半固态挤压铸造铝ZL104合金连杆的显微组织及力学性能

来源期刊:中国有色金属学报(英文版)2018年第2期

论文作者:王永飞 赵升吨 张晨阳

文章页码:235 - 243

关键词:铝合金;半固态挤压铸造;半固态显微组织;抗拉强度;伸长率;连杆

Key words:aluminum alloy; semi-solid squeeze casting; semi-solid microstructure; tensile strength; elongation; connecting rod

摘 要:分别采用液态挤压铸造和半固态挤压铸造工艺成形ZL104铝合金连杆,研究不同工艺参数对连杆的显微组织及力学性能的影响规律。结果表明:与传统液态挤压铸造相比,半固态挤压铸造连杆的抗拉强度和伸长率分别提高了22%和17%。半固态挤压铸造过程中,随着重熔温度的增加,平均晶粒尺寸和形状因子都增大;随着模具预热温度的升高,平均晶粒尺寸增大,形状因子先增加后减小;这两种情况下连杆的抗拉强度和伸长率都先增加后减小。但随着挤压压力的提高,平均晶粒尺寸减小,且形状因子增大,连杆的力学性能明显提高。此外,成形半固态挤压铸造连杆的最佳重熔温度、挤压压力及模具预热温度分别为848 K、100 MPa及523 K。

Abstract: Semi-solid squeeze casting (SSSC) and liquid squeeze casting (LSC) processes were used to fabricate a ZL104 connecting rod, and the influences of the process parameters on the microstructures and mechanical properties were investigated. Results showed that the tensile strength and elongation of the SSSC-fabricated rod were improved by 22% and 17%, respectively, compared with those of the LSC-fabricated rod. For SSSC, the average particle size (APS) and the shape factor (SF) increased with the increase of re-melting temperature (Tr), whereas the tensile strength and elongation increased first and then decreased. The APS increased with increasing the mold temperature (Tm), whereas the SF increased initially and then decreased, which caused the tensile strength and elongation to increase initially and then decrease. The APS decreased and the SF increased as squeezing pressure (ps) increased, and the mechanical properties were enhanced. Moreover, the optimal Tr, ps and Tm are 848 K, 100 MPa and 523 K, respectively.

Trans. Nonferrous Met. Soc. China 28(2018) 235-243

Yong-fei WANG, Sheng-dun ZHAO, Chen-yang ZHANG

School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, China

Received 12 September 2016; accepted 21 April 2017

Abstract: Semi-solid squeeze casting (SSSC) and liquid squeeze casting (LSC) processes were used to fabricate a ZL104 connecting rod, and the influences of the process parameters on the microstructures and mechanical properties were investigated. Results showed that the tensile strength and elongation of the SSSC-fabricated rod were improved by 22% and 17%, respectively, compared with those of the LSC-fabricated rod. For SSSC, the average particle size (APS) and the shape factor (SF) increased with the increase of re-melting temperature (Tr), whereas the tensile strength and elongation increased first and then decreased. The APS increased with increasing the mold temperature (Tm), whereas the SF increased initially and then decreased, which caused the tensile strength and elongation to increase initially and then decrease. The APS decreased and the SF increased as squeezing pressure (ps) increased, and the mechanical properties were enhanced. Moreover, the optimal Tr, ps and Tm are 848 K, 100 MPa and 523 K, respectively.

Key words: aluminum alloy; semi-solid squeeze casting; semi-solid microstructure; tensile strength; elongation; connecting rod

1 Introduction

A semi-solid metal forming (SSMF) process combines the advantages of a traditional hot forging and casting because of the thixotropic characteristics of a semi-solid slurry [1-4][Xu, 2014 #702][Wang, 2013 #540]. Furthermore, squeeze casting (SC) can achieve near-net shape metal parts in only one forming step with superior mechanical properties because of the high-pressure solidification behavior of SC [5,6]. Semi-solid squeeze casting (SSSC) is a combination of SSMF and SC; the semi-solid slurry can flow steadily, which decreases the porosity that often occurs in liquid squeeze casting (LSC) [7,8]. Meanwhile, the semi-solid slurry will be solidified under high pressure, which can also further enhance the mechanical properties of the castings [5]. Additionally, the formed parts can also undergo heat treatment to further improve their mechanical properties. Therefore, SSSC can increase material utilization, simplify production process and improve product quality [9].

The microstructures and mechanical properties in SSSC are different from those in liquid forming processes [10-12]. BURAPA et al [13] studied the effects of primary phase morphology on the mechanical properties of Al-Si-Mg-Fe alloy during the SSSC process and concluded that the ultimate tensile strength and elongation increased as the primary α(Al) particle size decreased and the shape factor (SF) increased. LEE and KANG [14] investigated the injection velocity and solid volume fraction of the semi-solid slurry during the vertical rheological SC of a front-wheel suspension support, and fine microstructure and mechanical properties were obtained when the solid fraction was 0.5 and the injection velocity was 1.0 m/s. DAI et al [15] studied the effects of optimal parameters, including squeezing pressure (ps), mold temperature (Tm) and heat treatment, on the microstructure and mechanical properties of rheological SC of Al-Cu-5Mn-Ti alloy. They found that the tensile strength and elongation were improved by 6.5% and 47%, respectively, compared with the conventional SC samples. Therefore, the microstructure and mechanical properties of the SSSC were affected not only by ps, but also by re-melting temperature (Tr), and Tm. However, few studies have reported the effect of the process parameters on fabricating a ZL104 connecting rod by SSSC.

ZL104 alloy is a widely used hypoeutectic Al-Si-Mg based aluminum alloy, which is advantageous for SSSC because of its relatively wide solidification range and superior semi-solid formability. Therefore, the present study aims to compare the microstructure and mechanical properties in the fabrication of a connecting rod with SSSC and LSC and in optimizing the main process parameters to obtain the best microstructure and mechanical properties.

2 Experimental

2.1 Material

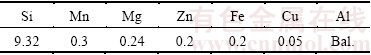

The commercial ZL104 aluminum alloy was used as an experimental material, and its chemical compositions are presented in Table 1. Differential scanning calorimetry (DSC) analysis was conducted to obtain the semi-solid range. From the result, the solidus and liquidus temperatures for the ZL104 alloy were 828 and 871 K, respectively.

Table 1 Chemical compositions of commercial ZL104 alloy (mass fraction, %)

2.2 Procedure

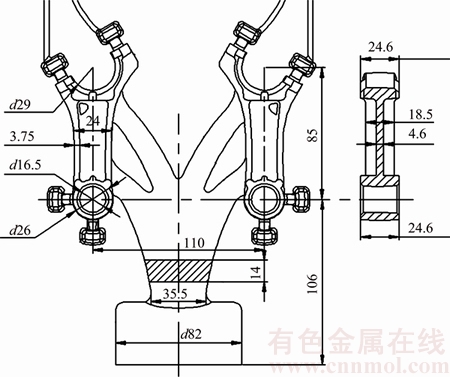

Figure 1 illustrates a common aluminum connecting rod casting, which is widely used in the automobile industry. The casting consists of two same connecting rods linked by two branch runners and a main runner.

Before the experiments, a semi-solid aluminum alloy billet prepared by electromagnetic stirring (EMS) was machined to remove the oxide skin and surface defects. The semi-solid bar (d60 mm × 100 mm) was partially re-melted in a resistance furnace at 838-853 K for 20 min. Meanwhile, the mold was preheated to the preset temperature, and then the lubricant was sprayed uniformly. Finally, the re-melted billet was placed in the barrel of the SC machine, and SSSC was performed at the preset parameters. The ps was applied to the billet from the gate of the mold cavity, and it was held until solidification was completed. The LSC was also conducted for comparison. The specific experimental parameters are displayed in Table 2. The T6 heat treatment of the connecting rod was conducted as follows: the rods were isothermally held at 808 K for 3 h, quenched in water at 343 K, and then isothermally held at 448 K for 10 h.

Table 2 Different experimental parameters for LSC and SSSC

2.3 Microstructure and mechanical properties

Fig. 1 Schematic diagram of connecting rod casting (unit: mm)

The metallographic specimen was cut from an arm of connecting rod A. All samples were ground, polished, and etched with an aqueous solution of 0.5% HF. The microstructural observation was conducted using an Olympus GX5 optical microscope. The average particle size (APS) and SF were calculated by using Eqs. (1) and (2) [16,17]. The tensile specimen (ASTM E8) was obtained from connecting rod B and tested on a universal material testing machine at a tensile rate of 1.25 mm/min.

(1)

(1)

(2)

(2)

where P is the perimeter of the particle; A is the area of the particle; and SF is a value varying from zero (for acicular particles) to one (for a perfectly round sphere).

3 Results and discussion

3.1 Microstructure of raw material and semi-solid slurry prepared by EMS and typical connecting rods fabricated by SSSC

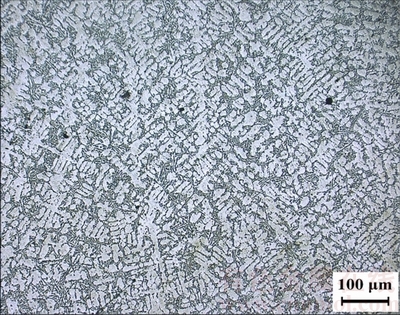

Figure 2 shows the microstructure of a raw material. As shown in Fig. 2, the ZL104 alloy has a typical dendritic microstructure, and the coarse primary and secondary dendrites have obvious orientations. Moreover, the primary and secondary dendrite arm spaces were approximately 100 and 20 μm, respectively.

Fig. 2 Microstructure of commercial ZL104 alloy

Compared with Fig. 2, the microstructure of the EMS-treated ZL104 semi-solid billet was fine, and the evenly distributed non-dendritic structure is illustrated in Fig. 3(a). The near-spherical particles were separated by numerous lathy needle-shaped eutectic silicon owing to the relatively high silicon content in the ZL104. The partial re-melted microstructures of the EMS-treated semi-solid billet presented isolated and spherical particles that were evenly distributed in the eutectic phase (Fig. 3(b)) when the re-melting temperature was 853 K and the isothermal holding time was 20 min. The APS and SF were 32 μm and 0.76, respectively. Liquid pockets were trapped in some large spherical grains because the adjacent non-dendritic particles were merged with one another during the partial re-melting process. The needle-shaped eutectic silicon evolved into a thick strip or a broken lump around the spherical grains.

Fig. 3 Microstructures of ZL104 semi-solid slurry

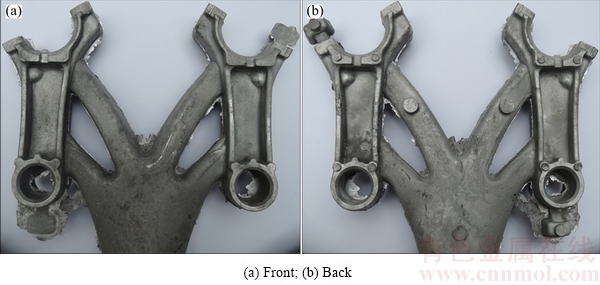

The mold cavity under different parameters can be filled fully, and the typical connecting rod fabricated by SSSC (Tr=848 K, ps=100 MPa, and Tm=523 K) is presented in Fig. 4. The casting was filled perfectly with sharp outlines and fine surface because of the close contact between the slurry and the mold cavity, which demonstrates the good flow ability and formability of the semi-solid slurry.

3.2 Microstructure and mechanical properties of connecting rods fabricated under different re- melting temperatures

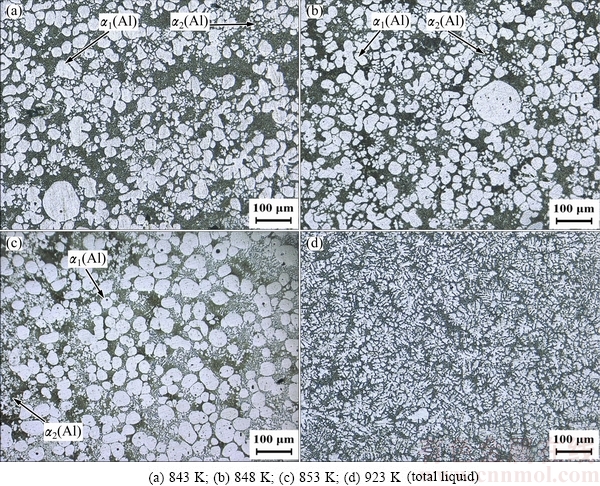

Figure 5 illustrates the corresponding microstructure under the Tr of 843, 848, 853, and 923 K (total liquid), ps of 100 MPa, and Tm of 523 K. In Fig. 5, the microstructure of the connecting rod fabricated by SSSC at different Tr (843-853 K) were mainly composed of large α1(Al) spherical grains and small α2(Al) particles that were uniformly distributed in the eutectic phase. The APS of α1(Al) spherical grains was 30-50 μm, whereas that of the α2(Al) particles was about 10 μm. However, the microstructure of the LSC-fabricated connecting rod (923 K) mainly consisted of fine dendrites and eutectic phases distributed among the dendrite arms as depicted in Fig. 5(d).

Fig. 4 Typical connecting rod fabricated by SSSC (Tr=848 K, ps=100 MPa, Tm=523 K)

Fig. 5 Microstructures of connecting rod fabricated at different re-melting temperatures

The formation of the microstructures during the SSSC process can be divided into two stages [18]. First, the primary α(Al) reserved in the partial remelting process was further coarsened during the mold filling and the high-pressure solidification processes, which finally grew into large and spherical α1(Al) grains. Second, heterogeneous nucleation occurred in the residual liquid phase, and the crystal nucleus further grew into fine α2(Al) particles under high applied pressure during the filling and pressure-retaining processes [18]. The α2(Al) particles could not grow fully during the rapid solidification process because of the low Tm and the thin wall of the connecting rod casting. Therefore, most α2(Al) particles showed poor morphology.

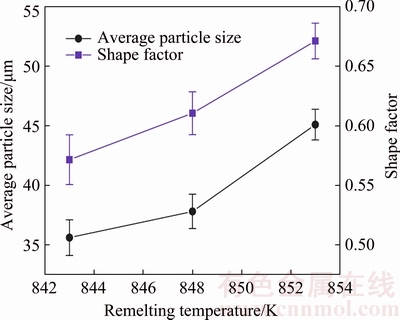

Figure 6 depicts that the APS and SF increased with the increase of Tr. The microstructure presented fine spherical α1(Al) grains and numerous small α2(Al) particles with irregular shapes when the Tr was 843 K, resulting in small APS and SF values of α1(Al) and α2(Al) particles. When the Tr increased to 848 K, the α1(Al) grains did not grow coarser, whereas the α2(Al) particles became coarser, and the spheroidization degree was further improved. Therefore, the APS and SF slowly increased. The coarse α1(Al) grains became more spherical with a further increase of Tr up to 853 K, whereas the α2(Al) particles were too small for calculation, leading to a rapid increase of APS and SF.

Fig. 6 Variations of APS and SF with different re-melting temperatures

Figure 7 presents the histogram of tensile strength and elongation with different Tr for the connecting rod fabricated by SSSC and LSC. The tensile strength and elongation increased first and then decreased as Tr increased, and the maximum values were obtained at 848 K. Furthermore, the tensile strength and elongation of the SSSC-fabricated rod were obviously improved by 22% and 17%, respectively, compared with those of the LSC-fabricated rod, which may be due to the typical dendritic structure in the LSC-fabricated rod.

Fig. 7 Tensile strength and elongation variations with different re-melting temperatures

A similar trend in the mechanical properties was reported with the increase of pouring temperature in the LSC, which was attributed to the low pouring temperature refined the microstructure but deteriorated the cast densification, causing the mechanical properties to first increase and then decrease [9]. Similarly, low pouring temperature also refined the microstructure in SSSC; however, the decreased mechanical properties may be mainly caused by the morphology and size of the α(Al) grains, especially the α2(Al) particles. At low Tr, a high undercooling rate led to the sharp increase of nucleation rate. Finally, the crystal nucleus developed into a number of fine α2(Al) particles with irregular shapes, as illustrated in Fig. 5(a). The spheroidization degree of the α1(Al) grains was further improved with the increase of Tr, whereas the α2(Al) particles further grew into more spherical ones evenly distributed around the α1(Al) grains (Fig. 5(b)). The homogeneous distribution and good morphology of the α2(Al) particles improved the tensile strength and elongation at 848 K compared with those at 843 K. However, the sufficient liquid phase at high Tr (853 K) ensured that the α1(Al) grains completely grew into coarse spherical grains, whereas small α2(Al) particles were developed from a limited number of crystal nucleus during the filling process under applied pressure (Fig. 5(c)), which may deteriorate mechanical properties. Therefore, 848 K was the optimal Tr in the SSSC process.

Figure 7 also demonstrates that the T6 heat treatment increased the tensile strength of both SSSC-fabricated and LSC-fabricated rods and decreased their elongation. By comparison, the tensile strength and elongation of SSSC remained higher than those of LSC by 19% and 20%, respectively. The flaky eutectic silicon was transformed into a granular eutectic silicon, and other fine intermetallic compound precipitates were dispersed from the supersaturated solid solution, which surrounded the grain boundary of the α(Al) particles during the T6 heat treatment. The refinement and morphological change of the eutectic phase remarkably affected the mechanical properties [15]. These precipitates inhibited the dislocation and enhanced the tensile strength of the alloy. However, some precipitated phases may damage the continuity of the aluminum alloy matrix, and the stress concentration at these points could accelerate the formation and extension of cracks, which may reduce the toughness and elongation of the alloy.

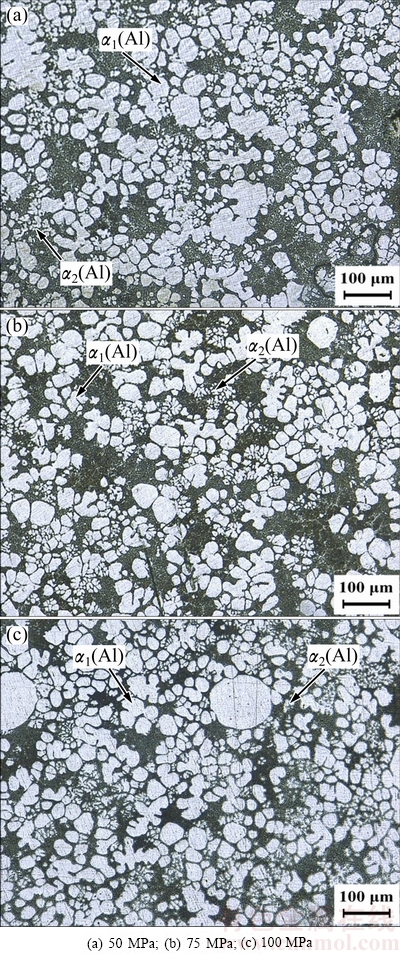

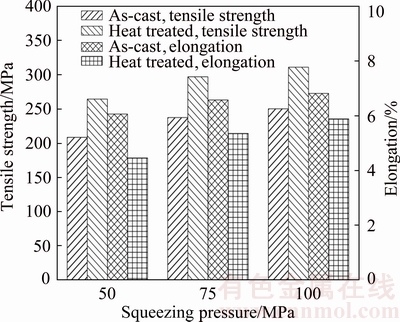

3.3 Microstructure and mechanical properties of connecting rod fabricated under different squeeze pressures

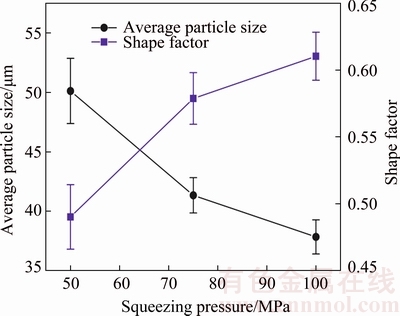

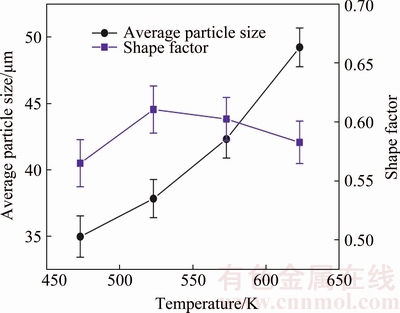

Figure 8 shows the microstructure of the connecting rod under the ps of 50, 75, and 100 MPa, Tr of 848 K, and Tm of 523 K. The corresponding variations of the APS and SF with increasing ps are illustrated in Fig. 9. Some coarse rosette-like α1(Al) grains and non-uniformly distributed α2(Al) particles with irregular shapes were found under the ps of 50 MPa (Fig. 8(a)). The α1(Al) grains transformed into spherical and fine ones with further increase in ps. Particularly at 100 MPa, the spheroidization degree of the α1(Al) grains was further improved, and small α2(Al) particles were distributed around them as presented in Fig. 9(c). A few large rosette-like α1(Al) grains transformed into more spherical ones as ps increased from 50 to 100 MPa. This transformation may be due to the coalescence of the neighboring grains with similar orientations during the filling and pressure solidification processes. In Fig. 9, the increased ps reduced APS and improved SF. In addition, the downtrend of APS and the uptrend of SF were gradually decreased when ps exceeded 75 MPa.

Fig. 8 Microstructures of connecting rod fabricated by SSSC under different squeezing pressures

Fig. 9 Variations of APS and SF with different squeezing pressures

The influence of ps on the microstructural evolution during the SSSC could be attributed to the increased solidification temperature and cooling rate of the slurry [8]. First, Clausius-Clapeyron equation can be used to indicate the effect of ps on the solidification temperature [15,19].

(3)

(3)

where Tf is the equilibrium solidification temperature; Vl and Vs are the specific volumes of the liquid and solid, respectively; DHf is the latent heat of fusion, and p is the applied pressure. Equation (3) indicates that solidification temperature increases with pressure, which leads to a high degree of undercooling, resulting in grain refinement and spheroidization. Moreover, a high ps promotes the close contact between the semi-solid slurry and the mold. Consequently, the heat transfer coefficient and cooling rate were increased [20], inhibiting the excessive coarsening of the α1(Al) and α2(Al) grains. Hence, APS was decreased, and SF was increased with the increase of ps, as depicted in Fig. 9.

Figure 10 illustrates the tensile strength and elongation variations with ps. The tensile strength and elongation of the castings increased with the increase of the ps, with or without T6 heat treatment. The tensile strength and elongation were increased obviously when ps increased from 50 to 75 MPa. However, growth slowed down to a stable state at 100 MPa. Based on investigating the LM13 alloy SC [21], when ps exceeded 100 MPa, the mechanical properties would not improve obviously. First, the casting densification may be maximized because the semi-solid slurry and the mold surface achieved a completely close contact [21]. Only a slight improvement in the microstructure was attained because the effect of the ps reached some dynamic balance with the grain refinement. Moreover, excessively high applied pressure may damage the mold and equipment. Therefore, the ps for SSSC should be limited to 100 MPa.

Fig. 10 Tensile strength and elongation variations with different squeezing pressures

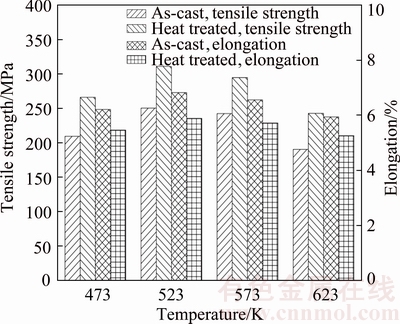

3.4 Microstructures and mechanical properties of connecting rod fabricated at different mold temperatures

Figure 11 depicts the corresponding microstructures at the Tm of 473, 523, 573, and 623 K, Tr of 848 K, and ps of 100 MPa. When Tm was 473 K, some rosette-like α1(Al) grains and small and irregularly shaped α2(Al) particles formed (Fig. 11(a)). The α1(Al) grains were coarsened, and the morphology was improved as Tm increased to 523 K, whereas the α2(Al) particles grew slightly, as shown in Fig. 11 (b). With further increase in Tm, the α1(Al) grains further grew into large and spherical grains, and the α2(Al) particles gradually changed to small dendritic particles located around the α1(Al) grains as illustrated in Figs. 11(c) and (d).

Figure 12 shows the effect of Tm on APS and SF. The APS was increased with the increase of Tm, whereas SF was increased at first and then decreased when the Tm exceeded 573 K. This phenomenon was caused by the numerous dendritic α2(Al) particles that coalesced with the α1(Al) grains at 573 and 623 K. Figure 13 shows tensile strength and elongation variations with Tm. The mechanical properties of the castings at 523 K were obviously higher than those at 473 K. However, further increase in Tm from 523 to 623 K could decrease the tensile strength and elongation.

Fig. 11 Microstructures of connecting rod fabricated by SSSC at different mold temperatures

Fig. 12 APS and SF variations with mold temperature

Fig. 13 Tensile strength and elongation variations with mold temperatures

At low Tm, high undercooling degree caused the rapid solidification of the slurry, which markedly increased the amount of α2(Al) particles. However, α1(Al) grains and α2(Al) particles cannot grow and coarsen because of the high heat transfer coefficient and cooling rate. Consequently, the morphologies of α1(Al) grains and α2(Al) particles deteriorated, resulting in small APS and SF. Moreover, the solidified skin may form on the surface of the mold cavity because of the chilling effect. The skin was broken into pieces and drawn into the casting during the high pressure filling [15]. All these factors resulted in the poor mechanical properties at low Tm. On the contrary, at high Tm, the α1(Al) grains grew excessively, and some of them coalesced with one another, forming irregularly shaped grains, whereas the α2(Al) particles grew into small dendrites and attached to the coarse α1(Al) grains. The deteriorative morphology of the α(Al) grains reduced the tensile strength and elongation of the castings. Based on the results, the Tm for SSSC should be restricted to approximately 523 K.

According to the experimental results presented in this study within a certain range of the parameters, the optimal microstructure and mechanical properties of the connecting rod fabricated by SSSC were obtained. The optimal parameters were Tr=848 K, ps=100 MPa, and Tm=523 K. Under these parameters, the tensile strength and elongation of SSSC were obviously improved by 22% and 17%, respectively, than those of LSC before the T6 heat treatment; they were also increased by 19% and 20%, respectively, than those of LSC after the T6 heat treatment.

4 Conclusions

1) Compared with the LSC-fabricated connecting rod, the tensile strength and elongation of SSSC- fabricated connecting rod improved by 22% and 17%, respectively. These increases were mainly attributed to the improved morphology, as well as the size of the fine α1(Al) grains and the small α2(Al) particles in SSSC.

2) Both APS and SF increased with the increase of Tr, whereas tensile strength and elongation increased first and then decreased. The best mechanical properties were obtained at 848 K.

3) The APS decreased with the increase of ps, whereas the SF increased. The tensile strength and elongation were enhanced as ps increased.

4) Both APS and SF increased with the increase of Tm, thereby enhancing the mechanical properties. However, when the Tm exceeded 573 K, the APS further increased, whereas the SF decreased, and the mechanical properties of the connecting rod were deteriorated.

5) The optimal process parameters in the SSSC for the fabrication of the connecting rod are as follows: Tr is 848 K, ps is 100 MPa, and Tm is 523 K.

References

[1] GUAN Ren-guo, ZHAO Zhan-yong, ZHANG Qiu-Sheng, LEE C S, LIU Chun-ming. Effect of the casting temperature on temperature field and microstructure of A2017 alloy during an innovative continuous semisolid rolling process with a vibrating sloping plate device [J]. International Journal of Advanced Manufacturing Technology, 2013, 67(1-4): 917-923.

[2] JIANG Ju-fu., WANG Ying, LIU Jun, QU Jian-jun, DU Zhi-ming, LUO Shou-jing. Microstructure and mechanical properties of AZ61 magnesium alloy parts achieved by thixo-extruding semisolid billets prepared by new SIMA [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 576-585.

[3] HU Zhao-Hua, WU Guo-Hua, ZHANG Peng, LIU Wen-Cai, PANG Song, ZHANG Liang, DING Wen-Jiang. Primary phase evolution of rheo-processed ADC12 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 19-27

[4] SALLEH M S, OMAR M Z, ALHAWARI K S, MOHAMMED M N, MAMALI M A, MOHAMAD E. Microstructural evolution and mechanical properties of thixoformed A319 alloys containing variable amounts of magnesium [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(8): 2029-2042

[5] HUANG X S, HE L J, MI G B, LI P J. Characteristics of defect bands and their formation mechanisms in A356 wheel fabricated by horizontal squeeze casting [J]. Materials Science and Technology, 2014, 31(4): 400-408.

[6] LU Shu-lin, WU Shu-sen, NIU Z, AN P, MAO Y. Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 20(S3): s758-s762.

[7] CHEN Qiang, YUAN Bin, ZHAO Gao-zhan, SHU Da-yu, HU Chun-kai, ZHAO Zu-de, ZHAO Zhi-xiang. Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting–solid extrusion [J]. Materials Science and Engineering A, 2012, 537(2): 25-38.

[8] ASHIRI R, KARIMZADEH F, NIROUMAND B. On effect of squeezing pressure on microstructural characteristics, heat treatment response and electrical conductivity of an Al-Si-Mg-Ni-Cu alloy [J]. Materials Science and Technology, 2014, 30(10): 1162-1169.

[9] DAO V, ZHAO Sheng-dun, LIN Wen-jie, ZHANG Chen-yang. Effect of process parameters on microstructure and mechanical properties in AlSi9Mg connecting rod fabricated by semi-solid squeeze casting [J]. Materials Science and Engineering A, 2012, 558(51): 95-102.

[10] MO Wen-fei, ZHAND Liang, WU Guo-hua, ZHANG Yang, LIU Wen-cai WANG Cun-long. Effects of processing parameters on microstructure and mechanical properties of squeeze-cast Mg-12Zn-4Al-0.5Ca alloy [J]. Materials and Design, 2014, 63: 729-737.

[11] LIN Bo, ZHANG Wei-wen, LUO Zhao-Hui, ZHANG Da-tong, LI Yuan-yuan. Comparative study on microstructures and mechanical properties of the heat-treated Al-5.0Cu-0.6Mn-xFe alloys prepared by gravity die casting and squeeze casting [J]. Materials and Design, 2014, 59: 161-168.

[12] MASOUMI M, HENRY H. Influence of applied pressure on microstructure and tensile properties of squeeze cast magnesium Mg-Al-Ca alloy [J]. Materials Science and Engineering A, 2011, 528 (10-11): 3589-3593.

[13] BURAPA R, JANUDOM S, CHUCHEEP R, CANYOOK J, WANNASIN J. Effects of primary phase morphology on mechanical properties of Al-Si-Mg-Fe alloy in semi-solid slurry casting process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s857-s861.

[14] LEE S M, KANG C G. Effect of solid fraction on formability and mechanical properties in a vertical-type rheo squeeze-casting process [J]. Proceedings of the Institution of Mechanical Engineers (Part B): Journal of Engineering Manufacture, 2011, 225(B2): 184-196.

[15] DAI Wei, WU Shu-sen, LU Shu-lin, LIN Chong. Effects of rheo- squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy [J]. Materials Science and Engineering A, 2012, 538: 320-326.

[16] XU Yan, HU Lian-xi, JIA Jian-bo, XU Bo. Microstructure evolution of a SIMA processed AZ91D magnesium alloy based on repetitive upsetting-extrusion (RUE) process [J]. Materials Characterization, 2016, 118: 309-323.

[17] TAO Jiang-quan, JIANG Ju-fu, CHEN Hong, XIAO Yuan-lun, ZHANG Rong-chao, HUA Hu-qiang, ZHAO Jun, ZHAO Qiang. Application of cyclic upsetting-extrusion to semi-solid processing of AZ91D magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 909-915.

[18] HITCHCOCK M, WANG Yun, FAN Z. Secondary solidification behaviour of the Al-Si-Mg alloy prepared by the rheo-diecasting process [J]. Acta Materialia, 2007, 55(5): 1589-1598.

[19] WU Shu-sen, ZHONG Gu, AN Ping, WAN Li. ZHONG J X X. Microstructural characteristics of Al-20Si-2Cu-0.4Mg-1Ni alloy formed by rheo-squeeze casting after ultrasonic vibration treatment [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2863-2870.

[20] VIJIAN P, ARUNACHALAM V P. Optimization of squeeze cast parameters of LM6 aluminium alloy for surface roughness using Taguchi method [J]. Journal of Materials Processing Technology, 2006, 180(3): 161-166.

[21] MALEKI A, NIROUMAND B, SHAFYEI A. Effects of squeeze casting parameters on the microstructure of LM13 alloy [J]. Journal of Materials Processing Technology 2009, 209(8): 3790-3797.

王永飞,赵升吨,张晨阳

西安交通大学 机械工程学院,西安710049

摘 要:分别采用液态挤压铸造和半固态挤压铸造工艺成形ZL104铝合金连杆,研究不同工艺参数对连杆的显微组织及力学性能的影响规律。结果表明:与传统液态挤压铸造相比,半固态挤压铸造连杆的抗拉强度和伸长率分别提高了22%和17%。半固态挤压铸造过程中,随着重熔温度的增加,平均晶粒尺寸和形状因子都增大;随着模具预热温度的升高,平均晶粒尺寸增大,形状因子先增加后减小;这两种情况下连杆的抗拉强度和伸长率都先增加后减小。但随着挤压压力的提高,平均晶粒尺寸减小,且形状因子增大,连杆的力学性能明显提高。此外,成形半固态挤压铸造连杆的最佳重熔温度、挤压压力及模具预热温度分别为848 K、100 MPa及523 K。

关键词:铝合金;半固态挤压铸造;半固态显微组织;抗拉强度;伸长率;连杆

(Edited by Xiang-qun LI)

Foundation item: Project (51335009) supported by the National Natural Science Foundation of China; Project (2014JQ7273) supported by the Natural Science Foundation of Shaanxi Province of China; Project (CXY1514 (1)) supported by the Xi’an Science and Technology Plan Projects, China

Corresponding author: Yong-fei WANG; Tel: +86-13488126840; E-mail: yongfeio@126.com

DOI: 10.1016/S1003-6326(18)64656-4