用铁粉和稀硫酸还原反萃P204中Fe3+

肖 纯1, 2,唐谟堂1,杨声海1,李 倩1

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 贵州师范大学 材料与建筑学院,贵州 贵阳,550059)

摘 要:针对湿法炼锌过程中P204萃取除铁铁反萃困难的问题,比较铸铁板、锌板、铁粉和锌粉分别作还原剂的还原反萃效果,确定铁粉为最好的还原反萃剂;提出新的Fe3+反萃方法,该法以铁粉作还原剂,稀硫酸作反萃剂,在机械搅拌和强保护气氛下边还原边反萃负铁P204中的Fe3+;考察还原反萃时间、负载有机相中Fe3+含量、铁粉加入量、反应温度、反萃剂酸度对Fe3+还原反萃率和还原铁粉指数的影响及其与反萃液中Fe2+的含量的关系。研究结果表明:在最优条件下,还原铁粉指数为1.087,Fe3+还原反萃率达73%;反萃液中Fe2+的质量浓度富集到61.8 g/L,可满足制备FeSO4?7H2O的要求。

关键词:湿法冶金;P204萃取;还原反萃Fe3+;铁粉

中图分类号:TF813 文献标识码:A 文章编号:1672-7207(2007)04-0663-06

Reductive stripping iron from P204 by iron powders and

dilute sulphuric acid

XIAO Chun1, 2, TANG Mo-tang1, YANG Sheng-hai1, LI Qian1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials and Civil Engineering, Guizhou Normal University, Guiyang 550059, China)

Abstract: In order to solve the problem of stripping Fe3+ from P204 to remove iron in zinc hydrometallurgy process, comparison and analysis were made of the experimental results of reduction and stripping by use of four reductive agents such as cast iron plant, zinc plant, iron powders and zinc powders, and a new technique by use of iron powders as reductive agent of Fe3+ was proposed. In this process iron powders were used for reducing Fe3+ to Fe2+ in P204 stripped by a dilution H2SO4 solution in the case of mechanical stirring and having strong protective atmosphere. The effects of reductive stripping time, Fe3+ content in P204, iron powder adding content, reaction time, acid concentration of stripping agent on the stripping rate and the reducer index of iron powders were investigated. The relationship between the concentration of Fe2+ in the striping solution and the factors was also examined. The results show that under the optimum conditions, the reducer index of iron powders is 1.087, the stripping rate of Fe3+ can reach 73% and the concentration of Fe2+ in the striping solution is 61.8 g/L, which can satisfy the need of industrial preparation of FeSO4?7H2O.

Key words: hydrometallurgy; extracting by P204; reductive stripping Fe3+; iron powders

湿法炼锌过程中传统的沉淀除铁法存在操作复杂、有价金属损失大,以及沉淀堆放造成二次污染等缺点[1-4]。在铁的萃取方面,磷酸二(2-乙基己基)脂即P204工业使用比较普遍[5-10],其萃取率和萃容量都很高,25%(体积分数)的P204对铁的萃取量就达25 g/L,且铁锌分离系数较高[11-14] 。这类萃取剂最大缺点是铁反萃困难,要求高酸度下反萃,即使用5~6 mol/L硫酸反萃也不理想[15-16]。鉴于此,国外有专家学者提出过用废钢渣作还原剂、水作反萃剂还原反萃负载有机相中Fe3+的设想[17],但还原剂纯度较低,反萃效果不佳。在此,本文作者提出用铁粉和稀硫酸从P204中还原反萃Fe3+,解决Fe3+反萃难的问题,使铁反萃液得以提纯,制备出FeSO4?7H2O,这对湿法冶金的清洁生产具有重大意义。

1 实 验

1.1 原 料

主要实验原料和试剂有:14.7 g/L Fe2(SO4)3溶液;30%P204+70%磺化煤油;硫酸;工业铁粉和氩气。

1.2 实验装置

主要实验装置有:275 r/min定时振荡机;500 mL和1 000 mL玻璃分液漏斗;能通入高纯氩气保护的还原反萃装置;JBV-Ⅲ机械搅拌;反应器为1 000 mL密闭平底烧瓶;DKB-501超恒温水浴槽。

1.3 分析方法

有机相和水相中的Fe2+及全Fe用重铬酸钾滴定法进行测定[18]。只是在含铁量较低时,增大分析取样量来提高准确度。

1.4 萃取实验方法

a. 萃取实验一:测定萃取剂中P204的含量对铁在有机相中饱和容量的影响。在环境温度(15 ℃)下,按照水油比1?1,在3个分液漏斗中分别加入20% P204+ 80%磺化煤油,30% P204+70% 磺化煤油,40% P204+ 60%磺化煤油各50 mL,然后,各加入50 mL 14.7 g/L Fe2(SO4)3溶液,混合振荡10 min以达到充分混合,再静置20 min使两相完全分层,排出水相,记录萃余 液的体积,分析其中Fe3+的含量;再在有机相中加入14.7 g/L新鲜Fe2(SO4)3溶液。重复以上萃取操作,直到排出的萃余液中Fe3+的质量浓度与料液中Fe3+的质量浓度接近时为止,每次都测定水相中Fe3+质量浓度,并计算负载有机相中Fe3+含量。

b. 萃取实验二:测定混合振荡时间对萃取的影响。在环境温度(15 ℃)下,用含30% P204有机相与 14.7 g/L Fe2(SO4)3溶液按照水油比1?1混合振荡,每隔一定时间,待水相与有机相分离后取1 mL水相分析Fe3+含量,计算出Fe3+的萃取量与萃取时间的关系。

c. 萃取实验三:测定萃余液酸度对萃取率的影响。在环境温度(15 ℃)下,按照水油比1?1,在分液漏斗中装入的50 mL 30% P204,然后加入29.4 g/L Fe2(SO4)3溶液25 mL,根据酸度要求加入60.27 g/L不同体积的H2SO4,补加蒸馏水到100 mL,测出6~30 g/L H2SO4浓度下的萃取率。

综合分析实验一、二和三的结果,确定最佳萃取条件下的萃取剂,作为还原反萃的原料。

d. 还原反萃实验:有机相中的Fe3+还原是一个电化学反应过程,即将有机相中难以反萃的Fe3+还原为易反萃的Fe2+。即以1 mol/L的硫酸溶液作反萃剂;经锌板、锌粉、铸铁板以及铁粉作还原剂的比较实验,发现锌粉加入到有机相中导致其黏度增大,而锌板和铁板还原性很弱,故选用铁粉作还原剂;以最高萃取率的负载有机相为还原反萃的试料;经氮气、氩气和高纯氩气实验比较,发现氮气与氩气使还原反萃效果不好,故选用高纯度氩气作保护性气体,即强保护性气体;还原反萃的搅拌速度为400 r/min。考察还原反萃时间、铁粉加入量、负载有机相铁量、温度和反萃剂酸度对Fe3+的还原反萃率的影响,在改变其中某一因素、固定其他4个因素的条件下,进行单因素还原反萃实验。反萃结束后,分离水相和有机相,分别记录体积,分析负载有机相中的Fe3+、水相中的Fe2+和全铁含量,据此计算出被还原反萃的Fe3+含量和用于还原反萃所消耗的铁粉量。

2 结果与讨论

2.1 萃铁的实验

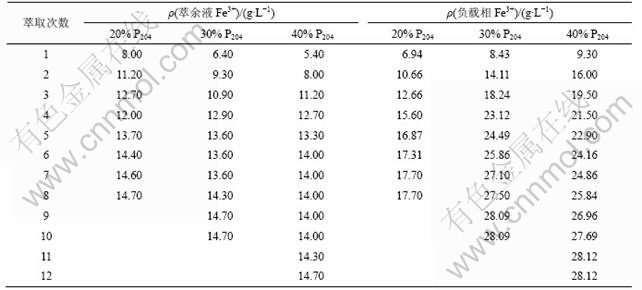

2.1.1 P204含量对铁萃取的影响

P204含量对铁萃取的影响如表1所示。可见,随着P204含量的增高,Fe3+饱和容量也增大;但是,40% P204负载有机相中Fe3+含量在萃取到第3次就没有30% P204的高,其原因是前者粘度较大,故选取的体积分数为30% P204。从表1还可以看出,当P204的体积分数分别为20%,30%和40%时,其负载有机相中Fe3+饱和容量分别为17.70,28.08和28.12 g/L。显然,选择体积分数为30% P204,具有最大饱和容量,但在实际中,负载有机相的含铁量往往低于饱和容量。

表1 不同P204含量的萃取结果

Table 1 Results of extraction with different P204 contents

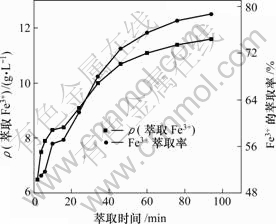

2.1.2 振荡混合时间对萃取的影响

当P204的体积分数为30%,水相含Fe3+ 14.7 g/L,水油比为1?1及室温条件下,考察振荡混合时间对萃取过程的影响,结果如图1所示。可见,在前15 min内,Fe3+的萃取增加的幅度较大,经1次萃取,有机相负载铁含量大于10.0 g/L。

图1 混合时间对铁萃取过程的影响

Fig.1 Effect of mixture time on extraction of Fe3+

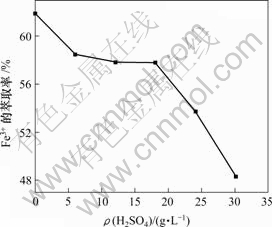

2.1.3 酸度对萃取的影响

在有机相浓度和萃取过程混合振荡时间固定的情况下,考察酸度对P204萃取Fe3+的影响,结果如图2所示。可见,酸度对萃取率影响不大,酸度越低,Fe3+的萃取率越高,当H2SO4溶液质量浓度为6~18 g/L时,萃取率为60%左右,可以满足当前除铁要求,此时萃取量约为10.0 g/L。

图2 酸度对萃取率的影响

Fig.2 Effect of acid concentration on extraction of Fe3+

2.2 还原反萃实验

采用含Fe3+ 12.4 g/L的负载有机相为试料,研究时间、铁粉用量、温度、酸度及反萃剂中Fe2+浓度对还原反萃率和还原反应铁粉指数(即参与反应的总铁粉质量与参与还原反应的铁粉质量的比)的影响,另外还研究负载有机相Fe3+浓度的影响规律。

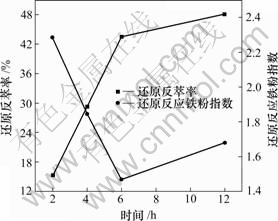

2.2.1 时间对还原反萃率与铁粉指数的影响

当铁粉用量为理论量的1.2倍,油水比为4.5?1,酸度为1 mol/L及40 ℃、机械搅拌、通氩气保护的条件下,考察时间对还原反萃的影响,结果如图3所示。可见,随着还原反应时间的延长,还原反萃率越来越高,6 h后增加的幅度不大;而反应铁粉指数在6 h前越来越低,降低幅度较大,但6 h后有所增加。这是由于6 h前,酸度高,酸溶铁粉多;6 h后,有机相中的Fe3+也大量还原,剩下的少量铁粉又被酸溶解,故还原反萃时间定为6 h为好。

图3 时间对还原反萃率的影响

Fig.3 Effect of time on reductive stripping rate

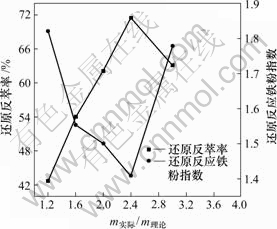

2.2.2 铁粉加入量对还原反萃率与铁粉指数的影响

因为还原反应是固液反应,增加铁粉的加入量,即增大还原反应的面积,还原反应速度加快。铁粉加入量对还原反萃的实验结果如图4所示。可见,最佳铁粉加入量为其理论量的2.4倍。随着铁粉加入量的增加,还原反萃率在铁粉加入量为2.4倍理论量以前呈上升趋势,铁粉加入量为2.4倍理论量后有所下降;还原反应铁粉指数开始呈现下降趋势,后来急剧上升。这是由于随着铁粉量增加,还原反应表面积逐渐增大,还原效果较好,当增加到一定量后,反应体系的Fe3+浓度大大降低,使还原反应进行缓慢,后来趋于零,而增加的铁粉就只能与硫酸发生反应,这也导致还原反萃后期还原反应铁粉指数急剧增加。

图4 铁粉加入量对还原反萃率的影响

Fig.4 Effect of iron powder usage on reductive stripping rate

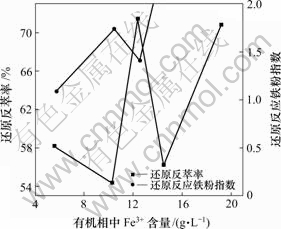

2.2.3 负载有机相中Fe3+含量对还原反萃率与铁粉指数的影响

在铁粉加入量固定为理论量的2.4倍,还原反萃时间为6 h时,考察负载有机相中Fe3+含量对还原反萃的影响,结果如图5所示。可见,随着负载有机相中Fe3+含量的增加,所需要的理论铁粉量就增加,还原反应的表面积增大,还原反应加强,还原反萃率总体呈上升趋势,只是在负载有机相中Fe3+含量为12.6 g/L时还原反萃率最高,而在14.2 g/L时还原反萃率又很低,这是由于前一个样所用铁粉纯度较高,而在做后一个样时新换铁粉纯度较低。还原反应铁粉指数总体呈上升趋势,是由于负载有机相中Fe3+含量增加,反萃剂的硫酸量增加,与铁粉直接反应的机会增大,但并不是呈线性关系。这说明反萃剂的总硫酸量与加入的铁粉量和负载有机相中Fe3+的含量对还原反应铁粉指数有综合影响。考虑到还原反萃率要高,而还原反应铁粉指数要低,故选取负载有机相中Fe3+的含量为10 g/L。

图5 有机相中Fe3+含量对还原反萃率的影响

Fig.5 Effect of concentration of Fe3+ in organic phrase on reductive stripping rate

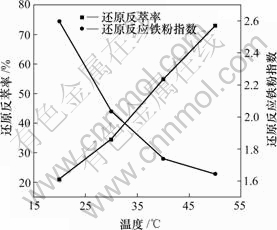

2.2.4 温度对还原反萃率与铁粉指数的影响

在负载有机相中Fe3+含量为10.2 g/L,铁粉用量为理论量的2.4倍,时间为6 h时,考察温度对还原反萃的影响,结果如图6所示。可见,随着温度的升高,化学反应都得到加强,但由于水相体积相对有机相体积较少,在强烈搅拌下,铁粉与有机相中Fe3+接触的机会远比与硫酸接触的机会多,故参与还原反应的铁粉量多,而与硫酸反应的铁粉量就少,所以,还原反萃率逐渐提高,还原反应铁粉指数逐渐降低,这样,温度应选择高一些。但是,随着温度的升高,有机相中的稀释剂磺化煤油将会挥发,当温度达到50 ℃时,磺化煤油有挥发现象,为了确保P204的含量不变,还原反萃温度确定为40 ℃。

图6 反应温度对还原反萃率的影响

Fig.6 Effect of temperature on reductive stripping rate

2.2.5 酸度对还原反萃率与铁粉指数的影响

在保证被还原的Fe2+都能够与硫酸反应生成FeSO4,要降低硫酸的浓度,就必然减小油水比,这样,铁粉与有机相接触的机会就相对减少,还原率就必然会降低,当硫酸浓度很低时就可能达不到还原的效果;若硫酸浓度太高,油水比增大,混合相的黏度增大,反应难以进行。当硫酸浓度为0.6 mol/L时还原反萃率最高,但还原反应铁粉指数是在硫酸浓度为 0.2 mol/L时最低。

2.2.6 反萃剂中Fe2+的富集

为了使反萃溶液得到利用,工业上往往采用电积铁或结晶硫酸亚铁。结晶硫酸亚铁的制备工艺简单,成本较低,但要求反萃溶液中硫酸亚铁的浓度尽量高。在负载有机相中Fe3+含量为10.2 g/L,铁粉加入量为理论量的2.4倍,在反萃剂含Fe2+ 49.6 g/L,H2SO4 0.2 mol/L时,进行还原反萃的循环实验,使反萃液中Fe2+的质量浓度富集到61.8 g/L以上,可以满足工业生产FeSO4?7H2O的要求。

3 结 论

a. 用铁粉作还原剂,稀硫酸作反萃剂,可从负载Fe3+的P204有机相中还原反萃铁,还原反萃率可达到73%,还原反应铁粉指数为1.087,工艺可行,可望为湿法炼锌过程中铁资源的利用提供一种新途径。

b. 还原反萃的最佳工艺参数是:负载有机相中Fe3+含量为10.0 g/L左右,铁粉加入量为理论量的2.4倍,还原反萃时间为6 h,还原反萃温度40 ℃。

c. 反萃液中的Fe2+可以富集到61.8 g/L以上,可满足结晶FeSO4?7H2O的要求。

参考文献:

[1] 彭容秋. 铅锌冶金学[M]. 北京: 科学出版社, 2003.

PENG Rong-qiu. Metallurgy of lead and zinc[M]. Beijing: Science Press, 2003.

[2] 张保平, 唐谟堂, 杨声海. 氨法处理氧化锌矿制取电锌[J]. 中南工业大学学报: 自然科学版, 2003, 34(6): 619-623.

ZHANG Bao-ping, TANG Mo-tang, YANG Sheng-hai. Treating zinc oxide ores using ammonia-ammonium chloride to produce electrolysis zinc[J]. Journal of Central South University of Technology: Natural Science, 2003, 34(6): 619-623.

[3] 舒见义. 湿法炼锌设计与环境保护[J]. 湖南有色金属, 2002, 18(2): 20-22.

SHU Jian-yi. The design and environmental protection of zinc hydrometallurgy[J]. Hunan Non-ferrous Metals, 2002, 18(2): 20-22.

[4] 何学斌, 赵效如, 陈康清. 湿法炼锌中矾渣的分离[J]. 有色金属:冶炼部分, 2004(5): 14-18.

HE Xue-bin, ZHAO Xiao-ru, CHEN Chang-qing. Separation of iron alum slag on zinc hydrometallurgy process[J]. Nonferrous Metals: Extractive Metallurgy, 2004(5): 14-18.

[5] 李洪桂. 湿法冶金学[M]. 长沙: 中南大学出版社, 2002.

LI Hong-gui. Hydrometallurgy[M]. Changsha: Central South University Press, 2002.

[6] 谢海云, 刘中华, 陈 雯, 等. P204萃取脱出铜精矿浸出液中铁[J]. 过程工程学报, 2005, 5(5): 514-516.

XIE Hai-yun, LIU Zhong-hua, CHEN Wen, et al. Removal of Fe3+ by solvent extraction with P204 from bacterial leaching solution of copper concentrate ore[J]. The Chinese Journal of Process Engineering, 2005, 5(5): 514-516.

[7] ZENG Dong-ming, HU Ai-ping, SHU Wan-yin, et al. Study on the method of recovering and separating indium from residue containing indium[J]. J Cent South Univ Technol, 2002, 9(2): 104-106.

[8] 陈家镛, 于淑秋. 湿法冶金中铁的分离与利用[M]. 北京: 冶金工业出版社, 1991.

CHEN Jia-yong, YU Shu-qiu. Separation and utilization of iron in the hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1991.

[9] 王开毅. 溶剂萃取化学[M]. 长沙: 中南工业大学出版社, 1991.

WANG Kai-yi. Solvent extraction chemistry[M]. Changsha: Central South University of Technology Press, 1991.

[10] 朱 屯. 萃取与离子交换[M]. 北京: 冶金工业出版社, 2005.

ZHU Tun. Solvent extraction & ion exchange[M]. Beijing: Metallurgical Industry Press, 2005.

[11] 郑国渠, 唐谟堂. 含铍氟硫化铋精矿氯化浸出液中铋、铍、铁物种研究[J]. 中南工业大学学报: 自然科学版, 1997, 28(6): 543-546.

ZHENG Guo-qu, TANG Mo-tang. A study on the species of Bi, Be and Fe in the chlorination-leaching solution of shizhuyuan bismuth concentrate containing Be and F[J]. Journal of Central South University of Technology: Natural Science, 1997, 28(6): 543-546.

[12] 许秀莲, 唐冠中, 刘长生. 磷类混合萃取剂对铟、铁分离的研究[J]. 南方冶金学院学报, 2002, 21(1): 55-59.

XU Xiu-lian, TANG Guan-zhong, LIU Chang-sheng. Research on separation of indium-iron with a phosphorous mixer extractant[J]. Journal of Southern Institute of Metallurgy, 2002, 21(1): 55-59.

[13] 杨大锦, 谢 刚, 王吉坤, 等. 硫酸锌溶液的萃取工艺研究[J]. 有色金属: 冶炼部分, 2006(2): 9-13.

YANG Da-jin, XIE Gang, WANG Ji-kun, et al. Study on solvent extraction of zinc sulfate solution[J]. Nonferrous Metals: Extractive Metallurgy, 2006(2): 9-13.

[14] Demopoulos G P, Pouskouleli G. Solvent extraction of iron(Ⅲ) from acid sulphate solutions by mono(2-ethylhexyl) phosphoric acid[J]. Can Metall Quart, 1989, 28(1): 13-18.

[15] 邹 兴, 朱旺喜, 朱 荣, 等. 低品位硫化锌矿生物浸出液中锌的富集和铁的去除[J]. 北京科技大学学报, 2003, 25(1): 30-32.

ZOU Xing, ZHU Wang-xi, ZHU Rong, et al. Concentration of zinc and separation of ferric iron from the biochemical lixivium of low-grade zinc sulfide by solvent extraction[J]. Journal of University of Science and Technology Beijing, 2003, 25(1): 30-32.

[16] 窦明民, 周德林. 湿法炼锌除铁新工艺[J]. 有色冶炼, 2000, 29(3): 27-29.

DOU Ming-min, ZHOU De-lin. A study on new technology for removing iron by phosphate[J]. Nonferrous Metallurgy, 2000, 29(3): 27-29.

[17] Sun J, O’Keefe T J. An evaluation of steel scrap as a reducing agent in the galvanic stripping of iron from D2EHPA[J]. Minerals Engineering, 2002, 15: 177-185.

[18] 北京矿冶研究院分析室. 矿石及有色金属分析手册[M]. 北京: 冶金工业出版社, 1990.

The Analysis Center of Beijing Research Institute of Mining & Metallurgy. Handbook of mines and non-ferrous metals analysis[M]. Beijing: Metallurgical Industry Press, 1990.

收稿日期:2006-12-22

基金项目:国家“863”高新技术项目(2004AA649081)

作者简介:肖 纯(1967-),女,贵州遵义人,副教授,从事锌的清洁冶金研究

通讯作者:肖 纯,女,副教授;电话:13595001305; E-mail: gzsdclxc@163.com