文章编号:1004-0609(2012)05-1462-06

煤种对嘉峪关某菱铁矿直接还原的影响

闫树芳,孙体昌,许 言

(北京科技大学 土木与环境工程学院,北京 100083)

摘 要:为研究煤种对某菱铁矿直接还原-磁选的影响,进行两种煤在不同煤用量条件下的对比试验,并运用XRD和SEM探讨两种煤的灰分及挥发分指标对直接还原过程的影响机理。结果表明:在采用两种煤的条件下,还原铁的品位都随煤用量的增加而降低,烟煤回收率随煤用量增加先增加后降低,石煤回收率随煤用量增加而增加。在同样煤用量时,烟煤焙烧产物铁颗粒较石煤大且向矿石边缘积聚明显,主要是与石煤相比,烟煤灰分较低,挥发分较高,导致烟煤对菱铁矿直接还原的速度不平稳。

关键词:煤;菱铁矿;直接还原

中图分类号:TD9254 文献标志码:A

Effects of coals on direct reduction roasting of siderite ore from Jiayuguan

YAN Shu-fang, SUN Ti-chang, XU Yan

(School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to research effect of coal on the process of direct reduction-magnetic separation of siderite, comparative tests of two coals were conducted under conditions for different consumptions of coal, and the influence mechanisms of ash and volatility index of the two coals for direct reduction process were investigated by means of XRD and SEM. The results show that: under conditions using the two coals, the iron grades of the products decrease according to coal consumption increasing; the recovery rate for using bituminous coal increases first and then reduces with coal dosage increasing, and the recovery rate for using stone coal increases with coal dosage increasing. In the same coal consumption, the roasting iron particles for using bituminous coal are bigger than those for using stone coals, and obviously gather to the edge of ore. It is primarily that the ash of bituminous coal is lower than that of stone coal, and the volatility of bituminous coal is higher than that of stone coal, which leads to the speed of siderite direct-reducting relatively unstable.

Key words: coal; siderite; direct-reducting

随着我国国民经济的高速发展及钢铁工业对矿石需求量的增大,铁精矿短缺的矛盾日益突显,因此,复杂难选铁矿石的工艺矿物学研究以及对复杂难选铁矿石的开发利用已成为日益关注的焦点。

菱铁矿为复杂难选矿种之一,常用的选矿方法有重选、强磁选、焙烧-弱磁选、焙烧-弱磁选-反浮选等[1]。由于理论铁品位低(FeT 48.27%),各地产出差异大,且常与钙、镁、锰发生类质同象,采用物理选矿方法铁精矿品位很难达到45%以上[2]。大量研究表明,直接还原菱铁矿可以得到较好的指标,常用的直接还原工艺主要分为气基和煤基两种[3]。我国是煤炭大国,煤炭资源不仅丰富,而且分布广泛、品种齐全。所以,在我国发展煤基直接还原焙烧-弱磁选处理复杂难选菱铁矿符合国情,前景广阔。

嘉峪关某菱铁矿石铁品位低,有用矿物嵌布粒度细,硫含量高,属复杂难选铁矿石之一,长期以来没有得到开发。本文作者所在课题组对嘉峪关某菱铁矿选矿进行了大量研究,其中采用煤基直接还原焙烧磁选工艺,在最佳的试验条件下,可以得到品位为94.70%,回收率为90.28%的还原铁产品[4]。近年来,徐承焱等[5]针对难选铁矿石(赤铁矿、菱铁矿)开展了一系列的原矿直接还原研究,认为煤种对直接还原过程和最终指标的影响较大[5]。本文作者在此考察两种煤的不同用量对嘉峪关某难选菱铁矿石直接还原-磁选的影响。

1 实验

1.1 矿石性质

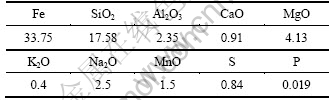

试验用的铁矿石由某公司提供,为菱铁矿石,以下称为原矿,其化学多元素分析如表1所列。由表1可以看出,原矿铁品位仅为33.75%,有害元素硫的含量较高,为0.84%,没有其他可以回收的金属元素。

表1 原矿多元素化学分析结果

Table 1 Multi-elementary analysis results of raw ore (mass fraction, %)

工艺矿物学研究表明,原矿中铁的矿物形式主要为菱铁矿,另有少量赤铁矿。主要脉石矿物为石英和斜绿泥石。菱铁矿多呈不等粒集合体与脉石矿物胶结共生,菱铁矿的颗粒大小为50 mm至几微米,同时其中含类质同象元素镁、锰。总体而言,该铁矿石属于高硫低品位难选菱铁矿石。

1.2 煤样性质

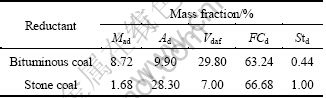

选用两种性质不同的煤作为还原剂,一种煤为烟煤,另一种煤为石煤,两种煤的工业分析结果如表2所列。

从煤样的工业分析结果可以看出,选用的两种煤固定碳均较高且差别不大,而水分、挥发分、灰分含量差别较大,对于研究煤种对菱铁矿石直接还原的影响较有利。

1.3 试验方法

原矿和煤都破碎到粒径小于4 mm,和助熔剂按一定比例混匀后,装入石墨坩埚,然后将坩埚置于马弗炉中进行还原焙烧,焙烧产物冷却后进行磨矿、磁选。为区别直接还原-磁选与一般的磁化焙烧-磁选,将磁选所获得的磁性产品称为还原铁(DRI)。还原剂和助熔剂的用量是指所添加的还原剂或助熔剂与原矿的质量比,用百分数表示。

表2 试验用煤样的工业分析结果

Table 2 Proximate analysis of different coal samples used in tests

2 结果与讨论

2.1 两种煤不同用量的试验结果

影响煤基直接还原过程的重要因素主要有焙烧温度、煤的种类和用量、焙烧时间等[4, 6],本研究主要考察煤的种类和用量对直接还原过程和结果的影响,其他焙烧条件按闰树芳等[4]对本矿石研究所确定的最佳条件:固定条件为助熔剂用量5%,焙烧温度1 200 ℃,焙烧时间60 min;焙烧产品进行两段阶段磨矿,一段磨矿细度为粒径小于74 μm占72.96%,二段磨矿细度为粒径小于43 μm占95.89%,两段磁选,磁场强度均为111.44 kA/m。试验结果如图1所示。图1中及后述烟煤品位、石煤品位、烟煤回收率和石煤回收率是指以烟煤或石煤为还原剂时所得还原铁的品位和回收率。

图1 两种煤的用量对还原铁品位和回收率的影响

Fig. 1 Effects of dosages of two coals on Fe grade and recovery rate

由图1可见,煤种和煤用量对还原铁指标影响很大。在试验煤用量范围内,还原铁的品位都随煤用量的增加而降低,当煤用量小于18%时,烟煤品位高于石煤品位,当煤用量大于18%时,石煤品位高于烟煤品位;烟煤回收率随煤用量增加先增加后降低,石煤回收率随煤用增加而增加。

2.2 两种煤不同用量时的焙烧产物的组成分析

为研究不同煤种条件下焙烧过程中矿物的变化情况,对两种煤在不同用量条件下的焙烧产物进行了XRD分析,结果如图2所示。

图2 原矿及两种煤在不同用量条件下焙烧产物的XRD谱

Fig. 2 XRD patterns of roasted products at different dosages of two coals: (a) Bituminous coal; (b) Stone coal; A—Quartz; B—Siderite; C—Hematite; D—Clinochlore; E—Muscovite; F—Iron; G—Fayalite; H—Tridymite

由图2可见,原矿中的菱铁矿、赤铁矿、斜绿泥石、白云母等衍射峰在焙烧产物中都消失了,而石英在焙烧产物中仍存在,但衍射强度减弱;在煤用量较少的情况下,有铁橄榄石和金属铁生成,随煤用量的增加,铁橄榄石逐渐消失,铁的衍射峰增强,同时有磷石英生成。

原矿中少量的斜绿泥石、白云母经焙烧后消失,可能是由于在焙烧过程中生成其它复杂的化合物或者玻璃态物质,用XRD方法检测不出来。原矿中的菱铁矿、赤铁矿经焙烧后衍射峰消失,主要是在还原过程中菱铁矿、赤铁矿与石英等脉石生成了铁橄榄石,进而随煤用量的增加被还原成铁所致。这是由于在高温还原性气氛下,氧化铁矿还原焙烧主要矿物属于FeO-SiO2二元体系的化合物。直接还原过程主要步骤为:1) 煤和铁矿石的接触面上发生固一固直接还原反应,产生CO气体;2) 气体还原剂CO吸附在铁氧化物表面;3) 吸附的还原剂与固相之间进行界面反应,还原剂从铁氧化物内夺取氧;4) 气体产物脱附;5) 金属铁迁移到含SiO2界面并发生固相反应,生成铁橄榄石(2FeO·SiO2);6) 金属铁扩散至铁橄榄石界面并在其界面上生长[6]。在还原反应初期,铁还原相变仅在铁氧化物表面某些质点上进行,金属铁的形成,一方面,由于必须克服成核位垒,因此有很大困难;另一方面,还原过程中生成的金属铁扩散至含SiO2等矿物界面发生固相反应而生成铁橄榄石等,使得金属铁相更难形成[7]。试验在煤用量为5%时,由于还原剂不足,还原反应以初期反应为主,从XRD谱上看(见图2),铁的衍射峰较低且有铁橄榄石的衍射峰出现。当新相金属铁相、铁橄榄石形成以后,铁橄榄石充当了成核剂,使得金属铁成核位垒降低;当继续在还原气氛中反应时,铁橄榄石可能发生一系列的化学变化释放出含铁物质并生成SiO2新结晶相磷石英;随着反应界面的扩大及金属铁的生成,金属铁便在铁橄榄石界面上生长,还原产物的铁颗粒不断增大[8]。

对比图2(a)和(b)可知,除煤用量为5%时出现石英的衍射峰外,石煤条件下焙烧产物的铁橄榄石、铁、石英的衍射峰均较烟煤条件下的强。这主要是由于在菱铁矿还原过程中,不同的煤所起的作用不同[9]。本研究所用两种煤成分的不同主要是挥发分和灰分含量不同(水分对直接还原的影响可忽略),从挥发分的角度分析,煤在高温条件下析出挥发分物质,其中还原性物质有CO、H2等[10]。由于煤中挥发分的析出过程可在十几秒至几十秒内完成[11],因此,在相对密闭的空间中,反应初期菱铁矿石周围的还原气氛较强,还原速度较快;后期由于铁层对CO扩散至铁橄榄层的阻碍作用,还原反应速度较慢。由于本研究中烟煤的挥发分较高,因此,在烟煤条件下,直接还原菱铁矿的反应速度不稳定,在一定的时间内,可能导致菱铁矿的金属化不彻底。从灰分的角度分析,煤中灰分是不可燃成分,在高温条件下,灰分对煤的氧化特性起阻碍作用[12]。由于石煤灰分含量较高,因此,其对固定碳的氧化反应阻碍作用较大。在相同的反应时间内,石煤夺氧后为铁矿物还原过程提供CO的速度就相对较慢;在相对密闭的条件下,CO的浓度也相对较稳定,短时间内在铁矿物表面生成的铁和铁橄榄石也较少,对CO渗透到菱铁矿内部的阻碍作用相对小。同时,由于石煤的固定碳含量相对较高,使石煤条件下直接还原反应进行得更平稳有效,铁橄榄石转化过程和铁金属化速度相对平稳且转化率高。由于石煤的灰分较高,从灰分中带入焙烧产物的石英也较多,因此,在相同煤用量及相同还原时间内,石煤条件下的铁、铁橄榄石、磷石英的XRD衍射峰较强。两种煤不同用量时焙烧产物的变化结果,可以很好地解释图1所示试验结果,即采用两种煤做还原剂煤用量低于18%时,由于烟煤的挥发分较高,反应活性较强,因而其还原效果比石煤的好。但在煤用量大于18%以后,在较高的温度下,碳气化反应占主导地位,从而导致石煤的还原效果更佳,其回收率随之增大[13-14]。而煤用量为5%时,石煤条件下的石英衍射峰较烟煤的弱,可能是由于还原剂不足导致的,有待于进一步研究。

鲕状赤铁矿煤基直接还原过程中铁矿物的转变顺序一般如下:Fe2O3→Fe3O4→FeO→Fe。在煤用量不足时,焙烧产物中有FeO生成[6, 15]。本研究中菱铁矿的直接还原焙烧产物在不同煤用量时XRD分析都未发现FeO,菱铁矿煤基直接还原过程中铁矿物的转变顺序有待进一步研究。

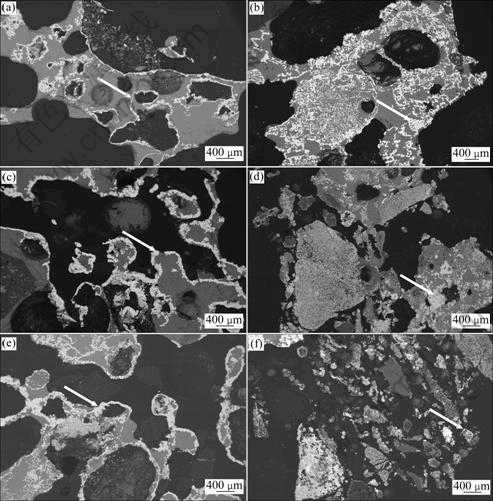

2.3 两种煤不同用量时焙烧产物金属铁颗粒分布状态比较

分别对两种煤不同用量条件下的焙烧产物进行SEM分析,结果如图3所示。由图3可见,亮白色的部分均为金属铁,由此可知,直接还原产物的铁颗粒随煤用量的增加而增大;在相同煤用量条件下,烟煤条件下焙烧产物的铁颗粒粒度较大且向边缘积聚(如图中箭头所示),而石烟条件焙烧产物的铁颗粒相对小且向边缘积聚不明显。

图3 原矿及两种煤在不同用量条件下焙烧产物的SEM形貌

Fig. 3 SEM morphologies of roasted products at different dosages of two coals: (a) Bituminous coal, 5%; (b) Stone coal, 5%; (c) Bituminous coal, 15%; (d) Stone coal, 15%; (e) Bituminous coal, 35%; (f) Stone coal, 35%

如前所述,铁颗粒的长大是在铁橄榄石的界面进行的,当反应初期形成少量微细的铁,这部分铁主要成为晶粒长大的晶核。由于铁橄榄石熔点低于1 200 ℃,在1 200 ℃高温且在强还原气氛条件下,铁橄榄石发生软化和熔化,进而生成大量液相包裹在矿石的表面,使矿物原料表面的空隙率下降。在直接还原过程中,金属铁层一旦生成,就把铁橄榄石同还原剂分开,此后的还原过程主要是还原剂CO通过扩散还原铁橄榄石。在以固-气界面反应为主阶段,形成大量的铁原子,并通过长程扩散方式向初级阶段中的铁界面扩散并以其为晶核形成晶粒。还原过程中生成的金属铁和铁橄榄石充当了成核剂,使得金属铁晶粒成核位垒降低[10]。金属铁颗粒生成后,由于①颗粒越大,界面自由能越低;②颗粒越大,曲率半径越大,颗粒周围的溶质浓度越小,于是形成浓度梯度[16]。以上两方面原因引起溶质(Fe)由最小颗粒向最大颗粒方向扩散,因此,在具有流动性的液相铁橄榄石界面,大颗粒聚集长大,小颗粒缩小消失。最终在焙烧产物的SEM像上显示为铁颗粒粘连和长大。

两种煤在相同用量的试验条件下,石煤所含的灰分较高,对石煤从铁矿物表面夺氧特性的阻碍作用更明显。在固定碳含量相近且在相同的反应时间内,石煤在矿物还原过程中较烟煤提供CO的浓度更稳定,使石煤条件下直接还原反应进行得更平稳缓慢,同时,由于石煤的挥发分相对较低,在反应初期生成的液相铁橄榄石和金属铁也较少。综上所述,在石煤条件下,反应过程生成的液相铁橄榄石流动性或者铁晶粒长大的速度相对较慢,铁颗粒粘连也相对较少。因此,从焙烧产物的SEM像上看,在石煤条件下的铁颗粒细小且粘连相对少,而在烟煤条件下的铁颗粒向原铁矿石边缘积聚且粒径粗大。

3 结论

1) 煤种对还原铁指标影响较大。在试验煤用量范围内,还原铁的品位都随煤用量的增加而降低,烟煤回收率随煤用量增加先增加后降低,石煤回收率随煤用增加而增加。导致还原铁指标不同的主要原因是煤的灰分和挥发分,与石煤相比,烟煤挥发分较高,反应活性较强,在用量较少时指标相对较好;煤用量较多时,反应过程主要是煤的气化反应为主,与烟煤相比,石煤的气化反应较平稳,还原铁的指标较烟煤的好。

2) 烟煤和石煤都是在煤用量较少的情况下,有铁橄榄石生成,随煤用量的增加,铁橄榄石逐渐消失,金属铁逐渐增加,同时生成了磷石英。

3) 在煤用量相同的条件下,烟煤条件下焙烧产物的铁颗粒粒度较大且向原铁矿石边缘积聚,而石煤条件下焙烧产物铁颗粒相对小且向边缘积聚不明显。

4) 两种煤在用量相同的条件下,与烟煤相比,石煤灰分含量较高,挥发分含量低,石煤条件下还原反应进行得缓慢,使得焙烧产物中各矿物相间转化较彻底;且反应过程中形成的液相流动性小,导致铁颗粒长大和向原矿石边缘积聚不明显。

REFERENCES

[1] 罗立群. 菱铁矿的选矿开发研究与发展前景[J]. 金属矿山, 2006(1): 68-72.

LUO Li-qun. Explorative research on beneficiation of siderite and its development prospect [J]. Metal Mine, 2006(1): 68-72.

[2] 孙炳泉. 近年我国复杂难选铁矿石选矿技术进展[J]. 金属矿山, 2006(3): 11-13.

SUN Bing-quan. Progress in China’s beneficiation technology for complex refractory iron ore [J]. Metal Mine, 2006(3): 11-13.

[3] 杨双平, 冯燕波, 曹维成, 李武红. 直接还原技术的发展及前景[J]. 甘肃冶金, 2006, 28(1): 7-9.

YANG Shuang-ping, FENG Yan-bo, CAO Wei-cheng, LI Wu-hong. The development and foreground of the direct reduction technology [J]. Gansu Metallurgy, 2006, 28(1): 7-9.

[4] 闫树芳, 孙体昌, 寇 珏, 许 言. 嘉峪关某菱铁矿直接还原焙烧磁选工艺研究[J]. 金属矿山, 2011(5): 89-93.

YAN Shu-fang, SUN Ti-chang, KOU Jue, XU Yan. Research on direct reduction roast and magnetic separation process of a siderite ore from Jiayuguan [J]. Metal Mine, 2011(5): 89-92.

[5] 徐承焱, 孙体昌, 杨慧芬, 莫晓兰 杨大伟 贾 岩. 煤种对某难选铁矿石直接还原的影响[J]. 金属矿山, 2009(12): 64-67.

XU Cheng-yan, SUN Ti-chang, YANG Hui-fen, MO Xiao-lan, YANG Da-wei, JIA Yan. Effects of different types of coal on direct reduction of refractory iron ore [J]. Metal Mine, 2009(12): 64-67.

[6] 周继程. 高磷鲕状赤铁矿煤基直接还原法提铁脱磷技术研究[D]. 武汉: 武汉科技大学, 2007: 24-26.

ZHOU Ji-cheng. Study on dephosphorization technology for high phosphorus oolitic hematite by coal-based direct reduction [D]. Wuhan: Wuhan University of Science and Technology, 2007: 24-26.

[7] MOOKHERJEE S, RAY H S, MUKHERJEE A. Isothermal reduction of iron ore fines surrounded by coal or char fines [J]. Ironmaking and Steelmaking, 1996, 13(5): 229-235.

[8] 梅贤恭, 袁明亮, 左文亮, 陈 荩. 高铁赤泥煤基直接还原中铁晶粒成核及晶核长大特性[J]. 中南矿冶学院学报, 1994, 25(6): 696-700.

MEI Xian-gong, YUAN Ming-liang, ZUO Wei-liang, CHEN Jin. Studies on the nucleation and grain growth characteristics of metallic phase in direct reduction of high-iron red mud with coal base [J]. Journal Central South Institute Mining Metallurgy, 1994, 25(6): 696-700.

[9] STREZOV V, LIU G S, LUCAS J A. Computational calorimetric study of the iron ore reduction reactions in mixtures with coal [J]. Industrial and Engineering Chemistry Research, 2005, 44(3): 621-626.

[10] SUN S, LU W K. A theoretical investigation of kinetics and mechanism of iron ore reduction in an ore/coal composite [J]. ISIJ International, 1999, 39(2): 123-129.

[11] 张海飞. 煤中挥发份燃烧机理的试验研究[D]. 南京: 南京工业大学, 2005: 38-46.

ZHANG Hai-fei. Experimental study of coal volatile combustion mechanism [D]. Nanjing: Nanjing University of Technology, 2005: 38-46.

[12] 朱战岭. 高灰分煤对硅酸盐水泥熟料烧成过程的影响规律研究[D]. 武汉: 武汉理工大学, 2007: 28-41.

ZHU Zhan-ling. Research on the influence rules of high-ash coal on sintering of Portland cement clinker [D]. Wuhan: Wuhan University of Technology, 2007: 28-41.

[13] SHIVARAM A N, SAKAR S B, PRASAD K K. The role of internal coal in the reduction of composite pellets [J]. SEAISI Quarterly, 1996(2): 82-95.

[14] SEATON C E, FOSTER J S, VELASCO J. Reduction kinetics of hematite and magnetite pellets containing coal char [J]. Transactions of the Iron and Steel Institute of Japan, 1983, 23(6): 490-496.

[15] 周继程, 薛正良, 李宗强, 张海峰. 高磷鲕状赤铁矿直接还原过程中铁颗粒长大特性研究[J]. 武汉科技大学学报: 自然科学版, 2007, 30(5): 458-460.

ZHOU Ji-cheng, XUE Zheng-liang, LI Zong-qiang, ZHANG Hai-feng. Characteristics of grain growth of metallic phase in direct reduction of high phosphorus oolitic hematite [J]. Journal Of Wuhan University Of Science & Technology: Natural Science Edition, 2007, 30(5): 458-460.

[16] 史广全, 孙永升, 李淑菲, 韩跃新, 高 鹏. 某鲕状赤铁矿深度还原过程研究[J]. 现代矿业, 2009(8): 29-31.

SHI Guang-quan, SUN Yong-sheng, LI Shu-fei, HAN Yue-xin, GAO Peng. Study of deep reduction process of an oolitic hematite [J]. Modern Mining, 2009(8): 29-31.

(编辑 何学锋)

收稿日期:2011-07-21;修订日期:2011-10-21

通信作者:孙体昌,教授,博士;电话:13681437589;E-mail: suntc@ces.ustb.edu.cn