低频电磁铸造AZ41镁合金的热压缩流变与组织

王忠军1, 2, 乐启炽1, 郭世杰1, 崔建忠1, 张彩碚2

(1. 东北大学 材料电磁过程研究教育部重点实验室, 沈阳 110004;

2. 东北大学 理学院, 沈阳 110004)

摘 要: 采用Gleeble-1500D热模拟试验机、 差热分析仪和光学显微镜等对低频电磁铸造AZ41镁合金铸锭热压缩流变特征及微观组织进行研究。 结果表明: AZ41镁合金铸锭热压缩变形存在明显的动态回复和动态再结晶特征; 当温度为453~523K时, 以动态回复为主; 当温度为593~723K时, 以动态再结晶为主要机制; 当温度为593K, 应变速率为1.0s-1时, 形变激活能最低, 流变过程最稳定, 中心和边缘部位的晶粒得到明显细化。 在变形期间, Mg17Al12相的破碎和溶解促进动态再结晶显著发生。

关键词: AZ41镁合金; Mg17Al12 相; 低频电磁铸造; 动态再结晶 中图分类号: TG146.22

文献标识码: A

Thermal compressing flow and microstructure of AZ41 magnesium alloy cast by low frequency electrical magnetic field

WANG Zhong-jun1, 2, LE Qi-chi1, GUO Shi-jie1, CUI Jian-zhong1, ZHANG Cai-bei2

(1. Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education,Northeastern University, Shenyang 110004, China;

2. College of Science, Northeastern University, Shenyang 110004, China)

Abstract: The characteristics of thermal compressing flow and microstructure of AZ41 magnesium alloy cast by low frequency electrical magnetic field (LFEMC) were studied through thermal simulation tester Gleeble-1500D.The results show that there exist obviously dynamic recovery and dynamic recrystallization (DRX) during thermal compression of the LFEMC AZ41 magnesium alloy. The dynamic recovery is prominent character at 453-523K, but DRX is prominent behavior at 593-723K. The flow process is the most stable and the microstructures at the center and the edge of specimens are markedly refined by DRX at the temperature of 593K and the strain rate of 1.0s-1. The crash and dissolution of Mg17Al12 phase accelerate DRX during deforming.

Key words: AZ41 magnesium alloy; Mg17Al12 phase; low frequency electrical magnetic field; dynamic recrystallization

镁合金作为结构材料具有许多优点, 例如质轻, 易于热加工, 具有很高的刚度和抗震性能。 目前, 汽车工业对镁合金的需求与日俱增, 镁合金的使用大大减轻了车体质量, 减少了能源的消耗[1, 2]。 AZ41作为汽车轮箍合金, 具有变形能力高, 可热处理强化, 尺寸稳定性好等优点。 汽车轮箍锻造用镁合金需要尺寸大于300mm的铸锭。 目前, 通用的镁合金半连续铸造采用直接水冷(direct chill by water, DC)的方法。 DC铸锭存在较高的内应力和组织偏析, 后续热锻加工需要长时间退火, 耗费大量的能源且容易产生表面氧化。 崔建忠[3]成功地将低频电磁铸造(low frequency electrical magnetic casting, LFEMC)技术应用到合金铸造过程中。 LFEMC具有减小组织偏析, 提高晶粒内部合金元素含量, 改善铸锭表面质量, 避免裂纹, 细化晶粒, 减少夹杂和提高铸锭力学性能等优点。 经过长时间均匀化热处理的镁合金DC铸锭在温度为423K时, 热压缩变形的流变应力一般不高于150MPa[4], 可以完成热加工工艺过程。 但是, 长时间均匀化热处理需要耗费大量的能源, 提高了生产成本。 最近, 已有人将LFEMC技术应用到镁合金铸造过程中, 取得了非常明显的效果, 发现LFEMC镁合金铸锭纯度高, 组织均匀[5], 具有经过短暂的去内应力热处理后直接热锻加工的可行性, 减少了热处理的时间和表面氧化。 虽然对DC镁合金铸锭热变形过程中的组织与性能已经有了大量的研究[6-8], 但对LFEMC镁合金铸锭热变形流变过程中的组织与性能的变化机理却未见报道。 为了充分发挥LFEMC对于镁合金生产的积极作用, 降低生产成本, 本文作者研究了LFEMC镁合金铸锭热压缩流变过程中的应力应变曲线和再结晶的关系, 并探讨了形变激活能在不同的温度区间变化过程以及组织变化规律, 为制定合理的热加工工艺参数提供理论依据。

采用低频半连续电磁铸造(线圈施加的电磁频率为20Hz, 电流强度为120A)直径为300mm、 长度为1500mm的铸锭。 AZ41镁合金的化学成分光谱分析结果为: Al 4.1, Zn 1.2, Mn 0.32, Mg为余量(质量分数, %)。 在距离铸锭横截面中心0.75R处, 取得块状坯料, 然后机械加工成中心线一律与铸锭轴向平行的d8mm×15mm的热模拟试样。

高温压缩实验在Gleeble-1500D材料热模拟试验机上进行。 实验温度为453~723K; 加热速度为2K/min, 试样在压缩前升温, 到达预先设定的温度后保温3min。 应变速率分别为0.01, 0.1, 1.0, 2.0s-1。 实验在空气中进行, 热压缩后取出试样马上置于水中淬火, 保留组织形貌以备观察。 所得的应力应变数据采用Origin6.0软件处理与分析。

合金的相变点测定采用型号为Q-1000的DSC分析仪, 从室温开始以5℃/s速度缓慢升温至773K后快速冷却。

不同条件下高温热压缩金相试样经过1500#水磨砂纸研磨后, 采用绒布抛光和鹿皮加MgO膏研磨后, 采用自配的乙酸(65%水溶液)+苦味酸(70%水溶液)+甲醇(体积比10∶5∶85)腐蚀剂腐蚀后, 应用光学显微镜观察其原始晶界和再结晶组织。

2 结果与分析

2.1 热压缩流变特征

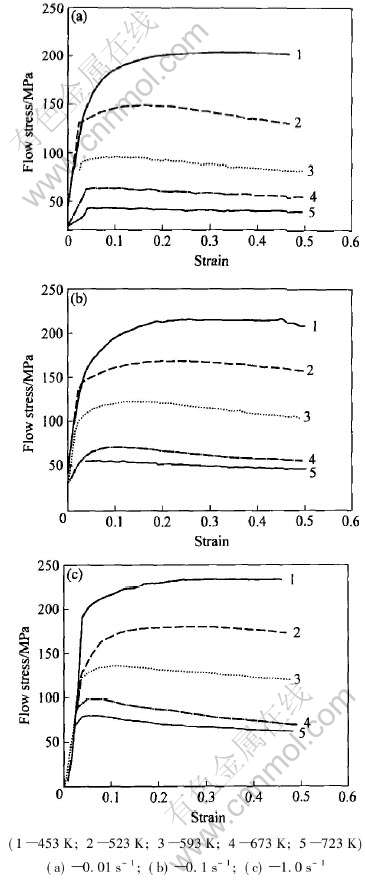

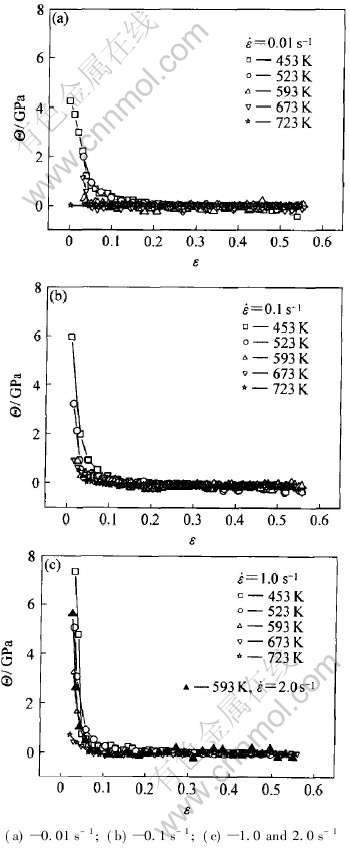

图1所示为应变速率为0.01, 0.1和1.0s-1的热压缩应力应变曲线。 由图1可看出, AZ41镁合金LFEMC铸锭的热压缩变形流变应力随着真应变的增加迅速上升, 而且都在出现一个峰值后逐渐下降, 当达到一定的真应变量后, 其流变应力基本不变, 各峰值应力与所对应的稳态流变应力间的差值随温度的上升而减小, 且应变速率越小, 这种趋势越明显。 当变形温度一定时, 峰值随应变速率的增加而提高; 当应变速率一定时, 峰值随变形温度的升高而降低。 随着应变速率的增大和温度的降低, 流变应力的峰值所对应的真应变值减小。 由此可以看出, AZ41镁合金在LFEMC铸造状态下的铸锭热压缩流变应力(大于200MPa)远远高于经过长时间均匀化热处理后镁合金DC铸锭的流变应力(不高于150MPa)[4], 且LFEMC铸锭热压缩在达到应力峰值后, 软化速度缓慢, 当温度达到593K时, 才开始发生显著软化, 而DC均匀化铸锭在423K就已经开始软化[9]。 由此可见, LFEMC铸锭需要较高的再结晶温度。

图1 不同应变速率时应力和应变的关系

Fig.1 Relations between strain and flow stress at different strain rates

如果采用Backofen公式[6] 表达流变应力σ、 应变速率 和应变速率敏感性指数m三者之间的关系, 则有

和应变速率敏感性指数m三者之间的关系, 则有

得

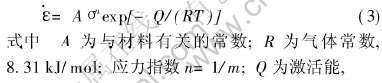

图2(a)所示为不同温度下的应力和应变速率关系曲线, 图中直线的斜率即为相应的m值。 而热变形受激活能控制, 流变应力和应变速率关系为

则

图2(b)所示为lnσ-1/T的实测数据, 由此可计算出每一点的斜率(lnσ/ln(1/T))。

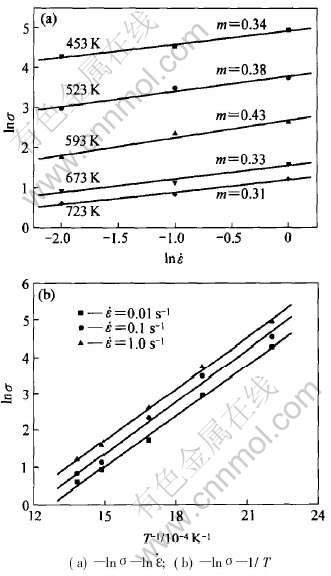

由式(4)和图2的结果可以计算出不同温度、 不同应变速率下的Q值, 结果如图3所示。 由图3可看出, 当温度不变, 应变速率为0.01~1.0 s-1时, Q值随着应变速率的增加而略有增加, 但绝对变化只有1.8kJ/mol; 如果Q取平均值为110kJ/mol, 相对变化量只有0.016, 应变速率对于Q值的影响可以忽略不计。

图2 AZ41镁合金热压缩参数综合分析

Fig.2 Constitutive analysis of parameters of AZ41 Mg alloy

图3 不同应变速率和不同温度下激活能与温度的关系

Fig.3 Relationship between Q and T at different strain rates and temperatures

当温度为453~593K时, Q值随着温度的增加迅速下降, 说明铸造状态的AZ41镁合金热压缩变形在此温度区间以连续动态回复为主要特征; 当温度为593~723K时, Q值随着温度的增加而迅速的上升, 可见在此温度期间发生了连续动态再结晶(DRX), 温度的上升导致了连续的DRX, 增加了晶界的面积, 晶界的迁移成为激活能增加的主要因素。 593K是连续动态回复机制向连续DRX机制转变的温度, 此时的激活能最低, 热压缩过程中的合金内部能量分布均匀, 为热变形的最佳温度。

镁合金在453K以下变形时, 只发生基面{0001}滑移(a位错), 滑移系受限, 导致变形以孪生形式发生; 在593K时, 锥面{1011}滑移系(a+c位错)启动, 发生交滑移和位错线的束集缠结, 从而导致亚晶胞的产生; 在673~723K时, 以位错攀移为主要机制[9-14]。

加工硬化率Θ(Θ= σ/

σ/ ε) 与真应变ε的关系能 够反映出热变形过程中位错的运动、 回复及连续DRX的协调关系。 图4所示为根据图1的结果计算出的Θ和ε的关系曲线。 由图4可看出, 在3种应变速率条件下, 热压缩初期是加工硬化, Θ 与ε呈直线关系, 随着应变量ε的提高, Θ值迅速下降, 说明位错和孪晶发生的速度极快, 大量的位错在晶界/孪晶界附近塞积, 产生畸变能应力场。 当真应变量ε大于0.25时, Θ值不再持续下降, 而是在一个很小的范围内(-0.2~0.2GPa)随着真应变量ε的增加呈周期性振荡, 反映了位错与晶界/孪晶界之间的相互作用。 当畸变能足够大时, 发生(a+c)位错, 从而释放了一部分能量; 当温度达到593K时, 发生交滑移, 高温区在673~723K时发生了攀移, 从而造成了能量的连续存储和释放, 发生了回复及连续动态再结晶, 加工硬化和软化两者达到了动态平衡。 由于形变引起的弹性畸变能达到或超过了(a+c)位错的临界剪切应力, 位错重组形成了三维空间上的再结晶晶核。 当加工硬化及回复的软化过程第一次达到平衡时, 再结晶晶核达到临界晶核尺寸从而发生再结晶。 再结晶晶核继续长大, 再结晶后的晶粒内部又发生了位错的塞积、 孪晶, (a+c)位错在孪晶和晶界处发生交滑移、 攀移和重组, 形核, 再结晶的过程, 周而复始。 因此, 从宏观上表现为Θ随ε的增加而周期性的往复振荡。 由图4可以看出, 随着应变速率的增加, Θ值的上下波动幅度逐渐降低, 当应变速率

ε) 与真应变ε的关系能 够反映出热变形过程中位错的运动、 回复及连续DRX的协调关系。 图4所示为根据图1的结果计算出的Θ和ε的关系曲线。 由图4可看出, 在3种应变速率条件下, 热压缩初期是加工硬化, Θ 与ε呈直线关系, 随着应变量ε的提高, Θ值迅速下降, 说明位错和孪晶发生的速度极快, 大量的位错在晶界/孪晶界附近塞积, 产生畸变能应力场。 当真应变量ε大于0.25时, Θ值不再持续下降, 而是在一个很小的范围内(-0.2~0.2GPa)随着真应变量ε的增加呈周期性振荡, 反映了位错与晶界/孪晶界之间的相互作用。 当畸变能足够大时, 发生(a+c)位错, 从而释放了一部分能量; 当温度达到593K时, 发生交滑移, 高温区在673~723K时发生了攀移, 从而造成了能量的连续存储和释放, 发生了回复及连续动态再结晶, 加工硬化和软化两者达到了动态平衡。 由于形变引起的弹性畸变能达到或超过了(a+c)位错的临界剪切应力, 位错重组形成了三维空间上的再结晶晶核。 当加工硬化及回复的软化过程第一次达到平衡时, 再结晶晶核达到临界晶核尺寸从而发生再结晶。 再结晶晶核继续长大, 再结晶后的晶粒内部又发生了位错的塞积、 孪晶, (a+c)位错在孪晶和晶界处发生交滑移、 攀移和重组, 形核, 再结晶的过程, 周而复始。 因此, 从宏观上表现为Θ随ε的增加而周期性的往复振荡。 由图4可以看出, 随着应变速率的增加, Θ值的上下波动幅度逐渐降低, 当应变速率 达到1.0s-1, 真应变值ε到达0.25以后, Θ 值稳定下来, 波动幅度趋于零, 这是由于回复和再结晶的速度和位错运动的速度得到了很好的匹配, 热压缩流变过程最稳定。 但是, 当温度为593K, 应变速率为2.0s-1时, 热压缩会导致裂纹产生, 表面裂纹使得金属在流变过程中变得不稳定(见图4(c))。 因此, 温度为593K和应变速率为1.0s-1是最佳的热压缩流变参数。

达到1.0s-1, 真应变值ε到达0.25以后, Θ 值稳定下来, 波动幅度趋于零, 这是由于回复和再结晶的速度和位错运动的速度得到了很好的匹配, 热压缩流变过程最稳定。 但是, 当温度为593K, 应变速率为2.0s-1时, 热压缩会导致裂纹产生, 表面裂纹使得金属在流变过程中变得不稳定(见图4(c))。 因此, 温度为593K和应变速率为1.0s-1是最佳的热压缩流变参数。

当加工硬化和软化首次达到平衡, 即Θ=0时,发生了动态回复或者动态再结晶。 由图4可以看出, 随着应变速率的增加, Θ=0时所对应的真应变值ε减少, 说明应变速率的提高使得动态回复或者动态DRX提前发生。

图4 加工硬化率Θ与真应变量ε的关系

Fig.4 Relationship between Θ and ε

2.2 流变组织分析

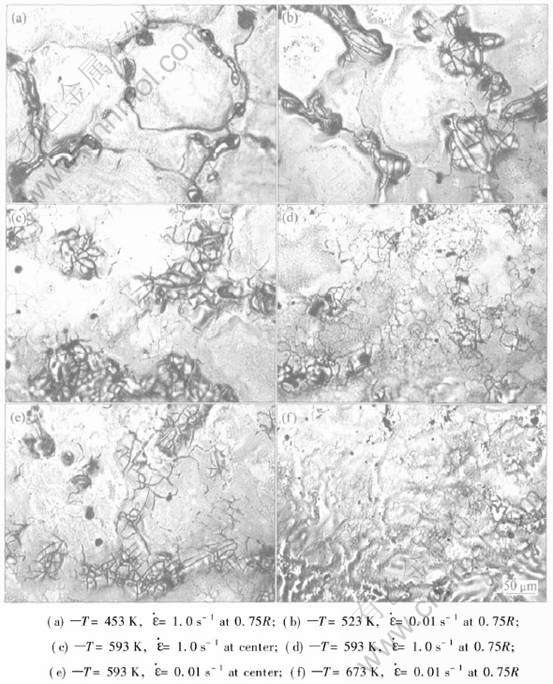

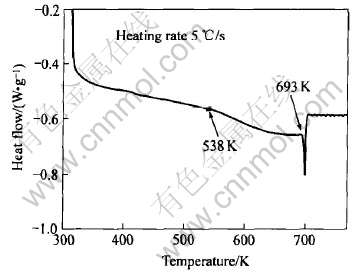

图5所示为AZ41镁合金铸锭热压缩后的显微组织。 图5(a)所示为453K压缩试样的横截面0.75R处的组织。 由图5可见, Mg17Al12相[11] 不连续地分布在原始晶界附近, 尽管发生了比较严重的塑性变形, Mg17Al12相并没有变形和破裂; 在523K时(见图5(b)), Mg17Al12相[10]开始软化, 由于受到压应力的作用产生了大量的裂纹。 但是, 原始晶界还是没有消失。 在593K时, 试样中心部分(见图5(c))的Mg17Al12相进一步破碎, 此时已经发生了DRX, 原始晶界消失。 当温度超过538K时, Al、 Zn和极少量的杂质元素为了填补由于热变形产生的大量空位迅速地向晶粒内部扩散, 原始晶界上的化合物大量消失[15, 16]。 图5(d)所示为593K时, 试样0.75R处的组织, 由于变形量较图5(c)的变形量大, Mg17Al12相基本消失, 在Mg17Al12相原先的位置产生了大量的细小再结晶组织, 这说明DRX与Mg17Al12相的分解密切相关。 严重的热变形促使Mg17Al12相提前分解, 加速DRX发生。 图6所示为[CM(22]AZ41镁合金的DSC分析结果。 Mg17Al12相的分解温度为693K, 而在593K时, Mg17Al12相就已经开始大量分解, 说明形变极大地降低第二相重熔温度, 促进了DRX的发生; 当温度大于673K时, 流变组织开始发生连续DRX和组织的过烧。 由图5(f)可看出, 当温度为673K时, 试样中心部分的DRX组织的金属流变不均匀, 残留部分过烧没有充分溶解的Mg17Al12相, DRX晶粒细小但不均匀。

图5 不同温度和应变速率时热压缩后AZ41镁合金的显微组织

Fig.5 Microstructures of AZ41 Mg alloy after hot compressing deformation at different temperatures and strain rates

图6 AZ41镁合金的差热分析曲线

Fig.6 DSC curve of AZ41 Mg alloy

在453~523K时, 热压缩变形激活能大, 温度低, 只能产生动态回复, 原始组织形态没有发生根本性的改变; 在673~723K时, 发生连续DRX和晶粒的长大, 组织极不均匀; 当温度为593K时, 形变激活能最低, 软化速度和动态回复与DRX相匹配, 组织均匀, 因此, 593K是热压缩变形的最佳温度。 图5(c)和(e)都是温度为593K时的中心部位组织, 但是应变速率不同, 分别为1.0和0.01s-1, 可见在相同温度下, 不同应变速率的组织略有不同。 由图5(c)可看出, 应变速率高, 再结晶晶粒细小; 而在图5(f)中, 应变速率低, 再结晶晶粒不明显, Mg17Al12相得到进一步的破碎和溶解, 说明应变速率低延长了变形时间, 使Al原子向晶粒内部的扩散时间充分, 因此Mg17Al12相的破碎溶解后, 还必须有足够高的应变速率和变形程度才能诱发DRX发生。

由此可看出, LFEMC铸锭可以通过比较大的变形量和适当的温度、 应变速率相结合直接锻造成型, 以及变形过程中的再结晶得到细小均匀的组织结构。 593K是形变激活能最低的温度, 在此温度下尽可能提高应变速率和变形程度则可以达到流变均匀稳定、 组织细小均匀的效果。 但是, 应变速率过大又会在表面产生裂纹, 极大地影响了流变的稳定。 因此, 在本研究条件下, 1.0s-1的应变速率最佳。 另外, DRX组织首先位于Mg17Al12相的原始位置, 细小Mg17Al12相的存在对DRX的发生具有促进作用。

3 结论

1) 当温度为453~723K, 应变速率为0.01~1.0s-1时, 热压缩变形存在明显的动态回复和动态再结晶特征。

2) 在一定温度条件下, 应变速率增加, 形变激活能提高, 但是影响并不显著; 提高应变速率能够促进DRX发生, 但过高会导致表面裂纹和流变不稳定。

3) 在热压缩变形过程中, 发生软化, 在453~523K时, 以动态回复为主要机制, 593K开始发生DRX, 593~723K以DRX为主要机制; 当温度为593K, 应变速率为1.0s-1时, 流变过程最稳定, 中心和边缘部位的晶粒得到明显细化;

4) Mg17Al12 相的破碎和部分溶解极大地促进了DRX的发生。

REFERENCES

[1]Polmear I J. Light Alloys: Metallurgy of the Light Metals[M]. London: Arnold Press, 1995.

[2]刘正, 张奎, 曾小勤. 镁基轻质合金理论基础及应用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Basic Theory and Application of Light Metal for Magnesium Matrix[M]. Beijing: China Machine Industry Press, 2002.

[3]CUI Jian-zhong. Solidification of Al alloys under electromagnetic field[J]. Trans Nonferrous Met Soc China, 2003, 13: 473-483.

[4]Zhou H T, Zeng X Q, Wang Q D, et al. A flow stress model for AZ61 magnesium alloy[J]. Acta Metal Sin, 2004, 17: 155-160.

[5]Guo S J, Cui J Z, Le Q C, et al. The effect of alternating magnetic field on the process of semi-continuous casting for AZ91 billets[J]. Mater Lett, 2005, 59: 1841-1844.

[6]Jiang L, Huang G, Godet S, et al. Particle-stimulated nucleation of dynamic recrystallization in AZ31 alloy at elevated temperatures[J]. Mater Sci Forum, 2005, 488-489: 261-264.

[7]ZHOU Hai-tao, WANG Qu-dong, WEI Yin-hong, et al. Flow stress and microstructural evolution in as rolled AZ91 alloy during hot deformation[J]. Trans Nonferrous Met Soc China, 2003, 13: 1265-1269.

[8]Yan Y Q, Zhang T J, Zhou L, et al. Mechanical pro-perties and microstructures of a wrought AZ91 alloy[J]. Rare Metals, 2004, 23: 220-225.

[9]Galiyev A. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Mater, 2001, 49: 1199-1207.

[10]Takuda H. Modeling on flow stress of Mg-Al-Zn alloys at elevated temperatures[J]. J of Mater Proc Tech, 1998, 80-81: 513-516.

[11]Mwembela A. Microstructural development in Mg alloy AZ31 during hot working[J]. Scripta Mater, 1997, 37: 1789-1795.

[12]Vagarali S S. Deformation mechanisms in H.C.P metals at elevated temperatures—Ⅰ. Creep behavior of magnesium [J]. Acta Metall, 1981, 29: 1969-1982.

[13]Klimanek P, Ptzsch A. Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates[J]. Mater Sci Eng, 2002, A324: 145-150.

[14]Kaibyshey R O, Sitdikoy O H. The relation of crystallographic slip and dynamic recrystallization to the local migration of grain boundaries[J]. Phys Met Metall, 1994, 78: 420-422.

[15]Ion S E, Homphreys F J, Whuce S H. Dynamic recrystallization and the development of microstructure during the high temperature deformation of magnesium[J]. Acta Metall, 1982, 30: 1909-1919.

[16]Emley E F. Principles of Magnesium Technology[M]. London: Pergamon Press, 1966.

(编辑李艳红)

基金项目: 国家自然科学基金资助项目(50374025); 国家高技术研究发展计划资助项目(2003AA331110)

收稿日期: 2005-04-14; 修订日期: 2005-09-20

作者简介: 王忠军(1969-), 男, 博士研究生

通讯作者: 崔建忠, 教授; 电话: 024-83681742; 传真: 024-23906316; E-mail: zhongjun_w@yahoo.com.cn