纤维体积分数对炭/炭复合材料力学性能的影响

李江鸿, 熊 翔, 张红波, 刘根山, 黄伯云

(中南大学 粉末冶金国家重点实验室, 湖南 长沙, 410083)

摘要: 以40%, 30%和25% 3种不同纤维体积分数的针刺整体毡为坯体, 经3次化学气相浸渗后制备C/C复合材料; 测定其未经热处理与经不同温度热处理后的石墨化度, 抗弯、 抗剪、 垂直与平行抗压强度; 在偏光下观察其微观结构; 采用扫描电子显微镜对其断口形貌进行观察; 研究纤维体积分数与C/C复合材料的力学性能的关系及不同热处理条件下C/C复合材料的断裂机理。 研究结果表明: 在不同热处理状态下, 当纤维体积分数为30%时炭/炭复合材料的抗弯、 抗压和抗剪强度均最高; 经热处理后的试样, 其力学性能降低, 断裂方式由脆性断裂转变为韧性断裂; 热处理温度越高, 其力学性能降低的程度越大。

关键词: 纤维体积分数; C/C复合材料; 力学性能; 断裂机理

中图分类号:TB332 文献标识码:A 文章编号: 1672-7207(2005)03-0375-05

Effect of fibre volume fraction on mechanical performances of C/C composites

LI Jiang-hong, XIONG Xiang, ZHANG Hong-bo, LIU gen-shan, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: C/C composites were prepared by needled felt with fibre volume fraction of 40%, 30% and 25% densifying through chemical vapour infiltration for three times. The graphitization degree of C/C composites at different high treatment temperatures was studied by means of X-ray diffraction .The effect of fibre volume fraction on the mechanical performances of C/C composites was investigated by measuring the flexural,shear,parallel compressive and vertical compressive stress. And the fracture mechanism was analyzed by observing the fracture surface morphologies through scanning electron microscope. The results show that C/C composites with 30% fiber volume fraction have the highest strength value than the other C/C composites with 40% and 25% fiber volume fraction; the strength decreases when the samples undergo high temperature treatment; the fracture mechanism changes from brittleness into toughness when the samples experience high temperature treatment; the higher the heat treatment temperature, the lower the value of strength.

Key words: fiber volume fraction; carbon/carbon composites; mechanical property; fracture mechanism

C/C复合材料是一种新型高温材料, 具有密度小(体积密度小于2.0 g/cm3, 仅为镍基高温合金密度的1/4, 陶瓷材料密度的1/2)、 模量和比强度高、 热膨胀系数低、 耐高温、 耐热冲击、 耐腐蚀及吸振性强等特点。 尤其是这种材料具有随着使用温度的升高(可达2200 ℃), 其强度不仅不降低, 甚至比室温时的强度还高的特点[1]。反映炭/炭复合材料的力学性能的因素很多,其中,强度和模量是反映其

力学性能的主要参数。 C/C复合材料的强度不仅与增强纤维的方 向、 含量以及纤维与基体界面结合程度有关, 而且与炭基体的性能有关[2-6]。 目前,人们对不同纤维体积分数对C/C复合材料力学性能影响的研究很少。 为此,对该问题进行研究。

1 试验方法

1.1 试样制备

40%, 30%和25% 3种不同纤维体积分数的C/C复合材料坯体(样品Ⅰ, Ⅱ及Ⅲ)经无纬布网胎叠层针刺而成。 化学气相预沉积以C3H6为炭源, N2为载气。 C/C复合材料毛坯的预沉积在真空感应气相沉积炉中进行, 石墨化处理在真空感应炉中进行。

1.2 石墨化度检测

用X射线衍射法测量(002)面的层间距d002表征石墨化度。 所用仪器为Rigaku D/MAX-3C型X射线衍射仪。 以CuKα为单色光辐射, 硅作内标。 根据所测2θ, 利用布拉格公式计算d002, 再利用公式(1)计算石墨化度。

g=(0.3440-d002)/(0.3440-0.3354)。(1)

其中: g为石墨化度, %; 0.3440为完全未石墨化炭的层间距, nm;0.3354为理想晶体的层间距,nm; d002为(002)面的层间距, nm。

1.3 力学性能检测

抗弯强度采用QC/HSC3309 标准, 测定时加载速度为1.00 mm/min, 试样取垂直于纤维铺层的方向, 尺寸(长×宽×高)为55 mm×10 mm×4 mm, 跨距为(40±0.02) mm, 抗弯强度由以下公式计算:

σf=3PmaxL/(2bh2)。(2)

其中: σf为抗弯强度, MPa; Pmax为试样断裂时的最大载荷, N; L为跨距, mm; ΔP/Δf为负荷位移起始段斜率; h为试样厚度, mm; b为试样宽度, mm。

剪切强度测试采用QC/HSC3310标准, 测定时加载速度为1.30 mm/min, 试样取垂直纤维铺层的方向, 试样尺寸(长×宽×高)为36 mm×10 mm×6 mm, 跨距L=(24±0.02) mm, 剪切强度按下式计算:

τ=3Pmax/(4bh)。(3)

其中: τ为剪切强度,MPa;d为试样的厚度,mm。

抗压强度采用QC/HSC3311标准, 测定时加载速度为1.0 mm/min, 分别取平行纤维铺层方向与垂直于纤维铺层的方向, 试样尺寸(直径×高)为10 mm×20 mm, 抗压强度计算公式为:

σ=4Pmax/(πD2)。(4)

其中:σ为试样的压缩强度, MPa; P′max为试样破坏时最大的压缩载荷, N; D为试样的直径, mm。

3种强度测试试样数均为8, 试验数据为8个试样的平均值。

2 结果与分析

图1所示为试样Ⅰ沉积态的金相照片。 因其工艺完全一致, 试样Ⅱ与Ⅲ的显微形貌与试样Ⅰ的显微形貌类似: 热解炭均为典型的光滑层, 具有明显的十字消光效应, 且环间存在裂纹(见图1)。 3次化学气相浸渗(CVI)增密后试样的密度均为1.70 g/cm3。

![]()

图 1 试样Ⅰ的微观结构

Fig. 1 Microstructure of sample Ⅰ

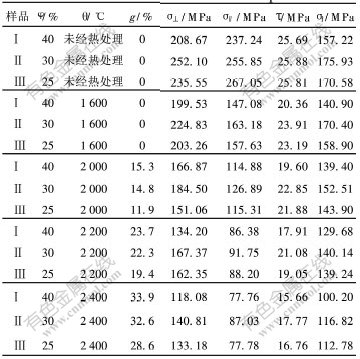

3次CVI增密后试样的石墨化度见表1。 可见, 由于试样中的纤维与光滑层热解炭均为难石墨化炭, 1600 ℃的高温热处理难以使其石墨化;2000 ℃的高温处理后,石墨化度很低; 经2200 ℃和2400 ℃的高温热处理后才出现较高的石墨化度;且热处理温度越高, 材料的石墨化度也越高。 不同热处理温度下试样的石墨化度随着纤维体积分数的增加而增加, 这是因为在热处理时, 纤维与热解炭的膨胀系数不同, 导致纤维与热解炭界面存在应力, 纤维体积分数越大, 界面面积也越大, 界面应力石墨化程度也越高。 所以, 纤维体积分数最大的试样Ⅲ的石墨化度高于其他2种试样的石墨化度。

尽管3种试样的密度只有1.70 g/cm3, 但未经热处理的这3种试样的抗压、 抗剪和抗弯强度均很高, 且平行方向与垂直方向的抗压强度没有明显差别。 因为热处理前纤维与热解炭均为乱层结构, 在承受载荷时, 纤维与热解炭的性能相似, 因此,两者在平行方向与垂直方向的抗压强度基本相同。 热处理后, 3种试样的各项强度均随热处理温度的升高而下降, 且垂直方向的抗压强度明显大于平行方向的抗压强度。 这是由于纤维比光滑层热解炭更难石墨化, 热处理后, 光滑层热解炭的石墨化度比纤维的石墨化度高, 尽管经1600 ℃热处理后X射线检测结果表明试样的石墨化度为零, 但光滑层热解炭的有序度相对乱层结构的纤维的有序度有所提高, 所以, 试样垂直方向的抗压强度远大于平行方向的抗压强度。

但无论热处理温度多高, 纤维体积分数为30%的试样Ⅱ其各项强度明显高于试样Ⅰ与Ⅲ的各项强度。 因为C/C复合材料的强度既与纤维体积分数有关, 也与材料的石墨化度、 基体炭的类型、 界面的结合强弱、基体炭的含量及分布密切相关[7-15]。 一方面, 纤维体积分数越高, 其承载负荷的能力越强; 另一方面, 纤维体积分数过高, 纤维的分散不均匀, 热解炭的沉积较不均匀且含量较低, 热解炭对强度的贡献较小。由于应力石墨化作用导致纤维体积分数最高的试样石墨化度最高, 这也在一定程度上使材料软化, 降低了材料的力学性能, 所以, 试样Ⅰ由于热解炭含量较低、 分布较不均匀且石墨化度较高,因而其力学性能较差; 试样Ⅱ由于其纤维体积分数适中,热解炭含量适中且分布较均匀,因而其力学性能较好。

表 1 3种试样在不同热处理温度下的石墨化度与力学性能

Table 1 Graphitization degree and mechanical

properties of 3 kinds of specimens

under different heat treatment temperatures

3 断裂机理

3种试样的微观结构类似, 其断裂机理也类似。 这里以试样Ⅰ为例, 探讨不同热处理温度下C/C复合材料的断裂机制。

图2所示为试样Ⅰ在不同热处理温度下的载荷—位移曲线。 图2(a)所示为试样Ⅰ的轴向抗压载荷—位移曲线, 其中曲线1, 2及3均显示典型脆性断裂特征: 载荷—位移曲线起初基本呈线性变化, 达到最大载荷后, 曲线陡降, 基体与纤维同时断裂, 且随热处理温度的升高,力学性能降低; 曲线4和5载荷—应力基本呈线性关系, 但达到最大载荷后, 曲线并没有陡降, 而是呈抛物线形, 说明试样的韧性增强,试样呈假塑性断裂。

图2(b)所示为试样Ⅰ抗弯的载荷—位移曲线。其中,未经热处理的曲线1的断裂机制为典型的脆性断裂; 经1600 ℃热处理的曲线2表现为脆性断裂与假塑性断裂的结合, 曲线中既有垂直下降段, 也有缓冲的平台, 曲线为锯齿的台阶状, 试样内部复合的层间破坏使载荷—位移曲线呈现锯齿形; 随着热处理温度的升高, 曲线3, 4和5均呈抛物线形, 表现为较强的韧性断裂, 且随着热处理温度的升高, 抛物线曲线的开口度增大, 顶点值降低。

图2(c)所示为试样Ⅰ抗剪的载荷—位移曲线。 同样可见未经热处理的曲线1达到顶点后, 垂直下降, 而曲线2, 3, 4和5均表现不同程度的韧性, 热处理温度最高的试样,其强度最低。

图3所示为试样Ⅰ未经热处理抗剪试样断口的SEM照片。 可见:低倍下试样断裂面基本平整; 高倍下基体与纤维结合紧密, 断裂面非常平整, 纤维与基体同时断裂。 这是因为未经热处理时, 基体炭与炭纤维的界面结合强度高, 不能产生界面脱黏, 表现为明显的脆性断裂。

图4所示为试样Ⅰ在2200 ℃热处理温度下抗剪试样断口的SEM照片。

a. 低倍下(图4(a))断面不平整, 有大量的纤维被拔出。 这是由于高温热处理使基体炭软化, 纤维与基体的界面结合变弱。 同时, 在高温热处理过程中,由于组元的热膨胀系数不匹配,而在界面引起的残余应力使炭纤维与基体炭脱粘, 径向残余压应力使界面产生摩擦力而使炭纤维拔出, 所以,断裂呈现“假塑性”。 此外, 高温热处理还会减少基体缺陷[CM(22] 和层错等, 使滑移及层间剪切更易进行, 所以其强度降低。

![]()

(a) 垂直抗压试样; (b) 抗弯试样; (c) 抗剪试样

1—未经热处理; 2—热处理温度为1600 ℃; 3—热处理温度为2000℃; 4—热处理温度为2200 ℃; 5—热处理温度为2400 ℃

图 2 试样Ⅰ在不同热处理温度下的载荷—位移曲线

Fig. 2 Load—displacement curves of sample Ⅰ at different heat treatment temperatures

![]()

(a) 低倍; (b) 高倍

图 3 试样Ⅰ未经热处理抗剪试样的断口形貌

Fig. 3 Fracture morphologies of shear specimen of sample Ⅰ without

high temperature treatment

![]()

(a) 低倍; (b),(c) 高倍

图 4 试样Ⅰ经2400 ℃热处理后抗剪试样的断口SEM照片

Fig. 4 Fracture morphologies of shear specimen of sample Ⅰ after

high temperature treatment at 2400 ℃

b. 高倍下, 纤维与热解炭之间存在缝隙(图4(c)), 热解炭之间也存在裂纹(图4(b))。 正是由于不同层次的光滑层热解炭之间存在环形裂纹, 当纤维从基体拔出时, 容易发生平行于纤维轴方向的分层, 使扩展裂纹发生偏转。 因此, 在试样断裂时这些缝隙与裂纹起缓冲应力的作用, 使材料表现一定的韧性。

4 结 论

a. 对于基体炭为典型光滑层结构的C/C复合材料, 坯体纤维体积分数为30%的试样的力学性能(强度、模量等)高于纤维体积分数为40%与25%的试样的力学性能。

b. 经热处理后, 试样力学性能降低, 但韧性增强,试样断裂方式由脆性断裂变为假塑性断裂与不同程度的韧性断裂; 当热处理温度从1600 ℃升至2400 ℃时, 试样的强度、模量等力学性能降低程度增大。

参考文献:

[1]Fitzer E .The future of carbon-carbon composites[J].Carbon, 1987, 25(2): 163-190.

[2]Oh S M, Lee J Y. Effects of matrix structure on mechamical properties of carbon/carbon composites[J]. Carbon, 1988, 26(6): 769-776.

[3]Sohn K Y, Oh S M, Lee J Y, et al. Failure behavior of carbon/carbon composites prepared by chemical vapor deposition[J]. Carbon, 1988, 26(2): 157-162.

[4]Hiroshi H, Keiji S, Satoshi S, et al. Strength improvement by densification of C/C composites[J].Carbon, 2001, 39(1): 83-90.

[5]Douarche N, Rouby D, Peix G, et al. Relations between X-ray tomography density and mechanical properties in carbon-carbon composites[J].Carbon, 2001, 39(10): 1455-1465.

[6]Chollon G, Siron O, Takahashi J, et al. Microstructure and mechanical properties of coal tar pitch-based 2D-C/C composites with a filler addition[J]. Carbon, 2001, 39(13): 2065-2075.

[7]Siron O, Chollon G, Tsude H, et al. Microstructural and mechanical properties of filler-added coal-tar pitch-based C/C composites: the damage and fracture process in correlation with AE waveform parameters[J]. Carbon, 2000, 38(11): 1369-1389.

[8]Fitzer E, Hiittner W, Manacha L M. Influence of process parameters on the mechanical properties of carbon/carbon composites with pitch as matrix precursor[J]. Carbon, 1980, 18(2): 291-295.

[9]Chtopek J, Stanistaw B, Angustyn P, et al. Mechanical properties of carbon-carbon composites[J].Ceramics International, 1993(19): 251-257.

[10]Casal E, Granda M, Bermejo J, et al. Influence of porosity on the apparent interlaminar shear strength of pitch based unidikectional C/C composites[J]. Carbon, 2001, 39(1): 73-82.

[11]Manocha L M, Bahl O P. Influence of carbon fibre type and weare pattern on the development of 2D carbon-carbon composites[J]. Carbon, 1988, 26(1): 13-21.

[12]Oh S M, Lee J Y. Fracture behavior of two-dimensional carbon/carbon composites[J].Carbon, 1989, 27(3): 423-430.

[13]Sakai M, Matsuyama R, Miyajima T. The pull-out and failure of a fibre bundle in a carbon fibre reinforced carbon matrix composite[J]. Carbon, 2000, 38(15): 2123-2131.

[14]Copp P D, Endis J C D, Mall S. Failure analysis and damage initiation in carbon-carbon composite materials under three-point bending[J]. J Comp Mater, 1991(25): 593-607.

[15]Grape J A, Gupta V. Failure mechanisms in laminated carbon/carbon composites under biaxial compression[J]. Acta Metall Mater, 1995, 43(7): 2657-2665.

收稿日期:2004 -05 -16

基金项目:国家“863”高技术计划项目(2002AA305207)

作者简介:李江鸿(1975-), 女, 湖南双峰人, 助理研究员, 博士研究生, 从事C/C复合材料研究

论文联系人:李江鸿, 女, 博士研究生;电话:0731-8830939; E-mail:LJH138@mail.csu.edu.cn