DOI: 10.11817/j.issn.1672-7207.2017.08.009

数控机床的能耗模型及实验研究

徐敬通1,李涛1,陈俊超2,杨淑德1,张洪潮1

(1. 大连理工大学 机械工程学院,辽宁 大连,116024;

2. 芜湖美智空调设备有限公司,安徽 芜湖,241009)

摘要:为了预测与评估数控机床能耗,提高机床能量利用率,对数控机床的能耗特性展开研究。根据机床能耗部件的特性,将数控机床整机能耗分解为4个部分:主传动系统空载能耗、进给系统空载能耗、辅助系统能耗、切削能耗(包含刀刃去除材料能耗和附加载荷损耗)。依据耗能机理和实验统计规律分别对这4个部分进行建模,进而建立机床整机一般能耗模型。在1台立式加工中心上开展相关能耗实验,将能耗模型应用于该机床的能耗研究分析。研究结果表明:机床能耗模型具有较好的适用性,可以较准确地预测机床能耗及其分布情况,这为机加工系统的能耗评估、节能优化以及低碳制造提供依据。

关键词:数控机床;能耗模型;节能;低碳制造

中图分类号:TG501 文献标志码:A 文章编号:1672-7207(2017)08-2024-10

An energy consumption model and experimental research of numerical control machine tools

XU Jingtong1, LI Tao1, CHEN Junchao2, YANG Shude1, ZHANG Hongchao1

(1. School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China;

2. Wuhu Maty Air-conditioning Equipment Co. Ltd, Wuhu 241009, China)

Abstract: In order to predict and assess the energy consumption of numerical control (NC) machine tools, as well as improve the energy efficiency, energy consumption characteristics of NC machine tools were studied. Based on energy-consuming characteristics, the energy consumption of NC machine tools was divided into four sections: no-load energy consumption of the main driving system, no-load energy consumption of the feed system, energy consumption of auxiliary systems, and energy consumption of the machining process, including tool tip cutting energy consumption and additional energy losses. Each section was modeled on the basis of energy-consuming mechanisms and experimental statistics, so as to form the general energy consumption model of the entirety. Then experiments were conducted on a vertical machining center to study energy consumption rules using the model. The results show that the model has good applicability, and can accurately predict the NC machine tool’s energy consumption and its distribution. Thus the energy consumption model is able to provide support for energy assessment and energy efficiency optimization of machining systems, which will contribute to low-carbon manufacturing.

Key words: numerical control machine tool; energy consumption model; energy efficiency; low-carbon manufacturing

机床作为装备制造业的“母机”,量大面广,耗能巨大[1]。而统计结果表明机床能量利用率十分低,普遍低于30%[2]。GUTOWSKI等[3]研究发现自动生产线上的大型加工中心能量利用率甚至低于15%,机床节能降耗潜力巨大。因此,研究机床的能耗特性,降低机床能耗,对于我国发展循环经济、推行绿色制造和应对气候变化具有重要意义。国内外学者针对机床的能耗特性开展了大量研究工作。刘飞等[4-5]从机床电机和机械传动系统一体化的角度出发,在考虑机床运行中多种能耗并存的情况下,建立了普通机床和变频调速数控机床主传动系统的能量传输数学模型。刘霜等[6]提出了一种基于时段能量模型的机床机电主传动系统的能量效率获取方法。DIAZ等[7]将机床能耗分解为空载能耗和切削能耗,但没有对其进行详细建模。AVRAM等[8-9]建立了机床不同部件能耗子系统的能耗模型,并结合数控程序来预测机床整机能耗,但预测精度有待提高。L 等[10]分析了机床各个基本动作的能耗,但没有将其统一到机床整机能耗。HU等[11]为提高机床能量利用率,搭建了机床能耗监测平台,用以优化切削参数和生产调度。GUTOWSKI等[12-14]则从机床加工比能的角度研究了机床能耗与工件材料去除率的关系,指出机床加工比能随工件材料去除率的增大而减小。从上述分析可以看出,对机床整机能耗的研究有待深入,用于预测机床能耗、指导节能生产的机床整机一般能耗模型尚待完善。为此,本文作者从机床各能耗部件的特点出发,将数控机床整机能耗分解为4个部分进行研究,从而建立机床整机一般能耗模型。将该模型应用于1台立式加工中心的能耗研究与分析中,初步验证模型的适用性与准确性。

等[10]分析了机床各个基本动作的能耗,但没有将其统一到机床整机能耗。HU等[11]为提高机床能量利用率,搭建了机床能耗监测平台,用以优化切削参数和生产调度。GUTOWSKI等[12-14]则从机床加工比能的角度研究了机床能耗与工件材料去除率的关系,指出机床加工比能随工件材料去除率的增大而减小。从上述分析可以看出,对机床整机能耗的研究有待深入,用于预测机床能耗、指导节能生产的机床整机一般能耗模型尚待完善。为此,本文作者从机床各能耗部件的特点出发,将数控机床整机能耗分解为4个部分进行研究,从而建立机床整机一般能耗模型。将该模型应用于1台立式加工中心的能耗研究与分析中,初步验证模型的适用性与准确性。

1 数控机床的能耗建模

数控机床能耗部件众多,能耗形式复杂,可根据各能耗部件的特点及与加工状态的关联性对其进行分类建模,进而建立机床整机一般能耗模型。机床整机功率可分解为4个部分:

(1)

(1)

式中:P为机床整机功率;Ps为主传动系统空载功率;Pf为进给系统空载功率;Paux为辅助系统功率;Pc+为切削功率,包括刀刃去除材料功率Pc和附加载荷损耗功率Pad。则机床整机能耗可表示为

(2)

(2)

式中:E为机床整机能耗;Es为主传动系统空载能耗;Ef为进给系统空载能耗;Eaux为辅助系统能耗;Ec+为切削能耗,包括刀刃去除材料能耗Ec和附加载荷损耗Ead。下面分别对4个部分的特性进行分析并建立相应模型,进而建立机床整机一般能耗模型。

1.1 主传动系统空载能耗建模

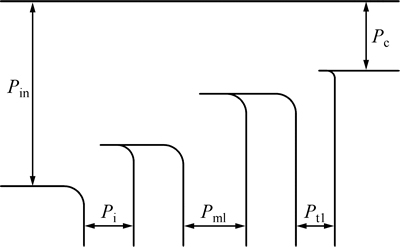

目前,数控机床主传动系统的驱动方式分为“变频器+异步电机+机械传动”和“伺服+永磁同步电机+机械传动”2种[15]。采用前种驱动方式的数控机床在我国应用最为广泛,其主传动系统功率流如图1所示。

图1 机床主传动系统功率流

Fig. 1 Power flow of main driving system

图1中:Pin为主传动系统输入功率;Pi为变频器消耗功率;Pml为主轴电机损耗功率;Ptl为机械传动损耗功率。

机床没有切削负载时主传动系统所消耗的功率称为主传动系统的空载功率,可通过计算机床空载功率和待机功率的差值得到。主传动系统空载功率Ps的理论模型可表示为[2]

(3)

(3)

式中:P0为电机空载功率,W;b0为电机的载荷系数;Mom为机床机械传动系统的非载荷库仑摩擦力矩;w为电机轴角速度;Bm为机械传动系统的黏性摩擦阻尼系数。

而在一定转速范围内主传动系统空载功率与主轴转速的统计关系[16]为

(4)

(4)

式中:M为主轴转速系数;n为主轴转速,r/min;C0为常数。

综合式(3)和(4)可知:主传动系统空载功率与主轴转速关系的基本形式为

(5)

(5)

式中:A,B和C为主轴转速系数,因其理论计算较为复杂,可运用实验结合统计分析确定。

则主传动系统空载能耗模型为

(6)

(6)

式中:ts为主轴旋转运动时间,s。

式(6)并没有单独区分主轴的加速和减速过程,原因在于:主轴的加速和减速所需时间很短;主轴减速时机床能量回收机制将主轴动能转化为电能并反馈给电网,抵消了部分加速能耗[17],主轴加速和减速过程主传动系统空载能耗的均值可近似用式(6)表示。

1.2 进给系统空载能耗建模

数控机床的进给驱动方式主要有“旋转伺服电动机+滚珠丝杠副”和“直线电动机直接驱动”2种[18]。前者是数控机床进给系统最常用的驱动方式,其i轴方向(i=X,Y,Z)进给运动空载功率可表示[19]为

(7)

(7)

式中: 为i轴方向进给运动空载功率;

为i轴方向进给运动空载功率; 为i轴方向进给速度,mm/min;ai,bi和ci为i轴方向进给特性系数,可通过实验获得。

为i轴方向进给速度,mm/min;ai,bi和ci为i轴方向进给特性系数,可通过实验获得。

则机床进给系统空载功率模型可表示为

(8)

(8)

式中: ,

, 和

和 分别为X轴方向、Y轴方向、Z轴方向进给运动空载功率。

分别为X轴方向、Y轴方向、Z轴方向进给运动空载功率。

机床进给系统空载能耗模型为

(9)

(9)

式中: ,

, 和

和 分别为X轴方向、Y轴方向、Z轴方向进给运动时间。

分别为X轴方向、Y轴方向、Z轴方向进给运动时间。

1.3 辅助系统能耗建模

数控机床辅助系统是指对机床完成加工任务起辅助作用的系统,包括数控系统、风扇系统、冷却系统等[20]。机床辅助系统工作时,其功率基本保持恒定[21]。机床辅助系统功率模型为

(10)

(10)

式中:m为机床辅助系统的个数;Pj为辅助系统j消耗功率;h(j)为开关函数, ,代表辅助系统j的开启与否。则机床辅助系统能耗模型为

,代表辅助系统j的开启与否。则机床辅助系统能耗模型为

(11)

(11)

式中:tj为辅助系统j的工作时间。

以1台立式加工中心(XH715)为例,式(11)可表示为

(12)

(12)

式中: ,

, ,

, 和

和 分别为风扇系统、数控系统、主轴电机控制系统和进给电机控制系统消耗功率;

分别为风扇系统、数控系统、主轴电机控制系统和进给电机控制系统消耗功率; ,

, ,

, 和

和 分别为对应的工作时间;

分别为对应的工作时间; ,

, ,

, 和

和 分别为润滑系统、照明系统、冷却系统和换刀系统消耗功率,

分别为润滑系统、照明系统、冷却系统和换刀系统消耗功率, ,

, ,

, 和

和 分别为对应的工作时间。

分别为对应的工作时间。

对于换刀系统,其能耗主要来自于刀库电机转动刀库,刀库电机运转时间 可由下式确定[22]:

可由下式确定[22]:

(13)

(13)

式中:N, ,

, ,

, 和

和 分别为换刀次数、第k次换刀时刀库起始位置、第k次换刀时刀库目标位置、刀库容量、刀库转速。

分别为换刀次数、第k次换刀时刀库起始位置、第k次换刀时刀库目标位置、刀库容量、刀库转速。

1.4 切削能耗建模

机床切削功率是指机床切削过程所消耗的功率,包括刀刃去除材料功率和附加载荷损耗功率。切削功率的计算可采用2种方法:1) 利用切削比能估算切削功率;2) 利用切削力和切削速度计算切削功率。由于切削比能并不是定值[23],第1种方法估算切削功率存在较大误差,本文采用第2种方法。考虑到车削和铣削作为最常见、最基本的切削加工方法,而铣削的切削机理相对复杂,现以铣削为例展开分析。

刀刃去除材料功率Pc的计算式为

(14)

(14)

式中:Fc为主切削力,N;v为铣削速度,m/min。

Fc可用切削参数的指数关系式[24]表示为

(15)

(15)

式中: 为铣削力系数,取决于加工条件和被加工材料;ap为背吃刀量,mm;fz为每齿进给量,mm/z;ae为侧吃刀量,mm;z为铣刀齿数;d为铣刀直径,mm;xF,yF,uF,qF和wF分别为背吃刀量、每齿进给量、侧吃刀量、铣刀直径和主轴转速的指数;

为铣削力系数,取决于加工条件和被加工材料;ap为背吃刀量,mm;fz为每齿进给量,mm/z;ae为侧吃刀量,mm;z为铣刀齿数;d为铣刀直径,mm;xF,yF,uF,qF和wF分别为背吃刀量、每齿进给量、侧吃刀量、铣刀直径和主轴转速的指数; 为加工条件改变时的修正系数。

为加工条件改变时的修正系数。

主轴转速n与铣削速度v的关系式为

(16)

(16)

将式(15)和(16)代入式(14),得刀刃去除材料功率模型:

(17)

(17)

式中: 为刀刃去除材料功率系数;wP,yP,xP和uP分别为铣削速度、每齿进给量、背吃刀量、侧吃刀量的指数。

为刀刃去除材料功率系数;wP,yP,xP和uP分别为铣削速度、每齿进给量、背吃刀量、侧吃刀量的指数。

机床附加载荷损耗功率Pad与刀刃去除材料功率Pc近似成正比[2, 25],即

(18)

(18)

式中: 为附加载荷损耗系数,在生产应用中可近似认为是常数。

为附加载荷损耗系数,在生产应用中可近似认为是常数。

则切削功率 可表示为

可表示为

(19)

(19)

将式(17)代入式(19),得切削功率模型:

(20)

(20)

式中: 为切削功率系数。

为切削功率系数。

由式(17)和式(20)可分别建立刀刃去除材料能耗模型和切削能耗模型:

(21)

(21)

(22)

(22)

式中:tc为切削时间。

对于其他切削加工方法,可参照其包含的切削参数对式(21)和式(22)进行适当修正,如车削加工时,fz修正为每转进给量f,uP为0。

1.5 整机能耗建模

将建立的主传动系统空载能耗模型、进给系统空载能耗模型、辅助系统能耗模型和切削能耗模型进行叠加,得到数控机床整机一般能耗模型为

(23)

(23)

式中: 可参照不同切削加工方法所包含的切削参数进行适当修正。

可参照不同切削加工方法所包含的切削参数进行适当修正。

2 实验研究与分析

为进一步研究机床能耗规律,确定数控机床一般能耗模型的适用性,在1台立式加工中心(XH715)上开展能耗实验。将PA2000mini功率分析仪连接于机床总线处,用以测量机床功率消耗和能耗。工件固定在Kistler 9257B三向测力仪上,用以测量切削力。

2.1 主传动系统空载能耗

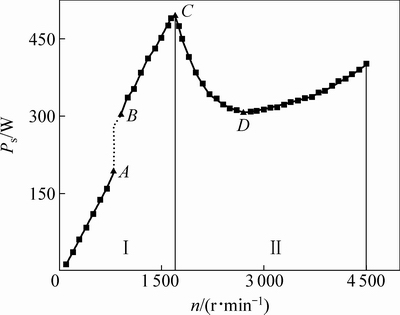

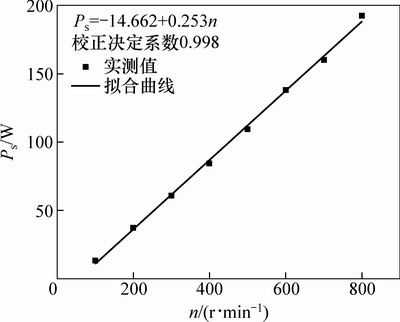

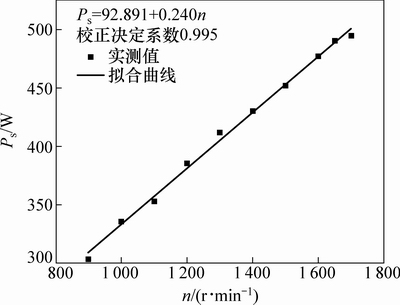

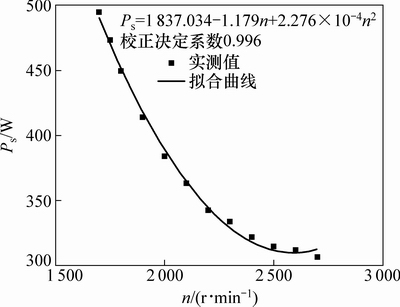

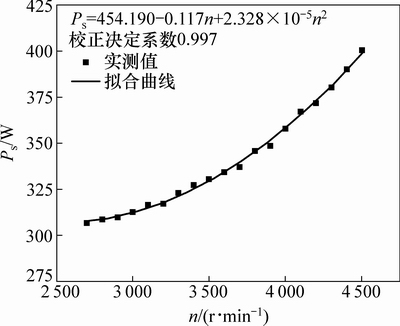

XH715加工中心的主传动系统采用“变频器+异步电机+机械传动”的驱动方式。用功率分析仪对主传动系统空载功率Ps进行测量,结果如图2~6所示。

图2所示为主传动系统空载功率随主轴转速变化的趋势。以C点为界限可分为2个阶段[26]:阶段Ⅰ,基频(50 Hz)以下调速阶段(n≤1 700 r/min);阶段Ⅱ,基频以上调速阶段(1 700<n≤4 500 r/min)。基频以下调速阶段电机气隙磁通基本保持不变,属于恒转矩调速[27],主传动系统空载功率与转速呈线性关系,如图3和图4所示。n从800 r/min(A点)到900 r/min(B点)时主传动系统空载功率发生了跳跃,原因可能是n在800 r/min附近时主传动链发生改变[28]。基频以上调速阶段气隙磁通随着频率的上升而减小,电机处于弱磁调速状态。1 700<n≤2 700 r/min(CD段)时电机定子铁耗和一部分定子铜耗随转速n的增加而减小,主传动系统空载功率逐渐减小[29],如图5所示。在n= 2 700 r/min(D点)时,主传动系统空载功率达到极小值。在n≥2 700 r/min时,电机轴承以及风阻等摩擦损耗随转速n的增加而增大,其对主传动系统空载功率的变化起主导作用,主传动系统空载功率逐渐增大,如图6所示。主传动系统空载功率模型和能耗模型分别如下:

(24)

(24)

(25)

(25)

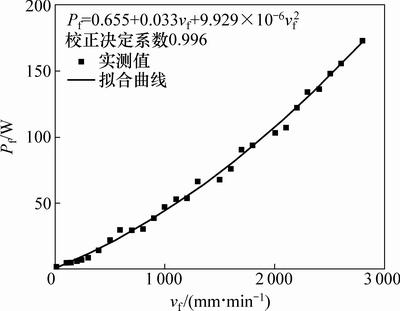

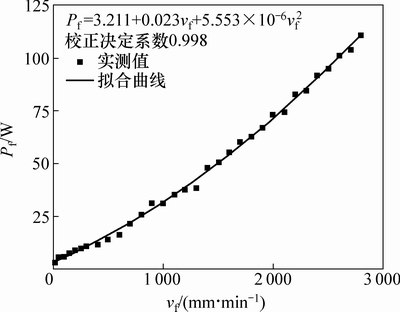

2.2 进给系统空载能耗

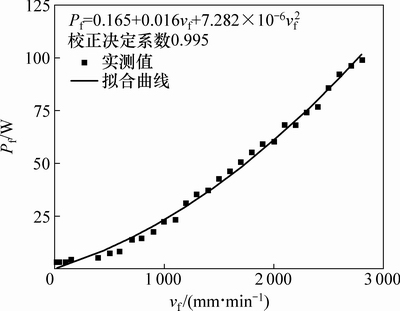

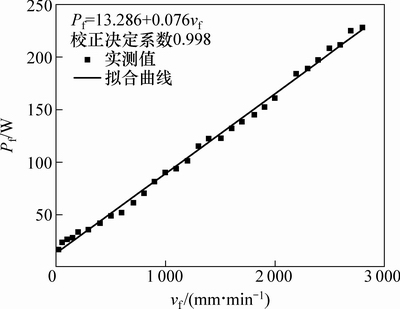

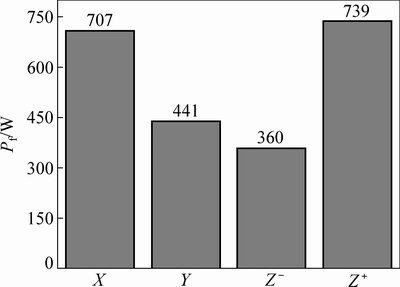

用功率分析仪分别对X轴方向、Y轴方向、Z轴方向的进给运动空载功率进行测量,结果如图7~11所示。由于立式加工中心Z轴方向进给运动受主轴箱、主轴等的重力影响,因此,其正方向和负方向进给运动空载功率模型不同。进给系统空载能耗模型如下:

图2 主传动系统空载功率随主轴转速的变化

Fig. 2 Power consumption changes of main driving system with spindle speed under no-load conditions

图3 主传动系统空载功率与主轴转速的关系曲线(A点前)

Fig. 3 Power consumption of main driving system under no-load conditions as function of spindle speed (before A)

图4 主传动系统空载功率与主轴转速的关系曲线(B-C)

Fig. 4 Power consumption of main driving system under no-load conditions as function of spindle speed (B-C)

图5 主传动系统空载功率与主轴转速的关系曲线(C-D)

Fig. 5 Power consumption of main driving system under no-load conditions as function of spindle speed (C-D)

图6 主传动系统空载功率与主轴转速的关系曲线(D点后)

Fig. 6 Power consumption of main driving system under no-load conditions as function of spindle speed (after D)

图7 X轴方向进给运动空载功率与进给速度的关系曲线

Fig. 7 Power consumption of X-axis feed movements under no-load conditions as function of feed rate

图8 Y轴方向进给运动空载功率与进给速度的关系曲线

Fig. 8 Power consumption of Y-axis feed movements under no-load conditions as function of feed rate

(26)

(26)

式中: ,

, ,

, 和

和 分别为X轴方向、Y轴方向、Z轴负方向和Z轴正方向的常速进给运动时间;

分别为X轴方向、Y轴方向、Z轴负方向和Z轴正方向的常速进给运动时间; ,

, ,

, 和

和 分别为X轴方向、Y轴方向、Z轴负方向和Z轴正方向的快速进给运动时间。

分别为X轴方向、Y轴方向、Z轴负方向和Z轴正方向的快速进给运动时间。

图9 Z轴负方向进给运动空载功率与进给速度的关系曲线

Fig. 9 Power consumption of Z-axis feed movements (in negative direction) under no-load conditions as function of feed rate

图10 Z轴正方向进给运动空载功率与进给速度的关系曲线

Fig. 10 Power consumption of Z-axis feed movements (in positive direction) under no-load conditions as function of feed rate

图11 X,Y和Z轴方向快速进给运动空载功率

Fig. 11 Power consumption of X-axis, Y-axis and Z-axis rapid feed movements under no-load conditions

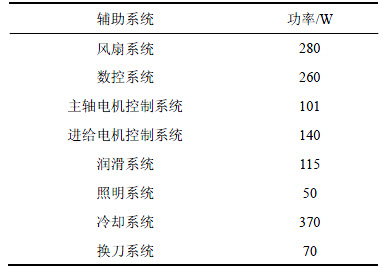

表1 各辅助系统功率

Table 1 Power consumption of auxiliary systems

2.3 辅助系统能耗

根据机床说明书和实验测量可得辅助系统的相关参数。XH715加工中心采用圆盘式刀库,刀库容量为16,刀库转速为6.37×10-2 r/s。各辅助系统功率消耗如表1所示。将各参数代入式(12),得辅助系统能耗模型为

(27)

(27)

2.4 切削能耗

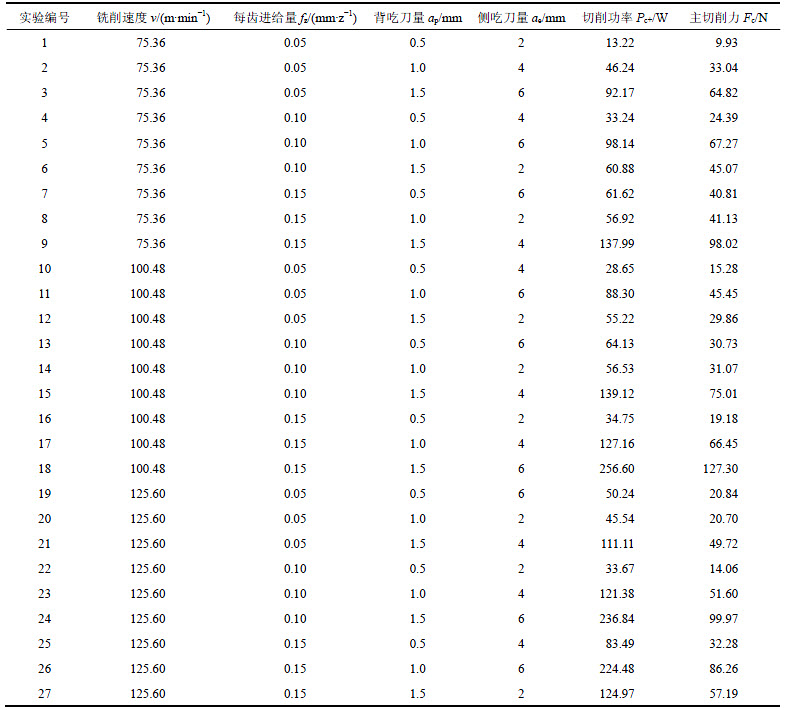

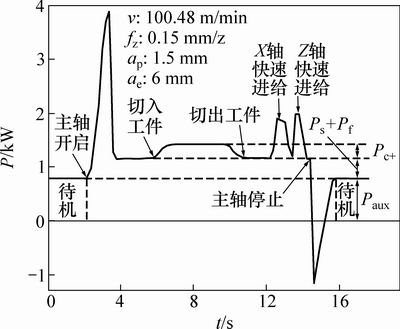

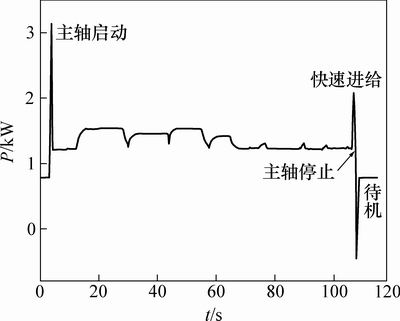

以铣削45钢材料为例,设计正交实验(L27),选取铣削速度、每齿进给量、背吃刀量、侧吃刀量为实验因子,因子水平取值参考机床和刀具技术指标确定。铣削过程中不使用切削液。铣削实验机床功率曲线如图12所示,正交实验结果如表2所示。对表2中切削参数与主切削力进行回归分析,得主切削力模型:

表2 铣削45钢的切削功率和主切削力

Table 2 Power consumption and main cutting forces of milling 45 carbon steel

图12 铣削实验机床功率曲线

Fig. 12 Power consumption profile of milling experiment from machine tool

(28)

(28)

代入式(14),得刀刃去除材料功率模型:

(29)

(29)

则刀刃去除材料能耗模型为

(30)

(30)

对表2中切削参数与切削功率进行回归分析,得切削功率模型:

(31)

(31)

则切削能耗模型为

(32)

(32)

2.5 整机能耗

将式(25),(26),(27)和(32)分别代入式(23),可得XH715立式加工中心铣削45钢材料的整机能耗模型。由此初步验证了数控机床一般能耗模型的适用性。

3 能耗模型的应用

3.1 机床能耗的预测

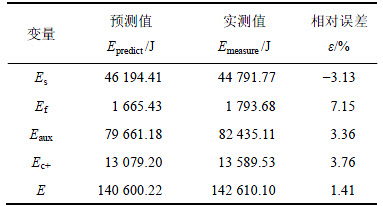

数控机床一般能耗模型是对数控机床能耗的概括性描述。鉴于机床能耗部件、加工材料以及刀具等的差异性,为将其应用到特定机床加工过程的能耗预测,需对机床进行相关能耗实验,以确定式(23)中各个系数。现以XH715加工中心加工1个45钢零件的某道工序为例,对机床能耗预测进行说明。将该工序加工工艺参数代入前面建立的XH715加工中心铣削45钢的能耗模型,计算得到加工过程能耗预测值;功率分析仪测量得到加工过程的能耗实测值。机床加工功率测量曲线如图13所示。能耗预测值、实测值及两者相对误差如表3所示。

图13 零件加工的机床功率曲线

Fig. 13 Power consumption profile of machine tool for machining part

表3 零件加工的能耗预测值、实测值及相对误差

Table 3 Predicted values, measured values and relative errors between them of energy consumption for machining part

由表3可以看出:在加工过程中,机床能耗4个部分的预测值与实测值相对误差的绝对值不超过7.5%,整机能耗的预测值与实测值相对误差不超过2%。可见,机床能耗模型可较好地用于机床加工过程的能耗预测。

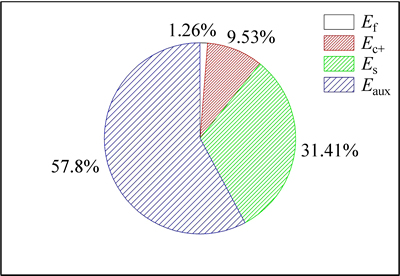

机床能耗4大部分(实测值)的比例如图14所示。由图14可知:机床进给系统空载能耗Ef所占比例最小;辅助系统能耗Eaux比例最大,其次是主传动系统空载能耗Es;切削能耗Ec+比例仅为9.53%,刀刃去除材料能耗Ec比例则低于9.53%。机床有效能耗只占机床总能耗的很小一部分。在实际加工中,通过优化工艺参数,减少机床待机和空行程时间,可以有效降低机床总能耗。

图14 机床能耗的4个部分所占比例

Fig. 14 Proportions of four energy consumption sections of machine tool

3.2 机床节能的指导

在批量生产加工的车间,对同一型号机床进行相关能耗实验,可建立此型号机床能耗模型。在制定加工方案时,利用式(33)和式(34)分别对机床能量利用率和加工比能进行预测与评估。根据评估结果对工艺参数和加工任务调度进行优化,可以有效提高机床能量利用率,降低机床能耗,达到低碳节能的目的。

(33)

(33)

(34)

(34)

式中:U和S分别为机床能量利用率、机床加工比能;V为工件材料去除体积。

4 结论

1) 根据数控机床各能耗部件的特性及与加工过程的关联性,将整机能耗分解为4个部分:主传动系统空载能耗、进给系统空载能耗、辅助系统能耗、切削能耗(包括刀刃去除材料能耗和附加载荷损耗)。依据耗能机理和实验统计规律分别对4个部分进行建模,进而建立机床整机一般能耗模型。

2) 机床能耗模型具有较好的适用性,可较准确地预测机床能耗及其分布情况,这为机械加工系统的绿色评估、节能优化提供了依据。

参考文献:

[1] 李涛, 孔露露, 张洪潮, 等. 典型切削机床能耗模型的研究现状及发展趋势[J]. 机械工程学报, 2014, 50(7): 102-111.

LI Tao, KONG Lulu, ZHANG Hongchao, et al. Recent research and development of typical cutting machine tool’s energy consumption model[J]. Chinese Journal of Mechanical Engineering, 2014, 50(7): 102-111.

[2] 刘飞, 徐宗俊, 但斌. 机械加工系统能量特性及其应用[M]. 北京: 机械工业出版社, 1995: 8-39.

LIU Fei, XU Zongjun, DAN Bin. Machining system energy consumption characteristics and its application[M]. Beijing: China Machine Press, 1995: 8-39.

[3] GUTOWSKI T, MURPHY C, ALLEN D, et al. Environmentally benign manufacturing: observations from Japan, Europe and the United States[J]. Journal of Cleaner Production, 2005, 13: 1-17.

[4] 刘飞, 徐宗俊. 机床主传动系统能量传输数学模型[J]. 重庆大学学报(自然科学版), 1990, 13(2): 8-14.

LIU Fei, XU Zongjun. Energy transmission mathematic models of main driving system of machine tools[J]. Journal of Chongqing University, 1990, 13(2): 8-14.

[5] 施金良, 刘飞, 许弟建, 等. 变频调速数控机床主传动系统的功率平衡方程[J]. 机械工程学报, 2010, 46(3): 118-124.

SHI Jinliang, LIU Fei, XU Dijian, et al. Power balance equation about the numerical control machine tool’s main driven by variable voltage variable frequency[J]. Chinese Journal of Mechanical Engineering, 2010, 46(3): 118-124.

[6] 刘霜, 刘飞. 机床机电主传动系统服役过程能量效率获取方法[J]. 机械工程学报, 2012, 48(23): 111-117.

LIU Shuang, LIU Fei. Energy efficiency acquisition method during the service process of machine tools[J]. Chinese Journal of Mechanical Engineering, 2012, 48(23): 111-117.

[7] DIAZ N, REDELSHEIMER E, DORNFELD D. Energy consumption characterization and reduction strategies for milling machine tool use [C]//Proceedings of the 18th CIRP International Conference on Life Cycle Engineering. Germany: Springer, 2011: 263-267.

[8] AVRAM O I, XIROUCHAKIS P. Evaluating the use phase energy requirements of a machine tool system[J]. Journal of Cleaner Production, 2011, 19: 699-711.

[9] HE Yan, LIU Fei, WU Tong, et al. Analysis and estimation of energy consumption for numerical control machining[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(2): 255-266.

[10] L Jingxiang, TANG Renzhong, JIA Shun. Therblig-based energy supply modeling of computer numerical control machine tools[J]. Journal of Cleaner Production, 2014, 65: 168-177.

Jingxiang, TANG Renzhong, JIA Shun. Therblig-based energy supply modeling of computer numerical control machine tools[J]. Journal of Cleaner Production, 2014, 65: 168-177.

[11] HU Shaohua, LIU Fei, HE Yan, et al. An on-line approach for energy efficiency monitoring of machine tools[J]. Journal of Cleaner Production, 2012, 27: 133-140.

[12] GUTOWSKI T, DAHMUS J, THIRIEZ A. Electrical energy requirements for manufacturing processes[C]//The 13th CIRP International Conference on Life Cycle Engineering. Leuven, Belgium, 2006.

[13] LI Lin, YAN Jihong, XING Zhongwen. Energy requirements evaluation of milling machines based on thermal equilibrium and empirical modeling[J]. Journal of Cleaner Production, 2013, 52: 113-121.

[14] VELCHEV S, KOLEV I, IVANOV K, et al. Empirical models for specific energy consumption and optimization of cutting parameters for minimizing energy consumption during turning[J]. Journal of Cleaner Production, 2014, 80: 139-149.

[15] 胡韶华, 刘飞, 何彦, 等. 数控机床变频主传动系统的空载能量参数特性研究[J]. 计算机集成制造系统, 2012, 18(2): 326-331.

HU Shaohua, LIU Fei, HE Yan, et al. No-load energy parameter characteristic of computerized numerical control machine tool main transmission system[J]. Computer Integrated Manufacturing System, 2012, 18(2): 326-331.

[16] BALOGUN V A, MATIVENGA P T. Modelling of direct energy requirements in mechanical machining processes[J]. Journal of Cleaner Production, 2013, 41: 179-186.

[17] DIETMAIR A, VERL A. A generic energy consumption model for decision making and energy efficiency optimization in manufacturing[J]. International Journal of Sustainable Engineering, 2009, 2(2): 123-133.

[18] 陈婵娟. 数控车床设计[M]. 北京: 化学工业出版社, 2005: 57.

CHEN Chanjuan. The design of CNC lathes[M]. Beijing: Chemical Industry Press, 2005: 57.

[19] 胡韶华, 刘飞, 胡桐. 数控机床进给系统功率模型及空载功率特性[J]. 重庆大学学报, 2013, 36(11): 74-80.

HU Shaohua, LIU Fei, HU Tong. Power model and tarepoewer characteristic of CNC machine tool feed system[J]. Journal of Chongqing University, 2013, 36(11): 74-80.

[20] 王秋莲, 刘飞. 数控机床多源能量流的系统数学模型[J].机械工程学报, 2013, 49(7): 5-12.

WANG Qiulian, LIU Fei. Mathematical model of multi-source energy flows for CNC machine tools[J]. Chinese Journal of Mechanical Engineering, 2013, 49(7): 5-12.

[21] 胡邵华. 数控机床通用能耗模型及其应用[J]. 组合机床与自动化加工技术, 2013(10): 113-115.

HU Shaohua. A general energy consumption model for CNC machine tools and its application[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2013(10): 113-115.

[22] GARA S, BOUZID W, AMAR M B, et al. Cost and time calculation in rough NC turning[J]. The International Journal of Advanced Manufacturing Technology, 2009, 40(9): 971-981.

[23] LI Wen, KARA S. An empirical model for predicting energy consumption of manufacturing processes: a case of turning process[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2011, 225(9): 1636-1646.

[24] 艾星, 肖诗钢. 切削用量简明手册[M]. 3版. 北京: 机械工业出版社, 1994: 110.

AI Xing, XIAO Shigang. The handbook of cutting parameters[M]. 3th ed. Beijing: China Machine Press, 1994: 110.

[25] HU Shaohua, LIU Fei, HE Yan, et al. Characteristics of additional load losses of spindle system of machine tools[J]. Journal of Advanced Mechanical Design, Systems, and Manufacturing, 2010, 4(7): 1221-1233.

[26] ABELE E, SIELAFF T, SCHIFFLER A, et al. Analyzing energy consumption of machine tool spindle units and identification of potential for improvements of efficiency[C]//Proceedings of the 18th CIRP International Conference on Life Cycle Engineering. Germany: Springer, 2011: 280-285.

[27] 吴清, 刘小成, 夏春明. 机电传动控制[M]. 广州: 华南理工大学出版社, 2011: 74-75.

WU Qing, LIU Xiaocheng, XIA Chunming. Electromechanical transmission control[M]. Guangzhou: South China University of Technology Press, 2011: 74-75.

[28] ARAMCHAROEN A, MATIVENGA P T. Critical factors in energy demand modelling for CNC milling and impact of toolpath strategy[J]. Journal of Cleaner Production, 2014, 78: 63-74.

[29] 吕景祥. 面向低碳制诰的数控机床能量供给建模研究[D]. 杭州: 浙江大学机械工程学院, 2014: 31-36.

L Jingxiang. Research on energy supply modeling of computer numerical control machine tools for low carbon manufacturing[D]. Hangzhou: Zhejiang University. School Mechanical Engineering, 2014: 31-36.

Jingxiang. Research on energy supply modeling of computer numerical control machine tools for low carbon manufacturing[D]. Hangzhou: Zhejiang University. School Mechanical Engineering, 2014: 31-36.

(编辑 陈爱华)

收稿日期:2016-09-23;修回日期:2016-12-09

基金项目(Foundation item):国家自然科学基金资助项目(51275074);国家重点基础研究发展计划(973计划)项目(2011CB013406) (Project(51275074) supported by the National Natural Science Foundation of China; Project(2011CB013406) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:李涛,博士,副教授,从事产品可持续性评价方法、制造与再制造工艺过程能耗评估等研究;E-mail:litao_dlut@163.com