双态组织Ti-6Al-2Zr-1Mo-1V合金的热拉伸变形行为与球化机理

来源期刊:中国有色金属学报(英文版)2018年第12期

论文作者:赵慧俊 王宝雨 巨东英 陈国金

文章页码:2449 - 2459

关键词:钛合金;双态组织;变形行为;球化机理;断口形貌

Key words:titanium alloy; bimodal microstructure; deformation behavior; globularization mechanism; fracture morphology

摘 要:通过等温拉伸实验研究双态组织Ti-6Al-2Zr-1Mo-1V合金的热变形行为、显微组织演变与断裂特征。结果表明:材料的流动软化由双态组织动态球化引起,并导致较高的应力指数和热激活能。结合SEM、EBSD和TEM显微组织观察发现,750 和800 °C下动态球化由α/α亚晶界的形成与β相的渗透共同导致;而在850 °C下由于低角度晶界向高角度晶界转化,生成呈项链状分布的细小晶粒,证明该温度下主要的球化机制为动态再结晶。随着变形温度的升高或应变速率的减小,合金的断裂机制由微孔聚集向沿晶断裂转变。

Abstract: The hot deformation behavior, microstructure evolution and fracture characteristics of bimodal microstructured Ti-6Al-2Zr-1Mo-1V alloy were investigated by isothermal tensile tests. Results reveal that flow softening is caused by dynamic globularization of the bimodal microstructure, which also results in a relatively high stress exponent and thermal activation energy. The corresponding SEM, EBSD and TEM observations indicate that the dynamic globularization at 750 and 800 °C is accomplished by the formation of α/α sub-grain boundary and penetration of the β phase. However, dynamic recrystallization (DRX) is the main globularization mechanism at 850 °C, which was proved by the generation of fine grains with a necklace-like character due to the transformation of low-angle boundaries (LABs) into high-angle boundaries (HABs). With an increase in the deformation temperature or a decrease in the strain rate, the fracture mechanism changes from microvoid coalescence to intergranular fracture.

Trans. Nonferrous Met. Soc. China 28(2018) 2449-2459

Hui-jun ZHAO1,2, Bao-yu WANG3, Dong-ying JU2, Guo-jin CHEN1

1. School of Mechanical Engineering, Hangzhou Dianzi University, Hangzhou 310018, China;

2. Advanced Science Institute, Saitama Institute of Technology, Fukaya 3690293, Japan;

3. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 25 October 2017; accepted 24 April 2018

Abstract: The hot deformation behavior, microstructure evolution and fracture characteristics of bimodal microstructured Ti-6Al-2Zr-1Mo-1V alloy were investigated by isothermal tensile tests. Results reveal that flow softening is caused by dynamic globularization of the bimodal microstructure, which also results in a relatively high stress exponent and thermal activation energy. The corresponding SEM, EBSD and TEM observations indicate that the dynamic globularization at 750 and 800 °C is accomplished by the formation of α/α sub-grain boundary and penetration of the β phase. However, dynamic recrystallization (DRX) is the main globularization mechanism at 850 °C, which was proved by the generation of fine grains with a necklace-like character due to the transformation of low-angle boundaries (LABs) into high-angle boundaries (HABs). With an increase in the deformation temperature or a decrease in the strain rate, the fracture mechanism changes from microvoid coalescence to intergranular fracture.

Key words: titanium alloy; bimodal microstructure; deformation behavior; globularization mechanism; fracture morphology

1 Introduction

Ti-6Al-2Zr-1Mo-1V alloy, also known as TA15 alloy, has been widely used in manufacturing structural parts in the aerospace industry because of its excellent high-temperature strength, weldability and thermal stability [1,2]. In general, there are several typical microstructures in TA15 alloys, such as lamellar, equiaxed and bimodal microstructures.

Many researchers have reported the flow softening mechanism of titanium alloys with lamellar microstructures [3-7]. It was attributed to bending/ kinking and dynamic globularization of lamellar α phase [3]. DONG et al [4] suggested that dynamic recrystallization and mechanical twin resulted in flow softening of titanium alloys with lamellar microstructure. SEMIATIN et al [5] concluded that the deformation of lamellar microstructured Ti-6Al-4V alloy was controlled by dislocation glide/climb processes, which was also observed by SONG et al [6]. Moreover, ZHAO et al [7] mentioned that flow softening was caused by the formation of macroscopic adiabatic shear bands. For initially equiaxed microstructures, flow softening was attributed to dynamic recrystallization in α phases and dynamic recovery in β phases [8,9]. In addition, an increase in mobile dislocation was an important consideration for flow softening of equiaxed micro- structured TA15 alloy, as reported by FAN et al [10]. ZENG et al [11] mentioned that the change in texture may also result in flow softening. However, the previous studies were mainly concentrated on titanium alloys with fully lamellar or fully equiaxed microstructures, and the hot deformation mechanism of bimodal microstructured titanium alloys has not been widely studied.

In the present study, the as-received TA15 sheets were subjected to vacuum annealing to obtain a bimodal microstructure. Then, the hot tensile deformation behavior of bimodal microstructured TA15 alloy was studied by isothermal tensile tests. The microstructural observations and quantitative analyses were used to investigate the dynamic globularization mechanism. The effects of deformation parameters on the fracture characteristics were discussed. The results can provide a basis for controlling the mechanical properties of titanium alloys with bimodal microstructures.

2 Experimental

2.1 Material details

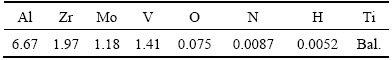

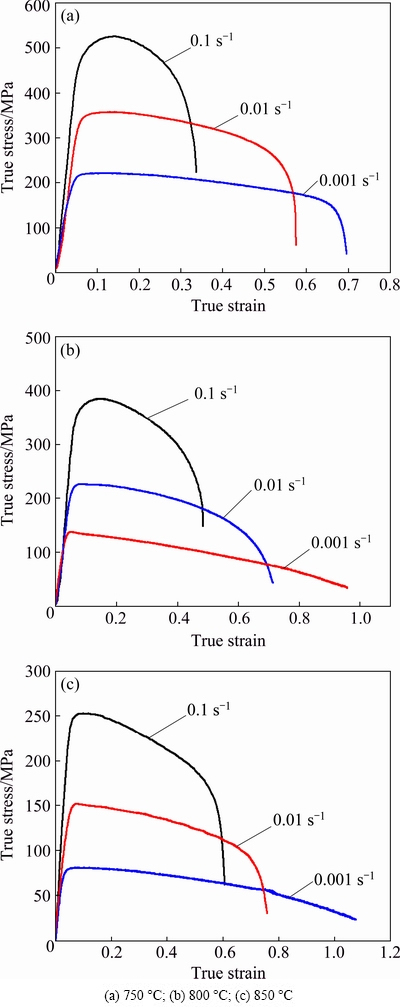

The material used in the present work was cold-rolled TA15 alloy sheet with the chemical compositions listed in Table 1. The β-transus temperature of the TA15 alloy is 990 °C.

Table 1 Chemical composition of as-received TA15 sheets (mass fraction, %)

2.2 Heat treatment

To obtain a bimodal microstructure, the as-received material was subjected to dual-annealing under vacuum. The specimens used for vacuum annealing were sealed in quartz glass tubes with a vacuum degree of 10 Pa. Firstly, the specimens were heated to 950 °C at a rate of 20 °C/s, held for 2 h and air-cooled. Then, the specimens were re-heated to 600 °C at a rate of 20 °C/s, held for 2 h and air-cooled.

The initial microstructure of the as-received TA15 sheets was an equiaxed microstructure consisting of α phase and β phase, and some grains were elongated in the rolling process, as shown in Fig. 1(a). After the heat treatment, a typical bimodal microstructure containing equiaxed α phase and lamellar β-transformed matrix (covered with secondary α lamellae and β lamellae) was obtained (Fig. 1(b)).

Fig. 1 SEM images of microstructures of TA15 sheets

2.3 Isothermal hot tensile test

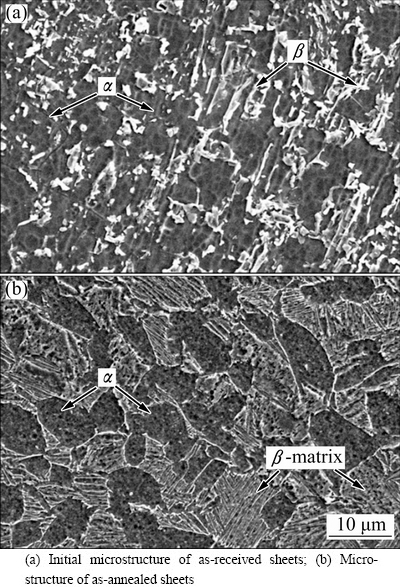

Isothermal tensile tests were carried out on a DDL50 computer-controlled universal testing machine with a heating device. The dimensions of the specimens are illustrated in Fig. 2. Prior to the tests, all specimens were coated with the high-temperature antioxidant Ti2 after heat treatment. Each specimen was heated to a given deformation temperature and held for 3 min to ensure a homogeneous temperature distribution. The deformation temperatures were 750, 800 and 850 °C. In addition, the strain rates were 0.001, 0.01 and 0.1 s-1. Firstly, the specimens were stretched to fracture at the aforementioned temperatures and strain rates. Then, hot tensile tests at different deformation amounts (30% and 60% of the fracture strains) were carried out. The deformed specimens were cooled in air after deformation.

Fig. 2 Dimensions of tensile specimens (unit: mm)

After the tensile tests, cross-sections of the deformed specimens were used for microstructural analysis. The microstructure evolution mechanisms of the studied alloy were investigated by scanning electron microscopy (SEM), electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). The globularization fractions were estimated using SEM images by a quantitative metallographic image analysis system (Image-Pro Plus), and the α phase with an aspect ratio (length/width ratio) lower than 2:1 was considered to be globular. The fractographs of the cracked specimens were also analyzed using SEM.

3 Results and discussion

3.1 Deformation behavior and microstructure evolution

3.1.1 Hot tensile behavior characteristics

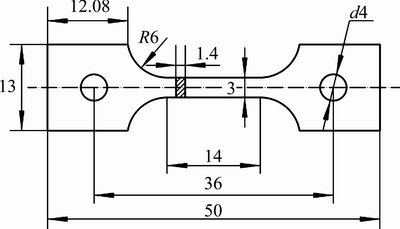

The tensile true stress-true strain curves of TA15 alloy under different deformation conditions are shown in Fig. 3. Clearly, the hot tensile deformation of the studied alloy was a competitive process among strain hardening, dynamic softening and ductile damage. The deformation behavior was strongly dependent on the deformation temperature and strain rate, and the flow stress decreased with a decrease in strain rate and an increase in deformation temperature.

Fig. 3 True stress-true strain curves of TA15 alloy at different deformation temperatures

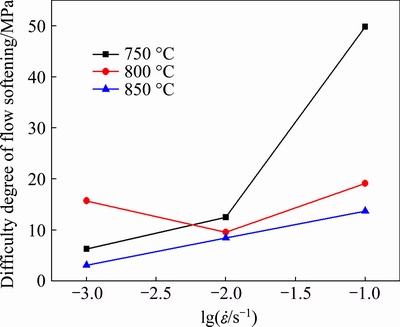

To investigate the effects of the deformation parameters on flow softening, the relationship between the difficulty degree of flow softening [12] (Δσ=σp-σs, here σp is peak stress and σs is the flow stress when true strain is 0.25) and the deformation parameters is shown in Fig. 4. The value of Δσ reflects the difficulty degree of the material from the work hardening stage to the flow softening stage, i.e. the smaller the Δσ is, the easier the flow softening is. As shown in Fig. 4, the effect of the deformation temperature on the difficulty degree of flow softening was more obvious when the strain rate was greater than 0.01 s-1, and it became weaker with increasing deformation temperature. Meanwhile, the effect of the strain rate on the difficulty degree of flow softening was more apparent at deformation temperatures equal to or lower than 800 °C. Furthermore, the maximum Δσ appeared at a deformation temperature of 750 °C and a strain rate of 0.1 s-1.

Fig. 4 Difficulty degree of flow softening under different deformation conditions

3.1.2 Dynamic globularization

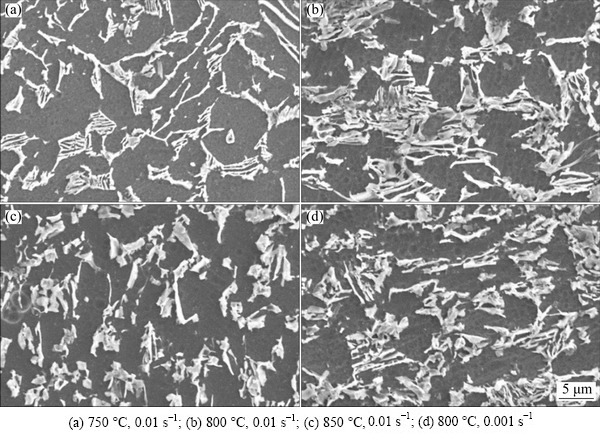

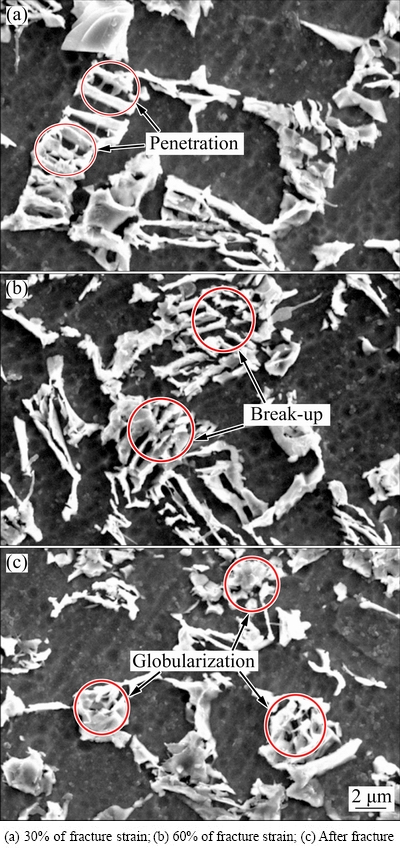

Figure 5 shows SEM images of the microstructures under different deformation conditions. As a result, the microstructure evolution reveals the dynamic globularization of the bimodal microstructured TA15 alloy during the hot tensile deformation. The magnified micrographs of the microstructures at different degrees of deformation illustrate the dynamic globularization process, as shown in Fig. 6. It can be found that the α phase was separated by the penetration of the β phase at lower deformation amounts (Fig. 6(a)). Then, the α laths and β laths within the colonies were bent, kinked and even broken up as further deformation occurred (Fig. 6(b)), which was favorable for dynamic globularization of titanium alloy with transformed β microstructures during hot deformation [13]. Therefore, globular microstructures were eventually formed via diffusion at greater degrees of deformation (Fig. 6(c)). Moreover, dynamic globularization was more obvious with increasing deformation temperature and decreasing strain rate. For instance, the microstructures were more broken and globular at a higher temperature of 850 °C (Fig. 5(c)) and a lower strain rate of 0.001 s-1 (Fig. 5(d)).

Fig. 5 SEM images of microstructures under different deformation conditions

Fig. 6 SEM images of microstructures with different degrees of deformation at 800 °C and 0.01 s-1

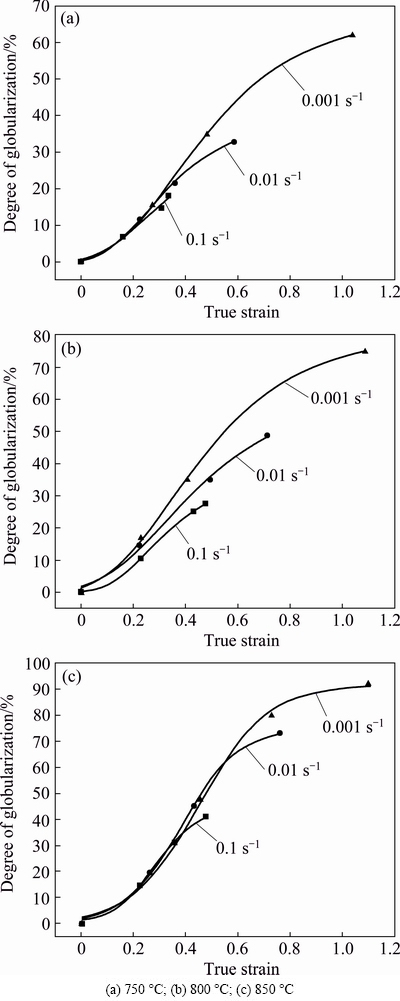

The globularization curves obtained by Image-Pro Plus are illustrated in Fig. 7. The curves appear as S-curves, which indicate that the globularization evolution is a thermal activation process. There was an incubation stage at the beginning of the deformation, after which the globularization rate rapidly increased once the strain was above the critical strain, but it began to decrease gradually with further deformation. It was reported that a lower critical strain resulted from a finer lamellar α phase. For example, the critical strain of the TA15 alloy with a lamellar thickness of 1 μm was 0.2-0.4 [14], and the critical strain of the TC11 alloy with a lamellar thickness of 2.5 μm was 0.4-0.8 [15]. This feature is favored for the dynamic globularization of titanium alloy. As shown in Fig. 7, the critical strain of the studied alloy was within 0.1 due to the relatively small average lamellar thickness of 0.43 μm.

3.2 Globularization mechanism

3.2.1 Thermal activation process

Generally, the hot deformation of metal materials is mainly controlled by a thermal activation process. The relationship between the flow stress and deformation parameters can be described using the Arrhenius equation (Eq. (1)):

(1)

(1)

where  is the strain rate, σ is the flow stress, n is the stress exponent, Q is the thermal activation energy, R is the mole gas constant, T is the deformation temperature, and A is a material constant.

is the strain rate, σ is the flow stress, n is the stress exponent, Q is the thermal activation energy, R is the mole gas constant, T is the deformation temperature, and A is a material constant.

Fig. 7 Globularization curves at different deformation temperatures

Equation (2) is obtained by taking natural logarithm of both sides of Eq. (1):

(2)

(2)

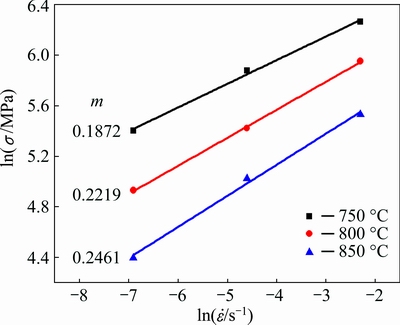

If the deformation temperature T is determined, the strain rate sensitivity coefficient (m) can be obtained by differentiating both sides of Eq. (2). Thus, m can be evaluated as the slope of ln σ-ln plot (Eq. (3)).

plot (Eq. (3)).

(3)

(3)

Figure 8 shows the effects of the deformation parameters on the strain rate sensitivity coefficient, which reflects the plastic deformation capabilities of the material. As shown in Fig. 8, the value of m increased with increasing deformation temperature. The flow softening occurred more easily and the plastic deformation capability of the alloy was enhanced, because the increase of deformation temperature accelerated the dislocation motion and annihilation. In addition, the value of m is less than 0.3 (above means superplasticity), so the deformation of the TA15 alloy under the current conditions is considered normal plastic deformation.

Fig. 8 Effects of deformation parameters on strain rate sensitivity coefficient

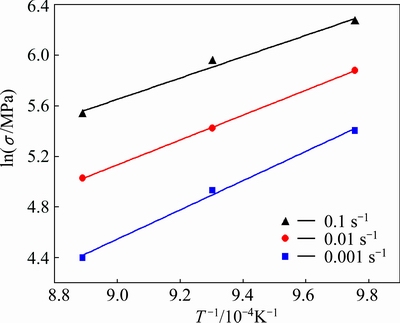

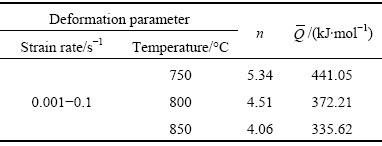

Meanwhile, when the strain rate  is determined, a linear relationship between ln σ and 1/T is shown in Fig. 9. Thus, the thermal activation energy can be obtained by Eq. (4):

is determined, a linear relationship between ln σ and 1/T is shown in Fig. 9. Thus, the thermal activation energy can be obtained by Eq. (4):

(4)

(4)

The stress exponent and the average thermal activation energy of the TA15 alloy under different deformation conditions are listed in Table 2. The thermal activation energy under the current deformation conditions is much higher than the self-diffusion activation energy of α-titanium (204 kJ/mol) [16] and β-titanium (153 kJ/mol) [17]. Meanwhile, the stress exponent is higher than n (3-4) [6,18] in a thermal deformation process controlled by typical diffusion and dislocation mechanism. This occurred because the bimodal microstructured TA15 alloy contained a mass of hard α lamellae and soft β lamellae, which caused the stress concentration and the globularization of α lamellae, increasing the stress exponent and thermal activation energy [6].

Fig. 9 Relationship between ln σ and 1/T at different strain rates

Table 2 Stress exponent and average thermal activation energy with different deformation parameters

However, the average thermal activation energy of TA15 alloy at 850 °C (335.62 kJ/mol) is in the range of the dislocation climb activation energy of α-titanium (200-360 kJ/mol) and close to the apparent deformation activation energy of α-titanium (346 kJ/mol) [6]. In addition, the stress exponent (4.06) at 850 °C is close to the range of 3-4 in the thermal deformation process controlled by a typical dislocation climb mechanism. Therefore, the deformation mechanism is different for bimodal microstructured TA15 alloy under the present deformation temperatures.

3.2.2 Effects of deformation temperature on globu- larization mechanism

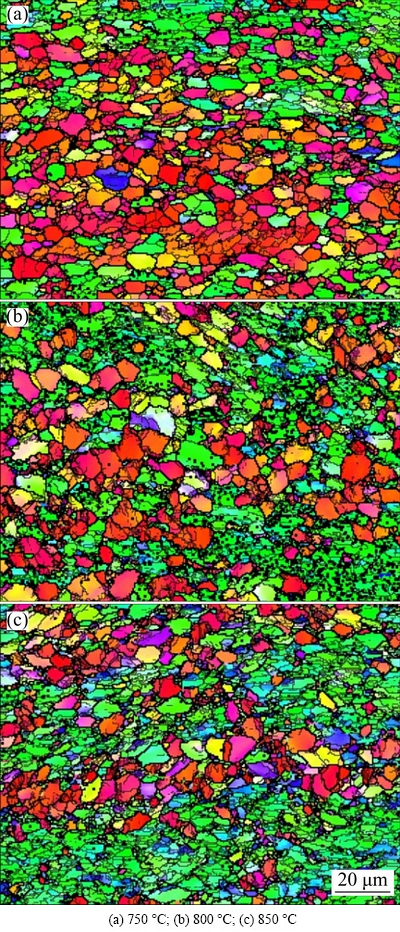

Figures 10 and 11 display EBSD images of the microstructures at deformation temperatures of 750-850 °C and a strain rate of 0.01 s-1. Figure 10 exhibits the crystal morphologies of the TA15 alloy under different deformation conditions. A small amount of globular grains were observed and concentrated in the upper and lower zones at 750 °C (Fig. 10(a)). At a higher temperature of 800 °C, the range of the globular grains was obviously increased (Fig. 10(b)). Furthermore, the dynamic globularization occurred more completely at 850 °C. It is worth mentioning that many very fine grains can be found around the original grains (Fig. 10(c)).

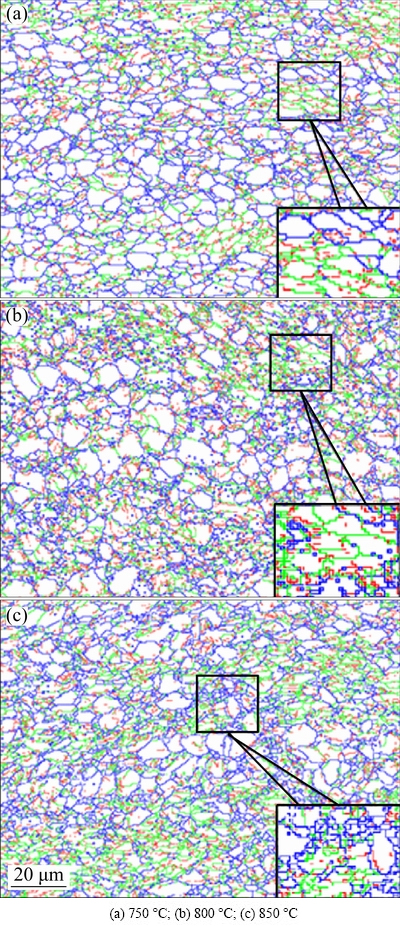

The corresponding grain boundaries and sub-grain boundaries are clearly shown in Fig. 11. The sub-grain boundaries are determined by the low-angle boundaries (LABs) with a misorientation between 2° and 15° (green lines), while the grain boundaries are determined by the high-angle boundaries (HABs) with a misorientation over 15° (blue lines). At a low temperature of 700 °C, the generated LABs were relatively sparse and primarily distributed in the upper and lower zones (Fig. 11(a)). With an increase in deformation temperature, the density of the LABs obviously increased at 800 °C (Fig. 11(b)). The LABs became denser and a mass of kinked HABs were generated at a higher temperature of 850 °C (Fig. 11(c)).

Fig. 10 Crystal morphologies of TA15 alloy at strain rate of 0.01 s-1 and different deformation temperatures

Fig. 11 Grain boundaries and sub-grain boundaries of TA15 alloy at strain rate of 0.01 s-1 and different deformation temperatures

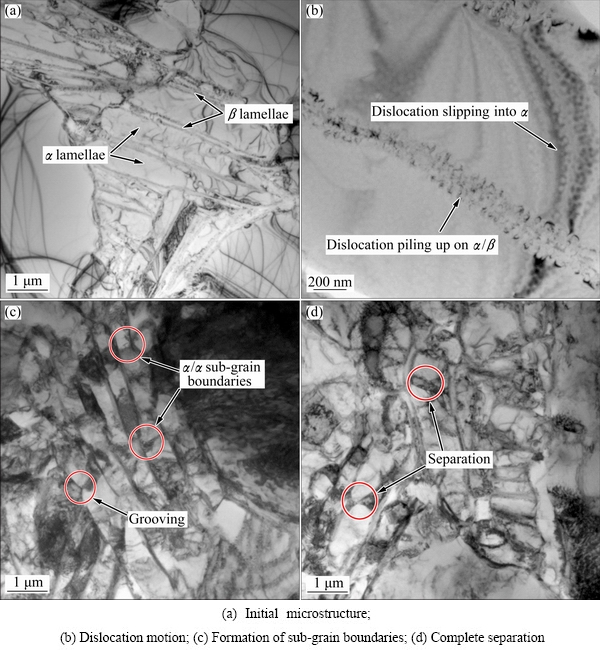

In addition, the magnified micrographs in Figs. 11(a) and (b) show that the lamellar grains were segmented by LABs generated in the grains, which were directly responsible for the dynamic globularization occurring at lower deformation temperatures of 750 and 800 °C. ZHEREBTSOV et al [19,20] identified two mechanisms of lamellar break-up in the globularization of α/β colonies during hot deformation of Ti-6Al-4V: one was associated with the α/α sub-grain boundaries within α lamellae, and the other was ascribed to the intense localized shear crossing the α lamellae. At present, the described lamellar break-up process for the bimodal structured TA15 alloy is illustrated in the TEM images shown in Fig. 12. The α and β lamellae were straight and smooth before deformation (Fig. 12(a)). Because the deformation occurred more easily on the soft β phase than on the hard α phase, the dislocations piled up along the α/β interfaces and slipped into α lamellae, forming α/α sub-grain boundaries with further deformation (Fig. 12(b)). A previous work [21] showed that 90° angle between the α/α boundaries and α/β interfaces was not possible because of the surface tension requirements. Therefore, the angles would be reduced, causing noticeable grooving (Fig. 12(c)), which provided a sufficient driving force for the penetration of β phase along the α/α boundaries, resulting in complete separation (Fig. 12(d)).

Apparently, the globularization mechanism is different at a higher deformation temperature of 850 °C from the magnified micrographs in Fig. 11(c). The kinked LABs and HABs were generated, forming fine grains around the original grains with a necklace-like character. This feature has been noted in many studies for dynamic recrystallization (DRX) [22,23]. As a result, the globularization of the studied alloy at 850 °C was more likely caused by DRX.

3.3 Fracture morphology analysis

3.3.1 Effects of deformation temperature on fracture morphology

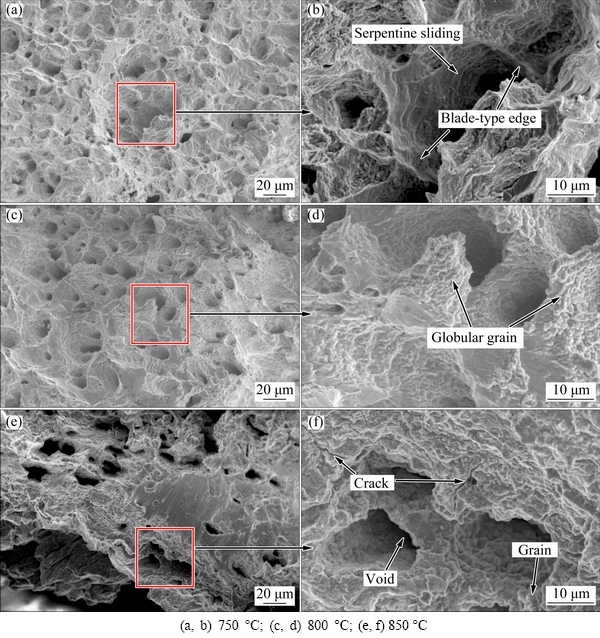

Figure 13 shows the fracture morphologies at deformation temperatures of 750-850 °C and a strain rate of 0.01 s-1. Thereinto, Figs. 13(b), (d) and (f) give the magnified micrographs denoted in Figs. 13(a), (c) and (e), respectively. The fracture surface was covered with many microscopic dimples and tearing edges at 750 °C (Fig. 13(a)). As shown in Fig. 13(b), the coalescence of dimples during deformation was proved by the blade-type edges on the walls of large dimples. In addition, the layered serpentine sliding was observed on the inner surfaces of dimples. It can be concluded that the material still experienced a certain degree of plastic deformation after the formation of dimples [24]. The results suggest that microvoid coalescence is the main fracture mechanism of the alloy at 750 °C.

The dimples and tearing edges on the fracture surface obviously decreased at 800 °C (Fig. 13(c)), and a large amount of globular grains were observed (Fig. 13(d)), which benefited the grain boundary sliding (GBS) [25]. The fracture mechanism of the material changed from microvoid coalescence to GBS with increasing deformation temperature.

The dimples and tearing edges can rarely be observed at 850 °C, while some large voids appeared on the fracture surface (Fig. 13(e)). Meanwhile, it can be seen that many grains, voids and cracks were distributed on the fracture surface from Fig. 13(f), showing the typical intergranular fracture morphology. More complete dynamic globularization promoted the occurrence of GBS at relatively high temperature. As a result, deformation was concentrated at the grain boundaries, and the growth and coalescence of microvoids were restricted. Once the local stress exceeded the grain boundary bonding strength at a certain deformation degree, intergranular fracture would occur.

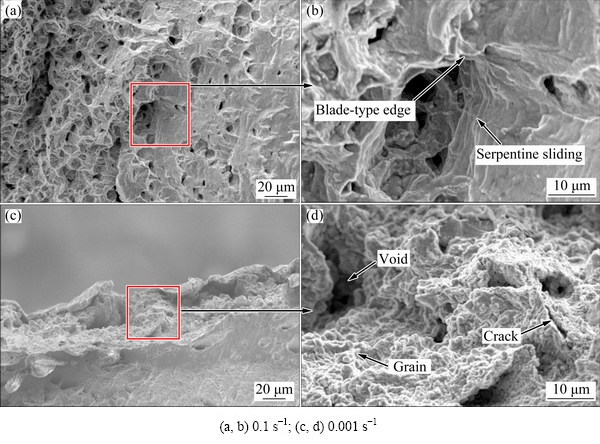

3.3.2 Effects of strain rate on fracture morphology

Figure 14 shows the fracture morphologies under the strain rates of 0.1 and 0.001 s-1 at 800 °C. Figures 14(b) and (d) give the magnified micrographs denoted in Figs. 14(a) and (c), respectively. The fracture surface was covered with many microscopic dimples and tearing edges (Fig. 14(a)). In addition, blade-type edges and serpentine sliding were observed on the walls of the coalescent dimples (Fig. 14(b)). As a result, the nucleation, growth and coalescence of microvoids led to the final fracture of specimens deformed at a strain rate of 0.1 s-1.

Fig. 12 TEM images of microstructures before and after deformation at 800 °C and 0.01 s-1

Similar to the previous analysis (Figs. 13(c) and (d)), GBS, not the microvoid coalescence, played a leading role in the fracture mechanism at a deformation temperature of 800 °C and a strain rate of 0.01 s-1. With decreasing strain rate, the fracture surface became cuspidal and thin at a lower strain rate of 0.001 s-1 (Fig. 14(c)), which suggested that the plastic deformation capability of the material was enhanced. A large amount of grains, voids and cracks were observed on the fracture surface (Fig. 14(d)), showing an obvious intergranular fracture characteristic, which was related to the occurrence of GBS and viscous glide [25]. These features were facilitated by more complete dynamic globularization at a lower strain rate of 0.001 s-1.

4 Conclusions

1) The flow softening of TA15 alloy with bimodal microstructure results from dynamic globularization. The critical strain of the alloy in the globularization process is within 0.1 due to a relatively small average lamellar thickness of 0.43 μm.

2) The stress exponent and thermal activation energy of bimodal microstructured TA15 alloy are relatively high. The dynamic globularization at 750 and 800 °C is accomplished by the formation of α/α sub-grain boundary and the penetration of the β phase.

3) Because of the transformation of LABs into HABs, increasing numbers of fine grains are generated around the original grains, forming a necklace-like character at 850 °C, which indicates that the main globularization mechanism is dynamic recrystallization.

Fig. 13 Fracture morphologies at strain rate of 0.01 s-1 and different deformation temperatures

Fig. 14 Fracture morphologies at deformation temperature of 800 °C and different strain rates

4) As the deformation temperature increases or the strain rate decreases, more complete dynamic globularization promotes the occurrence of grain boundary sliding, and the fracture mechanism develops from microvoid coalescence to intergranular fracture.

References

[1] FAN X G, YANG H, GAO P F, ZUO R, LEI P H, JI Z. Morphology transformation of primary strip α phase in hot working of two-phase titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 1294-1305.

[2] ZHAO H J, WANG B Y, LIU G, YANG L, XIAO W C. Effect of vacuum annealing on microstructure and mechanical properties of TA15 titanium alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1881-1888.

[3] LUO J, LI L, LI M Q. Deformation behavior of Ti-5Al-2Sn-2Zr- 4Mo-4Cr alloy with two initial microstructures during hot working [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 414-422.

[4] DONG X J, LU S Q, ZHENG H Z. Dynamic spheroidization kinetics behavior of Ti-6.5Al-2Zr-1Mo-1V alloy with lamellar micro- structure [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 1301-1309.

[5] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure [J]. Materials Science and Engineering A, 1999, 263: 257-271.

[6] SONG H W, ZHANG S H, CHENG M. Subtransus deformation mechanisms of TC11 titanium alloy with lamellar structure [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2168-2173.

[7] ZHAO Y L, LI B L, ZHU Z S, NIE Z R. The high temperature deformation behavior and microstructure of TC21 titanium alloy [J]. Materials Science and Engineering A, 2010, 527: 5360-5367.

[8] HUANG L J, GENG L, LI A B, CUI X P, LI H Z, WANG G S. Characteristics of hot compression behavior of Ti-6.5Al-3.5Mo- 1.5Zr-0.3Si alloy with an equiaxed microstructure [J]. Materials Science and Engineering A, 2009, 505: 136-143.

[9] ZONG Y Y, SHAN D B, XU M, LV Y. Flow softening and microstructural evolution of TC11 titanium alloy during hot deformation [J]. Journal of Materials Processing Technology, 2009, 209: 1988-1994.

[10] FAN X G, YANG H, GAO P F. The mechanism of flow softening in subtransus hot working of two-phase titanium alloy with equiaxed structure [J]. Chinese Science Bulletin, 2014, 59: 2859-2867.

[11] ZENG Z P, ZHANG Y S, JONSSON S. Deformation behaviour of commercially pure titanium during simple hot compression [J]. Materials and Design, 2009, 30: 3105-3111.

[12] PENG W W, ZENG W D, WANG Q J, ZHAO Q Y, YU H Q. Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of as-cast Ti60 titanium alloy [J]. Materials Science and Engineering A, 2014, 593: 16-23.

[13] SHELL E B, SEMIATIN S L. Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti-6Al-4V [J]. Metallurgical and Materials Transactions A, 1999, 30: 3219-3229.

[14] DONG X J. Research on plastic deformation characteristics and globularization in α+β phase region of TA15 alloy with lamellar structure [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2011. (in Chinese)

[15] SONG H W. Research and application on deformation mechanism in two-phase region of TC11 alloy with lamellar microstructure [D]. Shenyang: Graduate School of the Chinese Academy of Sciences, 2009. (in Chinese)

[16] BAO R Q, HUANG X, CAO C X. Deformation behavior and mechanisms of Ti-1023 alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 274-280.

[17] BALASUBRAHMANYAM V V, PRASAD Y V R K. Deformation behavior of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging [J]. Materials Science and Engineering A, 2002, 336: 150-158.

[18] CUI W F, JIN Z, GUO A H, ZHOU L. High temperature deformation behavior of α+β-type biomedical titanium alloy Ti-6Al-7Nb [J]. Materials Science and Engineering A, 2009, 499: 252-256.

[19] ZHEREBTSOV S, MURZINOVA M, SALISHCHEV G A, SEMIATIN S L. Spheroidization of the lamellar microstructure in Ti-6Al-4V alloy during warm deformation and annealing [J]. Acta Materialia, 2011, 59: 4138-4150.

[20] MIRONOV S, MURZINOVA M, ZHEREBTSOV S, SALISHCHEV G A, SEMIATIN S L. Microstructure evolution during warm working of Ti-6Al-4V with a colony-α microstructure [J]. Acta Materialia, 2009, 57: 2470-2481.

[21] YU Yang, XIONG Bai-qing, HUI Song-xiao, YE Wen-jun. Hot deformation behavior and globularization mechanism of Ti-6Al-4V-0.1B alloy with lamellar microstructure [J]. Rare Metals, 2013, 32(2): 122-128.

[22] MITSCHE S, SOMMITSCH C, HUBER D, STOCKINGER M, POELT P. Assessment of dynamic softening mechanisms in allvac 718plusTM by EBSD analysis [J]. Materials Science and Engineering A, 2011, 528: 3754-3760.

718plusTM by EBSD analysis [J]. Materials Science and Engineering A, 2011, 528: 3754-3760.

[23] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60 [J]. Acta Materialia, 2001, 49: 1199-1207.

[24] ZHOU M, LIN Y C, DENG J, JIANG Y Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy [J]. Materials and Design, 2014, 59: 141-150.

[25] LIN Y C, DENG J, JIANG Y Q, WEN D X, LIU G. Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy [J]. Materials and Design, 2014, 55: 949-957.

赵慧俊1,2,王宝雨3,巨东英2,陈国金1

1. 杭州电子科技大学 机械工程学院,杭州 310018;

2. Advanced Science Institute, Saitama Institute of Technology, Fukaya 3690293, Japan;

3. 北京科技大学 机械工程学院,北京 100083

摘 要:通过等温拉伸实验研究双态组织Ti-6Al-2Zr-1Mo-1V合金的热变形行为、显微组织演变与断裂特征。结果表明:材料的流动软化由双态组织动态球化引起,并导致较高的应力指数和热激活能。结合SEM、EBSD和TEM显微组织观察发现,750 和800 °C下动态球化由α/α亚晶界的形成与β相的渗透共同导致;而在850 °C下由于低角度晶界向高角度晶界转化,生成呈项链状分布的细小晶粒,证明该温度下主要的球化机制为动态再结晶。随着变形温度的升高或应变速率的减小,合金的断裂机制由微孔聚集向沿晶断裂转变。

关键词:钛合金;双态组织;变形行为;球化机理;断口形貌

(Edited by Wei-ping CHEN)

Foundation item: Project (LQ18E050007) supported by the Natural Science Foundation of Zhejiang Province, China; Project (20120006110017) supported by the Research Fund for the Doctoral Program of Higher Education, China

Corresponding author: Hui-jun ZHAO; Tel: +86-571-86919054; E-mail: zhaohuijun_ustb@126.com

DOI: 10.1016/S1003-6326(18)64891-5