Fe-Co-Ni-Zr-Mo-W-B 块体非晶合金的玻璃形成能力与热稳定性

陈庆军1, 范洪波1, 孙剑飞1, 沈 军1, 钱坤明2, 线恒泽1

(1. 哈尔滨工业大学 材料科学与工程学院, 哈尔滨 150001;

2. 中国兵器科学研究院 宁波分院, 宁波 315103)

摘 要: 采用铜模铸造法, 可以制备出直径为3mm的非晶圆柱棒。 结合差热分析、 X射线衍射和透射电镜分析测试结果, 从动力学和结构学等方面阐述了Ni元素对Fe58Co10-xNixZr10Mo5W2B15(x=0, 3, 4, 5, 6, 摩尔分数, %)合金系玻璃形成能力和热稳定性的影响。 结果表明: Ni元素含量的微量变化可以明显改善Fe58Co10-xNixZr10-Mo5W2B15(x=0, 3, 4, 5, 6)合金系的玻璃形成能力; 当Ni含量达到4%时, Fe58Co6Ni4Zr10Mo5W2B15具有最佳的玻璃形成能力, 晶化温度(Tx)、 玻璃转变温度(Tg)、 过冷液相区宽度(ΔTx)、 玻璃形成能力判据Trg和γ分别为887K、 957K、 70K、 0.5902和0.4004。

关键词: 块体金属玻璃; 玻璃形成能力; 非晶钢; 热稳定性 中图分类号: TG138

文献标识码: A

Glass-forming ability and thermal stability of Fe-Co-Ni-Zr-Mo-W-B bulk amorphous alloys

CHEN Qing-jun1, FAN Hong-bo1, SUN Jian-fei1, SHEN Jun1,QIAN Kun-ming2, XIAN Heng-ze1

(1. School of Materials Science and Engineering,Harbin Institute of Technology, Harbin 150001, China;

2. Ningbo Branch, Institute of China Enginery, Ningbo 315103, China)

Abstract: The 3mm-diameter amorphous rods were prepared by the copper mold casting technique. And the influences of Ni addition on the glass-forming ability (GFA) and thermal stability of Fe58Co10-xNixZr10Mo5W2B15 (x=0, 3, 4, 5, 6, mole fraction, %) alloys were presented from kinetics and structure aspects according to differential scanning calorimeter (DSC), X-ray diffractrometry (XRD) and transmission electron microscopy (TEM). The results show that the glass-forming ability of Fe58Co10-xNixZr10Mo5W2B15 alloys system can be obviously improved by the addition of Ni element. When the content of Ni element is up to 4%, Fe58Co6Ni4Zr10-Mo5W2B15 alloys with the crystallization temperature (Tx) of 887K, glass transition temperature (Tg) of 957K, temperature interval of supercooled liquid region (ΔTx) of 70K, reduced glass transition temperature (Trg) of 0.5902 and the value of a GFA parameter (γ) of 0.4004, has the highest GFA among the studied alloys.

Key words: bulk metallic glasses; glass-forming ability; amorphous steel; thermal stability

块体非晶合金具有独特的力学性能, 尤其铁基块体非晶合金的断裂强度高达4250MPa, 远高于晶态材料。 新型块体非晶合金具有类似于贫铀合金的高绝热剪切敏感性和更高的强度[1-3]。 用超强非晶合金制作的穿甲弹将替代贫铀弹, 成为抵御敌人地面坦克进攻, 击毁地下堡垒的重要武器, 这类新材料已引起美国军方的高度重视。 但是由于铁基非晶合金需要极高的冷却速度(106 K/s), 所以铁基金属玻璃的形状只局限于薄带、 丝、 粒等形状, 限制了它的商业应用。

如何提高铁基非晶合金的玻璃形成能力(GFA), 制备出块体铁基非晶材料, 成为相关工作者研究的焦点之一。 1995年, Inoue等[4, 5]在Fe-(Al, Ga)-(P, C, B, Si, Ge)合金系利用铜模喷铸法获得了直径达2mm的块体金属玻璃。 随后, 又在Fe-(Al-Ga)-(Co, Cr, Mo, Nb, Sb)-P-B-C合金系、 Fe-(Co, Zr, Nb, Ta, Mo, W)-B合金系利用铜模铸造法制备出大块金属玻璃并且获得当时玻璃形成能力最强的铁基块体非晶合金 Fe61Co7Zr10-Mo5W2B15, 最大直径可达6mm。 近年来, Lu等[6]在Fe-Y-Zr-(Co, Cr, Al)-Mo-B合金系利用铜模铸造法获得了最大直径为5mm 的块体金属玻璃。 Chiriac等[7]在 (Fe, Co, Ni)70(Zr, Nb, M)10B20 (M=Ti, Ta, or Mo) 合金系利用铜模铸造法可获得直径为0.5~3mm 的块体金属玻璃。 最近, Lu等[8], Ponnambalam等[9] 和Shen等[10]采用铜模铸造技术分别在(Fe44.3Cr5Co5Mo12.8Mn11.2C15.8B5.9)-Y1.5, Fe48Cr15Mo14C15B6Er2和Fe41Co7Cr15Mo14Y2-C15B6合金系制备出最大直径分别为12, 12和16mm的铁基块体非晶合金。 研究结果表明, 添加适当的合金元素可以显著提高玻璃形成能力, 但是人们至今还没有根本掌握块体金属玻璃形成的物理本质及其规律。

本文作者基于在基体中析出固溶体时, 可增加析出相之间的相互竞争和干扰作用的角度出发, 在Fe-Co-Zr-Mo-W-B 合金系中通过添加少量Ni元素, 制备出d3mm 的块体金属玻璃, 并对Ni元素添加与Fe58Co10-xNixZr10Mo5W2B15(x=0, 3, 4, 5, 6)合金系玻璃形成能力的相互关系进行了分析。

1 实验

母合金制备采用磁控钨极电弧炉熔炼, 原材料纯度分别为Fe(99.8%), Co(99.9%), Ni(99.99%), Zr(99.9%), Mo(99.9%), W(99.9%), 工业FeB (w(Fe)+w(FeB)=98.1%)。 首先抽真空至0.1Pa 时, 冲入高纯氩气, 再抽真空至0.1Pa, 反复3次, 最后抽真空至6.7×10-3 Pa, 准备熔炼。 熔炼之前先熔化钛进行除氧, 在磁搅拌的作用下将母合金熔炼4次以保证合金的均匀性, 然后将母合金吸铸到铜模具中成型。

采用D/MAX-RA型X射线衍射仪(XRD)对样品进行分析, 测试参数为: Cu靶Kα辐射, 石墨单色器滤波, 特征波长为0.154056nm, 扫描步长为0.02°, 衍射角(2θ)范围为20°~100°。 为了确保样品整体为非晶态结构, 沿样品最大截面处纵向切开进行X射线衍射观察。 采用Netzsch 449C型差示扫描量热计(DSC), 加热速率为0.66K/s, 在高纯氩气气氛下测量非晶合金热稳定性参数, 如: 玻璃转变温度(Tg), 初始晶化温度(Tx), 初始熔化温度(Tm), 液相线温度(Tl)。 采用Phillip CM20型透射电子显微镜(TEM), 加速电压为200kV, 对非晶样品进行内部结构分析。 透射电子显微镜样品的制备工序: 从非晶圆柱棒上线切割d3mm×0.5mm的圆片→手工磨制圆片厚度达到50μm→电解双喷减薄→清洗。 电解液采用高氯酸(10%)+乙酸(90%)。

2 实验结果

2.1 铁基块体非晶的形成

诸多复杂因素制约着金属玻璃的形成, 如何提高块体铁基多元合金系的玻璃形成能力(GFA)一直是材料研究者的一大难题。 本文作者针对Fe-Co-Zr-Mo-W-B合金系, 通过Ni元素的添加和优化的方法, 得出具有高玻璃形成能力的合金成分。 从铜模铸造法制备的d3mm Fe58Co6Ni4Zr10Mo5W2B15 块体金属玻璃表面形貌来看, 样品的表面光滑且具有金属光泽, 这就表明熔炼时高纯氩气在防止氧化方面是有效的。 熔炼和铸造过程中金属液的粘度和表面张力也比较大, 这也是制备块体非晶材料的必要条件。

2.2 非晶性质的确定

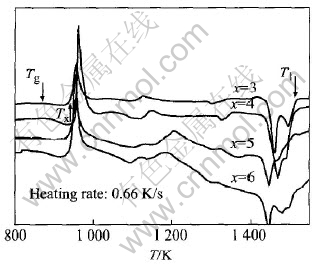

Fe58Co10-xNixZr10Mo5W2B15合金的DSC曲线如图1所示, Tg、 Tx和Tl的确定是采用切线相交法, 如图中点划线所示。 DSC曲线上的放热峰表明试样里含有非晶相而单一的放热峰预示着在加热过程中只有一个晶化过程[11]。 根据Fe58Co10-xNixZr10Mo5W2B15合金的热分析曲线, 可以看出, 当Ni含量为4%时Fe58Co6Ni4Zr10Mo5W2B15非晶合金的玻璃转变温度(Tg)、初始晶化温度(Tx)、过冷液相区(ΔTx=Tx- Tg)、 玻璃形成能力判据Trg(Tg/Tl)和γ(Tx/(Tl+Tg))分别达到887K、 957K、 70K、

图1 Fe58Co10-xNixZr10Mo5W2B15合金的差热分析曲线

Fig.1 DSC curves of as-cast Fe58Co10-xNixZr10Mo5W2B15 alloys

0.5902和0.4004。 采用铜模铸造法可制备的最大直径5mm的块体非晶合金Fe61Y2Zr8Co5Cr2Mo7-B15的ΔTx, Trg, γ分别为58K, 0.605和0.401[6]。 以上热力学参数表明, Fe58Co6Ni4Zr10Mo5W2B15非晶合金具有较高的热稳定性和玻璃形成能力。 由X射线衍射分析可知, 当x=4时, Fe58Co6Ni4Zr10-Mo5W2B15合金的X射线衍射谱线中没有尖锐的衍射峰出现, 而是表现出具有非晶合金特征的漫散射峰。 但是当x=0, 3, 5, 6时, X射线衍射谱线上却有尖锐的衍射峰出现, 这说明样品中已有晶化相析出(见图2)。 为了进一步验证Fe58Co6Ni4Zr10-Mo5W2B15合金的非晶性质, 在透射电子显微镜(TEM)下对Fe58-Co6Ni4Zr10Mo5W2B15块体非晶合金内部结构进行观察。 在明场下观察, 样品表现出均匀衬度的非晶特征, 观察不到晶化相析出的痕迹。 同时, 样品的选区电子衍射谱上也只有单一的晕环。 这些特征都暗示样品内部结构是无序的非晶态结构(见图3)。 根据X射线衍射、 差热分析和透射电镜分析结果可以确定直径3mm 的Fe58Co6Ni4Zr10Mo5W2B15 合金的内部结构是完全非晶态。

观察Fe58Co10-xNixZr10Mo5W2B15合金的DSC熔化曲线, 可以看出, 当Ni含量变化时, 液相线温度(Tl)也随之发生了变化。 当x=4时, Fe58Co6-Ni4Zr10Mo5W2B15合金可以有效抑制了高温相形成从而降低液相线温度(见图1)。 冷却时出现近似单个的放热峰, 意味着合金成分是近共晶成分[12]。 以上结果说明Ni含量的微量变化确实可改

图2 Fe58Co10-xNixZr10Mo5W2B15合金的X射线衍射谱

Fig.2 XRD patterns of as-cast Fe58Co10-xNixZr10Mo5W2B15 alloys

图3 直径3mm Fe58Co6Ni4Zr10Mo5W2B15非晶合金的明场像和选区电子衍射花样

Fig.3 Bright field image and corresponding SAED pattern of 3mm Fe58Co6Ni4Zr10Mo5W2B15 bulk amorphous alloy

变合金液的热力学性能(见图4)。 根据Ni含量与Tl、 Tm、 Tx、 Tg的关系, x=4时, Fe58Co10-x-Ni4Zr10Mo5W2B15合金系具有最佳玻璃形成能力。

3 讨论

研究表明, 对于Fe、 Co、 Ni、 Cu、 Mo、 Zn、 Nb、 Ta和Ti这些属于中等原子半径的过渡族金属元素, 仅当其含量超过3%时, 才可提高非晶合金的玻璃形成能力[13]。 从实验结果来看, Ni元素的微量添加确实对提高Fe-Co-Zr-Mo-W-B 合金系的玻璃形成能力及热稳定性起到重要作用。 Johnson[14]认为, 金属间化合物相在非晶合金的形成过程中可以看作是非晶相的竞争相。 因此, 非晶的获

图4 Fe58Co10-xNixZr10Mo5W2B15非晶合金中Ni含量与Tl, Tm, Tx和Tg的关系

Fig.4 Relationships between Ni content and Tl, Tm, Tx and Tg

得依赖于体系中竞争相之间的相互干扰和阻碍作用。 Ni元素的加入一方面会使合金组元增加从而使周围原子长距离的扩散变得困难以及阻碍了原子的高度有序, 有利于非晶相形成; 另一方面增加了金属间化合物析出相的种类, 在合金的冷却过程中金属间化合物的竞争和干扰作用增强, 使合金的玻璃形成能力得到增强(见图2)。

从结构学和动力学观点分析: Ni元素与非晶基体元素Fe有相似的物理和化学性质, 但更容易形成置换或间隙原子, 同时在熔化温度以上Ni原子能固溶在基体当中, 冷却时Ni原子要被排到固液表面处。 根据二元相图可知, Ni原子可与Zr、 Mo、 W、 B原子形成更多的金属间相[15], 增加了相析出的复杂性以及析出相之间的相互竞争, 从而使合金具有更密集、 混乱无序的结构, 原子的长程扩散变得困难势必造成在微小区域内形成一些团簇, 团簇的形成进一步增加了原子扩散的阻力, 从而难以达到晶化相析出的化学成分, 抑制晶化相析出。 当Ni含量小于4%时, 固液界面处的基体原子浓度比较高, Ni原子浓度比较低, 破坏了固液界面处的化学平衡, 导致固液界面能降低, Ni原子浓度难以满足多个相竞争析出的态势, 原子之间的相互束缚作用减弱, 不能有效的抑制其它原子的扩散。 当合金中的某一组元或多个组元达到晶化析出所需的成份时, 就会发生晶化, 进而更一步加快晶体的形核和长大速率。 当Ni含量大于4%时, 冷却过程中随着温度降低Ni在基体中的固溶度降低, Ni原子在固液界面处的浓度升高, 破坏了与基体原子的化学平衡和周围原子的相互束缚作用, Ni原子的扩散阻力减小, 导致固液界面能降低。 固液界面处不仅是一个动态平衡过程, 而且还受到浓度、 冷却速度和周围原子的影响, 所以一旦这个平衡被破坏, 就会造成化学成分的不均匀性。 因为Ni元素可与周围原子形成更多种类的金属间化合物, 所以当某处化学成分达到某一金属间相析出所要求的化学成分时, 也会在基体上析出晶化相。 这与X射线衍射分析的实验结果相吻合(见图2)。

从图4中可以看出, 当x=4时, Fe58Co10-x-NixZr10Mo5W2B15 (x=3, 4, 5, 6)合金系的液相线温度Tl最低, 玻璃转变温度Tg最高。 随着Tl-Tg间隔的缩小和玻璃形成能力判据Tg/Tl比值的增大, 都表明合金的玻璃形成能力得到提高[16]。 同时通过Ni的微合金化作用, 调整合金的成分趋于共晶成分点, 增加了合金的过冷度。

4 结论

通过添加具有中间原子半径的过渡族金属Ni, 可以制备出d3mm Fe58Co6Ni4Zr10Mo5-W2B15块体金属玻璃。 实验结果表明, 在Fe58Co10-x-NixZr10Mo5W2B15 (x=0, 3, 4, 5, 6)合金系中加入适当微量的Ni元素一方面能增加金属间化合物种类, 造成析出相间更复杂的竞争抑制了α-Fe和Fe3B晶体相的析出; 另一方面能增加合金液的随机堆错密度, 导致液相线温度降低, 玻璃转变温度升高。 从而提高了Fe-Co-Ni-Zr-Mo-W-B合金系块体非晶合金的玻璃形成能力以及热稳定性。

REFERENCES

[1]McHenry M E, Willard M A, Laughlin D E. Amorphous and nanocrystalline materials for applications as soft magnets[J]. Progress in Materials Science, 1999, 44(4): 291-433.

[2]黄劲松, 刘咏, 陈仕奇, 等. 锆基非晶合金的研究进展与应用[J]. 中国有色金属学报, 2003, 13(6): 1321-1332.

HUANG Jin-song, LIU Yong, CHEN Shi-qi, et al. Progress and application of Zr-based amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1321-1332.

[3]Ramamurty U, Jana S, Kawamura Y, et al. Hardness and plastic deformation in a bulk metallic glass[J]. Acta Materialia, 2005, 53(3): 705-717.

[4]Ikarashi K, Mizushima T, Makino A, et al. Preparation of bulk Fe-Al-Ga-P-C-B-Si glassy alloys in a ringed form by copper mold casting[J]. Mater Sci Eng A, 2001, 304-306: 763-766.

[5]Inoue A, Makino A, Mizushima T, et al. Ferromagnetic bulk glassy alloys[J]. Journal of Magnetism and Magnetic Materials, 2000, 215-216: 246-252.

[6]Lu Z P, Liu C T, Porter W D. Role of yttrium in glass formation of Fe-based bulk metallic glasses[J]. Appl Phys Lett, 2003, 83(13): 2581-2583.

[7]Chiriac H, Lupu N. Bulk amorphous (Fe, Co, Ni)70-(Zr, Nb, M)10B20 (M=Ti, Ta or Mo) soft magnetic alloys[J]. Journal of Magnetism and Magnetic Materials, 2000, 215-216: 394-396.

[8]Lu Z P, Liu C T, Thompson J R, et al. Structure amorphous steels[J]. Physical Review Letters, 2004, 92(24): 245503-1-245503-4.

[9]Ponnambalam V, Poon S J. Fe-based bulk metallic glasses with diameter thickness larger than one centimeter[J]. Journal of Materials Research, 2004, 19(5): 1320-1323.

[10]Shen J, Chen Q J, Sun J F, et al. Exceptionally high glass-forming ability of an FeCoCrMoCBY alloy[J]. Applied Physics Letters, 2005, 86(15): 151907-1-151907-3.

[11]Grabias A, Oleszak D, Kopcewicz M, et al. Structure and magnetic propterties of bulk amorphous Fe60Co10Ni10Zr7B13 alloy formed by mechanical synthesis and hot pressing[J]. Journal of Non-Crystalline Solids, 2003, 330: 75-80.

[12]Perepezko J H, Wilde G. Amorphization and alloy metastability in undercooled systems[J]. Journal of Non-Crystalline Solids, 2000, 274(3): 271-281.

[13]Men H, Hu Z Q, Xu J. Bulk metallic glass formation in the Mg-Cu-Zn-Y system[J]. Scripta Materialia, 2002, 46(10): 699-703.

[14]Johnson W L. Bulk glass-forming metallic alloys: science and technology[J]. MRS Bulletin, 1999, 24(10): 42.

[15]De Boer F R, Boom R, Miedema A R, et al. Cohesion in Metal Alloy[M]. Amsterdam, Netherlands: North-Holland Physics Publishing House, 1989. 294-297.

[16]Lu Z P, Li Y, Ng S C. Reduced glass transition temperature and glass forming ability of bulk glass forming alloys[J]. Journal of Non-Crystalline Solids, 2000, 270(1-3): 103-114.

(编辑陈爱华)

收稿日期: 2005-01-18; 修订日期: 2005-07-05

作者简介: 陈庆军 (1974-), 男, 博士研究生

通讯作者: 沈 军, 教授; 电话: 0451-86418317; 传真: 0451-86415776; E-mail: junshen@public.hr.hl.cn