文章编号: 1004-0609(2004)10-1671-06

高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层摩擦学特性

徐维普1, 2, 徐滨士2, 张 伟2, 吴毅雄1, 刘维民3

(1. 上海交通大学 材料学院, 上海 200030; 2. 装甲兵工程学院 装备再制造技术国防科技重点实验室, 北京 100072;

3. 中国科学院 兰州化学物理研究所 固体润滑国家重点实验室, 兰州 730000)

摘 要: 使用THT07-135高温磨损实验机对高速电弧喷涂FeAl, Fe-Al/Cr3C2, FeAlCr/Ni包Cr3C2复合涂层进行了滑动摩擦特性的研究, 并用SEM、 TEM、 XRD等手段观察分析了磨痕的形貌和成分、 涂层截面的组织和相结构。 结果表明: FeAlCr/Ni包Cr3C2复合涂层具有典型的层状结构和较高的结合强度和硬度; 从室温到250℃, 涂层的抗磨损性能下降; 从250℃到550℃, 涂层磨损性能变化不大; 550℃以后, 涂层的耐磨损性能重新增强; 剥层磨损是FeAlCr/Ni包Cr3C2涂层高温磨损的主要机理; Cr3C2增强相的加入, 大大提高了涂层的耐磨损性能; Ni的加入一定程度提高了涂层的结合强度和抗磨损性能。

关键词: 高速电弧喷涂; 摩擦学特性; FeAlCr/Ni包Cr3C2复合涂层 中图分类号: TG174.422

文献标识码: A

Tribological properties of high velocity arc sprayed FeAlCr/Ni wraped Cr3C2 coatings

XU Wei-pu1, 2, XU Bin-shi2, ZHANG Wei2, WU Yi-xiong1, LIU Wei-min3

(1. School of Materials Science and Engineering, Shanghai Jiaotong University,Shanghai 200030, China;

2. National Key Laboratory for Remanufacturing, Academy of Armored Force Engineering, Beijing 100072, China;

3. State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, China)

Abstract: THT07-135 high temperature wear machinery was used to analyse tribological properties of high velocity arc sprayed FeAl, Fe-Al/Cr3C2, FeAlCr/Ni wrapped Cr3C2 composite coatings. The wear scar morphologies and compositions of coatings were analyzed by SEM, TEM and XRD methods. Results show that FeAlCr/Ni wrapped Cr3C2 composite coatings have typically layer shaped structure and relatively high bonding strength and hardness. The wear resistance of coatings decreases in the range from room temperature to 250℃, and it changes little in the range from 250℃ to 550℃, then wear resistance of coatings rises again after 550℃.Shell tribology behavior is mainly the high temperature wear mechanism of coatings. The addition of Cr3C2 can improve the wear resistance of coatings highly; the addition of Ni can also relatively enhance bonding strength and wear properties of coatings.

Key words: high velocity arc spray; tribological characteristic; FeAlCr/Ni wrapped Cr3C2 composite coating

铁铝金属间化合物具有优良的高温耐腐蚀、 耐磨损、 抗氧化性能, 但因为低的塑性而难于加工。 高速电弧喷涂具有熔滴喷射速度高、 雾化效果好、 涂层的结合强度高和涂层的孔隙率低等优点[1, 2]。 利用高速电弧喷涂技术, 在结构材料上喷涂铁铝金属间化合物涂层, 既能解决铁铝金属间化合物加工成形困难的缺点, 又能充分发挥其优点, 可使铁铝金属间化合物在工业上有望推广应用。 但在室温下Fe-Al涂层的耐磨性较差。 而有些零部件要求从室温到高温都具有较好的耐磨性, 因此必须研究提高Fe-Al涂层室温耐磨性的方法。 Cr元素是唯一可以大幅度提高铁铝合金塑性的材料, 在涂层中添加Cr3C2增强相制备FeAlCr/Ni包Cr3C2复合涂层, 能有效地改善室温下铁铝金属间化合物的组织和性能[3-16], 具有广阔的应用前景。 本文作者对比研究了高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层和其它材料与Si3N4配副时的摩擦磨损特性, 探讨了涂层的摩擦磨损机理, 可为该复合涂层的工业应用提供理论依据。

1 实验

喷涂材料是d3mm的FeAlCr/Ni包Cr3C2粉芯丝材, 丝材外皮选用低碳钢08F钢带, 08F钢带具有良好的塑性加工性能, 不需要中间退火热处理; 填充的粉末主要为Fe、 Al、 Cr和Ni包Cr3C2。 粉芯丝材采用多辊连续轧制和多道连续拔丝减径的方法制造。 高速电弧喷涂用基体为20#钢。

高速电弧喷涂使用CDM AS300系统和装备再制造国防科技重点实验室研制的HAS-01高速喷枪。 喷涂参数为: 喷涂电压32V, 喷涂电流180A, 空气压力0.43MPa, 喷涂距离300mm。 将20#钢加工成尺寸为d25mm×7.7mm的圆柱体, 使用250μm的砂粒, 45°角度、 200mm距离进行表面喷砂处理; 对基体进行高速电弧喷涂后, 对涂层面相对的工件表面进行磨削加工; 最后对涂层表面进行再磨削加工, 试样的最终尺寸为d25mm×8.0mm, 涂层厚度约为0.4mm。

高温摩擦磨损试验使用瑞士产THT07-135型高温摩擦磨损试验机, 采用球-盘接触方式进行(见图1)。 上试样为d3mm的烧结Si3N4球, 硬度为HV1600。 试验在大气和干摩擦的条件下进行, 空气相对湿度为40%。 试验温度分别为室温(25℃), 200、 250、 300、 450、 550和600℃, 滑动速度为0.8m/s, 磨损半径为r=6mm, 载荷为5N, 滑行[CM(22]距离为500m。 在试验之前, 试样用丙酮超声清洗;固定了试样和对偶件后用酒精擦洗涂层与对偶件表面。

图1 球-盘接触摩擦示意图

Fig.1 Schematic diagram of ball-on-disc friction apparatus

使用带有EDAX的Philips Quant 200型扫描电子显微镜(SEM)分析涂层的截面组织及磨痕形貌。 用德国布鲁克AXS公司产D8 Advance型XRD和日立H800型TEM对涂层进行组织和相结构分析。

2 结果与分析

2.1 复合涂层的组织与性能

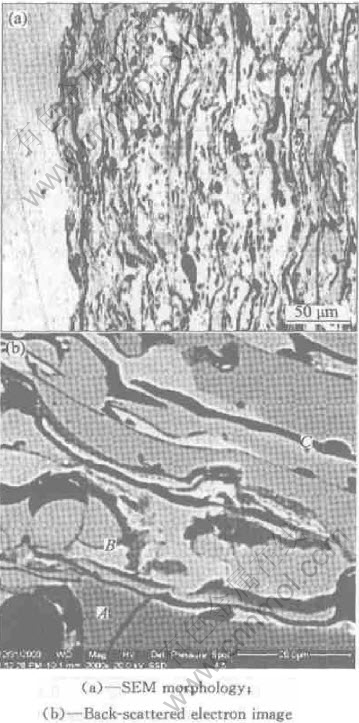

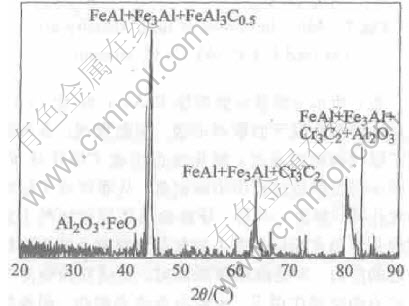

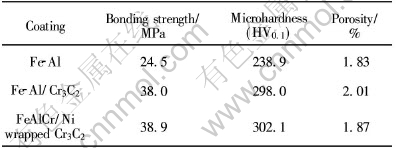

图2所示为高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层横截面的组织形貌。 从图2(a)可以看出, 涂层具有明显的层状结构, 层状的扁平颗粒之间是黑色的氧化物和孔隙。 对FeAlCr/Ni包Cr3C2复合涂层的XRD分析表明(见图3), 涂层主要相为Fe-Al金属间化合物(Fe3Al, FeAl)和AlNi相, AlFe3C0.5相和FeO·Al2O3, Cr3C2相, γ-Al2O3相, γ-(Fe, Ni)相; EDAX分析结果表明, FeAlCr/Ni包Cr3C2复合涂层的平均成分为Fe-15.02Al-2.49C-11.06Cr-3.42O-4.3Ni(质量分数, %)。 结合相分析和EDAX的结果可知图2(b)的SEM背散射照片中的灰色基体相为Fe-Al金属间化合物(Fe3Al, FeAl)和AlNi相(A), B区为硬质相, 扁平颗粒之间为黑色氧化物(C)。 表1列出了涂层的结合强度、 显微硬度及孔隙率等参数。 可以看出高速电弧喷涂铁铝涂层在添加Cr3C2 后涂层的结合强度和硬度显著提高; 而将硬质相包Ni以后, 涂层的结合更紧密, 结合强度和硬度又有提高。 其主要原因是在喷涂过程中发生了热化学反应, 对喷涂粒子进行了二次加热, 使喷涂粒子温度再次升高, 涂层冶金结合的倾向增加, 从而使涂层获得较高的结合强度。 由于Cr3C2在高温下少量分解生成了C与Cr, 因此具体放热反应为

图2 FeAlCr/Ni包Cr3C2复合涂层横截面SEM形貌

Fig.2 SEM images of cross section of

FeAlCr/Ni wrapped Cr3C2 composite coatings

图3 FeAlCr/Ni包Cr3C2复合涂层的XRD谱

Fig.3 XRD pattern of FeAlCr/Ni wrapped

Cr3C2 composite coating

表1 涂层的性能

Table 1 Properties of coatings

2.2 涂层摩擦磨损性能

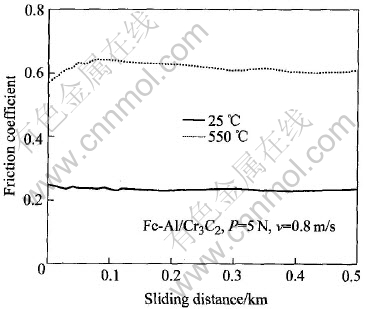

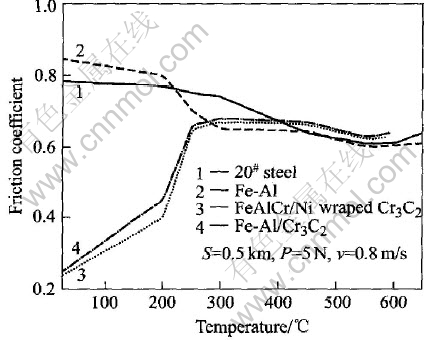

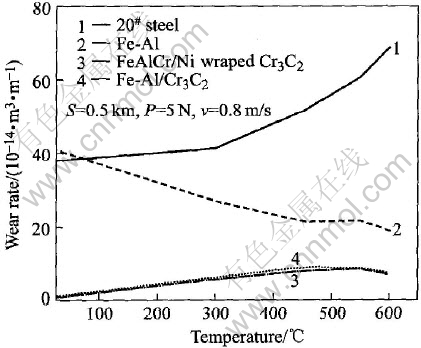

图4所示为高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层摩擦因数与摩擦距离的关系曲线。 涂层的摩擦因数随着摩擦距离的增长变化不大, 但常温下的摩擦因数比高温的小得多。 图5所示为温度与摩擦因数的关系曲线。 可以看出, 从室温到250℃, 涂层的摩擦因数随着温度的升高而升高, 在250~550℃变化不大, 在550℃以后略有升高。 图6所示为涂层磨损率随温度的变化曲线, 结合摩擦因数曲线发现, 涂层在常温下的耐磨损性能较高。

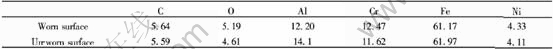

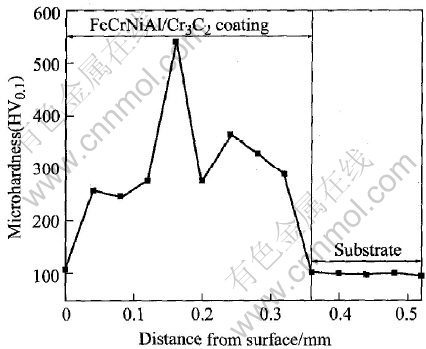

表2所列为高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层磨损面元素含量分析结果。 结果表明: 在常温下, 涂层表面在摩擦的作用下出现了游离的[CM(22]C, 在摩擦过程中起到了固体润滑的作用, 提高了涂层的耐磨损性能。 温度升高, 游离的C被烧损, 随着摩擦距离的增加, 表面磨屑的压入以及增强相的阻碍, 增大了摩擦阻力, 降低了抗磨损性能。 对于添加了Cr3C2的涂层, 由于在喷涂过程中生成了Cr2O3, 显著提高了Al2O3的蠕变性能, 细化了Al2O3晶粒, 减少Al2O3膜由生长应力导致的开裂, 故可以抑制氧化层的剥落, 促进Al的选择氧化, 使表面Al2O3氧化层增厚[8]。 对涂层的TEM观察表明, 由于涂层中的物相存在着平行的晶体学取向关系, 提高了涂层的结合能。 Cr3C2增强相与FeAl基体相良好的物理化学相容性可以提高涂层的强度和韧性[9]。 研究表明: Cr元素是唯一可以大幅度提高铁铝涂层常温塑性的元素, Cr3C2的存在提高了涂层的常温性能[10]。 增强相Cr3C2的最佳工作温度是550~980℃, 在此温度区间的耐磨损性能最佳, 也因此提高了涂层在550℃以后的耐磨损性能[11]。 从图7可以看出, 涂层存在硬度较高的区域, 这主要是增强相存在的区域, 增强相的存在提高了涂层的耐磨损性能。

图4 FeAlCr/Ni包Cr2C2复合涂层摩擦因数与摩擦距离的关系

Fig.4 Relationship between friction coefficient and sliding distance of FeAlCr/Ni wraped Cr3C2 composite coating

表2 FeAlCr/Ni包Cr3C2复合涂层磨损与未磨损表面EDS分析结果

Table 2 EDAX analysis results of worn and un-worn surface of FeAlCr/Ni wraped Cr3C2 coatings(mass fraction, %)

图5 温度对材料摩擦因数的影响

Fig.5 Effects of temperature on friction coefficient of materials

图6 温度对材料磨损率的影响

Fig.6 Effects of temperature on wear rate of materials

图7 高速电弧喷涂FeCrNiAl/Cr3C2涂层的硬度

Fig.7 Microhardness of high velocity arc sprayed FeCrNiAl/Cr3C2 coating

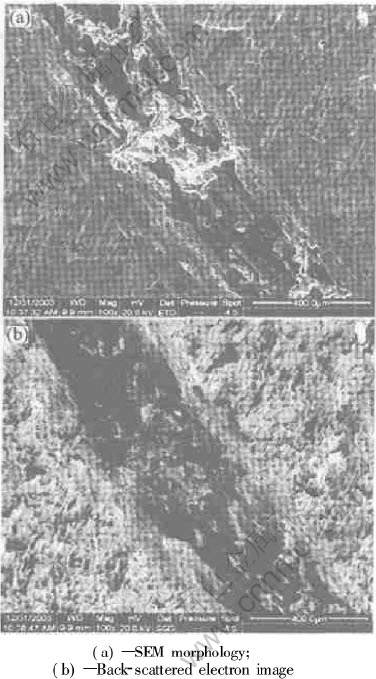

图8所示为高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层在高温下的磨痕形貌。 观察发现: 表面出现了层状剥离的迹象, 氧化膜也出现了层状分布, 表明涂层在摩擦过程中不断剥落, 从而形成了层状的氧化膜。 理论上分析, 导致涂层磨损破坏的主要原因是作用在涂层表面上的载荷和摩擦力的合力所引起的应力。 陶瓷球摩擦表面时, 涂层在拉应力与压应力的交替作用下, 不断出现疲劳损伤。 而涂层典型的层状结构, 加剧了这种趋势。 当疲劳损伤积累到一定程度时, 会在层间缺陷处形成微裂纹; 在交变应力的持续作用下, 这些微裂纹长大、 连接, 沿层间的缺陷扩展; 当这些裂纹扩展到临界长度时, 就会导致涂层中的扁平颗粒部分或整体脱落, 形成磨屑, 出现剥层磨损[2, 14]。 因此, FeAlCr/Ni包Cr3C2复合涂层在高温下的磨损机理主要是剥层磨损。

图8 FeAlCr/Ni包Cr3C2复合涂层在550℃的磨损SEM照片

Fig.8 SEM images of wear track of FeAlCr/Ni wrapped Cr3C2 coatings at 550℃

3 结论

1) 高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层具有典型的层状结构, 高于FeAl、 Fe-Al/ Cr3C2复合涂层的结合强度和硬度, 较低的孔隙率, 并且增强相在涂层中均匀分布。 Ni元素的添加一定程度上提高了涂层的结合强度和硬度。

2) 高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层的抗磨损性能在常温到250℃之间随温度升高而降低, 其变化趋势与Fe-Al/ Cr3C2复合涂层相似, 抗磨损性能却高于Fe-Al涂层。 主要原因是Cr元素的存在提高了铁铝涂层的常温性能, 而游离C的出现, 使得涂层在常温下的磨损形式相当于添加了固体润滑剂的磨损。

3) 由于Cr2O3的存在和Cr3C2与基体相良好的物理化学相容性以及增强相在高温下良好的性能, 保证了高速电弧喷涂FeAlCr/Ni包Cr3C2复合涂层在高温下具有较好的耐摩擦性能; 在高温下, 涂层主要是剥层磨损。

REFERENCES

[1] 徐滨士, 朱绍华, 刘世参, 等. 表面工程的理论与技术 [M]. 北京: 国防工业出版社,1999.

XU Bin-shi, ZHU Shao-hua, LIU Shi-can, et al. Thesis and Technology on Surface Engineering [M]. Beijing: Defense Industry Press, 1999.

[2] 朱子新. 高速电弧喷涂Fe-Al/WC涂层形成机理及高温磨损特性 [D]. 天津: 天津大学, 2002.

ZHU Zi-xin. Microstructure and high-temperature tribological process of Fe-Al/WC composite coating by HVAS [D]. Tianjin: Tianjin University, 2002.

[3] Ma Z Y, Tjong S C. High temperature creep behaviour of in situ TiB2 particulate reinforced copper-based composites [J]. Mater Sci Eng, 2000, A284: 70-76.

[4] Smith A V, Chung D D L. Titanium diboride particle-reinforced aluminium with high wear resistance [J]. Mater Sci, 1996, 31: 5961-5973.

[5] Deevi S C, Sikka V K, Liu C T. Processing, properties, and applications of nickel and iron aluminides [J]. Progress in Materials Science, 1997, 42: 177-192.

[6] Banovic S W, Dupont J N, Marder A R. Experimental evaluation of Fe-Al claddings in high-temperature sulfdising environments [J]. Welding Research, 2001 (3): 63-70.

[7] Sampson E R. Cored wire application using electric arc spray [A]. Proceedings of the 15th ITSC [C]. Nice, France, 1998. 133-137.

[8] 王永刚, 何业东, 齐彗滨, 等. Cr2O3薄膜对Fe3Al高温氧化的影响 [A]. 中国腐蚀与防护学会2000年学术论文集 [C]. 2000, 463-466.

WANG Yong-gang, HE Ye-dong, QI Hui-bin, et al. The effects of Cr2O3 to high oxidation of Fe3Al [A]. China Corrosion Control Conference 2000[C]. 2000. 463-466.

[9] 汤文明, 唐红军, 郑治祥, 等. Fe-Al金属间化合物基复合材料的研究进展 [J]. 中国有色金属学报, 2003, 13(8): 811-826.

TANG Wen-ming, TANG Hong-jun, ZHANG Zhi-xiang, et al. Progresses in studies on Fe-Al intermetallic matrix composites [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(8): 811-826.

[10] 杨王玥, 盛丽珍, 徐峰, 等. 代位合金元素对Fe3Al金属间化合物塑性与氧化行为的影响 [J]. 北京科技大学学报, 1996(3): 249-154.

YANG Wang-yue, SHENG Li-zhen, XU Feng, et al. Substitutional elements influences to the plastics and oxidation behavior of Fe3Al intermetallics [J]. Journal of University of Science and Technology Beijing, 1996(3): 249-154.

[11] Tanaka K, Saito T. Phase equilibria in TiB2-reinforced high modulus steel [J]. Phase Equilib, 1999, 20(3): 207-214.

[12] Degnan C C, Shipway P H. Elevated temperature sliding wear behaviour of TiC-reinforced steel matrix composites [J]. Wear, 2001, 251: 1444-1451.

[13] Sakamoto M, Liu Hua-Nan, Nomurab M, et al. Tribological stability of Al2O3 short fiber reinforced high Cr cast irons [J]. Wear, 2001, 251: 1414-1420.

[14] Jiang Jiaren, Stott F H, Stack M M. A mathematical model for sliding wear of metals at elevated temperatures [J]. Wear, 1995, 181-183: 20-31.

[15] Semenov A P. Tribology at high temperatures [J]. Tribology International, 1995(28): 44-50.

[16] 孙家枢. 金属的磨损 [M]. 北京: 冶金工业出版社, 1992.

SUN Jia-shu. Wear of Metals [M]. Beijing: Metallurgical Industry Press, 1992.

基金项目: 国家自然科学基金资助项目(50235030; 50005024)

收稿日期: 2004-03-16; 修订日期: 2004-05-30

作者简介: 徐维普, 男(1977-), 男, 博士研究生.

通讯作者: 徐维普, 电话: 010-66719225; E-mail: xwp@sjtu.edu.cn

(编辑 吴家泉)