DOI: 10.11817/j.issn.1672-7207.2015.02.008

2099铝锂合金微观组织及性能的演变

林毅,郑子樵,李世晨,孔祥,韩烨

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:对2099铝锂合金微观组织及性能在热机加工过程中的演变进行研究。研究结果表明:枝晶粗大,晶界偏析严重的铸态合金经双级均匀化(510 ℃/12 h+530 ℃/36 h)处理后,树枝晶消失,晶界偏析基本消除,晶界上残余有少量的AlCuFeMn/AlCuMn颗粒。均匀化后的铸锭在450℃进行热挤压,获得直径为16 mm的合金棒。合金经固溶处理后,平行于挤压方向上,中心区域形成强的{111}<112>织构和次强的{111}<110>织构,表层区域形成{112}<110>织构。中心区域的织构强度较表层的强。合金心部和表层硬度(HV)分别为95和120。在峰时效条件下,大量的T1和δ′相以及少量的θ′相在基体中析出。合金相应的抗拉强度,屈服强度和伸长率分别为613 MPa,597 MPa和7.9%。随着时效时间的延长,合金应力腐蚀敏感性降低。在过时效条件下,合金获得理想的抗应力腐蚀性能,强度损失率为5.5%。

关键词:2099铝锂合金;均匀化;挤压;织构;应力腐蚀破裂

中图分类号:TG116.3 文献标志码:A 文章编号:1672-7207(2015)02-0427-10

Evolution of microstructures and properties of 2099 Al-Li alloy

LIN Yi, ZHENG Ziqiao, LI Shichen, KONG Xiang, HAN Ye

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The evolution of microstructure and properties of 2099 Al-Li alloy during thermal mechanical process were investigated. The results show that coarsen dendrites and severe grain boundaries segregation of as-cast alloy are eliminated by two-step homogenization (510 ℃/12 h+530 ℃/36 h), and a few of small AlCuFeMn/AlCuMn particles remain around the grain boundaries. The homogenization alloy is extruded to rod with 16 mm diameter at 450 ℃. Along the extrusion direction, central zone of solution heat treated alloy formed major intense {111}<112> texture and secondary intense {111}<110> texture, surface zone formed {112}<110> texture, and the intension of texture of central zone is higher than that of surface zone. The hardness of central zone and surface zone is 95 and 120, respectively. In the peak-aged condition, a great number of T1 and δ′ phases as well as a few θ′ phases precipitated in the matrix, the corresponding tensile strength, yield strength and elongation of alloy are 613 MPa, 597 MPa and 7.9%, respectively. The stress corrosion cracking (SCC) susceptibility of alloy decrease with aging time, and the strength loss rate of over-aged alloy is 5.5%.

Key words: 2099 Al-Li alloy; homogenization; extrusion; texture; stress corrosion cracking

铝锂合金具有比强度高和比刚度高、疲劳裂纹扩展速率低和高、低温性能较好等特点,广泛应用于航天航空领域,成为减轻飞行器质量、提升飞行器有效载质量、提高燃油效率以及提高安全性能的重要途径[1-3]。2099合金属于第三代铝锂合金。20世纪90年代末期,美国空军致力于研发一种Li(质量分数)大于2%,而各向异性明显低于当时已有其他铝锂合金的新合金,通过成分和加工工艺优化研制出C489合金,虽然C489合金的产生较好地解决了铝锂合金各向异性的问题,但是C489铝锂合金峰时效下的伸长率过低,达不到到航空材料伸长率不低于5%的最低应用标准。随后,美国空军与Alcoa公司合作,在C489合金原有成分的基础上,通过适当降低锂含量和提高锆含量,研发出了伸长率更高,同时保持C489合金力学性能和各向异性小的C458合金,并于2003年,将该合金注册为2099[4-6]。目前,2099合金被大量的应用于制备Airbus 380 的结构件,如:2099-T83挤压件用于制造飞机地板横梁以及座位导轨、2099-T8E67挤压件用于制造机翼纵梁、2099-T8E77板材则用于制造飞机的其他零部件[7]。虽然2099铝锂合金时效工艺已发展成熟[8-9],但关于2099合金在整个热机加工过程中的微观组织、性能的演变却鲜有报道。合金微观组织决定了合金产品最终性能,而掌握合金微观组织在热机加工过程中的演变规律是改进加工工艺,进而改善合金性能,开拓合金应用新领域的重要途径。为此,本文作者通过光学显微镜、扫描电镜、透射电镜观察以及力学性能测试等分析方法,研究2099铝锂合金在热挤压以及热处理过程中微观组织以及性能的演变,并对影响合金微观组织以及性能的相关机理进行归纳,以便为2099铝锂合金国产化研制提供基础数据和理论参考。

1 实验方法

实验用2099铝锂合金成分见表1。合金以高纯Al,Mg,Zn和Li以及Al-Cu,Al-Mn,Al-Zr和Al-Ti中间合金为原料进行配制。首先将纯Al加入电阻炉中熔炼,当Al熔化后分别加入中间合金以及其他纯金属。熔炼过程进行除气,扒渣,以减少气体以及夹杂对铸锭组织的影响。随后,在760 ℃,于圆柱形水冷模中浇注,最终铸锭直径×长度为100 mm×230 mm。

铸锭首先在盐浴炉中进行双级均匀化(510 ℃/12 h+530 ℃/36 h)处理,均匀化后的铸锭在470 ℃的空气炉中退火4 h,然后在卧式挤压机中进行挤压,挤压速度为6.6 m/min,最终获直径为16 mm的合金棒。棒状试样在540 ℃盐浴中进行固溶处理,保温1 h,水淬至室温,然后进行2.5%拉伸预变形,最后进行双级时效(121 ℃/12 h+151 ℃/t,t为时效时间)。

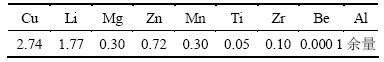

表1 2099铝锂合金化学成分(质量分数)

Table 1 Chemical composition of 2099 Al-Li alloy %

合金室温拉伸在电液伺服万能材料试验机 MTS 858上进行,拉伸速率为2 mm/min,试样标距为30 mm。采用慢应变拉伸实验评定合金在欠时效、峰时效和过时效状态下的耐应力腐蚀性能,实验在Letry 电子拉伸机上进行,腐蚀溶液是质量分数为3.5% NaCl水溶液,溶液温度为25 ℃,应变速率为2×10-6 s-1。合金显微组织分别在Leica光学显微镜、Quanta-200环境扫描电镜和TecnaiG2 200透射电镜上进行观察。

2 实验结果及分析

2.1 合金组织及性能在均匀化过程中的演变

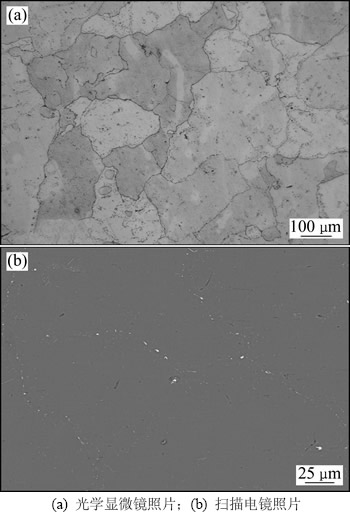

2.1.1 合金铸态组织

图1所示为2099合金在光学显微镜下观察到的铸态金相组织。从图1可以看出,合金铸态组织呈明显的树枝晶特征,且晶界粗大,晶界上存在非平衡共晶相。在扫描电镜下观察,晶界处的共晶相多呈形状不规则的骨状和块状,粒径较大(50~150 μm),如图2所示。图3所示为合金元素的面分布。由图3可知:铸态合金晶界上存在明显偏析,其中Cu偏析最严重,Zn次之,此外晶界上还存在一定数量的杂质元素Fe,而Mg和Mn偏析不明显。对晶界上粗大的第二相粒子进行能谱分析可知,其化学成分主要为Al2Cu,同时含有微量的Zn,Mn和Fe。

在合金铸锭晶界处形的偏析跟熔体凝固过程中溶质分配以及扩散不均匀有关。在凝固过程中,固-液界面前沿熔体由于存在负的温度梯度,固-液界面某些部突出生长进入液相,进入液相后突出部位生长速度增大,沿某一特定方向继续生长形成树枝晶[10]。晶粒生长过程中,晶界与液相接触处形成凹槽,为Cu,Zn和Fe在晶界富集提供了有利条件,同时晶粒结晶时有可能将溶质原子排在固-液界面,使溶质原子在晶界上富集[11],导致晶界偏析的产生。溶质原子Cu在晶界上富集为Al2Cu在晶界上形核生长提供了充足的原子,而且晶界本身是异质形核的有利位置,所以在金属液态凝固过程中,晶界上形成了大量的Al2Cu。

图1 2099铝锂合金铸锭显微组织

Fig. 1 Microstructure of as-casting 2099 Al-Li alloy

图2 2099铝锂合金铸锭扫描电镜照片

Fig. 2 SEM image of as-casting 2099 Al-Li alloy

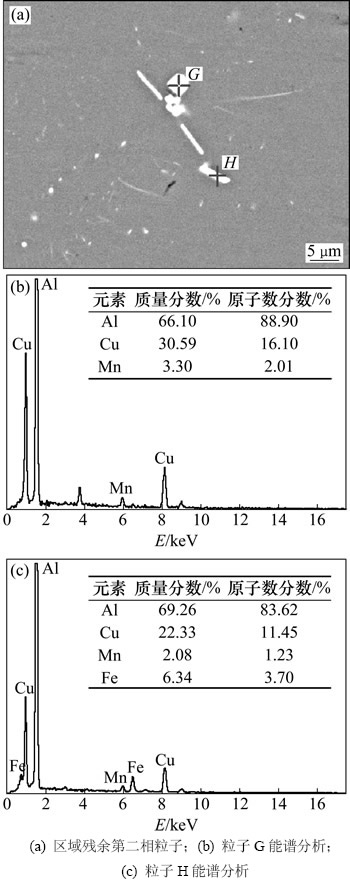

2.1.2 合金均匀化态组织

图4所示为合金在盐浴中经510 ℃/12 h+530 ℃/36 h均匀化处理后的显微组织。由图4(a)可知:经均匀化处理后,铸锭中的树枝晶已基本消除,晶界上大部分形状不规则共晶相已消失,晶界变得断断续续且不清晰,残余第二相粒子呈形状规则的细小点状(或块状)和棒状并沿晶界不连续分布(图4(b))。晶界上残余的第二相粒子形貌特征与研究[12]中的相似。对这些第二相粒子进行能谱分析,结果如图5所示,2种形貌的共晶相成分主要以Al和Cu为主,点状共晶相含有少量的Mn,而棒状共晶相除了含有Mn外,还含有少量杂质元素Fe。铸锭中的AlCuMn和AlCuFeMn相的形成可能是因为熔体凝固过程中,熔点比Cu的高,含量以及在铝中的溶解度远比Cu的低,Mn和Fe较Cu先从熔体中析出,成为第二相粒子的富Mn、富Mn/Fe的形核核心,随着熔体温度的不断下降,Cu原子逐渐在这些核心上沉积,最终形成AlCuMn和AlCuFeMn相。这些相一般熔点较高,难以通过均匀化的方法来彻底消除。

图3 2099合金铸锭合金元素分布

Fig. 3 Distribution of elements of as-casting 2099 Al-Li alloy

图4 2099铝锂合金均匀化态显微组织

Fig. 2 Microstructure of homogenized 2099 Al-Li alloy

2.1.3 均匀态合金室温力学性能

表2所示为合金经均匀化处理后的力学性能。由表2可知,随着经均匀化处理后,合金的强度和伸长率出现了不同程度的提高,其抗拉强度σb、屈服强度σ0.2和伸长率δ分别为342.4 MPa,235.3 MPa和7.7%,均匀化处理有效地提高了合金的强度和塑性,这与其微观组织的演变密切相关。均匀化处理后,铸锭中大部分易溶共晶相以溶质原子的形式回溶到Al基体中,提高了基体溶质原子的饱和度,对合金起到固溶强化的作用;晶界上粗大共晶相的消失、残余第二相粒子尺寸的减少及其形状的规则化,提高了晶界间的结合力,缓解了合金受力过程中晶界应力集中程度,避免了合金过早的在受力过程中由于晶界粗大第二相上萌生微裂纹而断裂,在一定程度上提高合金室温强度和塑性;树枝晶的消失,有利于合金在塑性变形过程中的均匀变形,获得较为理想的强度和塑性的配合。

图5 残余第二相粒子能谱分析

Fig. 5 Energy spectrum analysis of remained secondary particles

表2 2099铝锂合金的力学性能

Table 2 Mechanical properties of 2099 Al-Li alloy

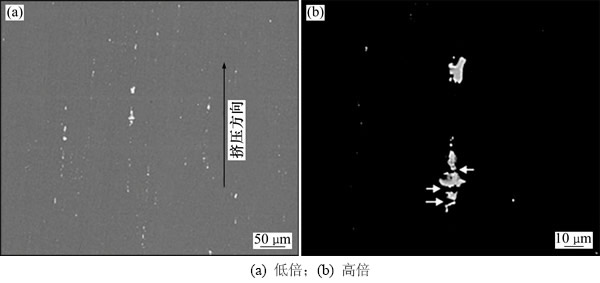

2.2 合金组织在挤压和固溶过程中的演变

图6所示为合金固溶淬火后平行于挤压方向的背散射电子形貌。在低倍数下观察(图6(a)),合金中的第二相粒子沿晶界分布并平行于挤压方向被拉长,这是由于粒子在热挤压过程中受到较大的平行于挤压方向的应力所致。在高倍数下观察合金组织时(图6(b)),将Al基体的颜色调为黑色,第二相粒子则显示为白色,发现大尺寸(粒径d>15 μm)的第二相粒子由于在挤压过程中受切应力作用,在其应力集中的位置(箭头所示)发生破碎,形成尺寸更小的沿晶第二相粒子。

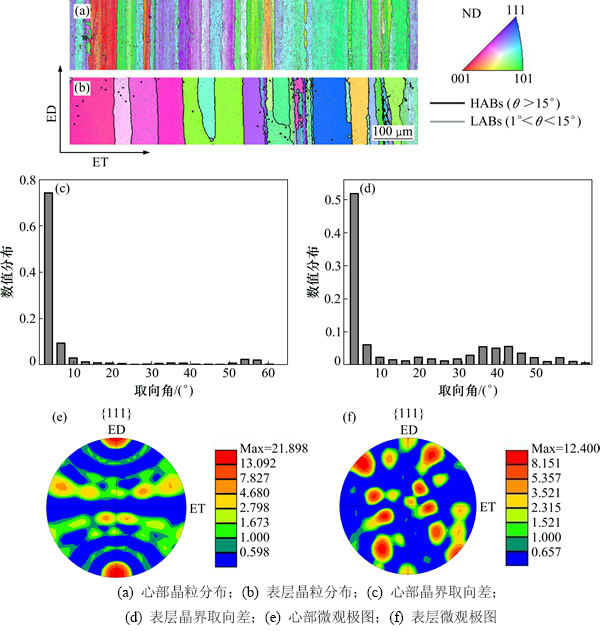

运用EBSD技术对固溶态合金平行于挤压方向的晶粒形貌及晶界取向进行分析,如图7所示。从图7(a)和(b)可知,晶粒在挤压过程中沿挤压方向被拉长,呈纤维状,其中,大角度晶界(θ>15°)用黑线表示,小角度晶界(1°<θ<15°)用灰线表示。不同部位晶粒取向差分布如图7(c)和(d)所示。合金心部组织小角度晶界约90%,而表层组织小角度晶界约65%,心部小角度晶界与表层小角度晶界的差异表明:心部组织具有强于表层组织的变形织构,这与图7(e)和(f)分析的结果相符。小角度晶界在合金不同部位数量上的差异主要源于以下原因:合金在挤压过程中,表层组织受到挤压模摩擦阻力的作用,产生强烈的剪切变形,剪切变形程度由表层向心部逐渐减少,而表层较大的剪切力使表层组织的小角度晶界的运动较心部组织的更容易,由于小角度晶界由位错组成,位错在运过程中与异号位错相遇将会产生异号相消的现象[13-14],且小角度晶界在运动过程中有可能受到亚晶界的阻碍作用,从而在亚晶界上堆积,导致晶界两边的晶粒取向差增大[15]。此外,在挤压过程中,合金表层较高的温度会使表层晶粒受力时发生转动,引起晶界的滑移,一定程度上促使小角度晶界向大角度晶界转变[16],所以,合金表层组织的小角度晶界所占比例较心部组织的低。从图7(e)和(f)可知:合金中心区域形成强的{111}<112>织构以及次强的{111}<110>织构,而表层区域主要形成{112}<110>织构。中心区域的织构强度较表层的强,这与小角度晶界在心部以及表层的分布相对应。织构在合金中心及表层分布的差异可能是两部位在挤压过程中所承受的切应力不同所致[17]。

图6 合金平行于挤压方向的第二相粒子分布

Fig. 6 Distribution of secondary particles along extrusion direction

图7 固溶态合金EBSD分析

Fig. 7 EBSD analysis of solution treated alloy

图8所示为固溶态合金沿挤压方向从心部到表层的显微硬度分布。合金硬度从心部到表层呈逐渐升高的趋势,其中,心部硬度为95(HV),表层硬度为120(HV)。挤压过程中表层组织受到挤压筒较大的摩擦力作用,表层组织残余应变比心部的大,使表层组织加工硬化程度较高,从而导致合金的表层硬度高于心部硬度。

图8 固溶态合金硬度分布

Fig. 8 Distribution of hardness of solution treated alloy

2.3 合金组织及性能在时效过程中的演变

2.3.1 常规室温拉伸性能

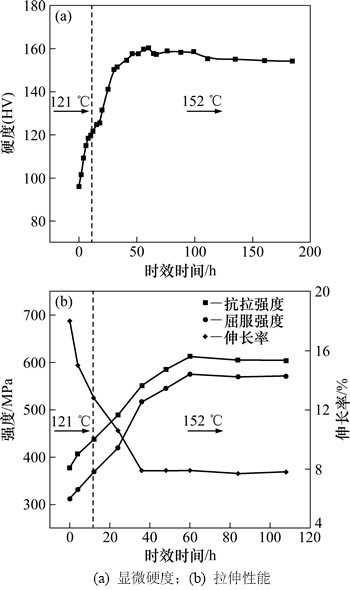

图9(a)所示为合金在时效过程中硬度变化趋势。在121 ℃下进行12 h一级时效后,合金硬度(HV)由80增至120,继续进行151 ℃二级时效,时效48 h后合金硬度(HV)达到最高,为160。合金硬度在一级时效和二级时效过程中的增幅各占硬度整体增幅的50%。图9(b)所示为合金室温拉伸性能变化趋势。室温拉伸性能的变化趋势与硬度的相对应,合金在151 ℃时效48 h后,达到峰时效,抗拉强度、屈服强度和伸长率分别为613 MPa,597 MPa和7.9%。当合金在151℃下时效96 h,其抗拉强度、屈服强度和伸长率分别为610 MPa,590 MPa和7.8%,过时效合金室温拉伸性能与峰时效合金室温拉伸性能相近。

2.3.2 合金微观组织

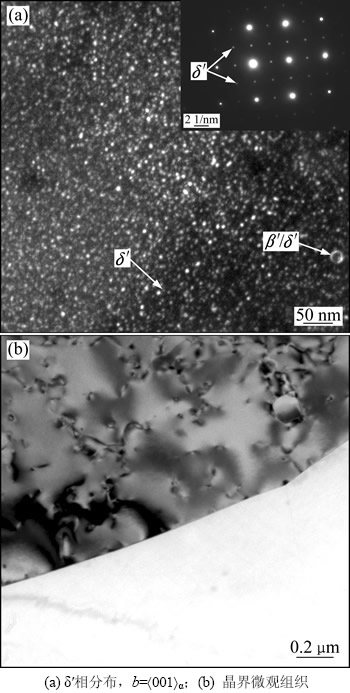

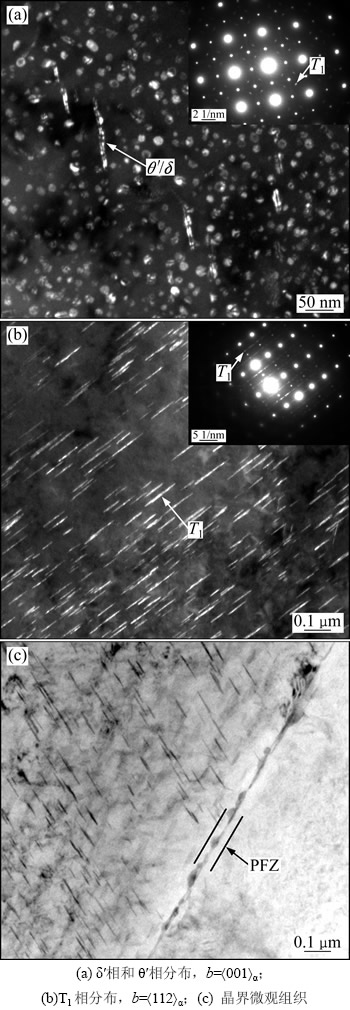

图10所示为合金在121 ℃时效12 h,欠时效条件下的TEM照片。欠时效下,合金基体中形成了大量、直径为2~10 nm的球状δ′(Al3Li)相,同时还形成了β′(Al3Zr)/δ′复合相粒子。晶界上并未有第二相析出。由于δ′相与基体共格,且尺寸较小,对合金的强化效果有限,因此,合金在121℃时效12 h后,强度仅提高60 MPa。图11所示为峰时效合金的TEM照片。峰时效下,(001)α上形成少量的条状θ′(Al2Cu)/δ′复合相;δ′相密度降低,且粗化为直径约20 nm的球形颗粒;在(111)α上形成了大量板状T1相。θ′(Al2Cu)/δ′复合相的形成是由于δ′相{002}的原子与和θ′相{001}的原子具有相同的排列以及Cu与Li有较强的结合能,从而促使部分δ′相在θ′相上形核并沿着θ′相宽面生长,δ′相的形成有利于降低θ′相与Al基体间的弹性应变能,此外,θ′/δ′复合相也有可能是原本孤立的相近的θ′与δ′相在生长的过程中发生交错而形成[18]。合金中θ′相的形成一定程度上提高了合金的强度。由于时效前的预变形增加了基体中的位错密度,使位错在(111)α或者相邻滑移面上运动形成与(111)α有相同伯格斯矢量,并且具有一定间距的割界,为T1相的沉淀析出提供良好的形核位置[19],从而促进了T1相在峰时效(121 ℃/12 h+151 ℃/48 h)大量析出,而且T1相是Al-Cu-Li系合金的主要强化相,所以,峰时效于(111)α上形成大量的T1相极大地促进了合金强度的提高。与欠时效合金相比,峰时效合金的晶界上有第二相析出,并形成一定宽度的无沉淀析出区(PFZ)。Al-Cu-Li系合金在时效过程中,T1,T2(Al6CuLi3),TB和δ(AlLi)相有可能在晶界析出并长大[20]。这些粗大的晶界析出相以及PFZ往往成为应力集中、裂纹萌生的优先位置,削弱了晶粒间的结合强度,使合金在外力作用下过早的发生断裂。因此,峰时合金的伸长率较欠时效合金的低。图12所示为过时效(OA,121 ℃/12 h+151 ℃/96 h)合金的TEM照片。在过时效下,(001)α上依然存在θ′相,而且δ′相更为粗大。(111)α上形成的T1相的数量以及形貌与峰时效的相差不大,这可能与T1相具有良好的热稳定性有关。此外,晶界析出相并未因时效时间的延长而发生明显粗化。由于过时效合金的微观结构与峰时效合金的微观组织相似,所以,2种状态下合金获得相近的室温拉伸性能。

图9 合金时效过程中硬度和拉伸性能的变化趋势

Fig. 9 Evolution trends of microhardness and tensile properties of alloy during aging treatment

图10 欠时效合金TEM照片

Fig. 10 TEM image of under-aged alloy

图11 峰时效合金TEM照片

Fig. 11 TEM image of peak-aged alloy

图12 过时效合金TEM照片

Fig. 12 TEM images of over-aged alloy

2.3.3 应力腐蚀性能

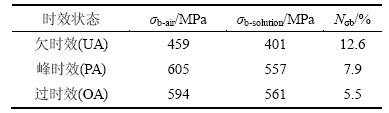

表3所示为不同时效状态的合金分别在空气以及3.5%NaCl溶液中进行慢应变拉伸的力学性能。其中,欠时效合金强度损失率Nσb最大,而过时效合金强度损失率最小。强度损失率表明随着时效时间的延长,合金抗应力腐蚀性能提高,即应力腐蚀敏感性降低。

表3 2099合金在空气和3.5%NaCl溶液中的拉伸性能

Table 3 Tensile properties of 2099 alloy in air and 3.5% NaCl solution

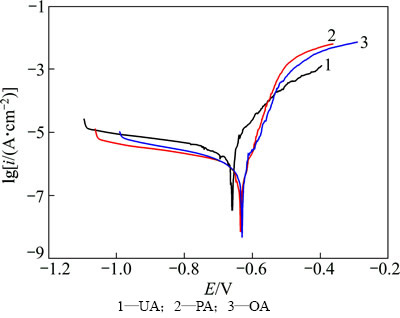

对不同时效状态的合金进行极化曲线以及阻抗谱测量。图13所示为合金不同时效状态下极化曲线。表4所示为合金进行极化曲线测量后,通过拟合极化曲线获得的电化学参数。随着时效时间的延长,腐蚀电流密度逐渐减少,而相应的极化电阻逐渐增大。在时效过程中,合金不同时效状态下腐蚀电流密度(J)和极化电阻(Rp)的关系可以分别表示为:JUA>JPA>JOA,Rp-OA>Rp-PA>Rp-OA。图14所示为不同时效状态合金的电化学阻抗谱。合金的电化学阻抗谱都是由1个高频容抗弧和1个低频感抗弧组成。随着时效时间的延长,低频感抗弧的直径逐渐增大,而高频容抗弧的直径则逐渐减小。感抗弧直径越大表明合金表面腐蚀速率越小,即合金抗腐蚀性能越好。综合电化实验结果可知,合金应力腐蚀性敏感性随时效时间的增加而降低。

图13 不同时效状态合金极化曲线

Fig. 13 Polarization curves of alloy in different aging conditions

表4 2099Al-Li合金在3.5% NaCl中的电化学参数

Table 4 Polarization characteristics of 2099 Al-Li alloy in 3.5% NaCl solution

图14 合金电化学阻抗谱

Fig. 14 Nyquist plots of alloys

合金的腐蚀性能与微观组织有着密切的联系。在欠时效条件下,基体中主要形成球状的δ′相,且晶界上未见有T1相析出,由此推断,合金低温时效过程中形成的相并未主导合金该阶段的腐蚀性能,该阶段的腐蚀性能可能主要受晶界上残留的大尺寸AlCuFeMn/AlCuMn相的影响(见图5)。在腐蚀环境中,AlCuFeMn/AlCuMn相的电位较铝基体正[21],充当阴极,而其周围的铝基体则充当阳极,导致合金发生以铝基体溶解为主的电化学反应,同时这类相在晶界的聚集会增加合金应力腐蚀敏感性[22]。在腐蚀过程中,铝基体首先沿着AlCuFeMn相周围发生点蚀,随着时间的延长,点蚀使铝基体不断地露出新鲜表面,腐蚀程度逐渐加深;腐蚀尖端产生的微裂纹在外加应力作用下将快速扩展,形成新的腐蚀通道,加速了合金的腐蚀;原本相互孤立的微裂纹相互连接,极大地降低了晶界间的结合强度;AlCuFeMn/AlCuMn相中的Mn在溶液中溶解,使颗粒发生自腐蚀,以上因素导致欠时效合金具有较高的应力腐蚀敏感性,并在应力作用下过早的发生断裂。在峰时效条件下,大量的T1相在基体中于预变形引入的位错上均匀的形核生长。T1相电位较铝基体负,其在基体中的均匀分布有利于促进均匀腐蚀,降低了晶界腐蚀驱动力,减缓了晶间腐蚀,降低合金应力腐蚀敏感性[23]。在晶界上形核的少量T1相会导致晶界附近形成PFZ,而晶界T1相的溶解以及PFZ上的应力集中将会增加晶界应力腐蚀开裂的风 险[24],但从总体来看,在基体中均匀分布的T1相提高合金应力腐蚀抗力的程度远大于晶界少量T1相和PFZ对合金耐应力腐蚀性能造成的不利影响,因此,峰时效合金具有理想的抗应力腐蚀性能。在过时效条件下,晶界上少量T1相的粗化以及部分PFZ的宽化可能增加晶界与晶内的电势差,导致合金应力腐蚀敏感性的增加[25],同时晶界相δ中Li的溶解将增加合金晶界腐蚀倾向,而晶界上形成的T2相可使晶界裂纹尖端发生钝化,有利于降低晶界和晶内的电势差[26-27]。由于T1相具有良好的热稳定性,大部分T1相依然保持着峰时效条件下的形态。此外,晶界析出相尺寸增大,析出相之间的间距增加。粗大的晶界析出相有利于捕捉腐蚀过程中产生的氢原子,并使之重新合成氢分子逸出,提高了合金的抗应力腐蚀性能,所以,过时效合金具有更优异的耐腐蚀性能。

3 结论

1) 枝晶粗大、晶界偏析严重的铸态合金经双级均匀化(510 ℃/12 h+530 ℃/36 h)处理后,枝晶消失,晶界偏析基本消除,晶界上残余少量的AlCuFeMn/AlCuMn颗粒。均匀化后的合金获得较铸态合金优异的室温拉伸性能,抗拉强度、屈服强度和伸长率分别为342.4 MPa,235.3 MPa和7.7%。

2) 合金经固溶处理,沿挤压方向上,中心区域形成强的{111}<112>织构以及次强的{111}<110>织构,而表层区域主要形成{112}<110>织构。中心区域硬度(HV)为95,表层区域硬度为120。

3) 合金在151 ℃下时效48 h后到达峰时效。峰时效合金抗拉强度、屈服强度和延伸率分别为613 MPa,597 MPa和7.9%。峰时效合金中形成大量的T1相和δ′相,以及少量的θ′相,晶界第二相沿晶界连续分布,晶界周围并形成一定宽度的PFZ。

4) 合金应力腐蚀敏感性随着时效时间的延长降低。过时效合金中T1相在基体的大量析出以及晶界析出相的不连续分布使合金获得良好的抗应力腐蚀性能,其强度损失为5.5%。

参考文献:

[1] 郑子樵, 李劲风, 陈志国, 等. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

ZHENG Ziqiao, LI Jinfeng, CHEN Zhiguo, et al. Alloying and microstructure evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2351.

[2] JIANG Na, GAO Xiang, ZHENG Ziqiao. Microstructure evolution of aluminum-lithium alloy 2195 undergoing commercial production[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 740-745.

[3] 魏修宇, 郑子樵, 李世晨, 等. 2197 铝锂合金的耐热性能[J]. 中国有色金属学报, 2007, 17(9): 1417-1422.

WEI Xiuyu, ZHENG Ziqiao, LI Shichen, et al. Heat resistance properties of 2197 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(9): 1417-1422.

[4] Romios M, Tiraschi R, Ogren J, et al. Design of multistep aging treatments of 2099 (C458) Al-Li alloy[J]. Journal of Materials Engineering and Performance, 2005, 14(5): 641-646.

[5] Ma Y, Zhou X, Thompson G E, et al. Distribution of intermetallics in an AA 2099-T8 aluminium alloy extrusion[J]. Materials Chemistry and Physics, 2011, 126(1/2): 46-53.

[6] Csontos A, Starke E. The effect of processing and microstructure development on the slip and fracture behavior of the 2.1% Li AF/C-489 and 1.8% Li AF/C-458 Al-Li-Cu-X alloys[J]. Metallurgical and Materials Transactions A, 2000, 31(8): 1965-1976.

[7] De P S, Mishar R S, Baumann J A. Characterization of high cycle fatigue behavior of a new generation aluminum lithium alloy[J]. Acta Materialia, 2011, 59(15): 5946-5960.

[8] Fragomeni J, Wheeler R, Jata K. Effect of single and duplex aging on precipitation response, microstructure, and fatigue crack behavior in Al-Li-Cu alloy AF/C-458[J]. Journal of Materials Engineering and Performance, 2005, 14(1): 18-27.

[9] Parrish C, Barba J, Oh H M, et al. Alternate heat treatments of C458 aluminum lithium alloy[J]. Materials Science Forum, 2000, 331/332/333/334/335/336/337: 655-662.

[10] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 167.

ZHENG Ziqiao. Journal of materis science[M]. Changsha: Central South University Press, 2005: 167.

[11] 刘全坤. 材料成形基本原理[M]. 北京: 机械工业出版社, 2006: 200.

LIU Quankun. Jonrnal of materials forming principle[M]. Beijing: China Machine Press, 2006: 200.

[12] Bois-Brochu A, Goma F A T, Blais C, et al. Al-Li alloy 2099-t83 extrusions: static mechanical properties, microstructure and texture[J]. Advanced Materials Research, 2011, 409: 29-34.

[13] Kaibyshev R, Sitdikov O, Mazurina I, et al. Deformation behavior of a 2219 Al alloy[J]. Materials Science and Engineering A, 2002, 334(1): 104-113.

[14] Biberger M, Blum W. Subgrain boundary migration during creep of lif: I. Recombination of subgrain boundaries[J]. Philosophical Magazine A, 1992, 65(3): 757-770.

[15] Kaibyshev R, Shipilova K, Musin F, et al. Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion[J]. Materials Science and Engineering A, 2005, 396(1): 341-351.

[16] Sitdikov O, Sakai T, Avtokratova E, et al. Microstructure behavior of Al-Mg-Sc alloy processed by ECAP at elevated temperature[J]. Acta Materialia, 2008, 56(4): 821-834.

[17] Kaneko S, Murakami K, Sakai T. Effect of the extrusion conditions on microstructure evolution of the extruded Al-Mg-Si-Cu alloy rods[J]. Materials Science and Engineering A, 2009, 500(1/2): 8-15.

[18] Howe J, Laughlin D, Vasudevan A. A high-resolution transmission electron microscopy investigation of the δ'-θ'precipitate structure in an Al-2 wt% Li-1 wt% Cu alloy[J]. Philosophical Magazine A, 1988, 57(6): 955-969.

[19] Cassada W, Shiflet G, Starke E. Mechanism of Al2CuLi (T1) nucleation and growth[J]. Metallurgical and Materials Transactions A, 1991, 22(2): 287-297.

[20] Lavernia E J, Srivatsan T S, Mohamed F A. Strength, deformation, fracture behaviour and ductility of aluminium-lithium alloys[J]. Journal of Materials Science, 1990, 25(2): 1137-1158.

[21] Birbilis N, Buchheit R G. Electrochemical characteristics of intermetallic phases in aluminum alloys[J]. Journal of the Electrochemical Society, 2005, 152(4): B140-B151.

[22] Dymek S, Dollar M. TEM investigation of age-hardenable Al 2519 alloy subjected to stress corrosion cracking tests[J]. Materials Chemistry and Physics, 2003, 81(2/3): 286-288.

[23] Rinker J, Marek M, Sanders T. Microstructure, toughness and stress corrosion cracking behavior of aluminum alloy 2020[J]. Materials Science and Engineering, 1984, 64(2): 203-221.

[24] Gregson P J, Flower H M. Microstructural control of toughness in aluminium-lithium alloys[J]. Acta Metallurgica, 1985, 33(3): 527-537.

[25] PADGETT B N, Investigation into the stress corrosion cracking properties of AA2099, an aluminum-lithium-copper alloy[D]. Ohio: The Ohio State University. School of Materials Science and Engineering, 2008: 255.

[26] Dorward R,Hasse K. Stress corrosion characteristics of AlCuLi AA 2090 alloy[J]. Corrosion, 1988, 44(12): 932-948.

[27] Wang Z, Zhu Z, Zhang Y, et al. Stress corrosion cracking of an Al-Li alloy[J]. Metallurgical and Materials Transactions A, 1992, 23: 3337-3341.

(编辑 赵俊)

收稿日期:2014-04-10;修回日期:2014-06-20

基金项目(Foundation item):配套年度计划项目(JPPT-K2008-9-1)(Projects (JPPT-K2008-9-1) supported by the Annual Pre-research Supporting Program)

通信作者:林毅,博士,从事高性能航天航空铝合金研究;E-mail:s-maloy@mail.csu.edu