DOI: 10.11817/j.issn.1672-7207.2015.03.006

基于类等势场法和模型的锻件预制坯设计

夏玉峰,陈邦华,杜婉婉,杨显红

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:利用塑性变形过程中金属的流动规律与静电场等势线分布类似这一特性,提出一种预制坯设计的新方法—类等势场法,并采用此方法对某齿轮锻件进行预成形设计。利用ANSYS软件得出预制坯形状,以此形状为局部变量,以压机速度、摩擦因数、温度为全局变量,以成形载荷、填充率、晶粒尺寸为优化目标,利用有限元软件DEFORM-3D进行数值模拟,并采用Matlab软件中的MBC(model-based calibration)工具箱对其进行数学建模及优化,最后在预锻工艺参数不变的条件下,得到终锻的最佳工艺参数组合是等势线ξ为0.205 V时的预制坯形状及压机速度为56 mm/s、摩擦因数为0.2、温度为1 000 ℃。生产实践表明:该方法设计的齿轮与传统方法相比,终锻成形载荷下降40%,材料利用率提高56.7%,而且组织得到细化。

关键词:齿轮锻件;等势场;预成形设计;优化;数值模拟

中图分类号:TG311 文献标志码:A 文章编号:1672-7207(2015)03-0804-08

Pre-forming design in forging process based on equipotential field and model

XIA Yufeng, CHEN Banghua, DU Wanwan, YANG Xianhong

(College of Material Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: According to the similarity between the metal flow law and the equipotential line of the electrostatic field, a new method for the pre-forming design in forging process was proposed as equi-potential field method and adopted for the per-forming design of gear forging. The preformed shapes were obtained by ANSYS software and chosen as a local variable, while speed of pressing machine, friction coefficient, temperature were chosen as the global variables, and forming load, filling ratio and grain size were chosen as optimization goals. DEFORM-3D software was used to simulate the forging process, model-based calibration(MBC) toolbox in Matlab software was used to build mathematics model, and finally, under the condition of pre-forging process parameters unchanged,the performed shape ξ of 0.205 V, the speed of pressing machine of 20 mm/s, the friction coefficient of 0.1 and the temperature of 600 ℃ were combined as the best parameters of finish forging. The production practice shows that the design of the gear compared with traditional methods reduces the forming load of finish forging by 40%, increases the utilization rate of material by 56.7%, and refines the microstructure.

Key words: gear forging; equipotential field; pre-forming design; optimization; numerical simulation

预成形设计是锻造工艺设计中的重要内容之一,预制坯与终锻件形状关联性强,直接影响金属的变形过程,从而影响到成形件的最终形状和成形质量[1-2],如何设计合理的预制坯形状是生产合格终锻件的关键,也是模具设计的难点之一,目前国内外在此方面的研究多集中于利用数值模拟技术进行设计结果验证的试错法,其基本思路仍与传统的试错法思路一样,但所用的验证手段不同[3-4],也有一些在设计理论和方法方面取得一些进展,例如Castro等[5]采用遗传算法求解考虑原始工件形状和加工温度为设计变量的金属预成形优化问题,Srikanth等[6]提出了有限黏塑性过程的形状灵敏度分析方法,但上述方法得到的结果精度不高。近年来,基于静电场的预制坯设计开始得到应用。Lee等[7]首先将电场设计预制坯的方法应用于盘形件设计,Ko等[8]应用神经网络的方法对锻造成形中目标函数进行优化,但针对的零件外形尺寸比较简单,得到的模型精度也不够高,肖军等[9]对轴对称件超塑性气压胀形过程进行了电场模拟,李超等[10]采用类等势场反推法对TC4合金板料胀形工艺进行了模拟,蔡军等[11] 采用一种基于三维静电场的TC4合金叶片预制坯设计方法。上述利用电场模拟得到的预制坯形状有很多种,但只是选择1种或者几种形状进行模拟验证,有一定的局限,而且每一种预制坯形状结合不同的工艺参数生产出的产品质量也不相同,不能以一种参数组合来进行预制坯形状优劣的验证。本文作者将电场模拟和Matlab工具箱相结合,对电场模拟得到的不同预制坯形状结合不同参数组合进行数学建模,并优化得到最佳的预制坯形状和参数组合查阅表,为工程师灵活地选择工艺参数组合提供了方便。最后经过实验验证,证明此方法的可靠性。

1 预制坯设计方法

由场论可知:速度场无旋则速度场有势,速度势函数φ表示为

(1)

(1)

由体积不可压缩条件知

(2)

(2)

由式(1)和(2)可得

(3)

(3)

同理,速度场的流函数ψ表示为

(4)

(4)

由式(3)和(4)可知速度场势函数和流函数均满足拉普拉斯方程。

由静电场理论可知,静电场中任一点的电势都满足泊松方程

(5)

(5)

式中:ρ为电荷密度; 为介电常数。

为介电常数。

根据电场理论,控制均匀电导率的空间电流场,其电位分布方程为

(6)

(6)

同样也满足拉普拉斯方程。由此可知,在不同电位的2个导体之间所产生的等势线描绘了材料变形终了形态和初始形态之间的最小变形功路径,而且材料成形过程中的金属流动也遵循最小功原理,所以基于这种场方程和能量最小原理的相似性,材料成形过程中的坯料形状就可以用静电场中的等势线形状来描述[12]。

本文以某齿轮为例来进行预制坯的设计,该齿轮是典型的圆饼状锻件,其生产方式是闭式精密锻造,对齿轮精度要求比较高,在实际生产中主要有折叠、充填不满、刮料等缺陷以及成形载荷过高、组织性能不合格等问题,仅靠经验进行预制坯设计已经无法满足要求。

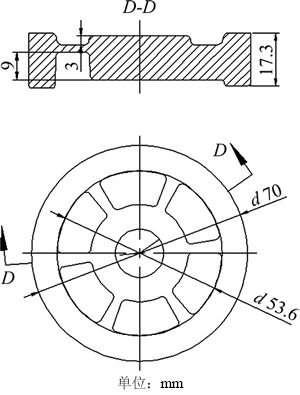

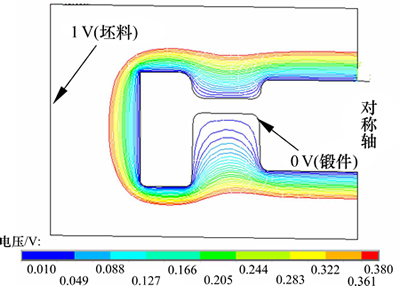

齿轮的结构示意图如图1所示。原始坯料尺寸(直径×高)为60 mm×30 mm的圆柱体,为了产生合适的等势线,需要将坯料按比例放大,通过对不同放大倍数的坯料及终锻件间所产生的电场分布规律的研究,认为坯料的放大倍数为2~3倍比较合适。本文将原始坯料放大2.5倍,将终锻件放在坯料的内部,对坯料和终锻件围成的闭合空间进行有限元网格划分,单元类型为四节点四边形单元,坯料边界料赋予1 V电压,终锻件边界赋予0 V电压。利用ANSYS软件进行模拟,其结果如图2所示,由于锻件为轴对称,因此模拟其1/2即可,从图2可以看出:当等势越大时,等势线的形状越接近坯料形状,因此,达不到预制坯设计的目的,当等势越小时,等势线的形状越接近终锻件的形状,同样也达不到预制坯设计的目的,因而根据等势线分布选择0.01~0.4 V之间的等势线作为优化目标范围,最终目的是得到此范围内的某条等势线作为预制坯模具的形状。

图1 齿轮锻件结构图

Fig. 1 Forging drawing of gear

图2 电场等势线分布

Fig. 2 Distribution of equipotential lines

2 目标参数的数字化表征

为了定量表征目标参数,需要对目标参数进行数字化。本文的目标参数有3个,成形载荷可以直接模拟得到,因此,需要对填充率和晶粒尺寸进行数字化处理。

2.1 填充率表征

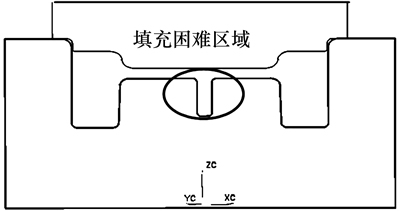

图3所示为齿端面充填不满示意图。由图3可见:齿轮圆角部位经常会遇到填充不满的情况,造成废品的产生。

根据填充率的定义,填充率可以由下式获得

(7)

(7)

其中:V1为型腔中坯料体积;V2为型腔体积。

2.2 晶粒尺寸的表征

将有限元法与Yada[13]微观组织模型结合,对齿轮锻造(预锻+终锻)过程中晶粒尺寸演变过程进行数值模拟。晶粒长大与临界应变有关,认为当真应变超过临界应变值时晶粒会长大,即

当 <

< 时,D1=D0;

时,D1=D0;

当 ≥

≥ 时,

时,

式中: 为等效应变临界值;D1和D0分别为瞬时和初始晶粒尺寸(μm)。根据实验结果,求得C1,C2,C3,C4分别为10 744,0.020 6,0.011 4和1 705.9。

为等效应变临界值;D1和D0分别为瞬时和初始晶粒尺寸(μm)。根据实验结果,求得C1,C2,C3,C4分别为10 744,0.020 6,0.011 4和1 705.9。

图3 齿端面充填不满示意图

Fig. 3 Unfilled defect diagram in rid’s end face

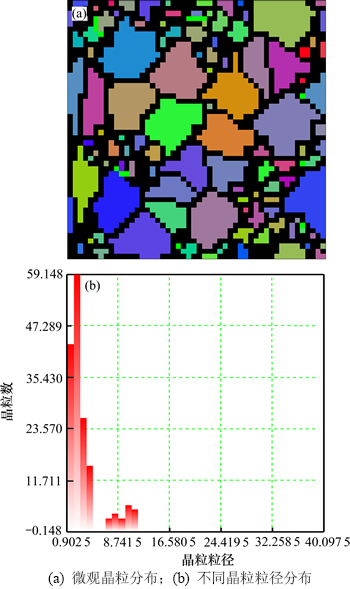

图4所示为Deform模拟齿轮在某参数下的晶粒尺寸,利用统计学的方法对晶粒进行统计计算,得出平均晶粒粒径 为

为

(8)

(8)

其中:Di为第i个晶粒粒径。

图4 微观晶粒粒径

Fig. 4 Microcosmic size of grains

3 数学建模及优化

利用Matlab软件中的MBC工具箱对齿轮锻造参数组合进行建模,主要有3个步骤:试验设计选择有代表性的参数组合点;通过实验的数据建立数学模型;基于模型对其进行优化[14-16]。

3.1 实验设计和仿真计算

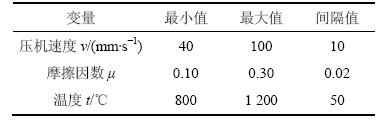

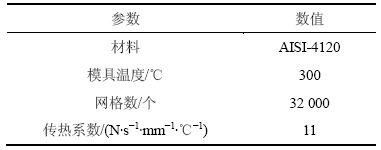

MBC提供了3种实验设计方法:经典设计方法,空间填充法,优化设计法。本文采用空间填充法中的拉丁超立方法(LHS)。实验设计的变量范围如表1所示。

表1 实验设计的变量范围

Table 1 Variables ranges in experimental design

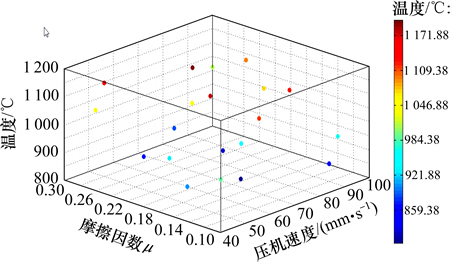

将表1中的参数利用拉丁超立方的抽样方法进行有代表性的抽样,得到20组全局变量的参数组合,抽样结果如图5所示。预制坯形状因子为组内局部变量,其抽样取值为:ξ1=0.059 V,ξ2=0.132 V,ξ3=0.205 V,ξ4=0.278 V,ξ5=0.351 V。

图5 拉丁超立方抽样结果

Fig. 5 Result of Latin hypercube sampling

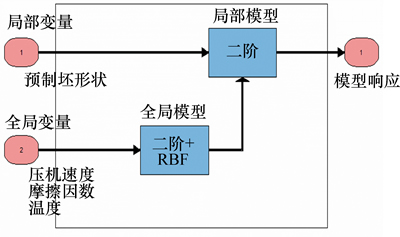

选取20组全局变量组合后,依次改变局部变量预制坯形状,得到100个数据点,并利用有限元软件Deform对各个组合进行数值模拟,有限元模拟参数见表2,表3为其中一种组合的模拟结果。

表2 数值模拟参数

Table 2 Parameters of numerical simulation

表3 某参数组合下的仿真结果

Table 3 Result of simulation under combined of some parameters

3.2 数学模型的建立

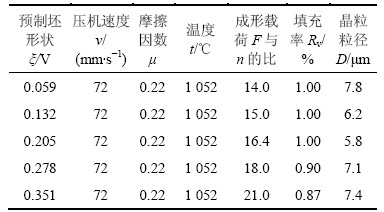

建立预成形设计模型就是通过统计建模的方法建立前面数值模拟的离散量之间的函数关系。需要建立的模型包括2类:局部模型和全局模型。局部模型和全局模型共同构成了预成形设计的2阶段模型,如图6所示。

图6 数学建模的2个阶段

Fig. 6 Two-stage of mathematics model

3.2.1 局部模型

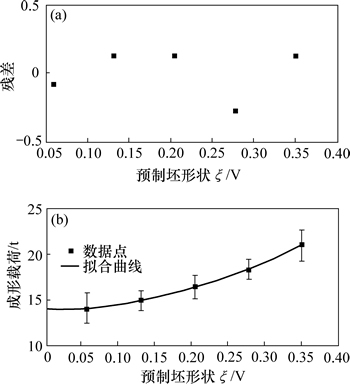

实验设计得到的数据根据局部变量预制坯形状因子ξ与输出量成形载荷F、填充率Rv和晶粒粒径D之间的二次多项式回归模型,即局部模型。其表达式为

(9)

(9)

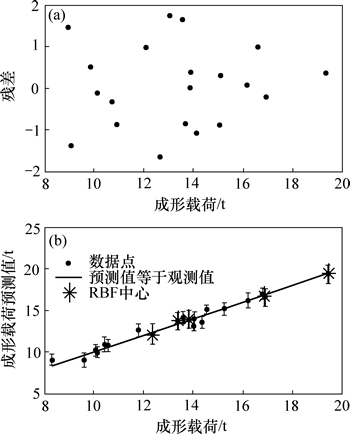

式中:a,b和c为回归系数。成形载荷的局部模型如图7所示,为其中某组的模型,由图7可以看出:模型的精度比较高,模拟点的误差范围均在0.2%以内。填充率和晶粒尺寸的局部模型与成形载荷的模型类似。

图7 成形载荷局部模型

Fig. 7 Local model of forming load

3.2.2 全局模型

式(9)中的回归系数为模型全局变量的二次多项式加径向基函数(RBF),即全局模型

(10)

(10)

则

(11)

(11)

其中:径向基函数(RBF)选择高斯函数

(12)

(12)

成形载荷的全局模型如图8所示,直线表示观测值与预测值相等,即数据点越靠近直线则模型的精度就越高,可以看出数据点非常接近直线,全部的数据点误差均在2%以内。填充率和晶粒尺寸的全局模型与成形载荷的全局模型类似。

图8 成形载荷全局模型

Fig. 8 Global model of forming load

3.3 对数学模型进行优化

局部模型和全局模型组成了预成形设计的数学模型,该模型包含了响应面与变量之间的内在关系,可以对其进行优化。

因为本文需要对成形载荷、填充率和晶粒粒径进行优化,属于多目标优化,为了更适应实际生产的需要,本文利用MBC工具箱自带的GAGE(trade-off)优化工具进行参数优化,此方法是一种通过对目标参数进行折中来达到最佳的参数组合的方法。

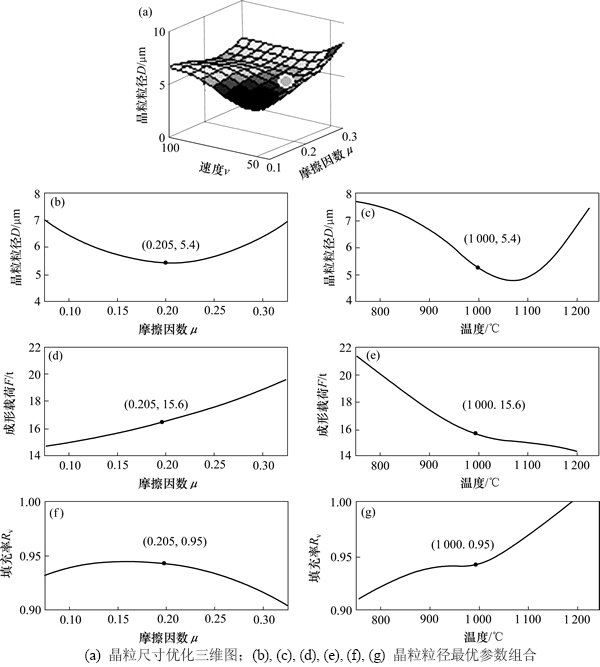

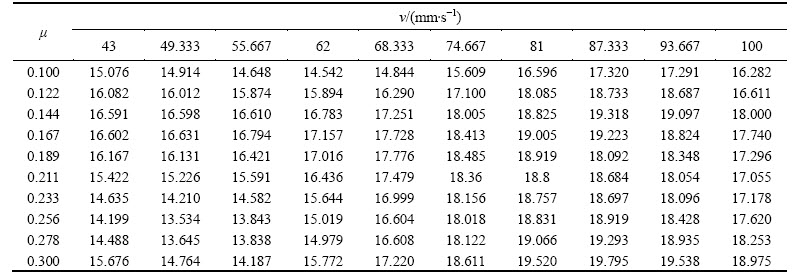

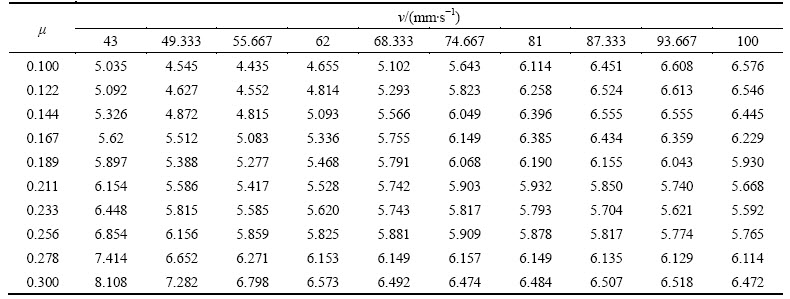

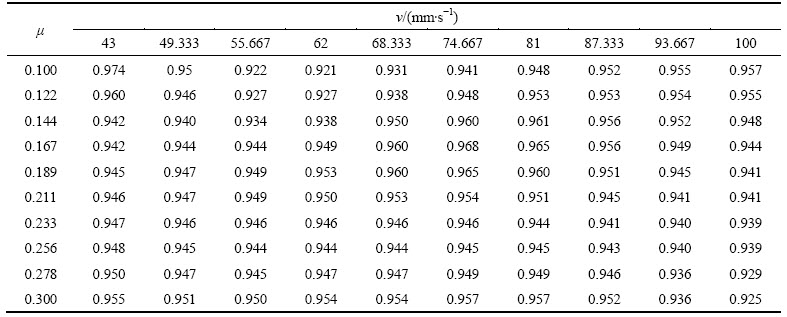

本文目的是使得输出量成形载荷F尽量小、填充率Rv尽可能大、晶粒粒径D尽量小以及当生产工艺条件发生改变时可以灵活地进行参数的选取以达到最佳的成形结果。图9所示为晶粒粒径的优化结果,成形载荷和填充率与此类似,结合齿轮生产的实际情况,希望生产中的摩擦因数控制在0.2,对3个目标参数进行折中选取,表4~6为3个优化目标的优化查阅表,通过对比后选取当坯料形状因子ξ=0.205 V、摩擦因数μ=0.2、压机速度V=56 mm/s、坯料温度t=1 000 ℃时,其优化得到的结果满足要求。另外,如果实际生产中希望控制压机速度或者温度等其他参数来进行优化参数组合的选择,其选择方法与此类似。

图9 晶粒粒径的优化结果

Fig. 9 Optimizing results of grain size

表4 成形载荷优化结果

Table 4 Optimizing results of forming load t

表5 晶粒尺寸优化结果

Table 5 Optimizing result of grain sizes μm

表6 填充率优化结果

Table 6 Optimizing result of filling ratio

4 生产实验验证

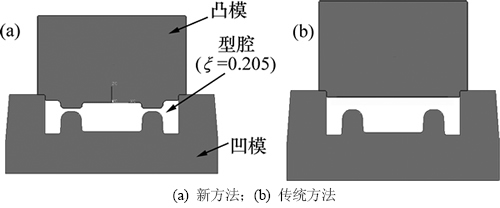

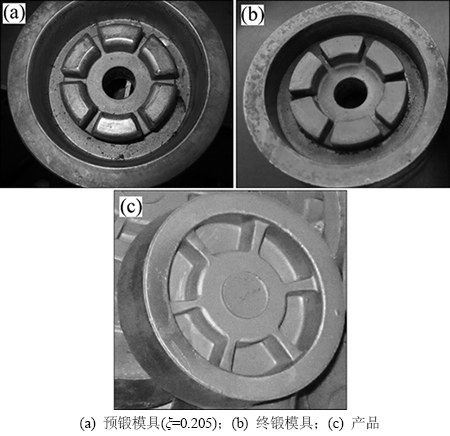

将优化得到的ξ=0.205 V的预制坯轮廓按照预锻件的最大外径小于最终锻件的最大外径,以及等势线所围成的空间与终锻件形状所围成的空间体积比相等的原则,通过换算得出预锻件的高度。图10所示为换算后得到的ξ=0.205 V的预制坯模具形状以及与传统设计形状的一个对比。根据所确定的参数组合,在300 t摩擦压力机上预锻成形,在400 t摩擦压力机上进行终锻,最终得到的预锻件如图11所示。

经过检测,齿轮筋部成形饱满,端部无折叠现象,成形载荷为156 kN,传统设计方法成形载荷为257 kN,与传统预制坯设计方法相比,载荷降低了40%,材料利用率提高了57.6%,验证了该方法在锻件预制坯设计上的可行性。

图10 新方法和传统方法预成形模具结构对比

Fig. 10 Comparison of pre-forging die structure between new and traditional method

图11 试验用模具及最终产品

Fig. 11 Die of experiment and final product

5 结论

1) 塑性变形过程中金属的塑形变形规律与静电场中的等势线具有相似性,从而为等势线法在锻件预制坯设计中的应用提供了理论依据。

2) 将电场模拟得到的预制坯形状结合不同的参数组合利用Matlab工具箱进行数学建模和优化,得出了最佳的参数组合,即当ξ=0.205 V,摩擦因数μ=0.2,压机速度v=56 mm/s,坯料温度t=1 000 ℃时,得到的锻件综合性能最佳,与传统预制坯设计方法相比具有简便、快捷、可靠的优点。

3) 基于电场和模型的方法能够得到优化目标的查阅表,在实际生产中,设计人员可以根据实际生产需要灵活的选择参数组合以便达到最优的成形结果。

参考文献:

[1] TangY C, Zhou X H, Chen J. Preform tool shape optimization and redesign based on neural network response surface methodology[J]. Finite Elements in Analysis and Design, 2008, 44(8): 462-471.

[2] Sedighi M, Tokmechi S. A new approach to preform design in forging process of complex parts[J]. Journal of Materials Processing Technology, 2008, 198(1/2/3): 314-324.

[3] Zheng P F, Chan L C, Lee T C. Numerical analysis of the sheet metal extrusion process[J]. Finite Element in Analysis and Design, 2005, 42(3): 189-207.

[4] Thiyagarajan N, Grandhi R V. Multi-level design process for 3D preform shape optimization in metal forming[J]. Journal of Materials Processing Technology, 2005, 170(1): 421-429.

[5] Castro C F, Antonio C A C, Sousa L C. Optimization of shape and process parameters in metal forging using genetic algorithms[J]. Journal of Material Processing Technology, 2004, 146(3): 356-364.

[6] Srikanth A, Zabaras N. Shape optimization and preform design in metal forming processes[J]. Computer Methods in Applied Mechanics and Engineering, 2000, 190(13/14): 1859-1901.

[7] Lee S R, Lee Y K, Park C H, et al. A new method of preform design in hot forging by using electric field theory[J]. International Journal of Mechanical Sciences, 2002, 44(4): 773-792.

[8] Ko D C, Kim D H, Kim B M, Choi J C. Methodology of preform design considering workability in metal forming by the artificial neural network and Taguchi method[J]. Journal of Materials Processing Technology, 1998, 80/81: 487-492.

[9] 肖军, 李付国. 轴对称件超塑性气压胀形过程的等势场模拟[J]. 塑性工程学报, 2006, 13(2): 14-19.

XIAO Jun, LI Fuguo. Equipotential field simulation for the gas pressure superplastic bulging of axisymmetrical circular sheets[J]. Journal of Plasticity Engineering, 2006, 13(2): 14-19.

[10] 李超. 李付国, 张莹, 等. 一种基于等势场的胀形坯料反推新方法[J]. 机械工程学报, 2005, 4(11): 131-137.

LI Chao, LI Fuguo, ZHANG Ying, et al. Reverse educing method of bulge-blank based on equipotential field[J]. Chinese Journal of Mechanical Engineering, 2005, 4(11): 131-137.

[11] 蔡军, 李付国, 张鹏. 基于三维静电场的TC4合金叶片预制坯设计[J]. 航空材料学报, 2009, 29(5): 66-71.

CAI Jun, LI Fuguo, ZHANG Peng. Preform design of TC4 alloy blade based on 3D electrostatic fields[J]. Journal of Aeronautical Material, 2009, 29(5): 66-71.

[12] 王晓娜, 李付国, 肖军, 等. 基于类等势场的粉末高温合金盘件预成形设计及有限元模拟[J]. 机械工程学报, 2009, 5(45): 237-243.

WANG Xiaona, LI Fuguo, XIAO Jun, et al. Preform design and finite element simulation of new-type P/M super alloy disk based on equipotential field[J]. Journal of Mechanical Engineering, 2009, 5(45): 237-243.

[13] Biglari F R, O’Dowd NP, Fenner R T. Optimum design of forging dies using fuzzy logic in conjunction with the backward deformation method[J]. International Journal of Machine Tools and Manufacture, 1998, 38(8): 981-1000.

[14] Ho T, Karri V. Hydrogen powered car: Two-stage modelling system[J]. International Journal of Hydrogen Energy, 2011, 36(16): 10065-10079.

[15] Poursina M, Arvizian J, Antonio C. Optimum pre-form dies in two-stage forging[J]. Journal of Materials Processing Technology, 2006, 174(1/2/3): 325-333.

[16] Hino R, Sasaki A, Yoshida F, et al. A new algorithm for reduction of number of press-forming stages in forging processes using numerical optimization and FE simulation[J]. International Journal of Mechanical Sciences, 2008, 50(5): 974-983.

(编辑 陈爱华)

收稿日期:2014-04-09;修回日期:2014-07-20

基金项目(Foundation item):中央高校基本科研业务费科研专项资金资助项目(CDJZR12130045);国家重大科技专项经费资助项目(2012ZX04010-081) (Project(CDJZR12110045) supported by the Fundamental Funds for the Central Universities; Project(2012ZX04010-081) supported by grants from the Special Funds for Major Projects of China’s Ministry of Science & Technology)

通信作者:夏玉峰,博士,副教授,从事塑性成形原理和模具设计方面的研究;E-mail: xyfeng@cqu.edu.cn