预还原球团吸波性能及其微波加热煤基直接还原

黄柱成1,吴锴1,胡兵1,吕丽丽1,姜涛1,彭虎2

(1. 中南大学 资源加工与生物工程学院,湖南 长沙,410083;

2. 长沙隆泰微波热工有限公司,湖南 长沙,410013)

摘要:研究预还原球团在微波场中的升温特性,考察预还原球团微波加热中对直接还原的影响,分析铁氧化物煤基微波加热的还原行为。研究结果表明:预还原程度越高,球团中的Fe3O4含量逐渐减少,浮氏体和金属铁含量逐渐增多,对微波的吸收性能逐渐减弱,但是仍然具有较好的吸波能力。预还原球团金属化率越高,得到的海绵铁金属化率越高,在预还原球团金属化率为42.85%(质量分数),温度为1 000 ℃,还原时间为48 min,碳氧质量比为1.75:1时,海绵铁金属化率达到97.29%。随着还原反应的进行,铁氧化物的成分不断改变,金属铁颗粒呈星点状分布于浮氏体之间,但并不会形成致密金属壳,为还原反应中的气体交换创造良好的动力学条件。

关键词:微波加热;升温特性;预还原球团;直接还原

中图分类号:TF533 文献标志码:A 文章编号:1672-7207(2011)11-3232-06

Pre-reduced pellets’ temperature rising behavior and direct reduction by coal in microwave field

HUANG Zhu-cheng1, WU Kai1, HU Bin1, L? Li-li1, JIANG Tao1, PENG Hu2

(1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Changsha Syno-Therm Co. Ltd., Changsha 410013, China)

Abstracts: The temperature rising behavior of pre-reduced pellets was studied, and the effects of the reductive degree on the behaviors of direct reduction and the reduction behavior of the iron oxides by microwave heating were investigated. The results show that, the higher lever of the pre-reduced pellet, the less content of the Fe3O4. And then, the contents of wustite and Fe increase gradually. Meanwhile microwave-absorbed characteristics tapers off which still has some absorbing ability. The higher degree of the pre-reduced pellet, the higher the sponge iron metallization is. The mass ratio of C to O is 1.75:1, reduction time is 48 min, the degree of the pre-reduced pellet is 42.85%, and the sponge iron metallization is 97.29% at 1 000 ℃. With the reaction of the direct reduction, the content of iron oxides changes. Iron granules disperse around the austenitic instead of formation of dense metal shell, which will create favorable conditions during the gas exchange and improve kinetics conditions.

Key words: microwave heating; temperature rising behavior; pre-reduced pellet; direct reduction

微波是频率在0.3~300 GHz的电磁波,微波加热是物料在电磁场中将自身吸收的微波能转化为热能,是一种体加热[1]。不同的物料因其本身的性质不同而具有不同的升温特性[2-3],即微波加热的选择性。另外,微波加热还具有降低反应活化能、促进反应、影响晶型结构变化等“非热效应”[4-8]。国内外研究者对含 碳铁矿粉及含碳铁矿球团微波碳热还原方面进行了大量研究,研究表明:铁矿物对微波具有较强的吸收能力,而脉石矿物吸波能力较弱[9];微波加热可以克服传统加热中球团矿的“冷中心”问题[10];在内配碳直接还原过程中,磁铁矿易发生晶界热碎裂,金属铁和浮氏体间不存在中间过渡相,有利于增强碳及CO的扩散还原能力[11];微波加热有助于赤铁矿的还原,提高反应速度[12]。但是对氧化球团矿外配煤微波碳热还原的研究并不多见,而氧化球团强度高,更适宜竖炉工业化应用。在还原反应过程中,随着FeO的形成,进一步还原比较困难,从 FeO到Fe的还原过程是影响产率和能耗的重要环节,利用微波的快速加热可以在FeO还原时及时迅速提供大量热量。本文作者以预还原球团为原料,研究了不同还原程度的球团在微波场中的升温特性;并以煤为还原剂,研究了不同还原程度的球团在微波场中的还原行为。

1 实验

1.1 原料性能

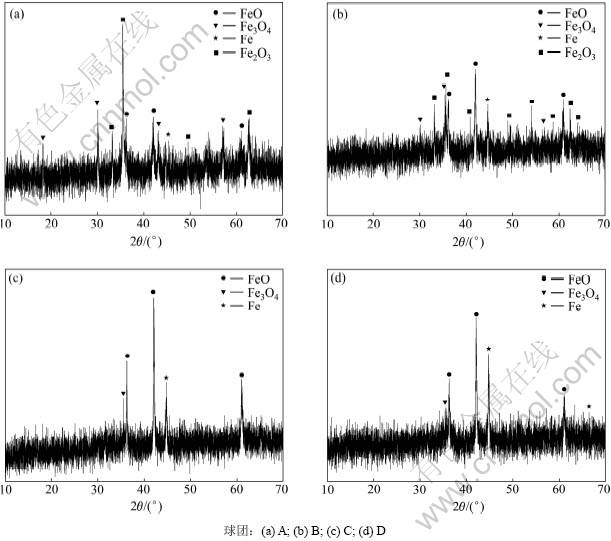

实验中所用的原料为氧化球团在半工业微波竖炉中相同条件下预还原后所得的A,B,C和D 4种预还原球团,其金属化率分别为15.03%,19.54%,38.69%和42.85%。4种预还原球团XRD衍射分析结果如图1所示。4种预还原球团的主要化学成分如表1所示。

从图1和表1可以看出:4种预还原球团所含的铁矿物中,铁氧化物主要以FeO和Fe3O4形式存 在。随着预还原球团金属化率的提高,Fe3O4的含量逐渐降低,FeO的含量逐渐增多;Fe2O3主要是以γ-Fe2O3形式存在,而且金属化率越高,γ-Fe2O3含量越低。SiO2和Al2O3的含量基本相同,在预还原过程中没有变化。4种预还原球团内均含有少量的碳。将4种球团的FeO和金属铁的含量结合在一起分别为53.63%,58.32%,76.13%和84.12%。

图1 球团A,B,C和D的XRD谱

Fig.1 XRD patterns of pre-reduced pellets A, B, C and D

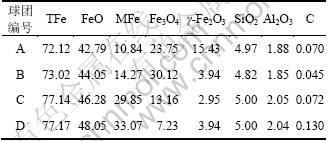

表1 预还原球团主要化学成分(质量分数)

Table 1 Chemical composition of pre-reduced pellets %

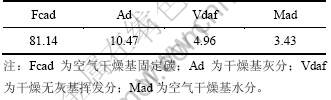

实验中所用的还原剂为无烟煤,其工业分析和粒度分布如表2和3所示。

表2 煤的工业分析(质量分数)

Table 2 Industrial analysis of anthracite %

表3 煤的粒度分布(质量分数)

Table 3 Size distribution of anthracite

从表2和3可以看出:无烟煤的固定碳含量较高,挥发分含量较低,为4.96%。无烟煤的粒度大部分小于3 mm。

1.2 实验设备

预还原球团在微波场中的升温特性采用MW-L0316V工业微波炉(微波频率为2.45 GHz,功率为3 kW(可调)),测温采用Raytek高精度红外测温仪。

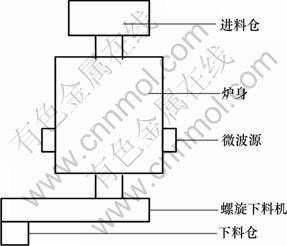

微波加热竖炉煤基还原设备采用长沙隆泰微波热工有限公司生产的AMV2连续式微波竖炉,微波频率为2.45 GHz,最大功率为13.5 kW,可调。试验装置示意图如图2所示。其中:进料仓采用双螺旋阀门控制;炉身上半部分没有安装微波源,在炉身下半部分的周围安装了若干组微波源,进行均匀辐射加热,并且可以进行联合控制,根据试验所需温度调节微波源的功率;在炉身的中段和下端高温区分别放置一个不锈钢热电偶,对炉体温度进行监控;通过螺旋下料机调控还原时间,并将还原出的球团进行冷却后运输至下料仓;下料仓同样采用双螺旋阀门控制,保持炉内球团与外界空气隔绝。

图2 AMV2连续式微波竖炉示意图

Fig.2 Schematic diagram of AMV2 continuously microwave shaft furnace

1.3 实验方法

在升温特性实验中,将4种预还原球团A,B,C和D及原矿各自取200 g分别装入由刚玉制成的坩埚(R=40 mm)中,将坩埚放入反应器,再将反应器放入微波炉中在常温下进行加热。实验开始前1 min控制微波输出功率为600 W,1 min后调整为1 500 W,记录升温时间及温度,直到预还原球团升温至1 050 ℃。

在连续式煤基竖炉微波加热直接还原实验时,将预还原球团与一定比例煤粉混合,通过进料斗进入料仓,然后在预热段被上升的热气流预热,进入还原段后,在微波源的辐射下,铁氧化物和配加的还原剂大量吸收微波能,快速升温,从而使还原剂与铁氧化物之间发生激烈的还原反应。直接还原后的海绵铁经冷却段沿着螺旋下料机至下料斗时在CO2的气氛中冷却至50 ℃以下,然后取样进行分析化验。

2 结果及讨论

2.1 预还原球团的升温特性

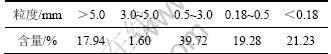

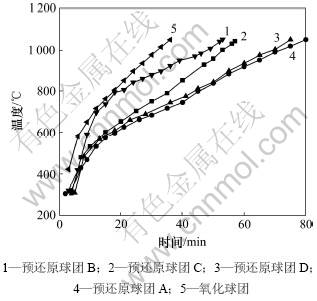

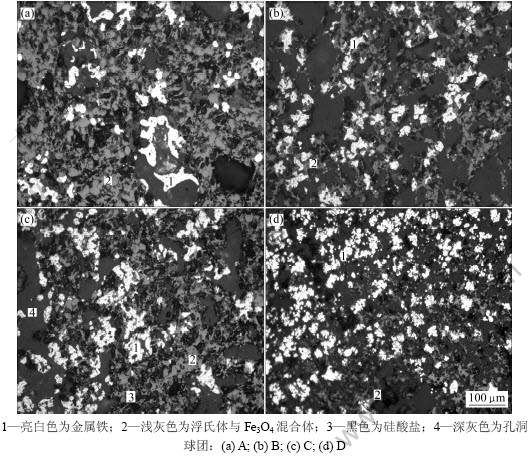

氧化球团以及A,B,C和D球团在微波加热中的升温曲线如图3所示。从图3可以看出:微波加热过程中,无论还原程度的高低,球团的升温曲线均呈现两段升温。分别为第1阶段近似于直线的快速升温和第2阶段的缓慢升温。另外,第1阶段直线升温的升温速度虽然差异不明显,但是也具有还原程度越高升温速率越低的趋势。从整个升温曲线来看,5种球团按还原程度的由低到高,从室温升到1 050 ℃所需的时间分别为35,54,57,75和80 min。这主要是因为:物料受到微波的辐射时会对微波产生反射、吸收和透过等作用。 物料对微波的吸收能力与物质本身的电阻率、复介电常数、复磁导率和介质损耗角正切等参数具有密切的关系[13],而物质的这些参数又由物质本身的晶体结构所决定。Fe2O3属于刚玉型结构的三方晶系,a=0.542 1 nm,是以金属键结合的晶体;Fe3O4常为八面体或者菱形十二面体,属于等轴晶系,其中,1/2的Fe3+填充正四面体空隙,Fe2+和另外1/2的Fe3+填充正八面体空隙,具有强磁性,是具有金属键-共价键的晶体;FeO属于立方晶系,属于离子键结合的离子晶体,存在杂质导电,介电常数和介电损耗都较低,对微波表现出非常弱的吸收能力。从化学结构上看,Fe3O4属于过渡键型的化合物,介电损耗因子较 大[14];并且,Fe3O4晶格中同时存在着Fe3+和Fe2+,形成非计量比的缺陷结构,产生偶极子,缺陷浓度增加,可以显著降低价带与导带间的能量差,提高其吸波升温性能[15]。Fe2O3具有金属键,对微波具有一定的吸收作用,因为具有金属键的矿物,存在电子导电,介电常数和介电损耗一般也较大[14]。事实上,Fe2O3刚开始吸波能力较弱,但在经过微波辐射一段时间后也会表现出较强的升温特性[16]。Fe具有很好的导电性,但是微波的透射深度很小,大部分微波会被反射[17]。A,B,C和D球团都属于预还原球团,其显微结构如图4所示。由图4可以看出:金属铁均以星点状分布在浮氏体及其他矿物之中金属铁颗粒小,结晶并不完善,且高度分散;同时,球团矿中孔隙高度发达,因此,微波吸收性能依然较好。A和B球团中含有较多的Fe3O4,C和D球团中的Fe3O4含量都较少;而且4种预还原球团中浮氏体以及金属铁总共含量依次增多。因此,A和B球团升温速度大于C和D球团。可以得出,预还原程度越高,浮氏体及金属铁总含量越高,Fe3O4含量越低,对微波的吸收性能越弱,但是依然对微波有一定的吸收性能。

图3 还原球团微波场中升温曲线

Fig.3 Temperature curves of pre-reduced pellets by microwave

图4 球团A,B,C和D的显微结构

Fig.4 Microstructures of pre-reduced pellets A, B, C and D

2.2 预还原程度对直接还原的影响

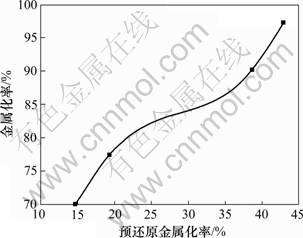

将4种预还原球团矿分别在电机转速为800 r/min(还原时间为48 min)、碳氧质量比为1.75:1,控制微波功率使高温还原段的温度保持在1 000 ℃左右的条件下进行还原反应后所得金属化率与预还原球团还原程度的关系如图5所示。

图5 预还原程度对微波加热还原的影响

Fig.5 Effects of pre-reduced degree on microwave reduction

从图5可以看出:随着预还原球团还原程度的提高,在相同的工艺条件下,微波加热还原预还原球团的金属化率越高,而当预还原球团的金属化率大于25%后,最终生成的海绵铁金属化率提高的幅度降低。这可能是因为,预还原球团还原程度低时,球团表面的金属铁颗粒非常少;而且相对来说,球团内的Fe3O4和浮氏体的含量较多,对微波的吸收能力较强,可以为直接还原迅速的提供热量,保证直接还原快速进行,因此,金属化率迅速提高。而随着球团预还原程度的提高,Fe3O4含量随着预还原程度的提高也逐渐减小,相反,FeO和Fe的含量逐渐升高,对微波的吸收能力有了一定程度上的减弱,此时微波的热效应就会下降,因此,最终生成的海绵铁金属化率提高的幅度逐渐降低。当预还原球团的金属化率大于33%后,海绵铁的金属化率又快速增加,在预还原金属化率为42.85%时,最终生成海绵铁的金属化率达到97%以上。这可能是因为预还原球团中金属铁颗粒虽然较多,但是都是以星点状分布于浮氏体中而没有形成金属壳,对微波仍然具有一定的吸收性能;另外,随着预还原程度的进一步提高,球团表面至球团内部产生了非常丰富的孔隙,为微波吸收提供了坚实的基础,同时提高了还原气体扩散的速度和反应速率。

2.3 预还原球团微波场中直接还原过程分析

预还原球团中只含有少量氧化铁,其主要含有Fe3O4,FeO和Fe。当温度大于843 K时,还原反应按照下列过程分步进行的:

Fe3O4→FeO→Fe

还原过程中的相变会使物料本身的电磁性能发生变化,从而改变微波加热的热效应。

碳是一种非常强的微波吸收物质,在微波的辐射下,碳的活性增大[18],布多尔反应不会像常规加热那样成为限制环节,因此,在还原初期,球团对微波的吸收性能最强,还原反应非常迅速,球团金属化率迅速提高。而当反应进行到一定程度的时候,金属铁颗粒开始在表面析出,呈星点状分布于表面,在一定程度上影响甚至削弱了对微波的吸收;另外,随着还原反应的进行,球团内部的物质组成也逐渐改变。随着反应的进行,球团中Fe3O4的含量逐渐减少,浮氏体含量增多,球团对微波的吸收能力也会下降,因此,微波的热效应有所下降,还原反应速度降低。但是,由于微波场中球团还原速度较快,气体的迅速交换使球团的表面产生丰富的孔隙,为微波加热提供热点,改善了还原反应的动力学条件。另外,虽然球团本身对微波的吸收性能下降,但是仍然具有较好的吸波性能,使还原反应高效快速的进行。

3 结论

(1) 氧化球团在还原过程中随着Fe3O4含量的减少和浮氏体以及金属铁的增加,其对微波的吸收性能也将不断降低。但是仍然具有较好的吸波性能。

(2) 预还原球团虽然在表面生成金属铁颗粒,但是金属铁颗粒并没有发生兼并长大形成整体,而是以星点状分布于其中,对微波吸收性能不会产生较大影响。而其产生的丰富孔隙为还原反应创造良好的动力学条件。

(3) 在微波加热还原时间为48 min、碳氧质量比为1.75:1,还原温度为1 000 ℃时,预还原程度越高,海绵铁的金属化率越高。在预还原球团的金属化率为42.85%时,最终得到的海绵铁的金属化率达到97%。

参考文献:

[1] 冯士明. 陶瓷微波烧结技术及其进展[J]. 陶瓷研究, 1995, 10(2): 80-83.

FENG Shi-ming. Development and technology of microwave sintering of ceramics[J]. Ceramic Research, 1996, 10(2): 80-83.

[2] 段碧林, 曾令可, 刘平安, 等. 微波辅助加热技术的应用及现状[J]. 陶瓷, 2005, 11(12): 11-15.

DUAN Bi-lin, ZENG Ling-ke, LIU Ping-an, et al. The application and status of microwave-assisted firing technology[J]. Ceramics, 2005, 11(12): 11-15.

[3] 闫志国, 胡勇, 吴元欣, 等. 微波烧结技术及其在制备催化剂中的应用[J]. 应用化工, 2006, 35(6): 455-460.

YAN Zhi-guo, HU Yong, WU Yuan-xin, et al. Microwave sintering technology and its application in the catalyst preparing[J]. Applied Chemical Industry, 2006, 35(6): 455-460.

[4] Gedye R N, Smith F E, Westaway K C. The rapid synthesis of organic compounds in microwave ovens[J]. Canadian Journal of Chemistry, 1988, 66(1): 17-26.

[5] 习岗, 杨云经. 电磁场对生物体系的非热效应及其作用机理[J]. 大学物理, 2008, 27(11): 50-55.

XI Gang, YANG Yun-jing. Non-thermal effect of electromagnetic field on biological system and its mechanism[J]. College Physics, 2008, 27(11): 50-55.

[6] 陈新秀, 徐盼, 夏之宁. 微波辅助有机合成中“非热效应”的研究方法[J]. 化学通报, 2009, 72(8): 674-677.

CHEN Xin-xiu, XU Pan, XIA Zhi-ning. Methods for non-thermal microwave effects in microwave assisted organic synthesis[J]. Chemistry, 2009, 72(8): 674-677.

[7] 赵晶, 陈津, 张猛, 等. 微波低温加热过程中的非热效应[J]. 材料导报, 2007, 21(11): 4-6.

ZHAO Jing, CHEN Jin, ZHANG Meng, et al. Non-thermal effect during microwave heating at low temperature[J]. Materials Review, 2007, 21(11): 4-6.

[8] 蔡卫权, 李会泉, 张懿. 微波技术在冶金中的应用[J]. 过程工程学报, 2005, 5(2): 228-229.

CAI Wei-quan, LI Hui-quan, ZHANG Yi. Recent development of microwave radiation application in metallurgical processes[J]. The Chinese Journal of Process Engineering, 2005, 5(2): 228-229.

[9] 陈津, 刘浏, 曾加庆, 等. 微波加热还原含碳铁矿粉试验研究[J]. 钢铁, 2004, 39(6): 1-5.

CHEN Jin, LIU Liu, ZENG Jia-qing, et al. Experimental research of microwave heating on iron ore concentrates containing coal and lime[J]. Iron and Steel, 2004, 39(6): 1-5.

[10] Standish N, Worner H. Microwave application in the reduction of metal oxides with carbon[J]. Microwave Power and Electromagnetic Energy, 1990, 25(3): 177.

[11] 陈津, 刘浏, 曾加庆, 等. 微波加热含碳铁矿粉还原矿相结构研究[J]. 电子显微学报, 2005, 24(2): 114-117.

CHEN Jin, LIU Liu, ZENG Jia-qing, et al. Metallography of iron coal containing ore concentrates reduced by microwave heating[J]. Journal of Chinese Electron Microscopy Society, 2005, 24(2): 114-117.

[12] Mourao M B, Carvalhojr I P, Takano C. Carbothermic reduction by microwave heating[J]. ISIJ International, 2001, 41(S): 27-30.

[13] 步文博, 徐洁, 邱泰, 等. 吸波材料的基础研究及微波损耗机理的探讨[J]. 材料导报, 2001, 15(5): 14-18.

BU Wen-bo, XU Jie, QIU Tai, et al. Discussion on fundamental research and microwave loss mechanism of microwave absorbing materials[J]. Materials Review, 2001, 15(5): 14-18.

[14] XIAO Jin-kai. Dielectric properties of minerals and their application in microwave remote sensing[J]. Chinese Journal of Geochemistry, 1990, 9(2): 169-177.

[15] 潘小娟. 含碳碳酸锰矿粉与含碳氧化锰矿粉微波加热特性对比研究[D]. 太原: 太原理工大学材料加工工程系, 2005: 51-53.

PAN Xiao-juan. A comparative study of microwave heating characteristics on manganese carbonate ore fines containing coal and manganese oxide ore fines containing coal[D]. Taiyuan: Taiyuan University of Technology and Science. Department of Material Process Engineering, 2005: 51-53.

[16] 肖金凯. 矿物的成分和结构对其介电常数的影响[J]. 矿物学报, 1985, 5(4): 330-334.

XIAO Jin-kai. The effects of mineral composition and structure on dielectric constants[J]. Acta Mineralogica Sinica, 1985, 5(4): 330-334.

[17] 金钦汉, 戴树珊, 黄卡玛. 微波化学[M]. 北京: 科学出版社, 1999: 287-288.

JIN Qin-han, DAI Shu-shan, HUANG Ka-ma. Microwave chemistry[M]. Beijing: Science Press, 1999: 287-288.

[18] 崔慧军, 陈津, 冯秀梅, 等. 微波场中含碳铬矿粉升温特性曲线数值模拟[J]. 中国冶金, 2007, 17(1): 30-34.

CUI Hui-jun, CHEN Jin, FENG Xiu-mei, et al. Numerical modeling of temperature-rising characteristic curve for carbon-containing chromite fines in microwave field[J]. China Metallurgy, 2007, 17(1): 30-34.

(编辑 陈爱华)

收稿日期:2011-02-22;修回日期:2011-04-26

基金项目:国家杰出青年科学基金资助项目(50725416)

通信作者:黄柱成(1964-),男,湖南长沙人,教授,博士生导师,从事微波冶金、综合利用和直接还原等研究;电话:0731-88830542;E-mail: zchuangcsu@126.com