文章编号:1004-0609(2017)-01-0008-07

冷却速率对Al-5Zr中间合金凝固组织的影响

朱庆丰1, 2,李 飞1, 3,王 嘉1, 2,王庆海1, 2,王文静1, 2,崔建忠1, 2

(1. 东北大学 材料电磁过程研究教育部重点实验室,沈阳 110004;

2. 东北大学 材料科学与工程学院,沈阳 110004;

3. 辽宁石油化工大学 机械工程学院,抚顺 113001)

摘 要:研究冷却速率对Al-5Zr中间合金中Al3Zr相尺寸形貌的影响,并分析冷却速率对Al3Zr相形核与长大速率的影响。结果表明:随冷却速率由耐火模的2.0 ℃/s提高到铜模的45.6 ℃/s,初生Al3Zr相由粗大板条状转变成细小的片层状。当冷却速率分别为2.0、29.3和45.6 ℃/s时,试样中初生Al3Zr相长轴平均长度分别为215、175和45 μm,对应最大尺寸Al3Zr相的长轴长大速率分别为5.4、53.2和38.4 μm/s,试样中形核数量分别为23、54和309 mm-2。

关键词:Al-Zr中间合金;冷却速率;凝固组织;形核

中图分类号:TG146.2 文献标志码:A

Zr元素是很多高性能铝合金中必不可少的微量元素。作为向铝合金添加Zr元素的重要载体,Al-Zr中间合金的优劣直接关系含Zr高性能铝合金的综合性能[1-3]。Al-Zr中间合金中Al3Zr相的形貌、尺寸以及分布会通过遗传效应影响铝合金制品的最终性能[4-5]。因此,高质量Al-Zr中间合金的制备是提高含Zr铝合金质量的关键技术之一。由Al-Zr二元相图可知,Al-Zr中间合金在凝固过程中属包晶反应,液相线温度随着Zr元素含量的增加迅速增加,凝固过程Al3Zr相在液相线温度以下开始形成,其形状、尺寸受浇铸温度、冷却速率等凝固条件影响较大[6-16]。BRODOVA等[14]研究了冷却速率(200和2000 ℃/s)对Al-1.5%Zr中间合金组织的影响,发现当冷却速率较慢时形成稳态的粗大针状Al3Zr相(DO23),当冷却速 率快时形成微米块状和蔷薇状亚稳态的Al3Zr相。ZHAO等[17]在研究利用熔盐反应法制备的铝基复合材料凝固时发现浇注温度对Al3Zr相形貌有较大影响,随着温度升高,Al3Zr相形貌由球状、块状逐渐演化成纤维状。

采用不同工艺制备Al-Zr中间合金的过程中,Al-Zr熔体在两相区所形成的Al3Zr相的形貌不同,这些在浇铸前熔体中形成的Al3Zr相会直接影响铸态组织中的Al3Zr相形貌与分布。之前的相关研究[17]并未对浇铸温度是否在两相区、以及该温度下熔体中Al3Zr相的形成过程进行重点关注。这导致一些特殊形貌Al3Zr相的成因难以解释清楚。为了探索不同形貌Al3Zr相的成因,作者对Al-Zr中间合金制备过程中的熔炼、铸造条件展开了较为系统的研究。本文作者重点关注液相线温度以上浇铸时冷却速率对Al-5%Zr中间合金中Al3Zr相形貌、尺寸及数量的影响,进而分析冷却速率对Al3Zr相形核、长大规律的影响。

1 实验

实验用合金为熔盐反应法制备的Al-5Zr中间合金,其合金成分如表1所列。将一定质量(2kg)的中间合金置于中频感应炉内的石墨坩埚中进行熔化,中间合金熔化后用热电偶监测铝合金熔体的温度,待铝合金熔体温度升至1260 ℃(合金液相线温度之上)并保温5 min后,用石墨棒对熔体进行充分的搅拌,搅拌后用涂有氮化硼涂料的不锈钢勺子将铝液舀出,浇铸到3种冷却速率的铸造模中。

表1 Al-5Zr中间合金的合金成分

Table 1 Chemical composition of Al-5Zr master alloy (mass fraction, %)

3种铸模的材质分别为紫铜、高纯石墨和耐火材料。3种铸模的形状尺寸基本一致,如图1所示,其型腔顶部直径为35 mm,底部直径30 mm,高50 mm。为了测量不同铸模的冷却速率,浇铸过程中用HIOKI公司生产的16通道测温仪进行测温,测温偶放置的位置如图1所示,测温点在距离下表面15 mm左右的铸锭中心处,测温过程中设定采集数据间隔为0.01 s。

图1 铸模示意图

Fig. 1 Schematic diagram of casting mold

取所制备的合金试样沿中轴线剖开,经磨光后,将其放入10%NaOH(质量分数)水溶液腐蚀5 min,再用25%HNO3(质量分数)清洗试样表面,然后观察其宏观组织形貌。微观组织分析在距离底部15 mm处取样,经240~3000号的砂纸磨光后,进行精抛,分别用SSX-550型扫描电镜和光学显微镜进行观察,并借助Image-Pro Plus图像分析软件详细分析不同试样中Al3Zr相形貌、尺寸及数量,并结合测温结果计算不同冷却速率下初生Al3Zr相的形核率即长大速率。

2 结果与分析

2.1 不同铸模的冷却曲线

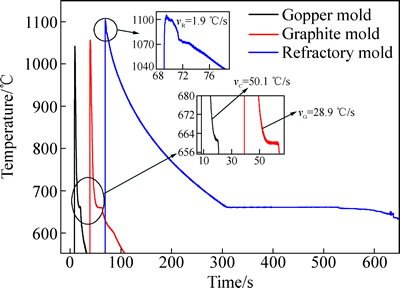

Al-Zr合金熔体在不同铸模中凝固过程中的冷却曲线如图2所示。由图2可以看出,1260 ℃浇铸时,3种铸模中铝液的温度均迅速降低;当温度降至660 ℃附近时,出现了一个恒温平台,结合相图可知这个平台为固相线温度。局部放大图还可以发现耐火模的冷却曲线在1075 ℃附近有一个拐点,结合相图可知此拐点应为该合金的液相线温度。由于石墨模及铜模的冷却曲线开始采集到的温度低于1075 ℃,故在相应的冷却曲线中未发现该合金液相线的拐点。对比3种铸模的冷却曲线可以看出,在Al3Zr相形成的温度区间(两相区)内,3种铸模的冷却速率明显不同,其中耐火模的冷却速率最慢,约为2.0 ℃/s;铜模的冷却速率最快,约为45.6 ℃/s;石墨模的冷却速率居中,约为29.3 ℃/s。

图2 不同铸模的冷却曲线

Fig. 2 Time-temperature curves of different molds

2.2 Al-5Zr中间合金的宏观微观形貌

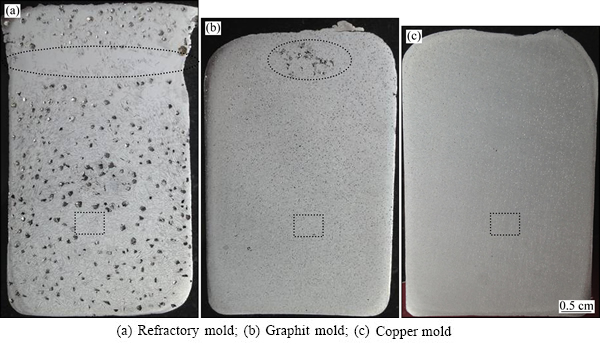

3种不同铸模中凝固的Al-5Zr中间合金的宏观形貌如图3所示,其中图3(a)、(b)、(c)所示分别为耐火模、石墨模以及铜模凝固试样竖直纵截面的宏观形貌,可以看出3种凝固条件下获得的铸锭的宏观形貌存在明显的差异。耐火模凝固试样上表面与模壁接触处几乎呈直角,无明显的缩孔,而在侧面距离上端约1 cm附近出现了一个明显的“缩径”,这表明此处是试样最后凝固的位置,耐火模试样纵截面上存在大量尺寸较大的圆形气孔,这些气孔的平均直径在0.8 mm左右,在基体中还分布着大量长条状黑色初生相,在“缩颈”处试样的内部黑色初生相与气孔数量均较少(见图3(a))。石墨模试样的上表面与模壁接触处呈圆角,试样中部距离上表面附近存在一个有较多大尺寸气孔聚集区,试样中其他区域存在着大量分布均匀的圆形气孔,这些气孔的尺寸明显较耐火模试样的小,而气孔的数量明显较耐火模试样的多,基体中的黑色相的大小已难以通过肉眼辨别。铜模凝固试样的外形与石墨模试样相似,但在上表面上有一个比较明显的缩孔,试样纵截面上分布着大量均匀细小的气孔,基体中的初生相无法用肉眼辨别。

图3 不同冷却速率铸造模条件下Al-5Zr 中间合金宏观凝固形貌

Fig. 3 Macrostructures of Al-5Zr master alloy in molds with different cooling rates

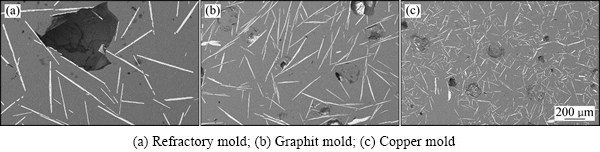

图4 不同冷却速率铸造模条件下试样的SEM像

Fig. 4 SEM images of Al-5Zr master alloy with different cooling rates

不同试样测温点位置附近(对应图3中虚线框处)的SEM像如图4所示。由图4可以看出,3种铸模凝固试样内均有大量白色的条状相,但不同试样中的相的尺寸明显不同。耐火模试样中的白色相尺寸最为粗大,长度可达600~700 μm(见图4(a));石墨模试样中白色相的尺寸较耐火模的明显减小(见图4(b)),其长度多为200~300 μm;铜模冷却条件下,试样中白色相的尺寸最小,长度均在200 μm以下(见图4(c))。

对图4中各试样的白色的相进行能谱分析,发现其均为含Zr相,典型能谱分析结果如图5所示,分析结果还表明白色相的Zr与Al的摩尔比约为1:3,可以确定这些白色条状相为Al3Zr相。

为了分析冷却速率对这些Al3Zr相的尺寸分布的影响,用光学显微镜对试样进行了观察,其典型显微组织如图6(a)、(c)、(e)所示。

图5 图4中典型白色相的能谱分析

Fig. 5 EDS spectrum of white phase shown in Fig. 4(a)

图6 不同铸模的Al-5Zr合金中初生Al3Zr相显微组织及其长轴的尺寸分布

Fig. 6 Microstructures and distribution of Al3Zr along length direction in Al-5Zr master alloy solidified in different molds

在光学显微镜下Al3Zr相呈暗灰色,Al3Zr相的尺寸分布情况与扫描电镜下的相近。用图像分析软件对图像进行分析统计,得出Al3Zr长度分布及其拟合曲线如图6(b)、(d)、(f)所示。冷却速率为2.0 ℃/s的试样中,最大Al3Zr相的长轴的长度大于1000 μm,长轴平均长度为215 μm(见图6(b))。冷却速率为29.3 ℃/s 的试样中,最大Al3Zr相的长轴长度小于800 μm,长轴平均长度为175 μm(见图6(d))。在冷却速率为45.6 ℃/s的样品中,最大Al3Zr相长轴长度小于160 μm,长轴平均长度为45 μm。随着冷却速率的增大,相对出现频率高的初生Al3Zr相尺寸逐渐减小,其高频率初生相长轴方向上的尺寸分别为76 μm(40.8%)、54 μm (43.7%)、28 μm(68.1%)。可见,随着冷却速率的增加初生Al3Zr相尺寸趋向于均匀一致。分析结果还表明3种试样中Al3Zr相总面积分数均为12%左右,这表明3种冷却速率并未明显影响Al3Zr相的总量。

2.3 不同冷却速率下Al3Zr相的形核与长大

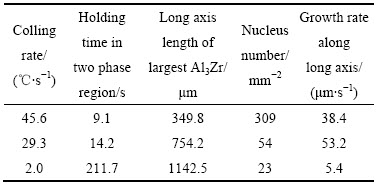

利用图像分析软件统计不同凝固条件下单位面积内Al3Zr相的个数,并计算单位面积内Al3Zr相的形核数量。根据测温曲线,计算熔体在两相区的停留时间。并假定试样中最大尺寸的Al3Zr相在液相线温度开始行形核,固相线温度停止生长,则可根据观测到最长Al3Zr相尺寸计算Al3Zr相长轴的长大速率。计算得出单位面积内Al3Zr相的数量、最大Al3Zr相长轴的长大速率如表2所列。可以看出不同冷却速率条件下,Al-5Zr合金熔体在两相区的停留时间明显不同,铜模条件下Al-5Zr合金熔体由1075 ℃降至660 ℃用时约为9.1 s,再根据测得铜模试样中最大Al3Zr相的尺寸,可计算出其长轴方向的长大速率约为38.4 μm/s;用同样的计算方法,石墨模试样中最大Al3Zr相长轴方向的长大速率约为53.1 μm/s;耐火模试样中最大Al3Zr相长轴方向的长大速率约为5.4 μm/s。可见,最大尺寸Al3Zr相长轴的生长速率随冷却速率的增加先升高再降低。同时还可以看出,单位面积内的形核数量随冷却速率的增加而增加,由耐火模冷却速率为2.0 ℃/s的23 个/mm2,增至铜模(冷却速率为45.6 ℃/s)的309 个/mm2。

表2 不同冷却速率下试样中的单位面积内Al3Zr相形核数量与长大速率

Table 2 Nucleation rate and growth rate of Al3Zr phase during solidification in different cooling rates

3 分析与讨论

由Al-Zr二元相图可知,Al-5Zr合金的凝固过程是典型的包晶反应过程,测温结果表明,其液相线温度约为1075 ℃,其固相线温度约为660 ℃。在高于液相线温度的1260 ℃浇铸时,Zr元素完全溶于铝熔体,故此本实验观察到的Al3Zr相是在凝固过程产生的,其形成是一个形核长大过程,Al3Zr相在液相线温度之下开始形核,并长大,当温度达到固相线温度后Al3Zr停止生长。本实验中利用不同铸模实现了对凝固过程中冷却速率的改变,冷却速率影响了Al3Zr相形核、长大速率以及熔体在两相区的停留时间,进而影响了最终获得的Al3Zr相的尺寸。

耐火模中凝固时,冷却速率低、形核数量少(23 mm-2)、生长速率慢(长轴生长速率约为5.4 μm/s)、熔体在两相区的停留时间长,这为Al3Zr相的生长提供了充足的时间,Al3Zr相经过长时间缓慢生长形成了粗大的板条状形貌。在石墨模中凝固时,冷却速率得到提高,形核数量和生长速率均增加,此时尽管Al3Zr相的长大速率增加很多,但熔体在两相区的停留时间变短,Al3Zr的生长时间有限,试样中形成Al3Zr相的尺寸减小。在铜模中凝固时,冷却速率进一步提高,Al3Zr相形核数量显著增加,Al3Zr相会因与相毗邻Al3Zr相“接触”而终止生长,因此,铜模试样(冷却速率为45.6 ℃/s)Al3Zr相的长大速率反而较石墨模试样(冷却速率为29.3 ℃/s)Al3Zr相的长大速率低;此时形核数量的多与少是影响Al3Zr相尺寸的主要因素。

由于本实验中Al-5Zr合金熔炼温度高,熔炼过程中容易吸气,因此在凝固过程中气体会从熔体中析出,其形成过程也是一个形核长大的过程,其受冷却速率影响与Al3Zr相相似,因此,在不同的铸锭中呈现出了不同尺寸的孔洞。

4 结论

1) 随着冷却速率由耐火模的2.0 ℃/s提高到铜模的45.6 ℃/s,Al3Zr相由粗大的板条状向细小的片层状转变。冷却速率分别为2.0、29.3和45.6 ℃/s时,Al3Zr相长轴平均长度为分别为215、175和45 μm,其高频率初生相长轴方向上的尺寸分别为76 μm(40.8%)、54 μm(43.7%)、28 μm(68.1%)。

2) 随着凝固过程中Al-5Zr中间合金中两相区冷却速率的增加,初生Al3Zr相单位面积内的形核数量不断增加;当冷却速率分别为2.0、29.3和45.6 ℃/s时,对应的单位面积内Al3Zr相的形核数量分别为23、54、309 mm-2。

3) 随着凝固过程中Al-5Zr中间合金中两相区冷却速率的增加,最大尺寸初生Al3Zr相的长大速率先升高后降低,冷却速率分别为2.0、29.3和45.6 ℃/s的试样内最大尺寸Al3Zr相长轴的长大速率分别为5.4、53.2和38.4 μm/s。

REFERENCES

[1] 谢优华, 杨守杰, 戴圣龙, 陆 政. 含锆超高强铝合金的研究及发展概况[J]. 材料导报, 2012, 6(5): 8-10.

XIE You-hua, YANG Shou-jie, DAI Sheng-long, LU Zheng. Research and development of ultra-high strength aluminum alloy containing Zirconium[J]. Materials Review, 2002, 16(5): 8-10.

[2] 谢优华, 杨守杰, 戴圣龙, 陆 政. 锆元素在铝合金中的应用[J]. 航空材料学报. 2002, 22(4): 56-61.

XI You-hua, YANG Shou-jie, DAI Sheng-long, LU Zheng. Research and development of ultra-high strength aluminum alloy containing zirconium[J]. Journal of Aeronautical Materials, 2002, 22(4): 56-61.

[3] 张映新. Al-Ti和Al-Zr中间合金组织遗传性对铝合金铸造组织的影响[J]. 轻合金加工技术, 1998, 26(11): 11-13.

ZHANG Ying-xin. Effect of structures heredities of Al-Ti and Al-Zr master alloys on casting structures of aluminum alloys[J]. Light Alloy Fabrication Technology, 1998, 26(11): 11-13.

[4] 余爱武, 杨成刚, 刘奋成. Ti、Zr对纯铝微观组织和力学性能的影响[J]. 稀有金属材料与工程, 2015, 44(8): 1964-1969.

YU Ai-wu, YANG Cheng-gang, LIU Fen-cheng. Effects of Ti, Zr on the microstructure and mechanical properties of pure aluminum[J]. Rare Metal Materials and Engineering, 2015, 44(8): 1964-1969.

[5] SEYED E S H, EMAMY M, POURKIA N. The microstructure, hardness and tensile properties of a new super high strength aluminum alloy with Zr addition[J]. Materials & Design, 2010, 31(9): 4450-4460.

[6] 汪小燕, 赵玉涛, 陈 刚, 程晓农, 张红杰, 章 照. Al-K2ZrF体系熔体反应法合成复合材料的微观组织和力学性能[J]. 稀有金属材料与工程, 2007, 36(2): 259-263.

WANG Xiao-yan, ZHAO Yu-tao, CHEN Gang, CHENG Xiao-nong, ZHANG Hong-jie, ZHANG Zhao. Rare microstructure and mechanical properties of composites synthesized by direct melt reaction in the Al-K2ZrF6 system[J]. Metal Materials and Engineering, 2007, 36(2): 259-263.

[7] OHASHI T, ICHIKAWA R. A new metastable phase in rapidly solidified Al-Zr alloys[J]. Metallurgical and Materials Transactions B, 1972, 22(6): 2300-2302.

[8] KNIPLING K E, DUNAND D C, SEIDMAN D N. Nucleation and precipitation strengthening in dilute Al-Ti and Al-Zr alloys[J]. Metallurgical & Materials Transactions A, 2007, 38(10): 2552-2563.

[9] HORI S, SAJI S, TAKEHARA A. Structure of rapidly solidified aluminum-zirconium alloys and its thermal stability[C]//4th Int. Conf. on Rapidly Quenched Metals, Sendai, Japan, 1981: 1545-1548.

[10] OHASHI T, DAI L, FUKATSU N, MIWA K. Precipitation of quasicrystalline phase in rapidly solidified Al-Mn-Zr alloys[J]. Scripta Metallurgica, 1986, 20(9): 1241-1244.

[11] CHAUDHURY Z A, SURYANARAYANA C A. TEM study of decomposition behavior of a melt-quenched Al-Zr alloy[J]. Metallography, 1984, 17: 231-252.

[12] 杜 刚, 杨 文, 闫德胜, 戎利建. Al-Mg-Sc-Zr合金中初生相的析出行为[J]. 中国有色金属学报, 2010, 20(6): 1803-1807.

DU Gang, YANG Wen, YAN De-sheng, RONG Li-jian. Precipitation behaviors of primary phases in Al-Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1803-1807.

[13] XU Cong, DU Rou, WANG Xue-jiao, HANADA S, AMAGATA H Y, WANG Wen-hong, MA Chao. Effect of cooling rate on morphology of primary particles in Al-Sc-Zr master alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2420-2426.

[14] BRODOVA I G, BASHLYKOV D V, MANUKHIN A B, STOLYAROV V V, SOSHINKOVA E P. Formation of nanostructure in rapidly solidified Al-Zr alloy by severe plastic deformation[J]. Scripta Materialia, 2001, 44(8): 1761-1764.

[15] ZHANG Wei, XING Yuan, JIA Zhi-hong, YANG Xiao-fang, LIU Qing, ZHU Chang-luo. Effect of minor Sc and Zr addition on microstructure and properties of ultra-high strength aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3866-3871.

[16] CONG Fu-guan, ZHAO Gang, JIANG Feng, TIAN Ni, LI Rui-feng. Effect of minor Sc and Zr addition on microstructure and properties of ultra-high strength aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3866-3871.

[17] ZHAO Yu-tao, ZHANG Song-li, CHEN Gang, CHEN Xiao-nong. Effects of molten temperature on the morphologies of in situ Al3Zr and ZrB2 particles and wear properties of (Al3Zr+ZrB2)/Al composites[J]. Materials Science and Engineering A, 2007, 457(1/2): 156-161.

Effects of cooling rate on solidification structure of Al-5Zr master alloys

ZHU Qing-feng1, 2, LI Fei1, 3, WANG Jia1, 2, WANG Qing-hai1, 2, WANG Wen-jing1, 2, CUI Jian-zhong1, 2

(1. Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education, Northeastern University, Shenyang 110004, China;

2. School of Materials Science and Engineering, Northeastern University, Shenyang 110004, China;

3. School of Mechanical Engineering, Liaoning Shihua University, Fushun 113001, China)

Abstract: The effects of the cooling rate on the morphology and size of the primary Al3Zr phase during solidification process were investigated. Base on the experiment results, the effects of the cooling rate on the nucleation and growth rate of the primary Al3Zr phase also were analyzed. The results show that with the cooling rate increasing from 2.0 ℃/s to 45.6 ℃/s, the coarse plate shape primary Al3Zr phases change to fine needle shape. When the cooling rates are 2.0, 29.3 and 45.6 ℃/s, respectively, the average lengths of the primary Al3Zr phase are 215, 175 and 45 μm, respectively, the growth rates along the major axes of the maximum size Al3Zr phase in the corresponding sample are 5.4, 53.2, 38.4 μm/s, respectively, and the nucleation numbers of the primary Al3Zr phase are about 23, 54, and 309 mm-2, respectively.

Key words: Al-Zr master alloy; cooling rate; solidification structure; nucleation

Foundation item: Projects(51204053, 51374067) supported by the National Natural Science Foundation of China; Projects(N130409005, N130709001, N130209001) supported by Central University Basic R&D Operating Expenses, China; Project(2015022003) supported by Liaoning Natural Science Foundation, China

Received date: 2015-12-28; Accepted date: 2016-08-04

Corresponding author: ZHU Qing-feng; Tel: +86-24-83685967; E-mail: zhuqingfeng@epm.neu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51204053,51374067);中央高校基本科研项目(N130409005,N130709001,N130209001);辽宁省自然科学基金资助项目(2015022003)

收稿日期:2015-12-28;修订日期:2016-08-04

通信作者:朱庆丰,副教授,博士;电话:024-83685967;E-mail: zhuqingfeng@epm.neu.edu.cn