DOI:10.19476/j.ysxb.1004.0609.2017.05.010

BaZrO3耐火材料在富钛熔体中的侵蚀机理

陈光耀1,李宝同1,张 浩1,高鹏越1,秦子威1,鲁雄刚1, 2,李重河1, 2

(1. 上海大学 材料科学与工程学院 上海市钢铁冶金新技术开发应用重点实验室,上海 200072;

2. 上海特种铸造工程技术研究中心,上海 201605)

摘 要:使用BaZrO3坩锅结合真空感应加热技术熔炼钛含量66%(摩尔分数)的富钛合金,通过宏观显微镜、X射线衍射仪、扫描电子显微镜及电子耦合仪分析BaZrO3坩锅与熔体接触后的显微组织及其组成元素(Ba,Zr和O)在合金中的熔解量;研究BaZrO3坩锅剥落损毁及与钛熔体界面反应机理。结果显示:BaZrO3坩锅受熔体侵蚀层厚度约2000 μm,合金中锆和氧含量随着熔体与坩埚接触时间增加而增加。界面反应产物BaO与空气中水分和CO2反应生成BaCO3,晶体体积变化破坏晶粒间结合力,导致坩埚剥落损毁。富钛熔体对BaZrO3耐火材料的溶解侵蚀是坩埚受损的主要原因。

关键词:BaZrO3耐火材料;富钛合金;侵蚀;界面反应

文章编号:1004-0609(2017)-05-0947-06 中图分类号:TQ17 文献标志码:A

钛合金在熔融状态下具有极高化学活性[1-2],能与SiO2[3],MgO[4]等常用耐火材料发生化学反应。KOSTOV等[5]指出ZrO2、CaO和Y2O3耐火材料对钛熔体呈现良好的热力学稳定性。但研究发现ZrO2仍会与钛熔体发生界面反应生成α-Ti(Zr,O)污染合金[6];相比ZrO2,CaO[7]和Y2O3[8]的稳定性更高,且不会与钛熔体发生化学反应。但CaO易水化[9],Y2O3原料成本高、抗热震性差等问题[10-11],导致其在实际应用方面受到了很大限制。因此,寻找一种新型的高稳定性耐火材料是感应熔炼制备钛合金的技术难题。

BaZrO3常用作制备电子导体[12],同时也是一种高熔点(熔点高达2750 ℃)、高稳定性耐火材料,是目前用来生长高质量YBa2Cu3O7-x (YBCO)单晶体极为理想的坩埚材料[13]。张钊等[14]使用自制BaZrO3坩埚感应熔炼TiNi合金,结果表明:BaZrO3坩埚对TiNi熔体呈现良好的反应惰性,熔炼后坩埚与合金可相互剥离,且并未见耐火材料组成元素进入合金中。周汉等[15]使用BaZrO3坩埚熔炼制备TiFe基储氢合金,储氢性能并不弱于石墨坩埚制备的合金性能,且无增碳的弱点。贺进等[16]使用BaZrO3坩埚感应熔炼TiAl合金,结果显示:制备的TiAl合金中并未见耐火材料夹杂物存在,熔体对BaZrO3耐火材料润湿性较差,但有少量耐火材料组成元素Ba、Zr和O元素熔解在合金中,合金侧发现厚度约40 μm耐火材料附着层。陈光耀等[17]通过对比研究两种钛含量(低钛含量50%和富钛含量66%,摩尔分数)合金熔体与BaZrO3坩埚间界面反应,发现BaZrO3坩埚不与低钛熔体发生界面反应,在熔炼富钛合金时,两者发生界面反应导致坩埚受侵蚀,耐火材料组成元素(Zr和O)大量进入合金。研究中虽提及BaZrO3坩埚受富钛熔体侵蚀后的损毁情况,但是针对受侵蚀坩埚的剥落损毁现象及相应的侵蚀作用机理并未开展深入的研究。

基于此,本文作者利用BaZrO3坩埚结合感应加热技术熔炼富钛含量(66%,摩尔分数)合金,结合光学显微镜(OM),X射线衍射仪(XRD)及扫描电子显微镜(SEM),分析坩埚剥落损毁情况及侵蚀层物相组成,并通过热力学计算对两者界面反应机理进行深入阐述。

1 实验

使用自制BaZrO3坩埚[14],坩埚内径尺寸约30 mm,外径尺寸约42 mm。钛含量66%的钛镍母合金使用海绵钛和镍板通过水冷铜坩埚制备。将约60 g母合金置于BaZrO3坩埚中,通过感应加热技术对合金进行加热,升温至合金待熔化时,反充氩气至900 Pa,迅速升温至1500 ℃保温5 min,将熔体倒入石墨坩埚,得到合金铸锭。使用BaZrO3坩埚熔炼3次母合金,取出坩埚,采用VHX-1000型光学显微镜观察坩埚受侵蚀层厚度。用JSM-6700F型扫描电子显微镜观察坩埚样品界面显微形貌,并进行能谱分析。用D/Max-2200型X射线衍射仪对坩埚内壁进行成分分析。采用PerkinElmer 7300Dv型原子发射光谱仪测定合金中BaZrO3耐火材料组成元素Zr和Ba的含量。采用脉冲加热惰气熔融-红外线吸收法测定合金中氧含量。

2 结果与讨论

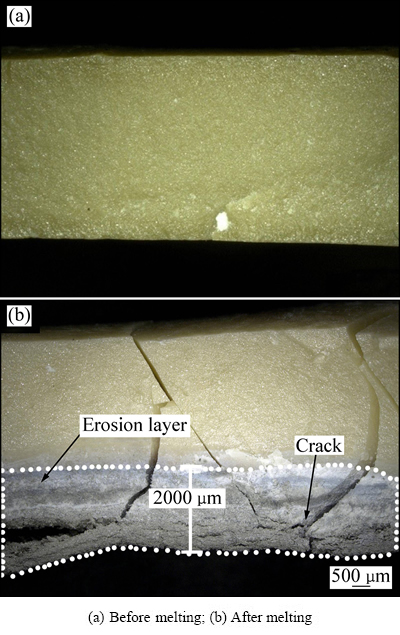

图1所示为BaZrO3坩埚熔炼前和熔炼后置于空气中1 h后的宏观照片。从图1(a)中可以看出,熔炼前的BaZrO3坩埚结构致密,整体呈淡黄色,并带有晶体光泽。而熔炼后的BaZrO3坩埚颜色较暗,内壁受侵蚀层厚度约2000 μm,结构疏松,有大量裂纹生成,同时还伴随着剥落现象出现。同时,未与熔体接触的坩埚基体部分也有少量裂纹生成,这是由于在熔炼过程中,高致密度坩埚抗热震性差[18],较快的升温速率导致坩锅破裂产生的裂纹,如图1(b)所示。

图1 BaZrO3坩埚宏观照片

Fig. 1 Macrographs of BaZrO3 crucibles

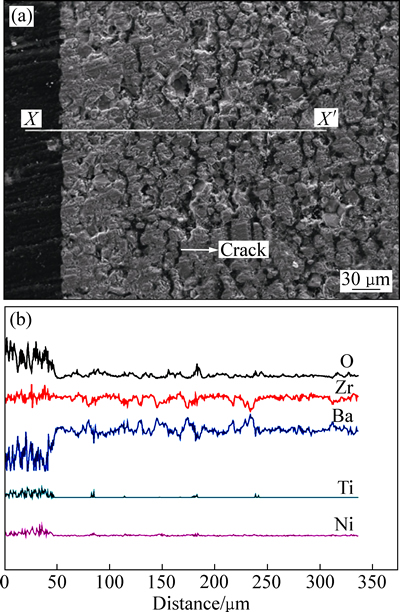

为考察钛熔体对BaZrO3坩埚侵蚀性影响,对熔炼后的BaZrO3坩埚剥落层进行显微结构分析。由图2(a)可以看出,坩埚受侵蚀内壁界面依旧完整,基体中出现较多裂纹。这是由于熔体受毛细管力作用,沿着坩埚内壁孔隙渗透侵蚀坩埚造成的。图2(b)所示为XX′线上组成元素分布图。由图2(b)可以看出,Ti和Ni元素在陶瓷侧扫描线平整,基本上没有波动,说明熔体中Ti和Ni元素并未在坩埚侧残留,图中Ti峰出现的波动可能是因为Ba与Ti强度峰相似,线扫描的精度限制无法对Ba和Ti进行区分而导致的。

图2 BaZrO3坩埚侧壁的SEM像和XX′线上元素分布

Fig. 2 SEM image of sidewall of BaZrO3 crucible (a) and compositional distribution profile along XX′ line (b)

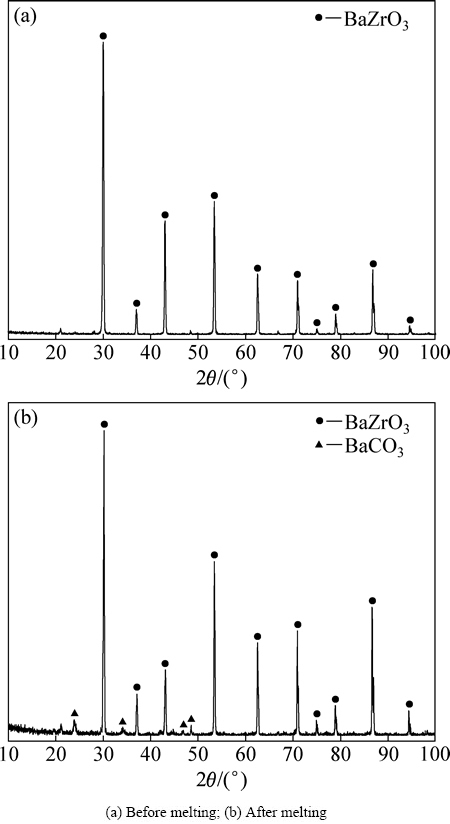

取坩埚熔炼前内壁和熔炼后剥落层进行X射线衍射(XRD)分析,结果如图3所示。从图3(a)中可以看出,熔炼前坩埚内壁主要由BaZrO3组成,并未见其他物质存在。熔炼后的剥落层除了BaZrO3,还有BaCO3存在,说明富钛熔体与BaZrO3坩埚在接触过程中发生了界面反应。而合金在熔炼过程中处于真空状态,并不会引入C元素,可知C元素的来源是将坩埚取出后,熔体与耐火材料的界面反应产物BaO先与空气中水汽反应生成Ba(OH)2,再与空气中CO2反应生成BaCO3而引入的。

图3 BaZrO3坩埚内壁的XRD谱

Fig. 3 XRD patterns of inner wall of BaZrO3 crucible

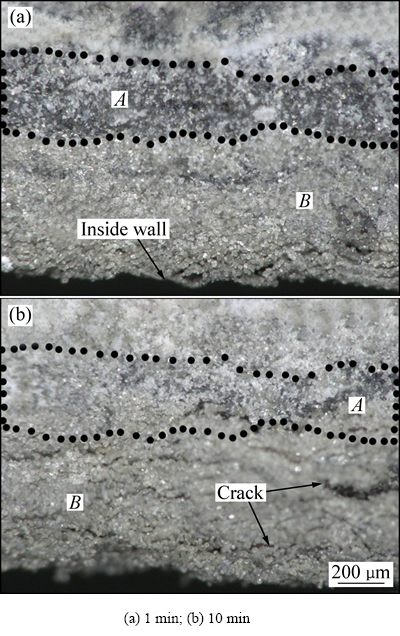

重复上述实验,待实验结束后,迅速将坩埚取出置于宏观显微镜下。图4所示为坩埚与空气在不同接触时间后的显微结构图。从图4(a)中可以看出,BaZrO3坩埚受熔体侵蚀后基体呈灰色,大量透明状物质BaO (BaO为无色晶体)分布在侵蚀层中,区域A中透明状晶粒状物质较少,区域B的则较多,这是由于合金在熔炼过程中熔体沿着耐火材料孔隙向内部渗透的深度不同而导致界面反应程度不同而引起的。当侵蚀层与空气接触10 min后,区域A中的透明状物质减少,灰色状物质明显增加,由于BaO迅速与空气中水汽和CO2发生反应,大量生成BaCO3 覆盖了灰色基体层。同时,BaO在空气中迅速与水汽反应生成Ba(OH)2的过程中, =2.13 g/cm3,相比

=2.13 g/cm3,相比 =5.72 g/cm3要小,从BaO转变为Ba(OH)2的过程中,晶体体积明显增大;相应的体积效应破坏晶粒与晶粒之间的结合力,导致区域B中有大量裂纹生成,这些裂纹逐渐扩展,最终引发坩埚破损和剥落。

=5.72 g/cm3要小,从BaO转变为Ba(OH)2的过程中,晶体体积明显增大;相应的体积效应破坏晶粒与晶粒之间的结合力,导致区域B中有大量裂纹生成,这些裂纹逐渐扩展,最终引发坩埚破损和剥落。

图4 BaZrO3坩埚与空气接触不同时间后的宏观照片

Fig. 4 Macrographs of BaZrO3 crucible after contacting with air for different time

1500 ℃时钛含量66%合金熔体与BaZrO3耐火材料的反应方程式如下;

(1)

(1)

反应吉布斯自由能ΔG=G(Ti2NiOx)-G(Ti2Ni)+ 664912.5x(x为钛熔体中的固溶氧含量);两者反应的发生需满足吉布斯自由能变化为负值的热力学条件,当反应吉布斯自由能ΔG=0 J/mol,熔体中固溶氧含量极少,仅约为3.5×10-5 mol,由此可知两者在1500 ℃下基本上不会发生反应。贺进等[16]对比了BaZrO3与TiO2标准生成吉布斯自由能随温度的变化关系,得出BaZrO3的标准生成吉布斯自由能小于TiO2的。因此,BaZrO3耐火材料对钛熔体呈现较好的热力学稳定性。

显然,BaZrO3耐火材料受钛熔体的侵蚀过程中热力学并不是主要的决定因素。SAHA等[19]和SUZUKI等[20]通过研究ZrO2及稀土氧化物等生成吉布斯自由均能高于TiO2的耐火材料与纯钛的界面反应,提出钛液与耐火材料之间作用是溶解侵蚀。BARBOSA等[21]和CUI等[22]使用热力学更加稳定的Y2O3坩锅定向凝固制备TiAl合金时,Y2O3耐火材料同样受熔体溶解侵蚀而导致坩埚受损,溶解方程式如下;

Y2O3(solid)=2Y(in melt)+3O(in melt) (2)

基于此,可知钛熔体与BaZrO3耐火材料之间界面反应主要为溶解侵蚀。BaZrO3与钛熔体接触时分解生成BaO和ZrO2,一部分BaO残留在坩锅基体中,一部分进入熔体,进入熔体中的BaO由于其较低的蒸汽压[23-24],向真空中挥发,在熔炼过程中会伴随冒烟现象出现,而实验过程中则可以明显见此现象。同时,BaO的挥发会导致熔体中Ba元素残留量极少,ICP检测结果显示,熔炼3次的合金中Ba元素含量均低于0.001%(质量分数)。而ZrO2则与熔体反应,导致合金中Zr和O含量大量增加。SUZUKI等[20]提出ZrO2在钛熔体中的溶解方程为

ZrO2(s)=Zr(in melt)+2O(in melt) (3)

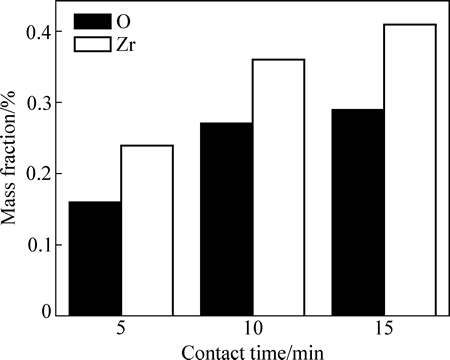

同时,伴随着熔炼过程中强烈的电磁搅拌,坩埚与熔体接触后内壁变得稀松,随着接触时间增加,坩埚与熔体接触面积逐渐变大,导致耐火材料在合金中溶解量也增加,从图5可以看出,随着坩埚与熔体接触时间增加,合金中氧含量(质量分数)从0.24%增加到0.41 %,锆含量则从0.16%增加到0.29%。BaZrO3耐火材料在钛熔体中的溶解方程式如下:

BaZrO3(solid)=BaO(in melt)+Zr(in melt)+2O(in melt) (4)

对熔炼前、后的BaZrO3坩埚内壁进行显微结构 分析,如图6所示。从图6(a)中可以看出,熔炼前的BaZrO3晶粒连接紧密晶粒结构完整;而熔炼后的锆酸钡晶粒表面出现明显的受熔体冲刷溶解后的片层状结构,如图6(b)所示。

图5 Zr和O在熔体中的熔解量

Fig. 5 Dissolution amount of Zr and O element in melt

图6 BaZrO3坩埚内壁的SEM像

Fig. 6 SEM images of inner wall of BaZrO3 crucible

以目前的研究来看,在使用BaZrO3耐火材料感应熔炼富钛合金时仍存在不足,基于BaZrO3耐火材料在富钛熔体中的溶解侵蚀作用进行更深层次的研究,可能是未来钛合金感应熔炼制备及钛合金精密铸造用耐火材料发展的一个方向。具体来说,首先通过提高坩埚的烧结温度和延长保温时间来增加坩埚烧结致密度,减少熔体与BaZrO3耐火材料的接触面积;其次通过使用Y2O3和CaO等高稳定性氧化物对BaZrO3耐火材料进行掺杂改性研究,进一步提高其热力学稳定性,减少熔体与耐火材料界面反应。

3 结论

1) BaZrO3坩埚熔炼富钛合金受侵蚀层厚度约2000 μm,侵蚀层中BaO与空气中水汽和CO2反应,晶粒体积变化破坏晶粒间结合力,导致坩锅剥落损毁。

2) 尽管BaZrO3耐火材料对钛熔体呈现良好的热力学稳定性,但耐火材料受熔体的溶解侵蚀是导致其受损的主要原因。

3) 通过提高BaZrO3坩埚烧成致密度及对BaZrO3耐火材料的掺杂改性研究降低熔体对耐火材料的溶解侵蚀作用,可能为钛合金感应熔炼制备及钛合金精密铸造用耐火材料的发展提供一种新的发展方向。

REFERENCES

[1] LUTJERING G, WILLIAMS J C. Titanium[M]. Berlin: Springer, 2007: 337-366.

[2] KROLL W. The production of ductile titanium[J]. Trans Electrochem Soc, 1940, 78(1): 35-47.

[3] GOPIENKO V G. Contact reaction of metallic titanium with oxide refractory materials[J]. Refractory, 1972, 78(1): 405-407.

[4] KUANG J P, HARING R A, CAMPBELL J. Investigate into refractories as crucible and mould materials for melting and casting γ-TiAl alloys[J]. Material Science and Technology, 2000, 16: 1007-1016.

[5] KOSTOV A, FRIEDRICH B. Predicting thermodynamic stability of crucible oxides in molten titanium and titanium alloys[J]. Comp Mater Sci, 2006, 38(2): 374-385.

[6] LIN K F, LIN C C. Interfacial reactions between Ti6Al4V alloy and zirconia mold during casting[J]. J Mater Sci, 1999, 34(23): 5899-5906.

[7] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[J]. 北京: 化学工业出版社, 2005: 21-24.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Titanium alloys and application[J]. Beijing: Chemical Industry Press, 2005: 21-24.

[8] FU Bin-guo, WANG Hong-wei, ZOU Chun-ming, MA Pan, WEI Zun-jie. Interfacial reactions between Ti-1100 alloy and CaO crucible during casting process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3118-3125.

[9] CUI Ren-jie, TANG Xiao-xia, GAO Ming, ZHANG Hu, GONG Sheng-kai. Thermodynamic analysis of interactions between Ti-Al alloys and oxide ceramics[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 887-894.

[10] GOMES F, BARBOSA J, RIBEIRO C S. Induction melting of γ-TiAl in CaO crucibles[J]. Intermetallics, 2008, 16(11/12): 1292-1297.

[11] TETSUI T, KOBAYASHI T, MORI T, KISHIMOTO T, HARADA H.Evaluation of yttria application as a crucible for induction melting of TiAl alloys[J]. Materials Transactions,2010, 51(9): 1656-1662.

[12] HOLCOMBE C E, SERANDOS T R. Consideration of yttria for vacuum induction melting of titanium[J]. Metall Trans B, 1983, 14(3): 497-499.

[13] MACMAUS-DRISCOLL J L, FOLTYNL S R, JIA Q X, WANG H, SERQUIS A, CIVALE L, MAIOROV B, HAWLEY M E, MALEY M P, PETERSON D E. Strong enhanced current densities in superconducting coated conductors of YBa2Cu3O7-x+BaZrO3[J]. Nat Mater, 2004, 3(7): 439-443.

[14] 张 钊, 朱凯亮, 刘岚洁, 鲁雄刚, 吴广新, 李重河. BaZrO3坩埚的制备及与钛合金熔体的界面反应[J].硅酸盐学报, 2013, 41(9): 1278-1283.

ZHANG Zhao, ZHU Kai-liang, LIU Lan-jie, LU Xiong-gang, WU Guang-xin, LI Chong-he. Preparation of BaZrO3 crucible and its interfacial reaction with molten titanium alloys[J]. Journal of the Chinese Ceramic Society Chin Cream Soc, 2013, 41(9): 1278-1283.

[15] 李重河, 周 汉, 陈光耀, 胡仁民, 吴 铸, 李志林. TiFe 基储氢合金的BaZrO3坩埚熔炼制备及其储氢性能[J]. 重庆大学学报, 2016, 39(2): 107-113.

LI Chong-he, ZHOU Han, CHEN Guang-yao, HU Ren-min, WU Zhu, LI Zhi-lin. Preparation of TiFe based alloys melted by BaZrO3 crucible and its hydrogen storge properties[J]. Journal of Chongqing University, 2016, 39(2): 107-113.

[16] 贺 进, 魏 超, 李明阳, 汪宏斌, 鲁雄刚, 李重河. BaZrO3 耐火材料与TiAl合金熔体的界面反应[J]. 中国有色金属学报, 2015, 25(6): 1505-1511.

HE Jin, WEI Chao, LI Ming-yang, WANG Hong-bin, LU Xiong-gang, LI Chong-he. Interfaical reaction between BaZrO3 refactory and melted TiAl alloys[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1505-1511.

[17] 陈光耀, 程治玮, 王树森, 秦子威, 鲁雄刚, 李重河. 高活性钛熔体与BaZrO3耐火材料界面反应机理[J]. 硅酸盐学报, 2016, 44(6): 892-897.

CHEN Guang-yao, CHEN Zhi-wei, WANG Shu-sen, QIN Zi-wei, LU Xiong-gang, LI Chong-he. Interfacial reaction between high reactivity titanium melt and BaZrO3 refractory[J]. Journal of the Chinese Ceramic Society, 2016, 44(6): 892-897.

[18] 贾德昌, 周 玉. 陶瓷材料抗热震性研究进展[J]. 材料科学与工艺, 1993, 1(4): 96-102.

JIA De-chang, ZHOU Yu. The progress of investigate on thermal shock resistance of ceramic materials[J]. Material Science and Technology, 1993, 1(4): 96-102.

[19] SAHA R L, NANDY T K, MISRA R D K, JACOB K T. On the evaluation of stability of rare earth oxides as face coats for investment casting of titanium[J]. Metall Trans B, 1990, 21(3): 559-566.

[20] SUZUKI K, NISHIKAWA K, MATUI H, WATAKABE S. Effect of centrifugal force on mould filling and solidification in precision casting of Ti-6Al-4V alloy[J]. Journal of the Japan Institute of Metals, 1996, 60(2): 853-862.

[21] BARBOSA J, RIBEIRO C S, MONTEIRO A C. Influence of superheating on casting of γ-TiAl[J]. Intermetallics, 2007, 15(7): 945-955.

[22] CUI R J, GAO M, ZHANG H. Interactions between TiAl alloys and yttria refractory material in casting process[J]. Mater Process Technol, 2010, 210(9): 1190-1196.

[23] KATO S, IGUCHI Y, BANYA S. Deoxidation equilibrium of liquid iron with barium[J]. Tetsu-to-Hagane, 1992, 78(2): 253-259.

[24] MIYAMOTO S, WATANABE M, NARUSHIMA T, IGUCHI Y. Deoxidation of NiTi alloy melts using metallic barium[J]. Mater Trans, 2008, 49(2): 289-293.

Corrosion mechanism of BaZrO3 refractory in titanium enrichment melt

CHEN Guang-yao1, LI Bao-tong1, ZHANG Hao1, GAO Peng-yue1, QIN Zi-wei1, LU Xiong-gang1, 2, LI Chong-he1, 2

(1. State Key Laboratory of Advanced Special Steel, Shanghai Key Laboratory of Advanced Ferrometallurgy, School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China;

2. Shanghai Special Casting Engineering Technology Research Center, Shanghai 201605, China)

Abstract: The titanium enrichment (66%, mole fraction) alloy was melted in the BaZrO3 crucible to investigate the crucible damage and erosion mechanism. By the optical microscopy, scanning electron microscopy, X-ray diffractometry and atomic emission spectrometry, the microstructure and the dissolution of BaZrO3 refractory after contacting the melt with different time were studied. The results show that the thickness of erosion layer of the BaZrO3 crucible is measured as about 2000 μm. The Zr and O elements contents in the alloys increase with rising the contacting time. The damage of BaZrO3 crucible is caused by the changing of crystal volume, as the BaO transforms into BaCO3. The main mechanism responsible for the erosion of BaZrO3 crucible is the dissolution of BaZrO3 refractory in the titanium enrichment melt.

Key words: BaZrO3; refractory; enrichment titanium alloys; erosion; interfacial reaction

Foundation item: Project(51574164, 51374142) supported by the National Natural Science Foundation of China; Project(2014CB643403) supported by the National Key Basic Research Program of China; Project (14JC1491400) supported by Basic Major Research Program of Science and Technology Commission Foundation of Shanghai, China

Received date: 2016-05-31; Accepted date: 2016-10-21

Corresponding author: LI Chong-he; Tel: +86-21-56332934; E-mail: chli@staff.shu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51574164,51374142);国家重点基础研究发展计划资助项目 (2014CB643403);上海市科委基础重点项目(14JC1491400)

收稿日期:2016-05-31;修订日期:2016-10-21

通信作者:李重河,教授,博士;电话:021-56332934;E-mail:chli@staff.shu.edu.cn