文章编号:1004-0609(2015)-01-0143-07

元素扩散对高铝青铜喷焊层显微组织及摩擦性能的影响

何艳艳1,李文生1,吴学军2,王大锋1,杨效田1,何 玲1

(1. 兰州理工大学 有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 金川集团机械制造有限公司,金昌 737102)

摘 要:采用等离子喷焊技术在d100 mm×30 mm 45号钢圆柱基体上制备厚度为5 mm的高铝青铜喷焊层,将制备的喷焊工件在距基体底部分别为32、33和34 mm处进行水平切割,切割后留在基体上的喷焊层厚度分别为2、3和4 mm。在室温条件下,研究喷焊层中元素扩散对其组织、硬度和摩擦磨损性能的影响。结果表明:随分隔层位置从基体到喷焊层纵深方向距离的增加,Fe元素扩散作用减弱;靠近基体的喷焊层中Fe元素含量较多,富Fe 的k相含量多,且呈点状或球状团聚在一起,喷焊层与铁基对摩件的组织相容性增加,在摩擦过程试样易与对摩件黏着;喷焊层硬度虽高,但磨损率较高;靠近喷焊层表面的喷焊层中Fe元素含量最低,k相相貌由粗大树枝状向细小树枝状和粒状组织转变,摩擦因数和磨损率均有所降低, 黏着磨损受到抑制,主要磨损机理为磨粒磨损。

关键词:等离子喷焊层;元素扩散;k相形貌;摩擦;磨损

中图分类号:TG174.442 文献标志码:A

Effects of element diffusion on microstructure and friction behavior of high-aluminum bronze plasma spray coating

HE Yan-yan1, LI Wen-sheng1, WU Xue-jun2, WANG Da-feng1, YANG Xiao-tian1, HE Ling1

(1. State Key Laboratory of Advanced Nonferrous Materials Process and Recycles,

Lanzhou University of Technology, Lanzhou 730050, China;

2. Jinchuan Machinery Manufacturing Co., Ltd., Jinchang 737102, China)

Abstract: High-aluminum bronze coating with a thickness of 5 mm was sprayed by plasma spray welding on 45 medium carbon steel with size of d100 mm×30 mm. The workpieces were cut at zones of 32, 33, and 34 mm from the bottom of the substrate. The thicknesses of coatings on the substrate were 2, 3 and 4 mm, respectively. The effects of element diffusion on the phase structure, microhardness, friction and wear behavior were analyzed at room temperature. The results show that Fe element coming from substrate diffuses into the coating. With increasing the distance from the interface, Fe element diffusion decreases. The volume fraction of Fe-rich k phase is relatively high on the sprayed layer near the substrate. This increases the compatibility of structure between the coating and Fe-based counterpart. The k phase of coating gathers into spots or globules. Such k phase tends to stick the counterpart during friction process, which even causes some particles. Therefore, its wear behavior is the worst despite of the high hardness of coating. However, in the sample near the surface of coating, the bulky dendritic k phases change to small dendritic and granular ones, and thus results in a decrease of adhesive wear, which causes a low friction coefficient and wear rate. The wear mechanism is characterized as abrasive wear.

Key words: plasma spray coating; element diffusion; phase morphology; friction; wear

不锈钢产品拉伸、压延过程中易与铁基模具如Cr12、合金铸铁、球墨铸铁等产生黏着现象,轻则在不锈钢制品表面产生划痕擦伤,增加产品后续抛光成本,重则因二者之间出现焊合,使模具报废[1-2]。国内外学者对此做了大量研究,发现在Cu-Al二元合金中添加Al、Cu、Mg和Zn等在铁中低固溶度的有色金属元素,能有效增加合金化,降低模具与不锈钢的黏着[3-4]。据此研究者开发了一种过共析的新型高铝铜合金模具材料(w(Al)≈14%),合金硬度达370~400 HB,抗压强度达1200 MPa,抗拉强度大于580 MPa,与铁基材料边界润滑的摩擦因数小于0.08,对改善压延产品的质量非常有益[5]。但是这种新型高铝青铜材料质硬性脆,切削加工困难,且在压延过程中块体模具易出现整体压溃和开裂现象,影响了该材料的广泛工业化应用[6]。

热熔敷技术能有效解决块体材料应用中容易开裂的弊端,且该技术能用于旧模的快速修复[7]。本文作者所在课题组成员在前期研究中曾采用等离子喷焊技术在45钢基体上制备了不同Ce含量的高铝青铜等离子喷焊层,研究结果表明,Ce元素能促进基体中Fe元素向喷焊层扩散,细化喷焊层组织。但添加过量Ce元素,喷焊层表面硬度增加,磨损量反而增多,与经典的Archard黏着磨损、Rabinowicz磨粒磨损模型等摩擦学理论相悖,这种反常现象是由喷焊层中析出的k相形貌分布决定的[8]。路阳等[9]发现,随Fe元素含量的增加,高铝青铜铸态组织中共析体含量增加,且k相形貌及分布发生变化,在后续研究中采用不同喷焊工艺在45基体上制备了该合金涂层,发现铁元素从基材到喷焊层之间呈持续的扩散过程[10],而对喷焊厚度控制喷焊层中富Fe和Al的k相分布、含量以及喷焊层厚度影响涂层摩擦学机理尚未见报道。

在此,本文作者采用等离子喷焊技术在45钢基体上制备厚度为5 mm的喷焊层,研究距离界面不同位置处喷焊层组织及性能的变化,并分析了界面元素扩散对凝固相组织结构及摩擦学性能的影响。

1 实验

1.1 实验材料及喷焊层制备

采用一次性共装熔炼法熔炼合金[11],合金化学成分(质量分数)为Al 14.16%,Fe 3.93%,Mn 0.89%,Cu 79.09%,其余为微量元素。用快速双流高压气雾水冷法制备合金粉末[12],并筛选出球形度较好、直径约为73 μm的粉末作为实验材料。

采用Lu-F500-F600等离子喷焊机在经丙酮清洗和机械粗化处理的d100 mm×30 mm的45低碳钢圆柱端面上制备喷焊层;喷焊过程中离子气流量为3~6 L/min,送粉气流量4~8 L/min,转移弧工作电压25.6~27 V,非转移弧电流26.6~28 A,转移弧电流165~180 A,送粉量18~23 g/min,喷枪至工件距离7~12 mm,喷枪内孔直径为6 mm,喷焊速度2 mm/s,喷焊层厚度为5 mm(喷焊试样标记为OC),工件在大气环境中自然冷却。将制备的喷焊工件在距基体底部分别为32、33和34 mm处进行水平切割,即切割后留在基体上的喷焊层厚度分别为2、3和4 mm,将切割的试样标记为SL1、SL2和SL3。即SL1为距界面2 mm分割层;SL2为距界面3 mm分割层;SL3为距界面4 mm分割层;OC为厚度5 mm喷焊层。

采用线切割技术分别在SL1、SL2、SL3和OC试样上切取尺寸为d 4.8 mm×12.7 mm的摩擦试样。

1.2 喷焊层硬度测试及摩擦磨损实验

采用HBRVU-187.5型布洛维氏硬度计测定各试样表面宏观硬度,载荷为0.49 N,加载时间为10 s,每个硬度值测量6次取其平均值。

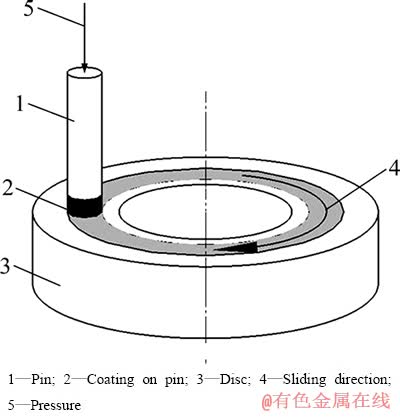

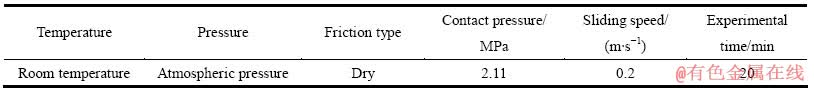

摩擦磨损试验在MM-A型万能实验机上进行,销盘式摩擦副如图1所示。上试样为圆柱销试样,尺寸为d 4.8 mm×12.7 mm,摩擦端面用砂纸精磨至粗糙度Ra小于0.8 μm。对摩件是尺寸为d 31.7 mm×10 mm的SUS304不锈钢盘(硬度为HB202),摩擦条件如表1所列。摩擦因数由系统自动记录,取磨损进入稳定磨损状态后的摩擦因数。用电子分析天平测试磨损前后摩擦试样的质量,计算磨损质量损失,误差为0.1 mg。摩擦磨损试验重复3次,摩擦因数和磨损质量损失为3次试验数据的平均值。用Quanta 450扫描电子显微镜结合EDS观察磨损表面形貌并且分析微区成分。

图1 销盘式摩擦磨损实验示意图

Fig. 1 Schematic diagram of pin-on-disc wear test apparatus

表2 实验条件

Table 2 Experiment condition

2 结果与分析

2.1 喷焊层组织与力学性能

图2(a)、(c)、(e)和(g)所示分别为试样SL1、SL2、SL3及OC的SEM像及Fe元素扫描分析结果。各样品组织均由黑色相、灰色相和白色相组成,黑色相均呈梅花状、树枝状或块状。区别在于各样品组织的形态、尺寸及分布不同。经XRD结合能谱点分析可知,黑色组织是k相,属富Fe和Al组织,灰色组织是β′相,白色组织是α相并伴有少量γ2相组成,为富Cu组织[13-14]。据元素能谱面分析结果可知,试样SL1、SL2、SL3和OC表面Fe元素含量分别为29.08%、28.03%、24.31%和25.31%,比合金粉末中Fe元素含量分别高6.4、6.1、5.1和5.2倍。图2(b)、(d)、(f)和(h)所示分别为图2(a)、(c)、(e)和(g)试样表面Fe元素分布面扫结果,可以看出,喷焊层中黑色树枝状或球状组织富集了大量的Fe等元素。测量背散射照片中富Fe黑色相面积与总视场面积的比值,即为物相体积分数,每组测量50个视场作为统计分析。试样SL1、SL2、SL3、OC中k相含量先急剧减小后缓慢增加,在SL3和OC之间的喷焊层中k相含量最低,且尺寸逐渐减小[13]。

图3所示为试样的宏观硬度。由图3可见,随着距界面距离的增加,喷焊层硬度先减小后增加,在SL3与OC之间喷焊层的硬度最小。SL1的硬度平均值为325.3HV,SL3的硬度平均值为306.3 HV,OC的硬度平均值为310.3HV。

等离子喷焊组织形成过程属于快速熔凝过程,扩散速度取决于等离子弧作用时间和原子迁移率,喷焊层中出现成分分布不均的现象。喷焊层形成过程中,在等离子弧的强烈搅拌和自身重力作用下,熔池中熔化的基体金属和合金粉末混合、产生互溶扩散和界面元素对流传质现象。由于基体激冷作用,喷焊熔池中处于熔合区附近的液态金属温度较低,流动性较差,并且受到机械搅拌作用较弱,母材成分所占的比例加大。经实验结果表明,由界面至喷焊层(SL1、SL2、SL3至OC)Fe元素扩散迁移率逐渐降低,在SL3分割层处Fe元素含量最低。据Cu-Al-Fe三相平衡相图[15]、非均质形核理论和界面能理论可知,Fe在铝青铜中的溶解度很低(约为0.5%~1.0%),凝固过程中超过此量的Fe元素则以熔点较高的含Mn和Al的k相析出,且k相与液态合金的原子之间结合力很好,可作为非均质形核的结晶核心,弥散分布于合金中,细化合金组织[16]。等离子弧的搅拌作用使基体中大量Fe元素扩散到靠近熔合线附近的喷焊层中,形成组织偏析严重的粗大的k相组织。距熔合线距离增加,喷焊层组织受基体元素影响减弱,k相组织转变为点状与细小枝状晶。空气强对流作用使得试样OC表面k相组织以细小的树枝状存在,k相含量比SL3中k相含量略高。

Fe 元素是铝青铜合金中的主要强化元素[17]。喷焊层中Fe含量增加时,先形核k相含量增加,即非均质形核质点增加,组织得到细化。喷焊层中硬质相k相(显微硬度≥650HV)均匀分布在基体上,起到弥散强化作用。实验结果表明,喷焊层中k相含量越高,表面宏观硬度越高。

2.2 喷焊层摩擦特性

图4所示为分层切割层在相同载荷下的磨损量及摩擦因数。SL1、SL2、SL3的磨损量逐渐降低,试样OC的磨损量较SL3的略微增加。距界面的距离从2 mm(SL1)增加到4 mm(SL3)过程中分割层的摩擦因数变化较小,OC喷焊层摩擦因数明显高于其他分割层的摩擦因数,喷焊层SL3的摩擦因数最小。

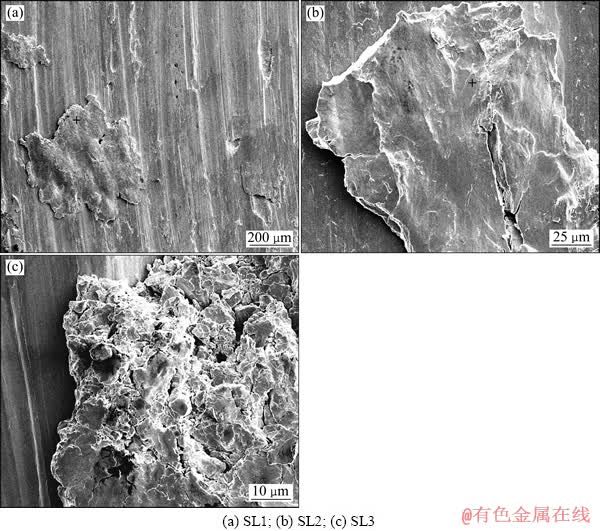

图5所示为试样摩擦磨损形貌的SEM像。由图5(a)、(b)和(d)可以看出,磨损表面有不同程度的黏着特征和剥落坑,以黏着和疲劳磨损为主。SL3磨损表面主要特征为犁沟且犁沟较光滑,具有良好的抗黏着能力,主要磨损形式为磨粒磨损(见图5(c))。图6(a)所示为SL1表面有饼状剥落块。SL2表面形成大块粗厚、有尖锐的棱角磨屑,如图6(b)所示(见图5(b)中A的放大图)。图6(c)所示为SL3表面磨屑形貌,从磨屑形貌来看,磨屑是由尺寸细小的颗粒团聚在一起形成的。

表3所列为未磨损试样、磨损试样表面和磨屑元素EDS点扫描结果,磨损试样表面和磨屑的扫描位置与区域和图5和图6所示。由表3可知, 磨损后试样SL1、SL2、SL3和OC中Fe元素含量比磨损前的Fe元素含量分别低47.7%、36.14%、2.92%和38.12%。与摩擦实验前SL3表面Fe元素的含量相比,剥落块的Fe元素含量喷焊层表面Fe元素含量变化不大。

图2 喷焊层分割示意图及分割层试样横截面的SEM像和Fe元素面扫描分布

Fig. 2 Schematic diagram of coating cutting, SEM images of sample cross-sections and section-distribution of Fe elements

图3 距界面不同距离处涂层硬度

Fig. 3 Hardness of coatings with different distances from cross-sections

对于涂层摩擦实现表现出来的特性,分析认为,材料的摩擦学性能与成分相关外,还取决于材料的组织结构。高铝青铜等离子喷焊层具有软质点α、γ2及共析相(α+γ2)包围硬质点k相生长的组织特征,在正常载荷下,表面的硬质相承受载荷,而软质相起支撑硬质相的作用[18]。在摩擦过程中,硬质相发生接触和相对滑动,由于材料的蠕变特性,硬质相陷入软基体中,使更多硬质相承载,达到载荷均匀分布的效果,摩擦系数保持在0.2563~0.2885之间,数值较小,表明与铁基材料摩擦时有良好的减摩特性。

互溶性大的材料黏着倾向大,即相同金属或晶格类型、晶间间距、电子密度、电化学能相近的金属之间更容易发生黏着[19]。由于试样SL1表面Fe元素含量高,并且富Fe的k相以树枝状和球状团聚在一起(见图2A-A),与Fe基对摩件互溶性大,在摩擦过程中易与对摩件产生黏着、焊合,摩擦磨损形式以黏着磨损为主,摩擦因数较大。由SL1、SL2、OC至SL3,试样表面的Fe元素逐渐降低,形成k相数目渐少,使这种黏着机制作用减小,摩擦因数也随之减小。

图4 涂层磨损量及摩擦因数

Fig. 4 Friction coefficients and wear loss of coatings

图5 分割层的磨痕形貌

Fig. 5 SEM images of wear scar of coatings

图6 磨损表面的磨屑形貌

Fig. 6 SEM images of wearing debris on worn surface

表3 磨损前、后喷焊层与磨屑的化学成分

Table 3 Chemical composition of coatings before and after wearing and wearing debris

另外,据经典磨损理论认为,硬度可以用来衡量材料的耐磨性能[20]。在本次试验中发现硬度较低的SL3在相同条件下磨损量最小,如图4中磨损量曲线所示,与摩擦学理论相悖。SL1中富Fe 的k相组织以粗大树枝状和球状团聚在一起,极易与对摩件产生黏着。与SL1相比,SL2中Fe元素的含量略低,k相分布更均匀且由粗大树枝状向细小点状分布转变,增强了其抵抗黏着的能力。在循环应力作用下,硬质k 相 “断裂”或脱离喷焊层表面形成大块粗厚、有尖锐的棱角磨屑,如图6(b)所示。摩擦过程中磨屑对涂层表面进一步微观切削,表面光滑且剥落凹坑较少,如图5(b)所示。试样SL3表层中k相由粗大树枝状向细小树枝状和粒状组织转变。同时具备硬度高和韧性良好的特性,裂纹失稳扩展时,裂纹扩展受到阻碍作用,导致磨损过程中产生的显微裂纹不易扩展[21]。局部接触产生的疲劳层经剥落、碾压及氧化,形成具有明显塑性变形的磨屑,如图6(c)所示。喷焊层磨损表面光滑,磨损形式以磨粒磨损为主。如图4所示,SL1、SL2、SL3的磨损量逐渐降低,而OC的磨损量较SL3的略微增加。其原因如下:一方面,在喷焊层形成过程中,从SL1、SL2、SL3变化到OC,Fe元素含量先减小后增加,导致k相含量在SL2与OC喷焊层之间最低。根据组织相容性,在高比压力和摩擦热的作用下Fe含量较高的组织更容易与铁基对摩件黏着,形成焊合点[22]。另一方面,空气强对流冷却作用使靠近喷焊层表面的k相组织细化,k相颗粒之间间距增大,对磨件产生黏着磨损的几率降低。磨屑EDS元素点扫描结果表明,试样SLI、SL2与OC磨损表面黏着物主要为富铁k相,而试样SL3磨损表面与磨损前喷焊层的Fe元素含量几乎相同,进一步说明试样SL3的黏着磨损得到抑制。

3 结论

1) 45钢基体高铝青铜分层切割层组织均由α+β′+k+γ2相组成。受喷焊层内部热传输和界面元素扩散的影响,随分隔层位置从基体到喷焊层纵深方向距离的增加,Fe元素的扩散作用逐渐减弱,在4 mm 处Fe元素含量最低,喷焊层中k相体积分数在4 mm处达到最小值。

2) 靠近基材的喷焊层组织中Fe元素较高,且富Fe的k相组织呈粗大树枝状分布,增加了喷焊层与对摩件的组织相容性,磨损机制以严重黏着磨损为主。随分隔层位置从基体到喷焊层纵深方向距离增加,喷焊层中Fe元素的含量下降,并且向点状、细小树枝状转变。k相分布间距增大,抑制了黏着磨损,距界4 mm处喷焊层的耐磨性能最好。

REFERENCES

[1] 任 辉. 冲压模具精加工过程控制浅析[J]. 装备制造技术, 2010(7): 161-162.

REN Hui. Analyze of finish cutting technology of punching die[J]. Equipment Manufacturing Technology, 2010(7): 161-162.

[2] 万义群, 彭智虎. 汽车镶块式组合模具TD覆层处理容易出现的问题及其解决方法[J]. 模具制造, 2010, 10(12): 86-88.

WAN Yi-qun, PENG Zhi-hu. Problems and solutions of TD cladding processing for the car mold with combined insert blocks[J]. Die & Mould Manufacture, 2010, 10(12): 86-88.

[3] 李文生, 路 阳, 彭欢先, 刘 华, 白创明. 挤压不锈钢用高铝青铜合金模具材料[J]. 有色金属, 2004, 56(2): 15-18.

LI Wen-sheng, LU Yang, PENG Huan-xian, LIU Hua, BAI Chuang-ming. New aluminum bronze for stainless steel squeezing mould[J]. Nonferrous Metals, 2004, 56(2): 15-18.

[4] 李文生, 王智平, 路 阳, 袁利华, 徐建林, 魏迪生. 高铝青铜Cu-14Al-X合金在3.5%NaCl溶液中的腐蚀行为[J]. 中国有色金属学报, 2006, 16(3): 511-517.

LI Wen-sheng, WANG Zhi-ping, LU Yang, YUAN Li-hua, XU Jian-lin, WEI Di-sheng. Corrosion behavior of Cu-14Al-X bronze alloy in 3.5%NaCl solution[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 511-517.

[5] LI W S, WANG Z P, LU Y, JIN Y H, YUAN L H, WANG F. Mechanical and tribological properties of a novel aluminum bronze material for drawing dies[J]. Wear, 2006, 261(2): 155-163.

[6] LI Wen-sheng, LIU Yi, WANG Zhi-ping, Chao MA, WANG Shun-cai. Effects of Ce in novel bronze and its plasma sprayed coating[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2139-2145.

[7] ROSOCHOWSK A, MATUSZAK A. Rapid tooling: the state of the art[J]. Journal of Materials Processing Technology, 2000, 106(1/3): 191-198.

[8] 李文生, 刘 毅, 王智平, 路 阳. Cu14Al4.5FeNiCe等离子喷焊层组织及摩擦学特性[J]. 焊接学报, 2011, 32(11): 19-20.

LI Wen-sheng, LIU Yi, WANG Zhi-ping, LU Yang. Microstructure and wear behavior of plasma spray welded Cu14Al4.5FeNi coatings[J]. Transactions of the China Welding Institution, 2011, 32(11): 19-20.

[9] 路 阳, 张 鹤, 苏义祥, 李文生, 卢 凯, 张思成. 铁对铸态高铝青铜组织和性能的影响[J]. 铸造, 2007, 56(2): 199-201.

LU Yang, ZHANG He, SU Yi-xiang, LI Wen-sheng, LU kai, ZHANG Si-cheng. Effect of iron on as-cast high aluminum bronze’s microstructure and properties[J]. Foundry, 2007, 56(2): 199-201.

[10] 路 阳, 李国全, 田国庆, 袁柯祥, 李文生. 铝青铜合金粉末涂层制备中Fe元素的扩散特性[J]. 兰州理工大学学报, 2009, 35(6): 1-4.

LU Yang, LI Guo-quan, TIAN Guo-qing, YUAN Ke-xiang, LI Wen-sheng. Dispersion characteristics of element Fe in preparation of aluminum bronze alloy powder coating[J]. Journal of Lanzhou University of Technology, 2009, 35(6): 1-4.

[11] 李文生, 姜 洁, 王智平, 路 阳. 高铝青铜Cu-14%Al-X合金的气孔及消除方法[J]. 铸造, 2003, 52(9): 682-686.

LI Wen-sheng, JIANG Jie, WANG Zhi-ping, LU Yang. Causes and preventive measures of the gas holes in the Cu-14%Al-X bronze castings[J]. Foundry, 2003, 52(9): 682-686.

[12] 王智平, 路 阳, 李文生. 多元铝青铜粉末及其制备方法: 中国, CN200910021904.1[P]. 2009-03-20.

WANG Zhi-ping, LU Yang, LI Wen-sheng. Multiple aluminum bronze powder and its preparation method: China, CN200910021904.1[P]. 2009-03-20.

[13] 李文生, 王大锋, 董洪峰, 褚 克. 高铝青铜等离子喷焊层组织及其形成过程[J]. 材料科学与工艺, 2013, 21(6): 97-103.

LI Wen-sheng, WANG Da-feng, DONG Hong-feng, CHU Ke. Microstructure and forming process of high-aluminum bronze plasma spray welding coating[J]. Materials Science and Technology, 2013, 21(6): 97-103.

[14] 李文生, 王大锋, 董洪峰, 褚 克, 徐尔东, 王 爽. 高铝青铜等离子喷焊层的组织及界面性能[J]. 中国有色金属学报, 2013, 23(7): 1944-1953.

LI Wen-sheng, WANG Da-feng, DONG Hong-feng, CHU Ke, XU Er-dong, WANG Shuang. Microstructure and interface properties of plasma spray welded high Al bronze coating[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1944-1953.

[15] 陈 辉, 苟国庆, 涂铭旌. 喷涂工艺对Fe-Ni-B喷涂涂层组织性能的影响[J]. 材料科学与工艺, 18(1): 145-148.

CHEN Hui, GOU Guo-qing, TU Ming-jing. Effect of thermal spray process on microstructure and properties of Fe-Ni-B coating[J]. Materials Science and Technology, 18(1): 145-148.

[16] 《铸造有色合金及其熔炼》 联合编写组. 铸造有色合金及其熔炼[M]. 北京: 国防工业出版社, 1980: 151-157.

Joint Compiling Group of Casting Nonferrous Alloy and Its Smelting. Casting nonferrous alloy and its smelting[M]. Beijing: National Defence Industry Press, 1980: 151-157.

[17] LI Yuan-yuan, ZHANG Datung, NGAI Tungwai Leo, XIA Wei, LONG Yan. Diffusion couple between a high strength wear-resisting aluminum bronze and machining tools materials[J]. Transactions of Nonferrous Metals Society of China, 1999, 9 (1): 6-10.

[18] 林高用, 曾菊花, 王 莉. 新型Cu-Al-Fe-Ni变形铝青铜的固溶和时效强化[J]. 中国有色金属学报, 2012, 22(6): 1586-1593.

LIN Gao-yong, ZENG Ju-hua, WANG Li. Solution and aging strengthening of novel Cu-AI-Fe-Ni wrought aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1586-1593.

[19] 李元元, 夏 伟, 张 文, 罗宗强. 高强度耐磨铝青铜合金及其摩擦学特性[J]. 中国有色金属学报, 1996, 6(3): 76-80.

LI Yuan-yuan, XIA Wei, ZHANG Wen, LUO Zong-qiang. Strong and wear-resist aluminium-bronze alloy and its tribological characteristics[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(3): 76-80.

[20] LI Y, NGAI T L, XIA W. Mechanical, friction and wear behaviors of a novel high-strength wear-resisting aluminum bronze[J]. Wear, 1996, 197(1): 130-136.

[21] 周科朝, 黄伯云, 曲选辉, 贺跃辉. TiAl基金属间化合物的显微组织与断裂韧性[J]. 中国有色金属学报, 1996, 6(3): 111-114.

ZHOU Ke-chao, HUANG Bai-yun, QU Xuan-hui, HE Yue-hui. Fine microstructures and fracture toughness of tial-based alloy[J]. The Chinese Journal of Nonferrous Metals, 1996, 6 (3): 111-114.

[22] 杨效田, 王智平, 路 阳, 李 霞, 周晶晶. 高铝铜合金粗粉超音速等离子喷涂层的边界润滑摩擦特性[J]. 中国有色金属学报, 2012, 22(11): 3100-3106.

YANG Xiao-tian, WANG Zhi-ping, LU Yang, LI Xia, ZHOU Jing-jing. Boundary lubrication tribological property of high-aluminium copper alloy coarse powders coating made by supersonic plasma spraying[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3100-3106.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51165021);甘肃省杰出青年基金资助项目(1111RJDA013);甘肃省高校科研基金资助项目(01-0506);中国科学院西部之光计划资助项目(2012180)

收稿日期:2014-05-27;修订日期:2014-09-18

通信作者:李文生,教授,博士;电话:0931-2976640;E-mail:Wensheng-li@sohu.com