High-quality aluminum turbocharger impellers produced by thixocasting

G. WALLACE1, A. P. JACKSON1, S. P. MIDSON2, Q. ZHU3

1. Aluminum Complex Components, Inc, Denver, USA;

2. The Midson Group, Inc., Denver, USA;

3. Cummins Turbo Technologies, Huddersfield, UK

Received 13 May 2010; accepted 20 June 2010

Abstract: The thixocasting process was chosen to produce the impellers as it is capable of producing castings with extremely high internal quality. Slugs cut from the DC cast bars are re-heated to the semi-solid casting temperature, and a specially-designed runner and gating system is used to prevent oxide from the surface of the slugs from becoming incorporated into the impeller. The technology used to produce the semi-solid impellers is described in detail. The semi-solid cast impellers, produced from an Al-Si-Mg-Cu alloy, are heat treated to the T6 temper. Results from testing are presented demonstrating that the impellers are free of porosity and other internal defects. Both mechanical property and fatigue data are presented showing that the semi-solid impellers have better properties than impellers produced by conventional casting and similar properties to forged and machined impellers. A short study is also described which identified suitable processing parameters to minimize hot tearing in the complex-shaped turbocharger impellers semi-solid cast from alloy 201. The surfaces of the impellers were examined using penetrant testing, and the results of modifying processing parameters on the propensity for surface cracking are presented. An aging study was performed to identify optimum mechanical strength.

Key words: semi-solid casting; turbocharger impeller; fatigue properties; alloy 201

1 Introduction

Commercial semi-solid castings are generally used in the T5 temper condition[1]. Although this avoids the tricky solution heat treatment (which often causes blistering in semi-solid castings), the properties achieved in the T5 temper are not significantly better than those achieved with existing casting processes, such as permanent mold casting.

However, when semi-solid castings are given the full T6 or T7 heat treatments (solution heat treatment, quench and aging), both static and dynamic properties are significantly better than those achieved by competing casting processes[2]. In fact, the properties of semi-solid castings can approach those of components produced from wrought alloys.

In this work, the process used to produce semi-solid cast turbocharger impellers is described. Impellers are in commercial production from an Al-Si-Cu-Mg alloys, heat treated to the T6 temper. In addition, experimental work is done to examine the castability, microstructure and properties of high strength aluminum alloy 201 produced in the impeller die.

2 Background

In simple terms, a turbocharger consists of a turbine wheel and an impeller on a common shaft (Fig.1). Waste energy from the exhaust turns the turbine, causing the impeller to provide compressed air to the engine. This allows the engine to produce more power and torque, as well as improve the overall efficiency of the combustion process. Turbochargers can be used in both gasoline and diesel engines, but the semi-solid cast impellers described in this work are currently used only in diesel engines[3-4].

The compression ratio for modern diesel engines can be up to 5:1, which can be only achieved using a complex impeller design and very high rotation speeds (up to 150 000 r/min for small impellers). The complex geometry and very high running speeds of impellers create high stresses at locations such as blade roots and around the bore, so impellers normally fail from fatigue. Therefore, it is vital to minimize defects while fabricating turbocharger impellers.

Fig.1 Section through turbocharger[3]

Current methods for producing aluminum turbocharger impellers are plaster casting or forging + machining. However, both of these current methods have serious drawbacks[5]. In this work, a new approach for producing turbocharger impellers, using semi-solid casting (Fig.2), is described. The parameters used to produce the impellers, and document their properties and performance, are studied. The technology to produce the impellers is the subject of a world-wide patent application[6].

Fig.2 Semi-solid cast turbocharger impeller of 98 mm in diameter

3 Semi-solid casting processes

There are three distinct semi-solid casting processes that are used commercially for the production of components: thixocasting, rheocasting and thixomolding[7-8]. All three require the special, “globular” microstructure at the semi-solid casting temperature. The processes generally differ in the manner in which this globular semi-solid structure is generated. Therefore, a decision had to be made which semi-solid process is to use to fabricate the impellers. Due to the stringent operating conditions for turbocharger impellers, it was decided that quality should be the main criterion for the choice of process. CAMPBELL[9] has developed one measure of the quality capability of a casting process by proposing ten casting rules that are required for the production of reliable castings. For castings produced by semi-solid processes, however, the rules need to be applied not only to the die filling process, but also during the generation of the globular microstructure in the feed material. CAMPBELL’s rules, as applied to semi-solid castings, can be summarized as follows: 1) Good quality melt; 2) Preventing liquid and semi-solid front damage, including no fall requirement; 3) No stopping of the semi-solid metal front during die filling; 4) Preventing bubble damage; 5) Avoiding outgassing from lubricants used in the casting mold; 6) Minimizing shrinkage porosity; 7) Avoiding convection damage; 8) Minimizing segregation; 9) Minimizing residual stresses; and 10) Providing location points.

A well designed thixocast component can meet all of these rules, and therefore has the capability to produce an extremely high quality casting. Most rheocasting processes, however, violate the second rule relating to liquid metal damage. For example, most rheocasting processes pour the liquid metal into some kind of container, where the liquid is cooled into the semi-solid temperature range[10-12]. Pouring violates the “no fall requirement” and has the potential to entrap gases and oxides. In addition, many rheocasting processes treat the liquid metal in a turbulent manner during the generation of the globular semi-solid slurry, again with the possibility of entrapping gases and oxides into the semi-solid slug. Therefore, thixocasting was chosen for the production of the semi-solid cast impellers.

4 Thixocasting impellers

The casting cell used to produce the impellers is shown in Fig.3, and the conditions used for the production of the impellers are summarized below.

The impellers are produced from an Al-Si-Cu-Mg alloy (Al-6.0%Si-3.0%Cu-0.35%Mg, mass fraction) and the feed material for the impeller casting is purchased from SAG. It is produced on a six-strand, horizontal dc casting unit using magnetohydrodynamic (MHD) stirring.

A carousel-style induction heater is used to re-heat the slugs. The induction heater has 24-stations with a 350 kW power supply and operates at 1 000 Hz. Total re-heating time for the slugs is approximately 10 min. The temperature of every slug is measured using a K-type thermocouple prior to transferring to the casting machine. The specified temperature range for the slugs is 569-578 °C, with slugs outside this range being discarded. Although relatively narrow, this temperature range is readily achieved. Fig.4 shows the measured temperatures of 100 slugs from a typical production run, showing that all the slugs are well within the 9 °C acceptable temperature range.

Fig.3 Semi-solid casting cell used to produce impellers

Fig.4 Measured temperatures for 100 slugs during production of casting

Once the slugs are at the correct semi-solid temperature, they are transferred to the shot sleeve of a real-time controlled Buhler die casting machine. This machine has the larger injection cylinder necessary to provide higher dynamic injection pressure for semi-solid casting.

Clearly, the shape of the impeller, including the 14 intricately-shaped blades, is very complex for production in a metal mold. Fig.5 shows the tooling necessary to manufacture the impeller, consisting of 14 petals, 2 split plates and a clamping ring. The blades of the impellers are essentially cast net-shape. The steel tooling shown in Fig.5 is ejected from the die along with the cast impeller, and a special station is utilized adjacent to the casting machine to disassemble the tool.

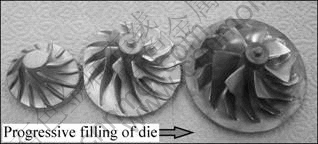

It is important that the semi-solid metal fills the die cavity in a non-turbulent manner, so that air pre-existing in the cavity is not mixed into the semi-solid slurry and trapped in the component. Fig.6 shows photographs of interrupted fills, illustrating the progressive filling of the die cavity. This type of plug flow is necessary to push the air ahead of the metal as it fills the cavity, ensuring that the air is exhausted from the cavity through vents strategically placed at the extremities of flow. Once the cavity is filled, the plunger applies more than 100 MPa pressure to ensure that shrinkage porosity is completely eliminated from the castings.

Fig.5 Steel tooling used to cast impellers: (a) CAD model; (b) Photograph

Fig.6 Progressive filling of semi-solid impeller die, demonstrating controlled flow

Testing has shown that the impellers are essentially free of porosity. Fig.7(a) shows a machined surface through an impeller, demonstrating the lack of porosity. However, published data from MAJOR[13] suggest that pores as small as 50 μm can reduce the fatigue resistance of aluminum alloys, and pores as this small size are difficult to detect on a machined surface. Consequently, to better evaluate porosity content, the aluminum smeared on the machined surface is removed by abrading using 600 grit paper followed by macro-etching with sodium hydroxide. The prepared surfaces are then penetrant tested, to determine if porosity is present. Testing has demonstrated that this procedure will reveal the presence of pores of 50 μm or smaller. Fig.7(b) shows a photograph viewed under ultraviolet light of a penetrant tested surface, showing the lack of porosity or other defects in the semi-solid cast impeller. Optical metallographic examination of the polished surface has proven the result that the SSM impellers are porosity free, as shown in Fig.7(c).

Fig.7 Sections through impellers showing lack of porosity: (a) Machined surface; (b) Machined and penetrant tested (viewed under ultraviolet light); (c) Optical metallography showing excellent integrity of microstructure

5 Testing and performance

To optimize strength and fatigue resistance, the semi-solid cast impellers are fully heat treated to the T6 temper. Careful choice of die design, casting parameters and die and plunger lubricants avoids blistering during T6 heat treating. Samples for tensile testing are machined from the center of the impellers and Table 1 shows the average mechanical properties of semi-solid cast impellers produced in January 2009.

Fig.8 shows a comparison of the fatigue life of impellers produced by casting, forging and semi-solid casting. This shows that the fatigue life of the semi-solid cast impellers is much better than conventional castings, and has a comparable fatigue life to the forged + machined impellers produced from a wrought aluminum alloy. As noted earlier, MAJOR[13] reported that the presence of defects such as porosity in components has a significant impact on fatigue properties, and MAJOR’s data[13] show that pores as small as 50 μm will reduce fatigue life. Sections through impellers shown in Fig.7 demonstrate that the semi-solid cast impellers described in this work are essentially porosity free, which explains their excellent fatigue performance.

Table 1 Average mechanical properties of SSM impellers produced in January 2009

Fig.8 Fatigue data for castings, forgings and semi-solid castings

6 Castability and properties of alloy 201 impellers

An experimental project was also performed to examine the castability, microstructure and properties of high strength alloy 201 in the impeller die. The nominal chemical composition of alloy 201 is listed in Table 2. Unlike many alloys used for the production of commercial semi-solid castings, the alloy does not contain significant amounts of silicon, instead being based on the Al-Cu system. In addition, alloy 201 contains 0.7% silver, to maximize precipitation hardening. Generally alloy 201 is considered the highest strength commercial aluminum casting alloy, and there has been a number of previous examinations of the semi-solid castability of this alloy[14-15].

Table 2 Nominal composition of alloy 201 (mass fraction, %)

Aluminum-copper casting alloys typically have poor resistance to hot tearing, especially when being cast in metal molds. However, previous work has shown that semi-solid casting generally reduces the tendency for hot tearing, most likely due to delaying the onset of particle coherency as a consequence of the globular particles used with semi-solid casting. However, most of the previous semi-solid casting work with alloy 201 has been performed with simple-shaped components. This project examined the castability and hot tearing resistance of the alloy when being cast in a complex-shaped tool.

The alloy 201 feed material used in this study was also continuously cast by SAG. Fig.9 shows the microstructure at the center of the cast bars. The microstructure consists of globular, primary aluminum particles of approximately 30-40 μm in diameter, surrounded by a continuous phase, which is probably an Al-Cu intermetallic.

Fig.9 Typical microstructure at center of alloy 201 feedstock

The casting cell shown in Fig.3 was used to cast test impellers from alloy 201. Essentially, the casting parameters were unchanged from the Al-Si-Cu-Mg alloy castings described above, although it was found that a 55% higher injection speed was necessary to adequately fill the impeller die with 201 alloy. Fig.10 shows the microstructure of the as-cast impellers, and it can be seen that the fraction of the globular primary aluminum phase is higher in the central hub of the impeller than in the extremities of the blades.

However, penetrant testing of the surface of the alloy 201 impellers showed numerous small cracks (hot tears), mostly at sharp corners or changes in section thickness. Fig.11 shows an example of an internal hot tear at a section change in the impeller. An examination of the technical literature revealed that increasing die pre-heating temperature decreases the tendency for hot treating in permanent mold castings (Fig.12)[16]. Therefore, the die temperature used in semi-solid of the alloy 201 impellers was increased from a range of 210-240 °C to 270-290 °C. Surface penetrant testing showed that increasing the die temperature eliminated the cracking, although it should be emphasized that in this study only a limited number of castings were examined, and a more comprehensive examination was recommended to confirm that hot tearing was completely eliminated.

Fig.10 Typical microstructures from as-formed impellers: (a) Central portion of hub; (b) Extremities of one of blades

Fig.11 Hot tear in alloy 201 impeller

Studies were performed both at Aluminum Complex Componeuts, InC. (ACC) and the University of Leicester (UK) to determine the impact of the full T6 heat treatment on microstructure and mechanical properties. Fig.13 shows the microstructure of the impellers after solution heat treatment and water quenching. The microstructure of the impellers considerably changed, now essentially consisting of single phase, equiaxed, and primary aluminum grains, both at the hub center and at the ends of the blades. The amount of intermetallic phase was significantly reduced during the solution heat treatment, with only a small amount being observed after the solution heat treatment.

Fig.12 Plots of hot tearing versus mold temperature for magnesium alloys produced by permanent mold casting[16]

Fig.13 Typical microstructure of central hub of alloy 201 impellers after solution heat treatment and water quenching (512 °C, 2 h+530 °C, 2 h)

Mechanical properties of the alloy 201 impellers heat treated to the T71 temper using a range of heat treatment conditions were examined, and the data in Table 3 show the optimum mechanical properties achieved. Strength is similar to the handbook data, while elongation is significantly improved.

Table 3 Comparison of mechanical properties of alloy 201-T71 impellers measured in this study versus handbook data

6 Summary and conclusions

The data presented in this work demonstrate that, when the appropriate component and processing conditions are chosen, semi-solid castings heat treated to the T6 or T7 tempers can provide better static and dynamic properties as compared with those of other casting processes, and the properties can compete directly against components produced from wrought alloys.

Acknowledgements

The authors would like to acknowledge Prof. Helen Atkinson of the University of Leicester (UK) who identified optimum heat treating conditions for the alloy 201 castings.

References

[1] DEWHIRST B, APELIAN D, JORSTAD J. Effect of artificial aging on microstructure and tensile properties of semi-solid processed A356 castings [C]//NADCA CastExpo’05. St. Louis, Missouri, USA, 2005: Paper T05-063.

[2] North American Die Casting Association. NADCA product specification standards for die castings produced by the semi-solid and squeeze casting processes [M]. 5th Edition. Wheeling, Illinois, USA, 2009.

[3] http://upload.wikimedia.org/wikipedia/commons/7/76/Turbocharger.jpg

[4] Diesel engine [EB/OL]. http://en.wikipedia.org/wiki/Diesel_engine

[5] ZHU Q, MIDSON S P. Semi-solid moulding: A competition to cast and machine from forging in making automotive complex components [C]// Proceedings of 11th International Conference on Semi-solid Processing of Alloys and Composites. Beijing, 2010.

[6] ZHU Q, JACKSON A. Method and apparatus for manufacturing of turbo compressor wheels. WO2007010181 [P]. 2007-01-25.

[7] MIDSON S P. Semi-solid casting of aluminum alloys: An update [J]. Die Casting Engineer, 2008: 14-16.

[8] NAFISI F, GHOMASHCHI R. Semi-solid metal processing routes: An overview [J]. Canadian Metallurgical Quarterly, 2005, 44(3): 289-303.

[9] CAMPBELL J. Casting practices: The ten rules of castings [M]. UK: Elsevier Publishers, 2004.

[10] YURKO J, MARTINEZ R A, FLEMINGS M C. The use of semi-solid rheocasting (SSR) for aluminum automotive castings [C]//Transactions of the Society of Automotive Engineers World Congress. 2003, 2003-01-0433.

[11] GOVENDER G, IVANCHEV L, JAHAJEEAH N, BEAN R. Application of CSIR rheocasting technology for the production of an automotive component [J]. Solid State Phenomena, 2006, 116/117: 501-504.

[12] KAMM R J, JORSTAD J L. Semi-solid molding method. US patent 6808004 [P]. 2004-10-26.

[13] MAJOR J F. Porosity control and fatigue behavior in A356-T61 aluminum alloy [J]. American Foundry Society Transactions, 1997, 105: 901-906.

[14] ASHTARI P, BIRSAN G, SHANKAR S. Favorable alloy compositions and melt temperatures to cast 2××× and 7××× Al alloys by controlled diffusion solidification (CDS)[C]//CAMPBELL J, CREPEAU P, TIRYAKIOGLU M. Shape Casting: Third International Symposium. TMS, 2009: 223-227.

[15] SYMEONIDIS K, APELIAN D, MAKHLOUF M M. Controlled diffusion solidification: Application to metal casting [J]. Metallurgical Science and Technology, 2008, 26(1): 30-36.

[16] SADAYAPPAN M, SAHOO M, WEISS D. Evaluation of hot tearing susceptibility of selected magnesium casting alloys in permanent molds [C]//Transactions of the American Foundry Society 111th Metalcasting Congress. 2007: Paper number 07-154.

(Edited by YANG Bing)

Corresponding author: S. P. MIDSON; Tel: +1-303-868-9766; E-mail: steve@themidsongroup.com

DOI: 10.1016/S1003-6326(09)60375-7