DOI: 10.11817/j.issn.1672-7207.2018.07.009

不同热处理材料在超细Al2O3颗粒作用下的冲蚀试验研究

刘子武,李剑峰,李方义,贾秀杰

(山东大学 机械工程学院高效洁净机械制造教育部重点实验室,山东 济南,250061)

摘要:利用高速冲蚀试验系统,选用超细Al2O3颗粒作为冲蚀颗粒,研究3种叶片材料不同热处理方式下的冲蚀行为。通过探讨材料冲蚀率、表面粗糙度、表面硬度等随冲蚀角度变化的规律,分析冲蚀特性曲线的异同,解释显微组织结构对冲蚀机理的影响。研究结果表明:3种材料冲蚀率都有1个最高点,材料塑性越好,冲蚀率最高点向低角度方向移动;在低角度冲蚀时,材料以微切削方式被去除,组织越硬抗冲蚀能力越强,其中回火索氏体组织中大尺寸碳化物能够直接起到抗冲蚀作用;在较高角度冲蚀时,材料表面首先发生塑性变形,偏向堆积沟槽末端,后续的粒子将这部分材料切除或者剪切折断去除;接近正向冲蚀时,材料经反复变形后,硬化剥落或剪切折断去除;表面粗糙度随冲蚀角度变化呈先增加后降低的趋势,且中高角度冲蚀的表面质量较差;塑性越好的材料冲蚀硬化越明显,正向冲蚀下的硬化程度最高。

关键词:冲蚀磨损;热处理;显微组织;冲蚀机理;粗糙度;冲蚀硬化

中图分类号:TB31;TH452 文献标志码:A 文章编号:1672-7207(2018)07-1634-09

Experimental study on erosion of materials with different heat treatment by ultrafine Al2O3 particles impacting

LIU Ziwu, LI Jianfeng, LI Fangyi, JIA Xiujie

(School of Mechanical Engineering & Key Laboratory of High Efficiency and Clean Mechanical Manufacture,Shandong University, Jinan 250061, China)

Abstract: The erosion behaviors of three materials under different heat-treatment conditions impacted by ultrafine Al2O3 particles on the erosion test equipment were studied. The variation laws of erosion rates, surface roughness, erosion hardening with impacting-angles were studied systematically. Differences and similarities among the characteristic curve of erosion were analyzed and the effect of microscopic structures on erosion mechanism was also explained. The results show that there is the peak value for three plastic materials, and with increasing the plasticity, the erosion peak will move towards the low angles. At low impact angles, the erosion is dominated by micro-cutting, and the harder the microscopic structure of material is, the stronger erosion-resisting becomes. Therein, large size carbides in the tempered sorbite will play an important role in anti-erosion directly. At higher impact angle, deformation dominates the erosion surface, and materials bias stack the end of the grooves, which will be cut down or broken off by subsequent particles. Close to the positive erosion, materials will be hardened and peeled off after repeated deformation. The surface roughness increases initially and then decreases, and the surface has poor quality at the middle impact angle. The better the ductility of material is, the stronger the erosion hardening becomes, and the degree of erosion hardening is the highest at the impact angle of 90°.

Key words: erosion; thermal treatment; microstructure; erosion mechanism; roughness; erosion hardening

FV520b型不锈钢及KMN型低合金高强钢,具有优良的耐蚀性能和良好的冲击性能,常用于离心鼓风机、压缩机叶轮的制造[1-2];45钢是优质碳素结构钢,由于经热处理后可获得良好的综合力学性能,广泛应用于齿轮、风机及水泵叶片等[3]。其中叶轮作为压缩机的主要做功部件,具有很高的旋转速度,极易受到固体颗粒的高速冲蚀磨损[4]。介质虽经滤芯进入压缩机内部,但仍有粒径为5 μm及以上的固体颗粒进入压缩机核心部件,对叶片造成冲蚀磨损。而叶片的导缘只要有极少量材料冲蚀出现,0.05 mm的缝隙便能引起局部失速,甚至引起事故[5-7]。研究材料的冲蚀行为,对于控制、减少冲蚀磨损,延长叶片使用寿命,具有重要的意义。BITTER等[8-15]研究了各种因素对粒子撞击磨损的影响,包括有粒子的形状、粒度、速度、冲击角度及材料性能等,并依据各自的试验结果建立了一些冲蚀理论。但现有的叶片固体粒子冲蚀磨损机理研究大多集中在20 μm以上的磨料粒径范围[16-19],对超细颗粒冲蚀行为与相关机理研究鲜见报道,并对热处理因素的影响研究得很少。而材料成分和组织结构的变化、对材料的耐冲蚀性和冲蚀机理都有很大的影响。基于此,本文作者以平均粒径为7 μm的Al2O3颗粒为冲蚀磨料,研究3种叶片材料不同热处理方式的冲蚀行为,探讨材料冲蚀率、表面粗糙度、表面硬度等随冲蚀角度变化的规律,分析冲蚀特性曲线的异同,解释显微组织结构对冲蚀机理的影响。

1 试验条件及方法

1.1 试验材料

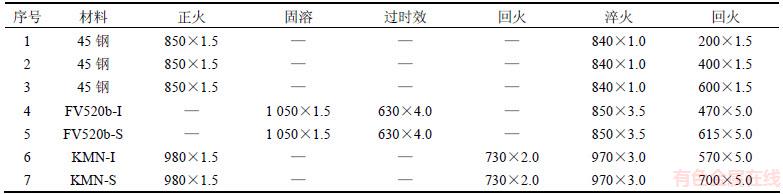

冲蚀试样长×宽×厚为70 mm×60 mm×5 mm的板材。试验材料的化学成分、热处理方式和力学性能见表1、表2和表3,材料的金相组织如图1(b)~(h)所示。对试样先去表面油污,再浸入丙酮进行超声清洗,清洗完毕吹干后放入干燥器中备用。

表1 金属材料的化学成分(质量分数)

Table 2 Chemical components of materials %

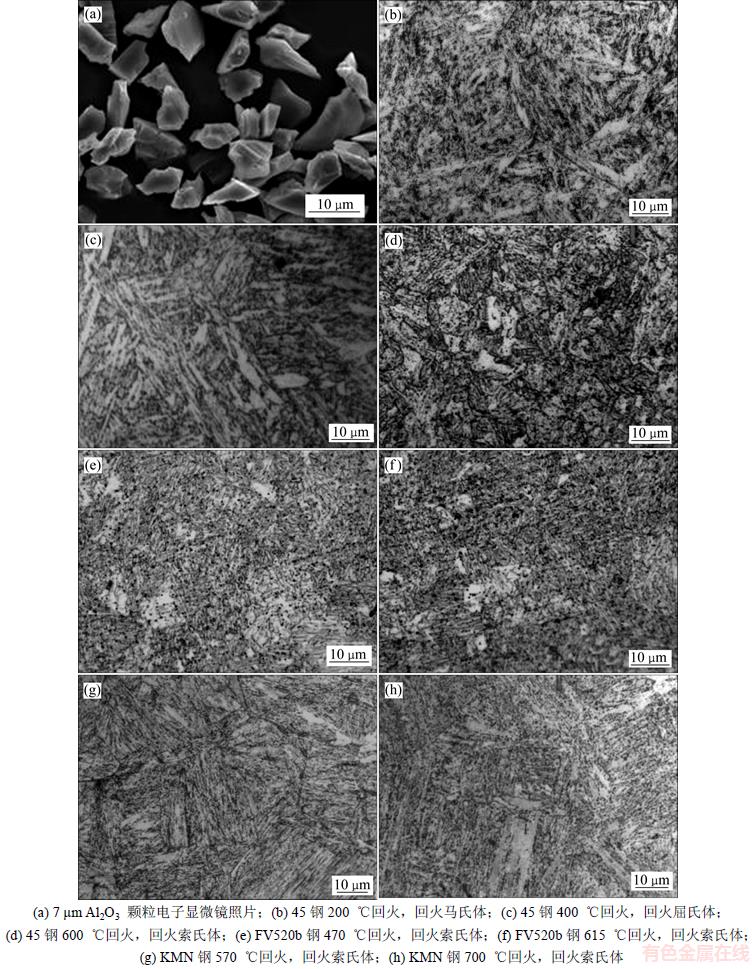

表2 材料热处理方式

Table 2 Heat treatment condition of materials ℃× h

表3 材料的力学性能

Table 3 Physical and mechanical properties of materials

图1 Al2O3颗粒电子SEM形貌及不同材料的金相组织

Fig. 1 Electron microscopic images of Al2O3 particles and microstructure observations of different materials

冲蚀料粉为白刚玉砂(Al2O3),粒度为7 μm,颗粒采用浮选法获得,主粒径质量分数在70%以上。Al2O3颗粒SEM照片如图1(a)所示。Al2O3颗粒是极难溶于水的白色粉末,无味,质极硬,堆积密度为1.53~1.99 g/cm3,真密度为3.9 g/cm3,努谱硬度为2 000~2 200 kg/mm2,莫氏硬度为9.0。

1.2 试验设备

本试验采用山东大学可持续制造中心设计的气流喷砂冲蚀试验机[20],进行12°~90°角度连续变化粒子冲蚀试验[1]。图2所示为试验装置示意图,主要由高速气流单元、螺杆加料单元、冲蚀试验单元和净化除尘单元4部分组成。通过调节排气阀和流量计,能够在喷枪喷嘴处得到0~200 m/s的气流冲击速度。通过试样旋转转台,在0°~90°之间改变冲蚀角度。借助螺杆加料器,能保证均匀加料。依靠数显电子秤,能实时测监测冲蚀颗粒的消耗,实现冲蚀过程有效控制。废气、粉尘经过滤筒式除尘器净化后再排放,保护试验现场和大气环境。

1.3 试验方案及评价方法

为研究各材质的冲蚀磨损特点和规律,对不同材质在12°~90°下进行对比冲蚀试验。试验前、后试样的质量用BS224S型精密电子天平测量,冲蚀区域微观形貌使用扫描电子显微镜(SEM)观察,利用金相显微镜观察表层金相组织。表面粗糙度测量及表面形貌观察采用Wyko NT9300型白光干涉仪测量。硬度选用MH-9型维氏硬度计进行测试。

图2 高速冲蚀试验设备示意图

Fig. 2 Sketch map of high speed erosion experimental machine

2 试验结果与分析

材料冲蚀能力常用材料质量损失与冲蚀颗粒质量比较,其定义如下:

(1)

(1)

式中ε为质量冲蚀率,mg/g;mt为靶材质量损失,mg;mt1为冲蚀前的靶材质量,mg;mt2为冲蚀后的靶材质量,mg;mp为冲击试件的粒子质量,g。

2.1 冲蚀试验结果

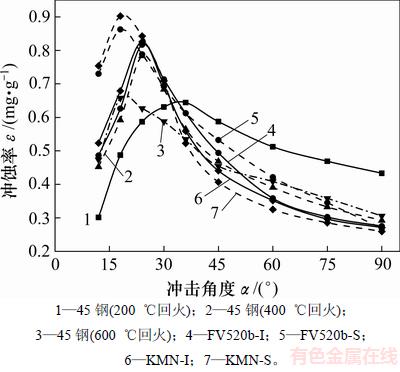

图3所示为各种材质在常温、粒子粒度为7 μm、颗粒冲击速度为180 m/s时[1],冲蚀率随冲蚀角度变化的关系曲线。从图3可见:

1) 除600 ℃回火45钢外,力学性能相似的材料,其冲蚀峰值略有差异,最大冲蚀角也都在相同范围内,冲蚀特性曲线规律也基本相似。对于力学性能不同的材料,冲蚀率随冲蚀角度有不同的变化规律。元素成分相同的材料相比,中高温回火组织在低角度冲蚀率大于高角度的冲蚀率,而200 ℃回火马氏体组织则是高角度冲蚀率大于低角度冲蚀率。元素成分不相同材料相比,在未达到最高冲蚀角之前,含碳量低的钢(FV520b及KMN)在低角度冲蚀下,硬度越高,其抗冲蚀性能越好;而45钢400 ℃回火索氏体钢硬度虽然高于600 ℃回火索氏体钢硬度,但在低角度下的冲蚀率差别不大。在高角度冲蚀下,除了硬度较高的回火马氏体组织冲蚀率较大外,无论是中温还是高温回火组织,冲蚀率都在较近的范围内。

图3 不同冲击角度下各材料冲蚀率对比

Fig. 3 Comparison of erosion rates at different impact angles

2) 每种材料的冲蚀率都有1个最高点。FV520b及KMN在相同热处理方式下有着类似的冲蚀特性曲线。除200 ℃回火45钢的冲蚀特性曲线较平缓外,其余冲蚀特性曲线都较陡峭。力学性能相似材料的最大冲蚀角度相似,且随着材料塑性提高,最高冲蚀点向低角度方向移动。

3) 在达到最大冲蚀率之前,硬度较高的材料冲蚀率较低。在硬度较低的材料达到冲蚀率峰值后的冲蚀角度时,其抗冲蚀性能却没有明显低于硬度较高材料的抗冲蚀性能。例如:在24°冲蚀角下,FV520b及KMN材料在较高温度回火形成组织的抗冲蚀性能与较低温度回火形成的组织的抗冲蚀性能相差不大。在36°冲蚀角下,45钢200 ℃回火马氏体组织的冲蚀率要高于其他材料回火温度的组织的冲蚀率。

2.2 冲蚀机理的研究

塑性材料不同角度的冲蚀机理示意图[21]如图4所示。如果磨料有棱角,对塑性材料来说,低角度冲蚀磨损的方式主要以微切削(曲线1)和犁削(曲线2)为主,高角度冲蚀去除机理主要为变形硬化折断方式(曲线3)。图5所示为FV520b-I,KMN-S和200 ℃回火的45钢在180 m/s速度冲击下的SEM形貌图。

2.2.1 曲线1阶段冲蚀磨损机理的研究

颗粒低角度冲击材料表面时,颗粒切向运动像刀具切削材料,如图4中曲线1所示,当形成有利于切削的角度时,将产生微切削现象。由图5(a)和(b)可知:在12°冲击下,粒子切面较为光滑,由于粒子水平速度大,切削能更有效地转化为材料质量损失,切痕为浅而长的沟槽,宽度为0.2~0.3 μm,长度约为2 μm,在沟槽两侧出现有细小切削唇片,沟槽后部很少出现唇片。可以认为在此角度下粒子完成了1次完整的切削过程,冲蚀率较大。随角度增大,沟槽变深,颗粒离开靶材时水平速度变小,冲蚀率逐渐增大。当颗粒离开靶材的水平速度为0时,颗粒刚刚能完成1次切削,冲蚀率达到最大值[8]。

图4 塑性材料不同角度的冲蚀机理示意图[21]

Fig. 4 Sketch map of erosion mechanisms occurring in ductile material at different angles[21]

图5 不同冲击角度下冲蚀微观形貌

Fig. 5 Surface morphology of eroded surfaces at different impact angles

在图4中曲线1的冲蚀角度下,冲蚀与磨粒磨损的微切削机制是相似的[8],如硬的基体能抵抗粒子的侵入。基体越硬,颗粒侵入材料深度越浅,从而导致较硬材料的冲蚀率低于较软材料的冲蚀率,且出现的冲蚀率峰值也较晚(或最大冲蚀角的角度越高)。由于大部分研究在10°~45°之间冲蚀试验较少(尤其是在20°~30°),最高冲蚀角度一般被认为发生在30°左右,因此,这些不能作为统计结果。从文献[8]可以看到:在粒径为250 μm的SiC颗粒冲蚀下,冲蚀峰值角度随材料硬度增加而增大,特别软的材质(例如纯铝,纯铜等)最大冲蚀角低于15°。维氏硬度约为200的SAE-1055钢(供货状态)的最大冲蚀角约为25°,完全淬硬硬度约为600的SAE-1055钢,其最大冲蚀角约为50°。

除45钢的600 ℃回火组织以外,温度较低的回火组织抗冲蚀性能高于温度较高的回火组织的抗蚀性能。45钢的200 ℃回火金相组织为回火马氏体,中温回火金相组织为回火屈氏体,FV520b和KMN的2种热处理方式以及45钢的高温回火金相组织均为回火索氏体,回火屈氏体及回火索氏体均为铁素体与渗碳体的机械混合物。一般情况,当回火温度达到400 ℃时,马氏体组织完全分解,α相保持马氏体态,因此,45钢在400 ℃回火时仍具有板条状特征,随着回火温度升高,回火组织析出碳化物相尺寸增大,数量增多,越来越密集地分布在铁素体基体上。而在600 ℃及以上回火时,α相发生再结晶,形成等轴晶粒,且碳化物聚集并粗化,硬度进一步下降。对于含有较多的Cr与Mo等溶质元素的合金钢FV520b及KMN,这些元素阻碍位错和晶界运动,不利于再结晶形成等轴晶粒,即使在高温下,显微组织的马氏体位向依旧明显,这也保证了这些组织仍具有良好的力学性能,FV520b-I及KMN-I即使回火温度较高,其强度及抗冲蚀性能也与45钢400 ℃回火组织的相差不大。

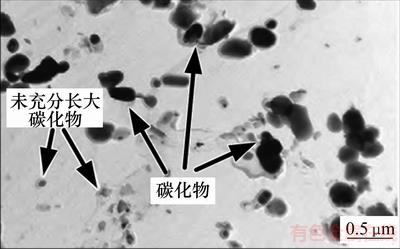

而45钢的600 ℃回火组织虽然较软,但是在曲线1角度下的冲蚀率很低。组织中碳化物的尺寸对磨损过程的影响如图6所示。

图6 45钢的600 ℃回火组织中碳化物TEM照片

Fig. 6 TEM images of carbide in 600 ℃ tempering organization of 45 steel

从图6可知:45钢600°C回火索氏体组织的碳化物高温回火后碳化物聚集成较大颗粒,能够达到0.15~0.30 μm,几乎可与切削沟槽宽度相比,而且硬度都大于磨料硬度的0.8倍[22],相对Al2O3是硬的材料,能使粒子棱角变钝[23]。能够直接起到抗冲蚀作用,所以,耐冲蚀明显提髙。而FV520b及KMN回火材料由于含碳量低,导致大部分碳化物没有充分长大,从而回火析出碳化物数量很少,尺寸也小,很容易被挖出而起不到抗冲蚀作用。

2.2.2 曲线2阶段冲蚀磨损机理的研究

如图4中曲线2所示,粒子不能完成1次切削时,则不会对表面直接切削去除,只是将材料挤出,在划痕的两侧和末端形成堆积唇,类似于犁耕切削,而由后续的粒子将这部分材料切除或者剪切折断去除。

从图5(d)可见:FV520b-I在冲击角为30°时,冲蚀形貌为较深而短的切削沟槽,宽度为0.3~0.4 μm,长度约为1.5 μm,冲蚀在沟槽两侧出现有较大切削唇片,沟槽后部出现大量唇片,一些唇片被后续粒子冲击剪切,冲蚀率开始下降。当冲击角为60°时(如图5(e)所示),不但在沟槽两侧及后部有大量的唇片,而且开始出现了大量的韧窝。但对于塑性较差的200 ℃回火的45钢,在30°冲蚀下粒子切削面仍比较光滑,且沟槽后基本没有唇片出现(如图5(c)所示),仍能完成1次切削,冲蚀率继续上升,这也是硬(塑性差)材料出现最大冲蚀角度较高的原因。同时可以发现:在36°冲蚀下,较软材质FV520b-I去除方式为犁耕切削,不能1次去除材料,从而导致在此角度下,冲蚀率开始高于较硬的200 ℃回火45钢的冲蚀率。

2.2.3 曲线3阶段冲蚀磨损机理的研究

如图4中曲线3所示,颗粒的法向运动像锤子一样锤击靶材表面,使得颗粒压入材料表面,形成冲击凹坑,如图5(f)所示。从图5(f)可知:90°冲蚀表面全部是深浅不一、麻点状的凹坑,在凹坑的周围有材料隆起和材料唇片,这些隆起和唇片在后续颗粒的不断锤击下,经过反复塑性变形,硬化剥落或剪切折断,而从靶材表面流失。

硬化剥落或剪切折断都是断裂的一种形式。材料越硬,表面引起的接触应力越大;材料越软,产生的塑性变形越大,接触应力越松弛,材料形成的隆起和唇片就不易剥落或者折断。冲击时应力幅度以及材料的塑性变形能力又与组织有关,一般塑性变形在基体相进行,回火马氏体为单相组织,强度和硬度髙,而塑性和冲击韧性低,冲击形成的材料隆起和唇片容易发生硬化剥落或剪切折断。根据金属学理论[24],一种硬相分布在塑性的基体相时,塑性变形只在基体相进行,若把连续分布的脆性相变成不连续分布,则可大大减弱它的脆性,回火屈氏体及回火索氏体中碳化物呈细粒状分布在塑性好的铁素体中,有利于塑性变形。松弛粒子冲击时产生应力,基体越软,抗冲蚀性能越好。

2.3 冲蚀前后表面粗糙度分析

表面粗糙度是影响材料疲劳及腐蚀等行为的重要因素。为了说明不同冲击角度下,冲蚀表面粗糙度差别较大的原因,测试FV520b-I,KMN-S及200 ℃回火45钢在不同角度冲蚀后表面粗糙度并进行分析,试验结果如图7所示。

图7 材料冲蚀表面粗糙度变化曲线

Fig. 7 Curves of erosion surface roughness at different impact angles

在低冲击角度下,冲蚀以微切削为主。在冲蚀初期,表面形貌为平行于冲蚀方向的浅而长的切削沟槽,沟槽两侧出现有细小切削唇片,后部出现极少唇片。在后续冲蚀时,虽然颗粒的实际冲击角度会有所变化,但是不明显。材料的去除仍以微切削为主,粗糙度较低。随角度增大,微切削沟槽逐渐变深变短,粗糙度越来越大。从图5(a)~(d)可以看出:材料硬,表面变形小,冲蚀微切削沟槽越浅。这说明材料表面的硬度影响着冲蚀形貌,表面硬度越小,塑性变形越严重,粗糙度越高。

在较高冲蚀角度下,在冲蚀初期,颗粒将材料犁耕铲削挤出,沟槽在划痕两侧和末端形成大量铲削唇片;进一步冲蚀,粒子的实际冲击角度将会因表面形貌的变化而发生变化。铲削沟槽及两边的唇片实际冲蚀角度变化不明显,颗粒冲蚀仍以铲削挤出为主,而铲削沟槽末端形成的初始唇片与颗粒的实际冲击角度将增大,主要以锻打挤压为主,难以去除唇片,导致该区域冲蚀率降低。初始形成唇片前方的材料在后续颗粒冲蚀下,铲削形成唇片被挤压到初始唇片前端,造成唇片堆积。随冲蚀角度升高,铲削沟槽逐渐变深,形成唇片也越大、越厚,并且铲削沟槽末端堆积唇片与颗粒逐渐接近正向冲蚀,更加难以去除,从而导致表面粗糙度增大。对于塑性差而硬的材料,由于堆积唇片易被锻打剥落或剪切折断,从而其表面粗糙度比软而塑性好的材料低。

在接近正向冲蚀角度下,颗粒冲蚀塑性靶材以以挤压变形为主。初期冲蚀时,在表面形成凹坑并在凹坑的周围形成挤压唇片。进一步冲蚀时,颗粒冲击初期形成的凹坑及早期唇片上。由于冲蚀角度较高,颗粒挤压材料形成的唇片水平位移极小,从而无法实现唇片堆积。后续颗粒冲击在初期唇片上,形成新凹坑及更细的唇片,同时由于早期唇片受颗粒下压而高度变低,导致表面粗糙度不高。

2.4 冲蚀前后表面硬度对比分析

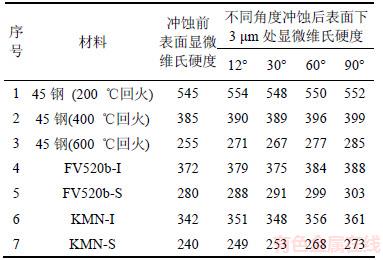

在冲蚀过程中,材料处于高压、大应变及大应变率的状态,这些作用会引起材料晶粒细化、位错增多,亚晶界增多,形成高位错密度的加工硬化层。RICHARDSON[22]在讨论磨粒磨损问题时发现材料相对耐磨性与加工硬化后(磨损后)的硬度关系比未经变形的材料硬度的关系更直接。测试各材料在不同角度冲蚀后表面下3 μm的显微硬度,结果如表4所示。选取FV520b-I材料在12°,30°,60°及90°冲蚀后试样每隔3 μm测量1次硬度,测试深度为18 μm,结果如图8所示。

对于FV520b-I,在不同角度下冲蚀硬化层深度测试结果如下:在12°及30°,硬化深度并不明显,为3~6 μm;在60°冲蚀时,硬化层深度为9~12 μm;在90°冲蚀时,硬化层深度约为15 μm。这是因为随着冲击角度增大,颗粒法向速度增加,冲击深度增大,使得更深层材料强度和显微硬度提高。一般认为,材料在弹性变形阶段是可恢复的,而达到塑性变形后是不可恢复的。塑性变形是引起材料位错密度增大及应变强化的根本原因。研究冲蚀磨损后硬化层深度可以预测颗粒冲蚀的应力影响深度。

表4 材料冲蚀后亚表层的显微硬度

Table 4 Erosion sub-surface hardness of materials

图8 亚表层显微硬度分布曲线

Fig. 8 Microhardness distribution curves of sub-surface at different impact angles

对于塑性材料,在各冲蚀角度下,颗粒冲击均会在浅表层产生硬化层。对于喷丸强化,随着颗粒冲击角度增大,相应的法向动能减小,对材料表面深度影响增大,从而表面及亚表面的强化效果会增强。但是,本试验的硬度并不随冲击角度增加而增大。根据试验结果,在低角度冲蚀时,基体都会出现硬化现象,随冲蚀率增加会有一个衰落的过程,当衰落达到一定程度时,开始回升。塑性好的材料其硬化会有大幅度提高,甚至维氏硬度增加30以上;对于塑性差的材料(200 ℃回火的45钢),因其变形程度低,硬化程度也较低,硬度增加量低于10。

冲蚀表面及亚表面硬化是因为颗粒动能被靶材吸收转变为塑性变形能,随着后续颗粒的冲击,亚表层材料塑性变形积累,位错密度增大,并产生交互作用,变形抗力增加,亚表层材料强度和显微硬度提高。随角度、冲蚀率增大,硬化下降,是由于冲蚀率高,导致材料还没充分硬化就已经被颗粒冲蚀。当角度继续增大时,颗粒冲击深度增大,并且冲蚀率下降,使得材料塑性变形充分积累,材料硬化程度提高。

3 结论

1) 各热处理材料均呈现出典型的塑性材料冲蚀特性。冲蚀率随着冲击角度的增大先增大后减小,且随着材料塑性的提高,最高冲蚀点向低角度方向移动。在30°左右低角度冲蚀时,较硬材料没有表现出更好的抗冲蚀性能。

2) 低角度粒子冲蚀磨损的机制是微切削,耐冲蚀性基本随硬度的增加而提高;当含碳量足以形成抗冲蚀碳化物尺寸时,材料的抗冲蚀性能提高;回火马氏体组织比回火索氏体组织抗冲蚀。高角度粒子冲蚀时,塑性材料经反复塑性变形后硬化剥落或折断去除;耐磨性一般随硬度的增加而下降,回火索氏体组织比回火马氏体组织耐冲蚀。

3) 较高的粗糙度会促进表面腐蚀和表面疲劳损伤,而冲蚀硬化则抑制表面腐蚀和表面疲劳损伤,因此,冲蚀粗糙度和冲蚀硬化是叶片损伤必须考虑的问题。在低角度冲蚀下,表面光滑且冲蚀硬化层较浅;在中高角度冲蚀下,表面粗糙度较高,冲蚀硬化层变深;接近正向冲蚀,表面质量较好,冲蚀率较低,且在表面会形成较深的冲蚀硬化层。

4) 机械性能影响冲蚀特性曲线及冲蚀表面特性,因此,叶片损伤部位的修复应建立修复材料与耐冲蚀性能、冲蚀表面特性、冲击角度之间的映射关系,从而选择合适材料。

参考文献:

[1] 王光存. 离心压缩机叶轮冲蚀磨损机理和规律的研究[D]. 济南: 山东大学机械工程学院, 2015: 1-33.

WANG Guangcun. Study on erosion wear mechanism and law of impeller in centrifugal compressor[D]. Jinan: Shandong University. School of Mechanical Engineering, 2015: 1-33.

[2] 赵彦华. KMN钢压缩机叶片激光熔覆修复及后续加工特性研究[D]. 济南: 山东大学机械工程学院, 2015: 1-16.

ZHAO Yanhua. Research on laser cladding repaired and subsequent processing characteristics of KMN steel compressor blade[D]. Jinan: Shandong University. School of Mechanical Engineering, 2015: 1-16.

[3] 庞佑霞, 李彬, 朱宗明, 等. 流体机械叶轮常用材料冲蚀与空蚀交互磨损特性研究[J]. 润滑与密封, 2013, 38(12): 23-26.

PANG Youxia, LI Bing, ZHU Zongming. Study on abrasion properties of common materials for fluid mechanical impeller at interactive erosion and cavitation wear[J]. Lubrication Engineering, 2013, 38(12): 23-26.

[4] UTAMURA M, FUKUDA T, ARITOMIi M. Aerodynamic characteristics of a centrifugal compressor working in supercritical carbon dioxide[J]. Energy Procedia, 2012, 14: 1149-1155.

[5] LIU Ziwu, LI Jianfeng, JIA Xiujie, et al. Establishment and analysis of erosion depth model for impeller material FV520B[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2016, 3(1): 27-34.

[6] 李剑峰, 龚宝龙, 贾秀杰, 等. 离心压缩机内固粒对叶轮磨损的数值模拟[J]. 中南大学学报(自然科学版), 2013, 44(10): 4147-4154.

LI Jianfeng, GONG Baolong, JIA Xiujie, et al. Numerical simulation of the solid particle erosion in a centrifugal air compressor impeller[J]. Journal of Central South University (Science and Technology), 2013, 44(10): 4047-4054.

[7] 孟根其其格. 离心式空气压缩机常见故障分析[J]. 内蒙古石油化工, 2011, 37(21): 55-56.

MENG Genqiqige. Analysis of common faults of centrifugal air compressor[J]. Petrochemical Technology of Inner Mongolia, 2011, 37(21): 55-56.

[8] BITTER J G A. A study of erosion phenomena—Part Ⅱ[J]. Wear, 1963, 6(3): 169-190.

[9] 钟萍, 李健. 聚脲涂层的冲蚀磨损机理研究[J]. 摩擦学学报, 2012, 32(2): 195-198.

ZHONG Ping, LI Jian. Study of erosion behavior of polyuria coating[J]. Tribology, 2012, 32(2): 195-198.

[10] LAGUNA-CAMACHO J R, MARQUINA-CH VEZ A, M

VEZ A, M NDEZ-M

NDEZ-M NDEZ J V, et al. Solid particle erosion of AISI 304, 316 and 420 stainless steels[J]. Wear, 2013, 301(1/2): 398-405.

NDEZ J V, et al. Solid particle erosion of AISI 304, 316 and 420 stainless steels[J]. Wear, 2013, 301(1/2): 398-405.

[11] DRENSKY G, HAMED A, TABAKOFF W, et al. Experimental investigation of polymer matrix reinforced composite erosion characteristics[J]. Wear, 2011, 270(3/4): 146-151.

[12] AKBARZADEH E, ELSAADAWY E, SHERIK A M, et al. The solid particle erosion of 12 metals using magnetite erodent[J]. Wear, 2012, 282/283(1): 40-51.

[13] YILDIZLI K, KARAMIS M B, NAIR F. Erosion mechanisms of nodular and gray cast irons at different impact angles[J]. Wear, 2006, 261(5/6): 622-633.

[14] MBABAZI J G, SHEER T J, SHANDU R. A model to predict erosion on mild steel surfaces impacted by boiler fly ash particles[J]. Wear, 2010, 257(5/6): 612-624.

[15] HUANG C K, CHIOVELLI S, MINEV P, et al. A comprehensive phenomenological model for erosion of materials in jet flow[J]. Powder Technology, 2008, 187(3): 273-279.

[16] CAI Liuxi. New features of solid particle erosion damage of control stage blades in supercritical steam turbine[J]. Proceedings of the Institution of Mechanical Engineers Part A Journal of Power & Energy, 2015, 230(1): 76-85.

[17] ZHANG Junqiu, HAN Zhiwu, YIN Wei, et al. Numerical experiment of the solid particle erosion of bionic configuration blade of centrifugal fan[J]. Acta Metallurgica Sinica (English Letters), 2013, 26(1): 16-24.

[18] 张永, 黄超, 刘召, 等. 挟沙风作用下风力机叶片涂层冲蚀特性研究[J]. 材料导报, 2016, 30(10): 95-99.

ZHANG Yong, HUANG Chao, LIU Zhao, et al. Research on erosion properties of wind turbine blade coating under the wind-carrying action[J]. Materials Review, 2016, 30(10): 95-99.

[19] 杨成虎. 不同热处理工艺下Cr12钢的冲蚀磨损性能及机理的研究[D]. 济南: 山东大学机械工程学院, 2012: 15-27.

YANG Chenghu. The research on erosion wear performance and mechanism of Crl2 steel in different heat treatment process[D]. Jinan: Shandong University. School of Mechanical Engineering, 2012: 15-27.

[20] 李剑峰, 王光存, 刘子武, 等. 一种气流喷砂式冲蚀磨损试验机: 中国, CN103760048A[P]. 2014-04-30.

LI Jianfeng, WANG Guangcun, LIU Ziwu, et al. An airflow sandblasting erosion tester: China, CN103760048A[P]. 2014-04-30.

[21] FINNIE I. Some reflections on the past and future of erosion[J]. Wear, 1995, 95(s186/187): 1-10.

[22] RICHARDSON R C D. The abrasive wear of metals[J]. Wear, 1969, 14(4): 290-291.

[23] RICHARDSON R C D. The wear of metals by relatively soft abrasives[J]. Wear, 1968, 11(4): 245-275.

[24] 余永宁. 金属学原理[M]. 北京: 冶金工业出版社, 2013: 422-423.

YU Yongning. Principles of metallography[M]. Beijing: Metallurgical Industry Press, 2013: 422-423.

(编辑 杨幼平)

收稿日期:2017-07-09;修回日期:2017-09-18

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2011CB013401);山东省泰山学者建设工程项目(20130925) (Project(2011CB013401) supported by the National Key Basic Research Program (973 Program) of China; Project(20130925) supported by the Taishan Scholars Construction Engineering of Shandong Province)

通信作者:李剑峰,博士,教授,泰山学者,从事机械加工工艺、绿色设计制造与再制造研究;E-mail: ljf@sdu.edu.cn