文章编号:1004-0609(2017)-02-0243-08

SiC颗粒参与下快冷镁合金异质形核与高温晶粒长大

杨 伟,殷海眯,商景利,王 祥,刘吕果

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用铜模喷铸与高温退火相结合,研究快冷AZ91+SiC合金组织细化与高温晶粒长大,揭示SiC颗粒对亚快速凝固镁合金异质形核及热稳定性的影响。结果表明:SiC可促进亚快速凝固过程中异质形核,阻碍凝固界面迁移,显著细化喷铸合金组织。400 ℃等温退火后,组织从枝晶向等轴晶转变并发生明显晶粒长大,快冷AZ91合金保温8 h后平均晶粒尺寸达78 μm。添加2%SiC后,晶粒长大得到有效控制,8 h退火处理后平均晶粒尺寸仅为22 μm。SiC的存在提高了基体中晶格畸变,退火组织中析出层片状与粒状共存的沉淀相。晶粒细化及SiC的添加提高了快冷镁合金显微硬度。随退火时间延长,合金硬度下降。沉淀相的析出导致AZ91+2%SiC合金硬度增加,最高可达111HV,比AZ91合金的硬度提高63.2%。

关键词:镁合金;凝固;冷却速率;异质形核;晶粒长大

中图分类号:TG146.2 文献标志码:A

镁合金作为轻质结构材料,具有比强度/比刚度高等优点,在航空航天、电子交通等领域具有重要的应用价值[1-3]。然而常规冷速条件下,镁合金铸件枝晶组织粗大、缩孔缩松严重、加工成形及耐蚀性差,直接影响材料的设计使用[4-5]。晶粒细化可有效提高合金强度及塑性等力学性能,改善第二相形貌及分布,抑制或消除有害相。因此,细晶镁合金的制备已成为改善传统组织结构、获得高性能新材料的有效途径[6]。

快速凝固作为亚稳新材料的重要制备方法,可以获得细小均匀分布的晶粒组织,同时改善晶界相形貌,提高材料耐蚀性[7-9]。近年来研发的SiC孕育剂,与镁具有相似的晶体结构及良好相容性,广泛应用于Mg-Al合金的组织细化。贾秀颖等[10]采用高能超声分散法,研究了SiC含量对AZ91镁合金组织及力学性能的影响。李元东等[11]分析了不同铸件尺寸条件下SiC颗粒对镁合金半固态组织的影响。EASTON等[12]研究了SiC对含Al、Mn的镁合金组织细化的影响。LELITO等[13]通过分析不同试样厚度时的凝固过冷度,建立了晶粒尺寸与SiC含量间的数学模型。然而上述研究主要集中于常规铸态或低冷速条件下合金细化效果,有关高冷速、尤其非平衡状态下SiC颗粒的异质形核潜力需要进一步研究。

由于受冷速限制,快冷合金大多为粉末或箔带 状,需要后续热压烧结才能满足实际使用[14-16]。采用较高的热压温度或较长的烧结时间固然有利于提高组织致密性,但不可避免地导致亚稳细晶发生晶粒长大[17-18]。通过加入Ca、Y、Nd等碱土或稀土元素,控制高熔点沉淀相的析出,可以抑制晶粒长大。ZHOU等[19]研究了快速凝固Mg-6Zn-Ca合金中Ca2Mg6Zn3析出相对晶界迁移的钉扎影响。AYMAN等[20]采用放电等离子烧结技术研究了快速凝固镁合金中沉淀相析出及长大规律。SHENG等[21]通过控制热压过程中Mg2Si相的析出,显著提高了AZ91快冷合金强度。然而以上细晶保持技术需要首先解决沉淀相粗化、形貌及择优生长取向等问题,尤其对于具有较高自扩散系数的镁合金,沉淀相的粗化更易发生。SiC与镁结合性良好, 且具有较高熔点,有望在抑制快冷镁合金高温晶粒长大方面发挥良好效果。

针对工业中广泛使用的AZ系镁合金,本文作者采用铜模喷铸与高温退火相结合的技术,系统研究不同SiC含量时快冷镁合金的组织细化及后续晶粒长大行为,为亚稳细晶材料的制备及热稳定性提高提供参考。

1 实验

基体材料选用AZ91镁合金,其成分如下(质量分数,下同):Al 8.5%~9.5%, Zn 0.45%~0.9%, Mn 0.17%, Si 0.05%, Fe 0.004%, Cu 0.015%, Ni 0.001%,其余为Mg。SiC颗粒的平均尺寸为2 μm。首先采用搅拌摩擦加工技术制备出6%SiC均匀分散的中间合金,然后按混合称量方式配比得到AZ91+1%SiC及AZ91+2%SiC合金。

采用真空感应熔炼+惰性气体保护相结合的手段,利用铜模喷铸方式实现快冷镁合金的制备。首先将配比好的合金原料装入石英坩埚内(尺寸:d 15 mm×150 mm,下方开有d 0.5 mm小孔),然后调整坩埚底部与铜模(外部尺寸d 80 mm×60 mm,内腔d 8 mm)的相对位置,确保正对铜腔中心。采用机械泵将真空室压力预抽至5 Pa后返充99.999%的高纯Ar气至0.03 MPa,以降低合金熔炼过程中氧化挥发。通过调节感应电源功率将最高熔炼温度控制在730 ℃,确保合金具有良好流动性的同时不出现明显挥发。熔体保温5 min均匀混合后,在坩埚上方通入0.02 MPa的Ar气,金属液被垂直喷射入铜模内腔,从而获得亚快速凝固试棒。为对比研究铜模激冷效果,未喷铸合金采用随炉冷却方式,获得铸态组织。高温晶粒长大实验在升降式坩埚电阻炉内进行,试样尺寸d 8 mm×3 mm,温度400 ℃。考虑晶界共晶相尺寸及含量差异,随炉冷却试样保温时间为20 h,快冷合金试样保温时间为2 h、4 h、6 h和8 h。

试样经镶嵌、打磨、抛光及腐蚀等标准金相制备步骤后,采用VHX-600E型三维超景深显微镜进行光学显微组织分析,并利用Image-ProPlus软件通过截线法测量平均晶粒尺寸。采用FEI-Nova NanoSEM450场发射扫描电子显微镜进行高倍组织观察,并利用Oxford-INCA 250X-MAX50型能谱仪对微区成分进行测定。采用HVD-1000IS型维氏显微硬度计进行硬度分析,所加载荷1.96 N,作用时间15 s。每个试样不同区域随机测试5个数值,去除最高及最低值后取平均结果作为最终硬度值。

2 结果与分析

2.1 不同条件下合金凝固组织分析

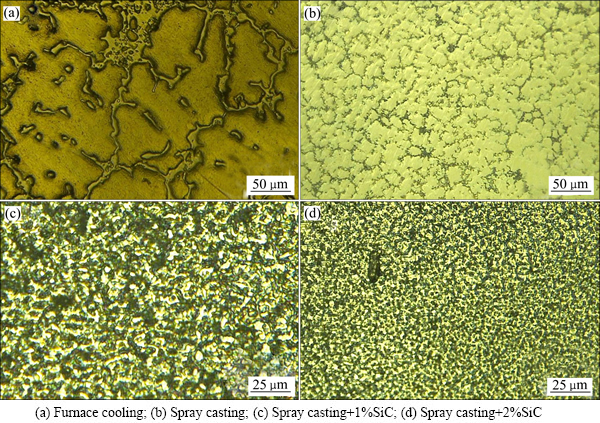

图1所示为炉冷、铜模喷铸及添加不同含量SiC(1%、2%)后的镁合金光学显微组织。炉冷条件下AZ91合金铸态组织主要由花瓣状的初生α-Mg晶粒及晶界网状分布的β-Mg17Al12相组成。由于冷速较慢,初生相生长充分,枝晶粗大。凝固后期随溶质再分配的进行,枝晶间残余液相富集溶质Al元素,形成离异共晶β相(见图1(a))。采用铜模喷铸后,快冷合金组织为细小粒状晶形貌,平均晶粒尺寸为24.8μm,相比炉冷显著下降(见图1(b))。随SiC颗粒加入,非平衡凝固镁合金晶粒圆滑程度有所下降,组织细化效果进一步增强,其中添加2%SiC时的晶粒尺寸最为细小(见图1(c)和(d))。

图1 不同制备工艺下镁合金光学显微组织

Fig. 1 Optical microstructures of AZ91 alloy fabricated by different experimental conditions

从凝固过程的完成到晶粒组织的形成,形核和生长在其间发挥着重要作用。根据经典形核理论,凝固过程中的有效晶粒数目N可表示为[12]

(1)

(1)

式中:I为异质形核速率;V为熔体体积;R为冷速;ΔTmax为最大凝固过冷度。铜模喷铸具有良好的激冷效果,可降低相变潜热对形核的抑制影响,提高ΔTmax,进而激发更多的形核事件,有利于组织细化。

由非热形核理论,异质颗粒参与下的有效形核尺寸为[22]

(2)

(2)

式中: 为液/固界面能;ΔS为熔化熵;ΔTn为形核过冷度。由于快冷条件下合金可获得较大过冷度,显著降低有效形核尺寸r,导致更多的细小颗粒满足形核发生条件,促进晶粒细化。此外随SiC含量增加,多余的颗粒随凝固过程的进行被推移到残余液相中,钉扎凝固界面迁移,抑制晶粒生长,最终有利于组织的进一步细化。

为液/固界面能;ΔS为熔化熵;ΔTn为形核过冷度。由于快冷条件下合金可获得较大过冷度,显著降低有效形核尺寸r,导致更多的细小颗粒满足形核发生条件,促进晶粒细化。此外随SiC含量增加,多余的颗粒随凝固过程的进行被推移到残余液相中,钉扎凝固界面迁移,抑制晶粒生长,最终有利于组织的进一步细化。

2.2 快冷合金高温晶粒长大

图2所示为400 ℃等温退火后合金光学显微组织。由于离异共晶β相高温时溶解到基体中,晶界由原始条带状变为细线状,晶粒组织更加清晰并最终转变为多边形等轴晶。对比分析可知,炉冷时晶粒组织最为粗大,平均尺寸高达200 μm以上(见图2(a))。(400 ℃, 2 h)退火处理后的快冷AZ91合金晶粒尺寸显著下降,平均晶粒尺寸约为34 μm(见图2(b))。随SiC颗粒加入,铜模喷铸合金组织更加细小,其中SiC含量1%、2%时的晶粒尺寸分别为19 μm和13 μm(见图2(c)和 (d)),从而进一步说明SiC颗粒可有效促进镁合金的异质形核。

图2 镁合金退火光学显微组织

Fig. 2 Optical microstructures of magnesium alloy after annealing at 400 ℃

合金快冷过程中所形成的亚稳细晶组织具有大量的晶界,高温退火时较高的界面自由能为晶粒长大提供驱动力,并决定了平均晶粒长大速度v[23]:

(3)

(3)

式中:M为随温度变化的晶界迁移率;rgb为晶界表面能;d为平均晶粒尺寸。图3所示为快冷镁合金经(400 ℃, 8 h)退火处理后光学显微组织。随保温时间延长,非平衡凝固AZ91合金中发生了明显晶粒长大,平均晶粒尺寸达78 μm (见图3(a))。

根据Zener理论,第二相粒子对晶界迁移的钉扎力PZ可表示为[18]

(4)

(4)

式中:rs和fV分别为第二相粒子的尺寸及体积分数;σs为晶界能。由于SiC颗粒能抑制高温晶界迁移,快冷合金高温晶粒长大得到有效控制,其中AZ91+2%SiC合金所对应的晶粒尺寸仅为22 μm(见图3(c)),相比退火2 h时的平均尺寸13 μm未发生显著长大,表明SiC颗粒能提高镁合金细晶组织热稳定性。

图3 (400 ℃, 8 h)退火处理后铜模喷铸镁合金的光学显微组织

Fig. 3 Optical microstructures of spray casted magnesium alloy after annealing at 400 ℃ for 8 h

为进一步描述亚稳细晶组织的高温晶粒长大行为,图4所示为不同保温时间下快冷镁合金的平均晶粒尺寸。随保温时间延长,3种合金晶粒尺寸均呈上升趋势,其中未添加SiC的AZ91合金晶粒尺寸增长速率最快。添加SiC颗粒后,晶粒长大程度有所减弱,相应曲线变化更为平缓。

图4 不同退火时间下铜模喷铸镁合金平均晶粒尺寸

Fig. 4 Average grain size of spray casted magnesium alloy after annealing at 400 ℃ for different time

2.3 快冷合金退火组织结构变化

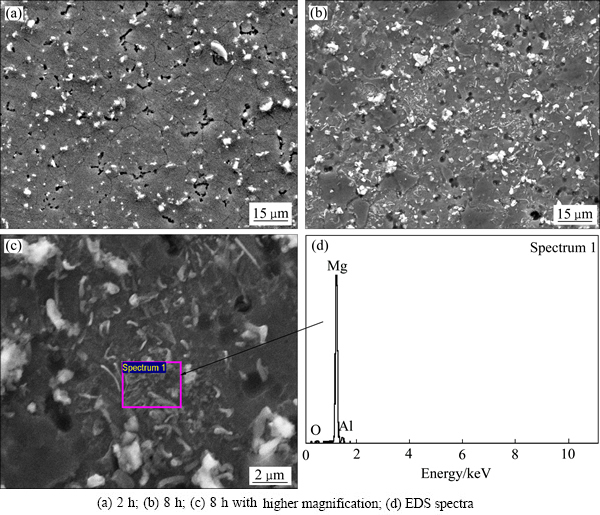

图5所示为AZ91+1%SiC快冷合金400 ℃退火处理后扫描电镜图,其中多边形基体组织中存在一定量的白色颗粒,主要分布于晶界区域,少部分出现在晶粒内部,未发现明显团聚现象(见图5(a))。随保温时间延长,白色粒状组织更为细小,尺寸大小不一(见图5(b))。结合能谱分析可知,该区域主要含有C、Si元素,含量分别为50.79%和39.38%,余量为Mg,从而可推断为合金中所添加的SiC颗粒。此外图中所观测的白色颗粒尺寸比原始颗粒尺寸2 μm要小,这一结果是因为采用搅拌摩擦加工制备母合金时,在较强机械挤压力作用下,硬脆的SiC陶瓷颗粒发生破碎。

图5 不同退火时间下铜模喷铸AZ91+1%SiC合金SEM像

Fig. 5 SEM images of spray casted AZ91+1%SiC alloy after annealing at 400 ℃ for different time

图6 不同退火时间下铜模喷铸AZ91+2%SiC合金SEM像

Fig. 6 SEM images of spray casted AZ91+2%SiC alloy after annealing at 400 ℃ for different time

图6所示为AZ91+2%SiC快冷合金400 ℃退火处理后扫描电镜图。与图5(a)相比,合金组织中SiC体积分数明显增多,分布更加均匀,无论晶粒内部还是晶界位置均有较多颗粒存在(见图6(a))。8 h退火处理后出现了较多层片状及粒状共存的混合组织,集中分布在SiC颗粒周围(见图6(b))。通过对该区域高倍组织分析,层片状相最长度约2 μm(见图6(c)),其中所选区域内Al原子平均含量为 6.2%,说明退火组织中发生了β-Mg17Al12沉淀相析出。由于400 ℃时离异共晶β相溶解,提高了基体中Al元素含量,形成过饱和固溶体。晶界处于高能量状态,β相优先在该区域析出[24]。本研究由于SiC颗粒的加入,提高了α-Mg基体中晶格畸变及应力分布[25],促进了沉淀相的析出,因此晶粒内部发生沉淀相的析出。

2.4 显微硬度分析

图7所示为SiC颗粒及退火处理共同作用下铜模喷铸镁合金显微硬度变化结果。分析可知,相同条件下SiC颗粒的加入导致合金硬度提高。结合上述组织分析,这一结果是由于SiC促进了快冷镁合金组织细化,同时其本身作为一种陶瓷颗粒,硬度值远高于镁合金的,二者共同影响下提高了合金显微硬度。随退火时间延长,即使SiC颗粒添加时晶粒长大仅是有所抑制,并非完全消除,因此合金硬度不断下降。由于AZ91+2%SiC合金8 h退火组织中析出β-Mg17Al12沉淀相(发生了图6(b),6(c)),该相作为高硬度脆性相[26],能显著提高合金硬度,导致相应硬度曲线不降反升,其中最高值为111HV,比同等条件下未添加SiC颗粒的AZ91合金硬度提高了63.2%。

图7 喷铸合金显微硬度变化

Fig. 7 Micro-hardness of spray casted alloy after annealing at 400 ℃ for different time

3 结论

1) SiC颗粒可促进铜模喷铸AZ91镁合金异质形核,同时残余液相中多余颗粒阻碍凝固界面迁移,共同导致AZ91+2%SiC快冷合金组织细化效果最好。

2) 400 ℃退火处理后,AZ91快冷合金发生明显晶粒长大。由于SiC对高温晶界迁移的钉扎效应,亚稳细晶组织热稳定性提高。退火时间由2 h延长到8 h时,快冷AZ91+2%SiC合金平均晶粒尺寸由13 μm增加到22 μm,晶粒长大得到有效控制。

3) SiC的存在提高了α-Mg基体中晶格畸变,促进β-Mg17Al12沉淀相析出。AZ91+2%SiC快冷合金经(400 ℃, 8 h)退火处理后,晶粒内部重新析出层片状与粒状共存的β相组织。

4) 晶粒细化与SiC颗粒共同提高了快冷镁合金显微硬度。随退火时间延长,晶粒长大导致硬度下降。AZ91+2%SiC合金中由于沉淀相的析出可获得最高硬度值111HV,比同等条件下AZ91合金的提高63.2%。

REFERENCES

[1] LUO A A. Magnesium casting technology for structural applications[J]. Journal of Magnesium and Alloys, 2013(1): 2-22.

[2] 杨文朋, 郭学锋, 梁世何. Ce对往复挤压-低温正挤压Mg-Zn-Ce合金组织与力学性能的影响[J]. 中国有色金属学报, 2015, 25(12): 3336-3343.

YANG Wen-peng, GUO Xue-feng, LIANG Shi-he. Effects of Ce on microstructures and mechanical properties of Mg-Zn-Ce alloys processed by reciprocating extrusion and low-temperature forward extrusion[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3336-3343.

[3] 王长义. AZ91HP镁合金疲劳裂纹扩展行为与断裂机理[J]. 失效分析与预防, 2015, 10(2): 87-91.

WANG Chang-yi. Fatigue crack propagation behavior and mechanism of AZ91HP magnesium alloy[J]. Failure Analysis and Prevention, 2015, 10(2): 87-91.

[4] YANG M B, DUAN C Y , LI H L, GUO T Z, ZHANG J. Effects of minor Ca addition on as-cast microstructure and mechanical properties of Mg-4Y-1.2Mn-1Zn(wt.%) magnesium alloy[J]. Journal of Alloys and Compounds, 2013, 574: 165-173.

[5] 梁键能, 林 翠. 温度对AZ91D镁合金初期大气腐蚀行为的影响[J]. 失效分析与预防, 2009, 4(1): 1-6.

LIANG Jian-neng, LIN Cui. Influence of temperature initial atmospheric corrosion behavior of AZ91D magnesium alloy[J]. Failure Analysis and Prevention, 2009, 4(1): 1-6.

[6] 王 军, 朱秀荣, 徐永东, 王 荣, 聂景江, 张立君. 稀土Ce和Y对AZ80镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(1): 25-35.

WANG Jun, ZHU Xiu-rong, XU Yong-dong, WANG Rong, NIE Jing-jiang, ZHANG Li-jun. Effects of rare earth Ce and Y on microstructure and mechanical properties of AZ80 Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 25-35.

[7] LIU F, YANG G C. Rapid solidification of highly undercooled bulk liquid superalloy: recent developments, future directions[J]. International Materials Reviews, 2006, 3: 146-170.

[8] 杨 伟, 陈寿辉, 张守银, 余 欢, 严青松, 蔡长春. 冷却速率对AZ91D镁合金非平衡凝固组织的影响[J]. 中国有色金属学报, 2014, 24(3): 593-599.

YANG Wei, CHEN Shou-hui, ZHANG Shou-yin, YU Huan, YAN Qin-song, CAI Chang-chun. Effect of cooling rate on non-equilibrium solidified microstructure of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 593-599.

[9] 余 琨, 黎文献, 王日初, 冯 艳, 吴志文. 快速凝固镁合金开发原理及研究进展[J]. 中国有色金属学报, 2007, 17(7): 1025-1033.

YU Kun, LI Wen-xian, WANG Ri-chu, FENG Yan, WU Zhi-wen. Research theory and development of rapidly solidified magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1025-1033.

[10] 贾秀颖, 高飞鹏, 张琼元, 刘世英, 李文珍. 高能超声法制备SiCp/AZ91D复合材料[J]. 特种铸造及有色合金, 2008, 28(12): 962-964.

JIA Xiu-min, GAO Fei-peng, ZHANG Qiong-yuan, LIU Shi-ying, Li Wen-zhen. Fabrication of nano-SiCp/AZ91D composites by high-intensity ultrasonic method[J]. Special Casting & Nonferrous Alloys, 2008, 28(12): 962-964.

[11] 李元东, 文 靖, 陈体军, 杨 建, 马 颖, 姜向东. 添加SiC对不同尺寸AZ91D镁合金坯料板固态组织的影响[J]. 中国有色金属学报, 2010, 20(3): 407-414.

LI Yuan-dong, WEN Jing, CHEN Ti-jun, YANG Jian, MA Ying, JIANG Xiang-dong. Effects of SiC addition on microstructure of AZ91D alloy initial billet with various size during semisolid isothermal treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 407-414.

[12] EASTON M A, SCHIFFL A, YAO J Y, KAUFMANN H. Grain refinement of Mg-Al(-Mn) alloys by SiC additions[J]. Scripta Materialia, 2006, 55: 379-382.

[13] LELITO J, ZAK P, SUCHY J S, KRAJEWSKI W, GREER A L, DARLAK P. 试验确定AZ91/SiC复合材料异质形核模型中决定于SiC质量分数和过冷度的晶粒密度函数[J]. 铸造, 2011, 60(3): 224-228.

LELITO J, ZAK P, SUCHY J S, KRAJEWSKI W, GREER A L,DARLAK P. Experimental determination of SiC and undercooling in AZ91/SiC composite heterogeneous nuclation model[J]. Foundry, 2011, 60(3): 224-228.

[14] CHEN Z, LIU F, YANG X Q, CHEN C J, ZHAO Y M. A thermokinetic description of nano-scale grain growth under dynamic grain boundary segregation condition[J]. Journal of Alloys and Compounds, 2014, 608: 338-342.

[15] 李俊杰, 王锦程, 杨根仓. 含第二项颗粒的晶粒长大过程相场法[J]. 稀有金属材料与工程, 2008, 37(10): 1746-1750.

LI Jun-jie, WANG Jin-cheng, YANG Gen-cang. Phase-field simulation of grain growth in systems containing second-phase particles[J]. Rare Metal Materials and Engineering, 2008, 37(10): 1746-1750.

[16] 盛绍顶, 陈 鼎, 陈振华, 陈 刚, 严红革. 快速凝固/粉末冶金AZ91/SiCp镁基复合材料的相组成及界面[J]. 中国有色金属学报, 2008, 18(7): 1185-1190.

SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua, CHEN Gang, YAN Hong-ge. Phase composition and interface of rapidly solidified/powder metallurgy AZ91/SiCp Mg-based composite material[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1185-1190.

[17] ZHOU Z Z, YANG W, CHEN S H, YU H, XU Z F. Combined effect of non-equilibrium solidification and thermal annealing on microstructure evolution and hardness behavior of AZ91 magnesium alloy[J]. Physica B, 2014, 443: 35-42.

[18] MOELANS N, BLANPAIN B, WOLLANTS P. Pinning effect of second-phase particles on grain growth in polycrystalline films studied by 3-D phase field simulations[J]. Acta Materialia, 2007, 55: 2173-2182.

[19] ZHOU T, YANG M B, ZHOU Z M, HU J J, CHEN Z H. Microstructure and mechanical properties of rapidly solidified/powder metallurgy Mg-6Zn and Mg-6Zn-5Ca at room and elevated temperatures[J]. Journal of Alloys and Compounds, 2013, 560: 161-166.

[20] AYMAN E, JUNKO U, KATSUUOSHI K. Application of rapid solidification powder metallurgy to the fabrication of high-strength, high-ductility Mg-Al-Zn-Ca-La alloy through hot extrusion[J]. Acta Materialia, 2011, 59: 273-282.

[21] SHENG S D, CHEN D, CHEN Z H. Effects of Si addition on microstructure and mechanical properties of RS/PM (rapid solidification and powder metallurgy) AZ91 alloy[J]. Journal of Alloys and Compounds, 2009, 470: 17-20.

[22] LELITO J, ZAK P L, GREER A L, SUCHY J S, KRAJEWSKI W K, GRACZ B, SZUCKI M, SHIRZADI A A. Crystallization model of magnesium primary phase in the AZ91/SiC composite[J]. Composites (Part B), 2012, 43: 3306-3309.

[23] ASHBY M F, EASTERLING K E. A first report on diagrams for grain growth in welds[J]. Acta Metallurgica, 1982, 30: 1969-1978.

[24] 刘 健, 王武孝, 张 莎, 张东杰. 热处理对Mg-7Al-1Si-1Gd合金组织及硬度的影响[J]. 特种铸造及有色合金, 2015, 35(7): 673-676.

LIU Jian, WANG Wu-xiao, ZHANG Sha, ZHANG Dong-jie. Effect of heat treatment on microstructure and hardness of Mg-7Al-1Si-1Gd alloy[J]. Special Casting & Nonferrous Alloys, 2015, 35(7): 673-676.

[25] 高文理, 苏 海, 张 辉, 刘洪波, 王建华. 喷射共沉积SiCp/2024复合材料的纤维组织与力学性能[J]. 中国有色金属学报, 2010, 20(1): 49-54.

GAO Wen-li, SU Hai, ZHANG Hui, LIU Hong-bo, WANG Jian-hua. Microstructures and mechanical properties of spray co-deposited SiCp/2024 aluminum matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 49-54.

[26] 金伟男, 张贵锋, 曾 祥, 张建勋. 采用Al及Al-12Si中间层的AZ31B镁合金TLP接头的组织与性能[J]. 失效分析与预防, 2013, 8(1): 25-29.

JIN Wei-nan, ZHANG Gui-feng, ZENG Xiang, ZHANG Jian-xun. Microstructure and mechanical properties of magnesium alloy AZ31B TLP joints using Al and Al-12Si interlayer[J]. Failure Analysis and Prevention, 2013, 8(1): 25-29.

Heterogeneous nucleation and grain growth at high temperature for quenched magnesium alloy containing SiC particle

YANG Wei, YIN Hai-mi, SHANG Jing-1i, WANG Xiang, LIU Lü-guo

(National Defense Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: Using copper-mould spray casting and annealing techniques, microstructure refinement and grain growth at high temperature for quenched AZ91+SiC alloy were analyzed. Effects of SiC on heterogeneous nucleation of sub-rapid solidified alloy and thermal stability were elucidated. Results show that SiC promotes heterogeneous nucleation and inhibits interface migration. Grain size in spray casted alloy reveals significant reduction. After annealing at 400 ℃, dendrite transits to equiaxed grain, accompanied by obvious grain growth. The grain size of quenched AZ91 alloy after annealing for 8 h is 78 μm, whereas it reduces to 22 μm after adding 2%SiC, indicating the suppression of grain growth. The increase of lattice distortion by SiC generates lamellar and granular precipitations. Grain refinement and SiC increase the micro-hardness of quenched alloy and reduction occurs for longer annealing time. The maximum hardness of 111HV can be obtained in AZ91+2%SiC alloy due to precipitates, which increases by 63.2% than that of AZ91 alloy.

Key words: magnesium alloy; solidification; cooling rate; heterogeneous nucleation; grain growth

Foundation item: Project(51461032) supported by the National Natural Science Foundation of China; Project(GJJ14504) supported by the Education Department of Jiangxi Province, China

Received date: 2016-03-26; Accepted date: 2016-09-06

Corresponding author: YANG Wei; Tel: +86-791-86453167; E-mail: weiyang@mail.nwpu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51461032);江西省教育厅资助项目(GJJ14504)

收稿日期:2016-03-26;修订日期:2016-09-06

通信作者:杨 伟,讲师,博士;电话:0791-86453167;E-mail: weiyang@mail.nwpu.edu.cn