T6热处理对触变锻造加低过热铸造制备的A356和A380铝合金的影响

来源期刊:中国有色金属学报(英文版)2018年第3期

论文作者:Ridvan GECU Serhat ACAR Alptekin KISASOZ Kerem Altug GULER Ahmet KARAASLAN

文章页码:385 - 392

关键词:T6热处理;触变锻造;低过热铸造;铝合金

Key words:T6 heat treatment; thixoforging; low superheat casting; aluminium alloy

摘 要:研究T6热处理对触变锻造A356和A380铝合金的影响。采用低过热铸造(LSC)技术制备用于触变锻造的样品。为了获得等轴晶粒并防止枝晶生长,将样品在高于液相温度20 °C时进行浇铸,将浇铸坯料再加热不同时间(20~80 min)后进行触变锻造,变形量为50%,再将触变锻造后的A356和A380铝合金样品进行T6 热处理。用光学显微镜、能量弥散X射线谱仪、扫描电镜和布氏硬度仪对经触变锻造、固溶处理和时效处理后样品的显微组织和硬度变化进行检测。结果表明,T6热处理后合金的显微组织更均匀,并分别在A356和A380坯料中形成了新的析出相Mg2Si和Al2Cu。相应地,经过人工时效后,样品的硬度大幅度提高,A356铝合金的硬度达到HB 93,A380铝合金的硬度达到HB 120。

Abstract: The effects of T6 heat treatment on thixoforged A356 and A380 aluminium alloys were studied. Low superheat casting (LSC) technique was carried out to prepare proper specimens for thixoforging process. The samples were poured at 20 °C above their liquidus temperatures which provided the formation of equiaxed grains instead of dendritic growth. Produced billets were reheated for varied time from 20 to 80 min and thixoforged with 50% deformation rate. After thixoforging process, the samples were T6 heat treated for both A356 and A380 alloys. The microstructural evaluation and hardness alteration of thixoforged, solution treated and aged specimens were examined comparatively by using optical microscopy, scanning electron microscopy with energy-dispersive X-ray spectroscopy and Brinell hardness equipment. T6 heat treatment provided relatively uniform microstructure with newly formed precipitates that are Mg2Si and Al2Cu for A356 and A380 billets, respectively. Accordingly, hardness after artificial aging was increased considerably and reached HB 93 for A356 and HB 120 for A380 alloys.

Trans. Nonferrous Met. Soc. China 28(2018) 385-392

Ridvan GECU, Serhat ACAR, Alptekin KISASOZ, Kerem ALTUG GULER, Ahmet KARAASLAN

Department of Metallurgical and Materials Engineering, Yildiz Technical University, Davutpasa Campus, 34210, Esenler, Istanbul, Turkey

Received 26 January 2017; accepted 17 May 2017

Abstract: The effects of T6 heat treatment on thixoforged A356 and A380 aluminium alloys were studied. Low superheat casting (LSC) technique was carried out to prepare proper specimens for thixoforging process. The samples were poured at 20 °C above their liquidus temperatures which provided the formation of equiaxed grains instead of dendritic growth. Produced billets were reheated for varied time from 20 to 80 min and thixoforged with 50% deformation rate. After thixoforging process, the samples were T6 heat treated for both A356 and A380 alloys. The microstructural evaluation and hardness alteration of thixoforged, solution treated and aged specimens were examined comparatively by using optical microscopy, scanning electron microscopy with energy-dispersive X-ray spectroscopy and Brinell hardness equipment. T6 heat treatment provided relatively uniform microstructure with newly formed precipitates that are Mg2Si and Al2Cu for A356 and A380 billets, respectively. Accordingly, hardness after artificial aging was increased considerably and reached HB 93 for A356 and HB 120 for A380 alloys.

Key words: T6 heat treatment; thixoforging; low superheat casting; aluminium alloy

1 Introduction

Lightweight alloys such as aluminium and magnesium have become recently prominent to overcome fuel efficiency and environmental pollution concerns in automotive industry. A356 and A380 aluminium casting alloys have been widely used in automobile components to provide progress on those concerns due to their tremendous castability, weldability, corrosion resistance and high strength-density ratio [1-3]. Semi-solid metal (SSM) processing of aluminium alloys has been developed as an alternative to conventional die casting method for manufacturing net-shaped products [4]. SSM techniques require non-dendritic structure in order to obtain “thixotropic” properties which are related to the success of the forming process [5]. Thixotropy can be described as a behaving of the materials like solid and liquid phases. This behavior enables to fill die more uniformly than fully liquid state casting methods owing to the laminar manner instead of turbulent flow [6]. To manufacture the starting material (ingot or billet) with thixotropic properties, several methods have been developed like recrystallisation and partial remelting (RAP), cooling slope (CS) casting, magnetohydrodynamic (MHD) stirring and strain induced melt activation (SIMA) [7,8]. Low superheat casting (LSC) is one of the attractive ways to produce proper starting material with reduced cost by comparison with other methods. In LSC process, subjected metal is cast at just above its liquidus temperature and equiaxed non-dendritic grains that spheroidize during further SSM process are formed. There are various explanations about the non-dendritic formation mechanism. According to MULLINS and SEKERKA [9], very low undercooling with very high saturation of nucleation sites may be the main reason for equiaxed grain formation instead of dendrites. Another claimed theory is “secondary nuclei” caused by applied agitation to molten metal during solidification [10]. Agitation causes to rupture dendrite arms, change growing morphology and generate grain-refined microstructure by dendrite fragmentation. CHALMERS [11] also showed that low casting temperature promotes the formation of equiaxed grains and makes them grow uniformly. In spite of those researches and unmentioned others, much work is required to know accurate conversion mechanism from dendritic to equiaxed particles.

SSM techniques are mainly divided into thixo and rheo routes. Thixoforging, which belongs to the thixo route, is a kind of SSM forming method where the material is heated into the temperature that both solid and liquid phases of alloy coexist, and then are shaped in an open die to manufacture near net-shaped components [12]. As for non-dendritic structure, wide solidification interval and continuous transition from solidus to liquidus temperatures are necessary for the success of thixoforging process. From this point of view, A356 and A380 aluminium alloys were chosen due to their adequate fluidity and castability features with thixotropic properties. Al-Si alloys are generally heat treated so as to acquire optimum combination of strength and ductility. WANG et al [7] conducted T6 heat treatment on A356 alloy wheels and reported that heat treated wheels show better tensile strength due to Mg2Si precipitation and eutectic transformation into globular Si particles. SALLEH et al [12] concluded that tensile strength of thixoforged A319 alloy reached 298 MPa after aging while it was 241 MPa for untreated sample. There is no comparative study about the effects of T6 heat treatment on thixoforged A356 and A380 alloys in the literature. In this work, T6 heat treatment was applied to thixoforged A356 and A380 billets obtained by LSC process. The micrographs with hardness measurements of both thixoforged and T6-treated alloys were given and results were discussed.

2 Experimental

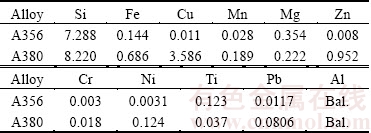

1000 g of recycled A356 and A380 alloy ingots were used for each casting operation. Chemical compositions of these alloys are shown in Table 1. Sliced ingots were melted in a clay/graphite crucible by using electric resistance furnace and poured into cylindrical steel mould. The pouring temperatures were selected 20 °C above the liquidus temperatures which were 615 °C for A356 and 595 °C for A380. Accordingly, LSC processes of A356 and A380 alloys were carried out at 635 and 615 °C, respectively. Produced billets were cut with the dimensions of 40 mm in diameter and 40 mm in height. One as-cast specimen of each alloy was reserved for further comparative analysis. The rest of the samples were reheated 20°C below their liquidus temperatures (595 °C for A356 and 575 °C for A380) and held in these semi-solid regions for 20-80 min. After holding step, specimens in a semi-solid condition were forged in a preheated open die with 50% deformation rate by using hydraulic press. All thixoforged samples were sliced into three pieces, one of them was reserved for characterization and the other two were subjected to subsequent T6 process. T6 heat treatment was conducted into the following steps: solution treatment, quenching and artificial aging. Solution treatment temperatures were chosen at 20 °C below the solidus temperatures of various alloys, thus A356 and A380 alloys were solution treated for 4 h at 535 and 520 °C, respectively. All treated samples were water-cooled and those of each two samples were analyzed at their existing state while the others were artificial aged at 180 °C for 4 h. For the microstructural investigations, ground and polished sample surfaces were etched with 0.5% HF solution. All micrographs were taken by Nikon Eclipse MA100 optical microscope and Brinell hardness measurements were performed by universal test device with load of 62.5 kg and tip diameter of 2.5 mm. Energy-dispersive X-ray spectroscopy (EDS) was used for elemental analysis by using a Jeol JSM 5410 LV scanning electron microscope (SEM).

Table 1 Chemical compositions of A356 and A380 aluminium alloys

3 Results and discussion

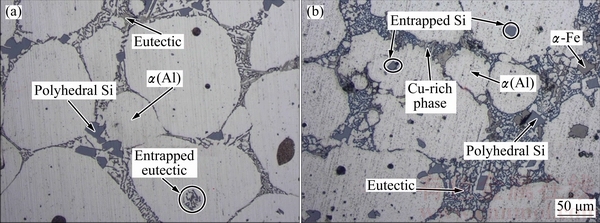

All SSM processes were carried out to avoid dendritic solidification structure that naturally was formed by conventional casting methods. LSC technique is one of the ways to produce billets with non-dendritic microstructures for using them in further thixoforging process. Thixoforged billets were also subjected to T6 heat treatment to enhance mechanical properties owing to precipitation of dissolved atoms. Different phases that formed after thixoforging of A356 and A380 alloys are shown in Fig. 1. α(Al), eutectic and polyhedral Si phases were formed in A356 billet while additionally Fe-rich and Cu-rich phases were observed in A380 alloy.

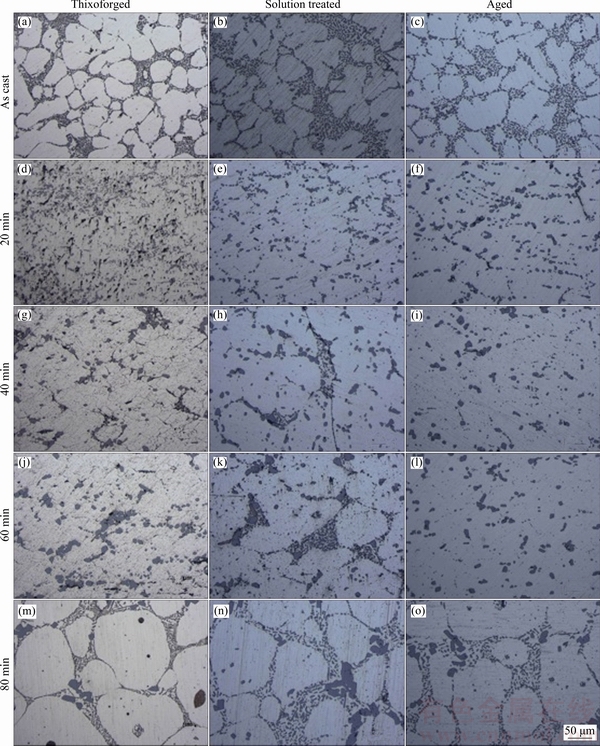

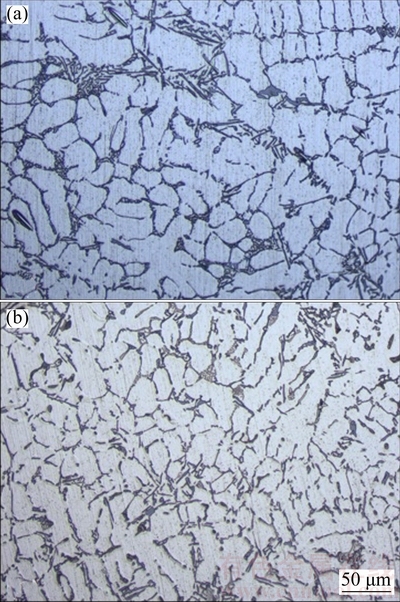

The micrographs of thixoforged and T6-treated A356 billets are shown in Fig. 2. A356 is a hypoeutectic Al-Si alloy that can flow adequately even under low superheat conditions. As a consequence of its remarkable fluidity, LSC operation was successfully done without any pouring problem and non-dendritic α(Al) phase surrounded by Al-Si eutectic structure was formed in the as-cast specimen. A356 and A380 were also manufactured by permanent mould casting at 730 °C for comparison and their microstructures are shown in Fig. 3. α(Al) was intrinsically solidified in dendritic structure and eutectic was formed as needle-like morphology. LSC process rearranged the eutectic with smaller needles and α(Al) phases with suppressing dendritic growth.

Fig. 1 Formed phases in thixoforged A356 (a) and A380 (b) billets

Fig. 2 Micrographs of thixoforged, solution treated and artificial aged A356 alloy billets

Fig. 3 Microstructures of A356 (a) and A380 (b) alloys produced by permanent mould casting at 730 °C

LSC technique can be considered as a beginning procedure of SSM process, so it should be combined with thixoforging to complete the operation. A356 billets obtained by LSC were thixoforged after holding them at a reheating temperature for 20, 40, 60 and 80 min, respectively. Thixoforging changed globular as-cast structure substantially. The sphericity of α(Al) was broken down and the deformation texture became observable except for 80 min reheated sample. Eutectic Si particles with polyhedral morphology were generated by released Si at reheating temperature from partially melted eutectic structure that contains α(Al) and spherical Si. With increasing reheating time, the average particle size of polyhedral Si was obviously increased. Some eutectic Si particles were formed inside α(Al). This might occur because of the grain growth and the coalescence of α(Al) and thusly eutectic region was entrapped there. Another possibility is that the applied pressure in thixoforging process may move partially melted regions from grain boundaries into α(Al) phase [13]. 80 min reheated sample differed from the other thixoforged samples with its coarsened spherical α(Al) structure surrounded by eutectic. Polyhedral Si particles also existed but their amounts were decreased dramatically by comparison with the other reheated samples. It was concluded that the eutectic was completely remelted during 80 min reheating and solidified as almost itself. As a result, the as-cast and 80 min reheated specimens appeared similarly except α(Al) grain growth and some polyhedral Si particles at grain boundaries of the latter.

Thixoforged specimens were T6 heat treated to improve mechanical properties with the following steps: solution treatment, quenching and artificial aging. Solution treatment provided homogenization of as-cast and thixoforged structures at room temperature after water cooling. The distribution of eutectic Si was much more uniformly than that of the non-treated samples. From 20 to 60 min reheated samples in Fig. 2, it can be said that some Si particles were dissolved into α(Al) matrix and α(Al) phase was coarsened. For 80 min reheated specimen, dissolved Si atoms from eutectic participated pre-existing polyhedral Si particles, as well as decomposition into α(Al) during solution treatment. Consequently, Si particle size was increased while eutectic was dissociated along grain boundaries in this sample.

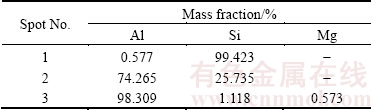

Artificial aging was performed at 180 °C for 4 h and the related microstructures of A356 are also shown in Fig. 2. New smaller precipitates appeared in addition to existing larger ones. Larger Si particles became much larger by the effect of diffusion that depends on the temperature and time. α(Al) grains were also coarsened and coalesced similarly. The SEM image of aged A356 sample reheated for 80 min is shown in Fig. 4, whereas related EDS results are shown in Table 2. Spot 1 in Fig. 4 indicates the light gray particulate containing very high amount of Si which can be interpreted as polyhedral Si. In Spot 2, the coexistence of Al and Si with resulted contents is a sign of eutectic structure. According to EDS results of Spot 3, it can be stated that β-Mg2Si phase precipitates inside the α(Al) matrix.

Fig. 4 SEM image and EDS spots in aged A356 sample reheated for 80 min

Table 2 Elemental contents of EDS spots in Fig. 4

The microstructures of thixoforged and T6-treated A380 samples are shown in Fig. 5. The chemical composition of A380 includes more Cu, Fe and Zn contents that formed intermetallic compounds, thus the microstructure of A380 was obtained more complexly. Eutectic Si platelets (bluish) and α-Fe (light gray region) existed together in eutectic region of A380. Normally, α-Fe is solidified as a Chinese script morphology, but LSC process caused α-Fe formation in a polyhedral version that had more compact form than Chinese script [14]. Reheating samples for varied time allowed the fragmentation of eutectic Si and α-Fe phases. Some Si and Fe-rich particles were entrapped inside α(Al) matrix which can be seen in Fig. 1(b) clearly. This phenomenon may occur by the abovementioned possible reasons for A356. More polyhedral Si constituents were obtained in the microstructure compared to A356 because of the higher Si content of A380. According to image analysis results, the amount of polyhedral Si varied between 8% and 12% for A356 alloy except the as-cast sample with approximately 3% content, whereas it varied between 13% and 20% for A380 alloy.

Fig. 5 Micrographs of thixoforged, solution treated and artificial aged A380 alloy billets

The microstructures of solution treated A380 showed similar behavior to A356. Uniform distribution of Si and α-Fe was achieved. Platelets of these phases were broke down and polyhedral forms occurred in as-cast sample. From 20 to 60 min reheated samples, it can be concluded that Si particles dominated the grain boundaries and the inside α(Al). For 80 min reheated sample, grain size enlargement of polyhedral Si was observed. Dissolved Si atoms from eutectic phase during reheating were diffused into pre-existing particles and made them much larger. α(Al) grains were also coarsened because of the heat exposure for sufficient time during treatment.

Aged micrographs of A380 showed that the amount of α-Fe was increased and its structure was much spheroidized. Usual skeleton type of α-Fe was fragmented to smaller particles. α(Al) grain size was increased and grain boundaries between α(Al) and round Si particles became imperceptible. New smaller particles were attained alongside the larger pre-existed ones.

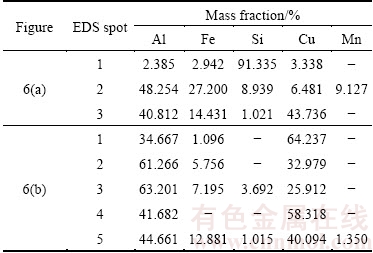

SEM image of aged A380 alloy reheated for 80 min is shown in Fig. 6. Elemental contents of the EDS spots are given in Table 3 for Figs. 6(a) and (b). Figure 6(b) shows the higher magnification image of the stated region with red square in Fig. 6(a). Spot 1 refers to polyhedral Si while Spot 2 most probably indicates that Al15(FeMn)3Si2 phase is as α-Fe. Spot 3 in Fig. 6(a) represents Al2Cu phase with significant amount of Fe. High Fe content is associated with the fact that both Fe-rich and Cu-rich phases locate around the eutectic. Spots 1, 4 and 5 in Fig. 6(b) show Al2Cu precipitates in higher magnification. A considerable amount of Si was observed in Spot 3. Elemental content of Spot 2 was nearly same to that of Spot 3 except non-existence of Si.

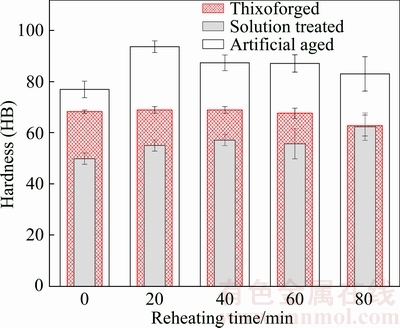

Brinell hardness measurement was taken and the results of A356 are shown in Fig. 7. For thixoforged A356 samples, hardness values were HB ~68 except 80 min reheated one which has hardness of HB 62. This slight decrease was arisen from the spheroidization and the coarsening of grains. Hardnesses were decreased considerably after solution treatment. With increasing reheating time, hardness increment from HB 50 to HB 62 in solution treated parts was obtained. This hardness variation can be explained by the growth rate of α(Al) grains. Only 80 min reheated specimen preserved its former hardness. The constancy of hardness values was explained by microstructural observations in Fig. 2.

Fig. 6 SEM image and EDS spots in aged A380 sample reheated for 80 min

Table 3 Elemental contents of EDS spots in Fig. 6

Treated and non-treated micrographs look similar to each other for 80 min reheated sample. Aged specimens showed more dramatic increase in hardness than both non-treated and solution treated ones. The highest change occurred in 20 min reheated specimen that has hardness of HB 93. Mg2Si precipitates along grain boundaries and inside α(Al) were responsible for the hardness changing, as well as homogenous redistribution of refined eutectic structure. Precipitates from other samples were coarsened and spheroidized and thus their hardness was decreased. The minimum hardness alteration was attained in as-cast specimen. Its globular α(Al) phase was remained as the same after aging and spherical morphology prevented increasing hardness. 4 h treatment looks efficient to improve mechanical properties without permitting excessive grain growth.

Fig. 7 Hardness values of A356 billets vs reheating rime

Hardness values of A380 billets are shown in Fig. 8. The hardness values of non-treated A380 billets varied between HB 82 and HB 109. Only 20 min reheated sample had an increase in hardness by comparison with the as-cast specimen. The most refined α-Fe phase and polyhedral Si particles were observed in this sample. With increasing reheating time, these phases were spheroidized and enlarged. The grain growth of both α(Al) matrix and surrounded phases caused decreasing in hardness values. Solution treatment affected samples in different ways. The hardness of 80 min reheated sample was increased after solution treatment process in spite of the α(Al) grain growth. Morphology and distribution of Si particles and refinement of eutectic structure may be the reason for this improvement. The other samples showed slight decrease in hardness after solution treatment as expected. Hardness values of aged specimens reached up to approximately HB 120. Al2Cu precipitates are the main reason for hardness increase after aging. The highest improvement was obtained in 20 min reheated sample. Refinement of polyhedral Si particles in this specimen was obviously seen in Fig. 5. The microstructure of the as-cast alloy was similar to that of 20 min reheated sample and thus second highest hardness was obtained from this specimen. Grain growth of α(Al) and polyhedral Si phases prevented further increase of 60 and 80 min reheated billets.

Fig. 8 Hardness of A380 billets vs reheating time

4 Conclusions

A356 and A380 aluminium billets were successfully poured by LSC technique that avoids dendritic formation. Thixoforging was applied to these billets after reheating them for various time. Eutectic Si was transformed into polyhedral form and polyhedral Si particles were coarsened with increasing reheating time for both alloys. Globular structure of α(Al) disappeared and deformation texture was observed after thixoforging, except 80 min reheated samples. The microstructure of A380 alloy also contains Fe-rich and Cu-rich intermetallic phases, in addition to α(Al) and eutectic phases. T6 heat treatment provided new smaller precipitates (Mg2Si for A356 and Al2Cu for A380) inside α(Al) matrix which are responsible for hardness increasing. The refinement of polyhedral Si particles was also increased hardness. The grain growth by increasing reheating time caused decrease in mechanical properties, thus the highest hardness after aging was attained in 20 min reheated sample for both alloys. The hardnesses of T6-treated specimens reached HB 93 for A356 and HB 120 for A380 billets.

References

[1] CHUNG I G, BOLOURI A, KANG C G. A study on semisolid processing of A356 aluminum alloy through vacuum-assisted electromagnetic stirring [J]. International Journal of Advanced Manufacturing Technology, 2012, 58: 237-245.

[2] JIANG W M, FAN Z T, LIU D J. Microstructure, tensile properties and fractography of A356 alloy under as-cast and T6 obtained with expendable pattern shell casting process [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 7-13.

[3] JIANG W M, FAN Z T, CHEN X, WANG B, WU H. Combined effects of mechanical vibration and wall thickness on microstructure and mechanical properties of A356 aluminum alloy produced by expendable pattern shell casting [J]. Materials Science and Engineering A, 2014, 619: 228-237.

[4] ZHU Q, MIDSON S P. Semi-solid moulding: Competition to cast and machine from forging in making automotive complex components [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1042-1047.

[5] ZHAO Z, CHEN Q, HU C, HUANG S, WANG Y. Near-liquidus forging, partial remelting and thixoforging of an AZ91D + Y magnesium alloy [J]. Journal of Alloys and Compounds, 2009, 485: 627-636.

[6] CHAYONG S, ATKINSON H V, KAPRANOS P. Thixoforming 7075 aluminium alloys [J]. Materials Science and Engineering A, 2005, 390: 3-12.

[7] WANG S C, ZHOU N, QI W J, ZHENG K H. Microstructure and mechanical properties of A356 aluminum alloy wheels prepared by thixoforging combined with a low superheat casting process [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2214-2219.

[8] FAN Z. Semisolid metal processing [J]. International Materials Reviews, 2002, 47(2): 49-85.

[9] MULLINS W W, SEKERKA R F. Morphological stability of a particle growing by diffusion or heat flow [J]. Journal of Applied Physics, 1963, 34(2): 323-329.

[10] WANNASIN J, MARTINEZ R A, FLEMINGS M C. Grain refinement of an aluminum alloy by introducing gas bubbles during solidification [J]. Scripta Materialia, 2006, 55: 115-118.

[11] CHALMERS B. The structure of ingots [J]. J Aust Inst Met, 1963, 8(3): 255-263.

[12] SALLEH M S, OMAR M Z, ALHAWARI K S, MOHAMMED M N, ALI M A M, MOHAMAD E. Microstructural evolution and mechanical properties of thixoformed A319 alloys containing variable amounts of magnesium [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 2029–2042.

[13] GENCALP IRIZALP S, SAKLAKOGLU N. Effect of Fe-rich intermetallics on the microstructure and mechanical properties of thixoformed A380 aluminum alloy [J]. Engineering Science and Technology, 2014, 17: 58–62.

[14] DINNIS C M, TAYLOR J A, DAHLE A K. As-cast morphology of iron-intermetallics in Al-Si foundry alloys [J]. Scripta Materialia, 2005, 53(8): 955-958.

Ridvan GECU, Serhat ACAR, Alptekin KISASOZ, Kerem ALTUG GULER, Ahmet KARAASLAN

Department of Metallurgical and Materials Engineering, Yildiz Technical University,

Davutpasa Campus, 34210, Esenler, Istanbul, Turkey

摘 要:研究T6热处理对触变锻造A356和A380铝合金的影响。采用低过热铸造(LSC)技术制备用于触变锻造的样品。为了获得等轴晶粒并防止枝晶生长,将样品在高于液相温度20 °C时进行浇铸,将浇铸坯料再加热不同时间(20~80 min)后进行触变锻造,变形量为50%,再将触变锻造后的A356和A380铝合金样品进行T6 热处理。用光学显微镜、能量弥散X射线谱仪、扫描电镜和布氏硬度仪对经触变锻造、固溶处理和时效处理后样品的显微组织和硬度变化进行检测。结果表明,T6热处理后合金的显微组织更均匀,并分别在A356和A380坯料中形成了新的析出相Mg2Si和Al2Cu。相应地,经过人工时效后,样品的硬度大幅度提高,A356铝合金的硬度达到 HB 93,A380铝合金的硬度达到HB 120。

关键词:T6热处理;触变锻造;低过热铸造;铝合金

(Edited by Wei-ping CHEN)

Corresponding author: Ridvan GECU; E-mail: ridvangecu@gmail.com

DOI: 10.1016/S1003-6326(18)64672-2