and size of Lead-Zinc oxide minerals[J]. Nonferrous Metals (Mineral Processing Section), 2012(3): 1-3.

[18] 梁冬云, 邹 霓, 李 波. MLA自动检测技术在低品位钼矿石工艺矿物学中的应用[J]. 中国钼业, 2010, 34(1): 32-34.

LIANG Dong-yun, ZOU Ni, LI Bo. Application of MLA automated quantitative mineralogy in process mineralogy research on low-grade molybdenum ore[J]. China Molybdenum Industry, 2010, 34(1): 32-34.

(编辑 李艳红)

收稿日期:2014-12-29;修订日期:2015-04-13

通信作者:李茂林,教授,博士;电话:13974851980;E-mail:13974851980@vip.163.com