DOI:10.19476/j.ysxb.1004.0609.2019.07.11

块状碳化物的形态演化及对镍基合金蠕变性能的影响

田 宁1,田素贵1, 2,于慧臣3,赵国旗1,闫化锦1,孟宪林2,张顺科1

(1. 贵州工程应用技术学院 机械学院,毕节 551700;

2. 沈阳工业大学 材料科学与工程学院,沈阳 110870;

3. 中航工业北京航空材料研究院,材料检测与评价航空科技重点实验室,北京 100095)

摘 要:通过不同工艺热处理、蠕变性能测试及组织形貌观察,研究了固溶温度对一种定向凝固镍基合金中碳化物形态演化与蠕变性能的影响。结果表明:铸态DZ125合金中存有粗大块状MC型碳化物,热处理期间合金中MC型碳化物可发生分解和形态演化,逐步转变成粒状M23C6型碳化物。随固溶温度提高、时间延长,碳化物发生分解及形态演化的几率增加,并使细小粒状M23C6型碳化物沿晶界不连续析出。与低温固溶处理合金相比,高温固溶处理合金在780 ℃具有良好的蠕变抗力。其中,以共格方式嵌镶在g 基体中的立方γ′相均匀分布在枝晶干和枝晶间区域,并有细小粒状碳化物沿晶界弥散析出,可抑制晶界滑移,是大幅度提高合金蠕变抗力的主要原因。在近780 ℃蠕变后期,与应力轴呈45°角的晶界承受较大的剪切应力。裂纹在沿与应力轴呈45°角的晶界处萌生与扩展,直至断裂是合金的蠕变断裂机制。

关键词:镍基合金;固溶温度;碳化物;形态;蠕变;裂纹萌生与扩展

文章编号:1004-0609(2019)-07-1427-10 中图分类号:TG115.9 文献标志码:A

定向凝固期间镍基高温合金以柱状晶形式沿[001]取向定向生长,且柱状晶沿[100]和[010]取向存在取向差。由于凝固期间合金消除了与应力轴垂直的横向晶界,可大幅度提高合金在高温的力学及蠕变性能[1-2],故已被广泛应用于制备航空发动机的热端部件。

定向凝固镍基合金的组织结构主要由立方 相以共格方式嵌镶在γ基体、及在晶界和晶内析出不同形态的碳化物组成,其中,加入W、Cr、Mo和Ta等高熔点难熔元素可强化

相以共格方式嵌镶在γ基体、及在晶界和晶内析出不同形态的碳化物组成,其中,加入W、Cr、Mo和Ta等高熔点难熔元素可强化 和γ两相,并在热处理和服役期间促使M6C、M23C6和MC等碳化物析出[3-4],当大量细小粒状碳化物在晶内和沿晶界析出、并均匀分布时,可阻碍位错运动、抑制晶界滑移,故可大幅度提高合金的蠕变抗力[5]。但随合金中碳化物尺寸增大、棱角增多,蠕变期间在近碳化物区域易于产生应力集中,并促使裂纹沿碳化物/基体界面发生裂纹的萌生与扩展,其中,汉字型和条状粗大MC型碳化物是可促使裂纹萌生的起源地[6],且碳化物与基体之间的界面是裂纹易于扩展的通道[7]。即:析出碳化物的形态、尺寸与分布对合金的高温性能、蠕变寿命和服役期间的可靠性具有重要的影响,因此,碳化物的演化规律及控制碳化物形态得到广泛的研究[8-9]。

和γ两相,并在热处理和服役期间促使M6C、M23C6和MC等碳化物析出[3-4],当大量细小粒状碳化物在晶内和沿晶界析出、并均匀分布时,可阻碍位错运动、抑制晶界滑移,故可大幅度提高合金的蠕变抗力[5]。但随合金中碳化物尺寸增大、棱角增多,蠕变期间在近碳化物区域易于产生应力集中,并促使裂纹沿碳化物/基体界面发生裂纹的萌生与扩展,其中,汉字型和条状粗大MC型碳化物是可促使裂纹萌生的起源地[6],且碳化物与基体之间的界面是裂纹易于扩展的通道[7]。即:析出碳化物的形态、尺寸与分布对合金的高温性能、蠕变寿命和服役期间的可靠性具有重要的影响,因此,碳化物的演化规律及控制碳化物形态得到广泛的研究[8-9]。

合金在凝固期间主要析出MC型块状碳化物[10],而粒状M23C6型碳化物则主要在热处理及服役期间因过饱和自基体和沿晶界析出[11],或由MC型碳化物蜕化而成[12]。由于沿晶界析出的粒状碳化物可抑制晶界滑移[7, 13],且延缓裂纹扩展速率,故断口呈现沿晶韧性断裂特征[14]。

尽管定向凝固合金中已消除了横向晶界,但仍存在与应力轴平行的纵向晶界,其蠕变损伤仍是合金在高温服役期间的主要失效形式[15-16]。由于高温蠕变期间碳化物的形态、尺寸、数量与蠕变抗力密切相关,故热处理对合金组织结构与性能的影响得到广大研究者所重视[17]。但合金中碳化物在热处理及服役期间的演化规律、及碳化物形态对裂纹萌生与扩展特征的影响并不清楚。

据此,本文通过对一种定向凝固镍基合金进行不同工艺的热处理,并对其进行蠕变性能测试和SEM、TEM形貌观察,考察热处理工艺对合金中碳化物尺寸、形态与分布的影响,研究碳化物形态对合金蠕变行为及断裂机制的影响,试图为合金的发展与应用提供理论依据。

1 实验

采用定向凝固技术在真空定向凝固炉中沿[001]取向制取直径为16mm、具有柱状晶结构的镍基合金试棒,其合金的化学成分如表1所示。其中,选取不同工艺热处理,以考察热处理对合金组织结构与蠕变性能的影响,选取的热处理工艺如下:

1) (1180, 2 h)+(1230 ℃, 4 h, AC)+(1100 ℃, 4 h, AC)+(870 ℃, 20 h, AC);

2) (1180 ℃, 2 h)+(1260 ℃, 4 h, AC)+(1100 ℃, 4 h, AC)+(870 ℃, 20 h, AC)。

合金经不同温度固溶及两级时效处理后,用线切割将试棒加工成横断面为4.5 mm×2.5mm,标距为20 mm的板状蠕变试样。经完全热处理后的蠕变样品经机械研磨和抛光,将其置入GWT504型高温蠕变/持久试验机中,在不同条件进行蠕变性能测定,分别在蠕变不同时间终止试验,将不同工艺热处理及蠕变不同时间的样品在SEM和TEM下进行组织形貌观察,考察热处理工艺对合金组织结构与蠕变性能的影响,研究不同工艺热处理合金在蠕变期间的变形与断裂机制。

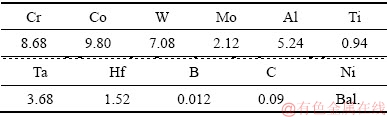

表1 合金的化学成分

Table 1 Chemical compositions of superalloy (mass fraction, %)

2 实验结果分析

2.1 热处理对碳化物形态的影响

铸态DZ125合金中(001)横断面的枝晶形貌,如图1(a)所示,可以看出,合金在横断面的枝晶规则排列,呈现整齐的“+”字花样。其中,一次枝晶的平均间距为150~160 mm,在同一晶粒内枝晶具有相同的排列取向,不同晶粒A、B中枝晶排列存在的取向差约为25°,如图中粗实线标注所示,且晶界处于A、B两晶粒之间。

铸态合金中的共晶组织及碳化物形态,如图1(b)所示,可以看出,共晶组织存在于枝晶间区域,并呈现放射状形态;放射状的心部组织细密,由细小 /g两相组成,如图1(b)中区域C所示,其放射状周围区域为粗大

/g两相组成,如图1(b)中区域C所示,其放射状周围区域为粗大 相。并有粗大块状碳化物存在于枝晶间和枝晶干区域,如图1(b)中箭头所示,SEM/EDS成分分析表明,块状碳化物中各元素的摩尔分数分别为:17.2% C, 13.4% B, 9.93% Hf, 12.49% Ta和10.34% W,其中,C、B和Hf、Ta、W的摩尔分数比约为1:1。由此可间接鉴定出,该碳化物为M(W, Ta, Hf)C(C,B)型碳化物。

相。并有粗大块状碳化物存在于枝晶间和枝晶干区域,如图1(b)中箭头所示,SEM/EDS成分分析表明,块状碳化物中各元素的摩尔分数分别为:17.2% C, 13.4% B, 9.93% Hf, 12.49% Ta和10.34% W,其中,C、B和Hf、Ta、W的摩尔分数比约为1:1。由此可间接鉴定出,该碳化物为M(W, Ta, Hf)C(C,B)型碳化物。

图1 铸态合金在(001)横断面的枝晶及组织形貌

Fig. 1 Dendrite morphology and microstructure of alloy on (001) plane

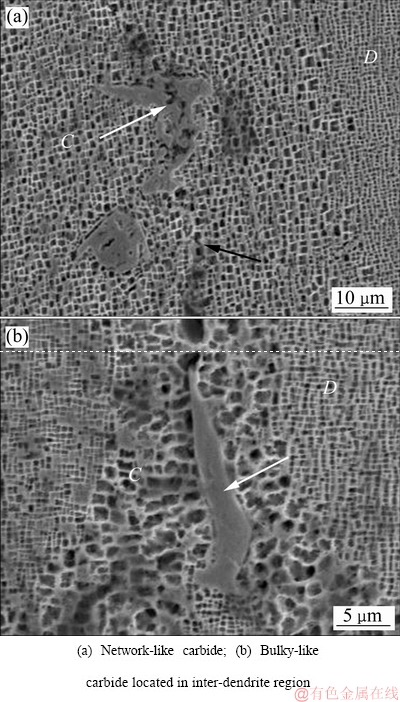

图2 合金经1230 ℃固溶及时效处理后不同区域的组织形貌

Fig. 2 Microstructures in different regions of alloy after solution treated at 1230 ℃

合金经1230 ℃及两级时效处理后的组织形貌,如图2所示。该合金中 相的溶解温度为1255 ℃,故经1230 ℃固溶处理期间,枝晶干区域的细小

相的溶解温度为1255 ℃,故经1230 ℃固溶处理期间,枝晶干区域的细小 相可溶解,而枝晶间区域的粗大

相可溶解,而枝晶间区域的粗大 相未溶解,致使其在后续热处理期间,枝晶间区域的

相未溶解,致使其在后续热处理期间,枝晶间区域的 相得以继续长大,如 图2(a)和(b)中区域C所示。而枝晶干区域的细小

相得以继续长大,如 图2(a)和(b)中区域C所示。而枝晶干区域的细小 相为固溶处理后的冷却期间析出,并在时效期间均匀长大所致,如图2(a)和(b)中区域D所示。同时可以看出,该区域原粗大块状碳化物已转变成网状形态,如图 2(a)中白色箭头所示,晶界如图2(a)中黑色箭头所示。但在另一枝晶间区域,仍存在粗大条状MC型碳化物,如图2(b)中白色箭头所示,且该粗大碳化物周围为粗大

相为固溶处理后的冷却期间析出,并在时效期间均匀长大所致,如图2(a)和(b)中区域D所示。同时可以看出,该区域原粗大块状碳化物已转变成网状形态,如图 2(a)中白色箭头所示,晶界如图2(a)中黑色箭头所示。但在另一枝晶间区域,仍存在粗大条状MC型碳化物,如图2(b)中白色箭头所示,且该粗大碳化物周围为粗大 相。

相。

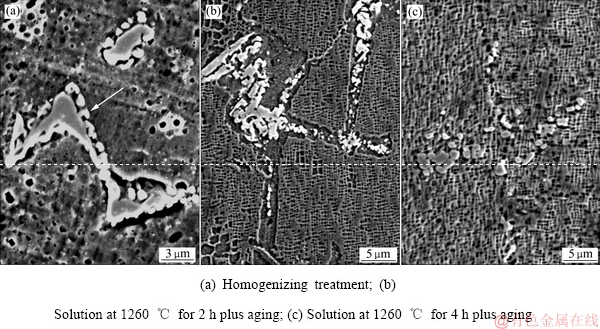

合金经不同工艺热处理后,其碳化物形态演化的形貌如图3所示。合金经1180 ℃保温2 h均匀化处理后的组织形貌,如图3(a)所示。可以看出,尽管均匀化处理的温度较低,时间较短,但合金中原块状碳化物边缘已经发生分解,转变成类粒状形态,分布于原块状碳化物周围,如图中箭头标注所示。合金经1260 ℃保温2 h固溶及时效处理后的组织形貌,如图3(b)所示,可以看出,原块状碳化物大部分已经分解,并转变成类粒状形态。

经1260 ℃保温4 h及时效处理后,合金的组织形貌如图3(c)所示,可以看出,合金中的碳化物已经分解,且以粒状形态分布在晶内和晶界。经SEM/EDS微区成分分析,确定出该类粒状碳化物中各元素的摩尔分数分别为:5.91% C,7.4% B,9.85% Hf,12.06% Ta,12.1% W,32.7% Cr。与粗大块状碳化物中碳浓度相比,粒状碳化物中的C含量明显降低。由于C、B和Hf、Ta、W和Cr的摩尔分数之比约为1:6,因此可以确定,该粒状相为M23C6型碳化物(已被图7的衍射斑点所证实)。

图3 合金经高温不同工艺热处理后的组织形貌

Fig. 3 Microstructures of alloy after heat treated at different regimes at higher temperature

对其形态演化的原因分析认为:合金中MC型碳化物与 和

和 两相相邻,在高温热处理期间,

两相相邻,在高温热处理期间, 基体中的Cr、W等元素可溶入MC型碳化物中,使碳化物中的C含量得到稀释,并转变成M23C6型碳化物。同时,该碳化物的体积分数增加,致使其碳化物界面向外迁移。在碳化物中碳浓度稀释、长大及界面迁移的过程中,界面能降低可促使其稀释后的碳化物转变成粒状形态,如图3(a)中箭头所示,此时,与粒状碳化物相邻的

基体中的Cr、W等元素可溶入MC型碳化物中,使碳化物中的C含量得到稀释,并转变成M23C6型碳化物。同时,该碳化物的体积分数增加,致使其碳化物界面向外迁移。在碳化物中碳浓度稀释、长大及界面迁移的过程中,界面能降低可促使其稀释后的碳化物转变成粒状形态,如图3(a)中箭头所示,此时,与粒状碳化物相邻的 和

和 两相中贫Cr。随固溶时间延长,远离该区域的高浓度Cr扩散至粗大MC型碳化物,继续溶入使其稀释,重复该碳化物中C含量稀释、长大及界面迁移的过程,并致使其转变成粒状M23C6型碳化物,直至原粗大MC型碳化物转变成粒状M23C6型碳化物,如图3(c)所示,其反应式可表示为:MC + Cr → M23C6。此外,上述反应中消耗了

两相中贫Cr。随固溶时间延长,远离该区域的高浓度Cr扩散至粗大MC型碳化物,继续溶入使其稀释,重复该碳化物中C含量稀释、长大及界面迁移的过程,并致使其转变成粒状M23C6型碳化物,直至原粗大MC型碳化物转变成粒状M23C6型碳化物,如图3(c)所示,其反应式可表示为:MC + Cr → M23C6。此外,上述反应中消耗了 基体的元素Cr,而MC型碳化物的分解可析出元素Ta,其相邻的g基体可吸收周围的Al、Ta原子,转变成

基体的元素Cr,而MC型碳化物的分解可析出元素Ta,其相邻的g基体可吸收周围的Al、Ta原子,转变成 相,即:

相,即: +Ta/Al→

+Ta/Al→ 。因此,热处理期间,合金中原粗大MC型碳化物转变成粒状M23C6碳化物的过程,可由反应式(1)表示,该式与文献[18]的结果相一致。

。因此,热处理期间,合金中原粗大MC型碳化物转变成粒状M23C6碳化物的过程,可由反应式(1)表示,该式与文献[18]的结果相一致。

(1)

(1)

但与1260 ℃高温固溶处理相比较,1230 ℃固溶处理温度较低,元素扩散较不充分,故MC型碳化物分解不完全,因此,经低温固溶+时效处理后,合金中仍存在粗大MC型碳化物,如图2(b)所示。

2.2 固溶温度对蠕变性能的影响

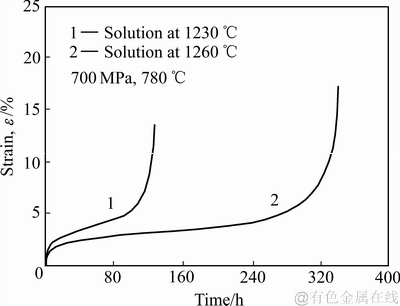

合金经不同工艺热处理后,在780 ℃和700 MPa条件下测定的蠕变曲线,如图4所示。经1230 ℃固溶及时效处理合金的蠕变曲线示于图4中的曲线1,可以看出,合金在施加载荷的瞬间,产生较大的瞬间应变;随蠕变时间延长,合金的应变速率降低,直至合金的蠕变进入稳态阶段。测定出合金在稳态期间的应变速率为0.044%/h,80 h后合金的蠕变进入加速阶段,直至127 h发生蠕变断裂。

图4 经不同工艺热处理合金在780 ℃和700 MPa条件下测定的蠕变曲线

Fig. 4 Creep curves of alloy heat treated by different regimes under conditions of 780 ℃ and 700 MPa

经1260 ℃固溶及时效处理后,合金在相同条件测定的蠕变曲线,示于图4中的曲线2,可以看出,合金在初始蠕变期间有较小的应变量,蠕变20 h进入稳态阶段,测定出合金在稳态期间的应变速率为0.0083%/h,260 h后进入加速蠕变阶段,合金的蠕变寿命为339 h。由此可见,采用高温固溶处理,合金在稳态蠕变期间具有较低的应变速率和较长的蠕变寿命。

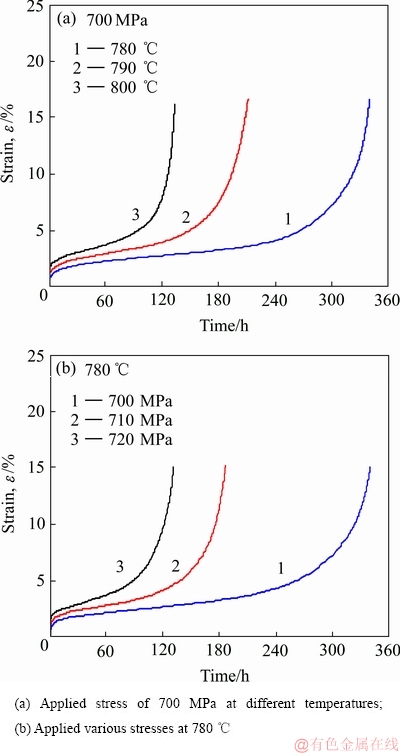

图5 合金在不同条件测定的蠕变曲线

Fig. 5 Creep curves of alloy under various conditions

经1260 ℃固溶及时效处理后,合金在不同条件测定的蠕变曲线,如图5所示。合金在不同温度施加700 MPa测定的蠕变曲线,如图5(a)所示,可以看出,合金在780、790和800 ℃稳态蠕变期间的应变速率分别为0.0083%/h、0.021%/h 和0.036%/h,蠕变寿命分别为339、211和133.4 h,蠕变温度由780 ℃提高到790 ℃,合金的蠕变寿命降低幅度为60.7%。合金在780 ℃施加700、710和720 MPa测定的蠕变曲线,如图5(b)所示,测定出合金在稳态蠕变期间的应变速率为0.0083%/h、0.024%/h和0.038%/h,蠕变寿命分别为339、186.7和131.3 h。这表明高温固溶处理合金具有较好的蠕变抗力和较长蠕变寿命。从图5(b)可以看出,当施加应力从700 MPa提高到710 MPa,稳态蠕变期间的应变速率从0.0083%/h 提高到0.024%/h,蠕变寿命从339 h减少到186.7 h,寿命降低幅度达81.6%。这表明与施加温度相比,在780 ℃当施加应力大于700 MPa时,合金呈现出明显的施加应力敏感性。

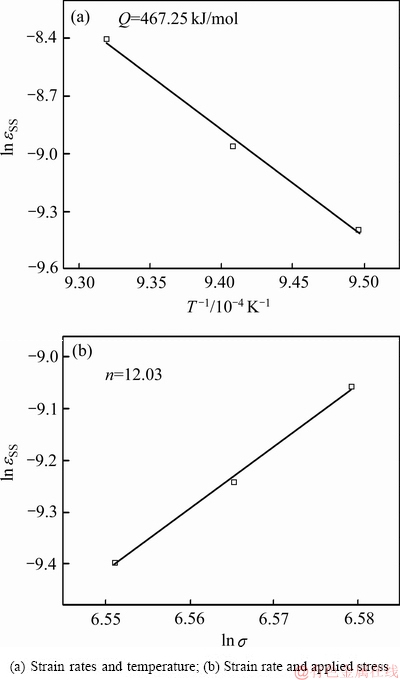

根据蠕变曲线的数据,求出合金在近780 ℃稳态蠕变期间的应变速率,绘出应变速率( )与施加温度、应力之间的关系,其中,应变速率与温度倒数之间的关系,如图6(a)所示;应变速率与施加应力之间的关系,如图6(b)所示。由此,计算出合金在780~800 ℃和700~720 MPa范围内稳态期间的表观蠕变激活能Q=467.247 kJ/mol,应力指数n=12.0。根据应力指数,推断出:在试验的温度和应力范围内,合金在稳态蠕变期间的变形机制为位错在g基体中滑移和剪切进入

)与施加温度、应力之间的关系,其中,应变速率与温度倒数之间的关系,如图6(a)所示;应变速率与施加应力之间的关系,如图6(b)所示。由此,计算出合金在780~800 ℃和700~720 MPa范围内稳态期间的表观蠕变激活能Q=467.247 kJ/mol,应力指数n=12.0。根据应力指数,推断出:在试验的温度和应力范围内,合金在稳态蠕变期间的变形机制为位错在g基体中滑移和剪切进入 相。

相。

图6 稳态蠕变期间合金的应变速率与施加温度、应力之间的关系

Fig. 6 Dependence of strain rates on applied temperatures and stresses during steady state creep of alloy

2.3 碳化物形态对变形机制的影响

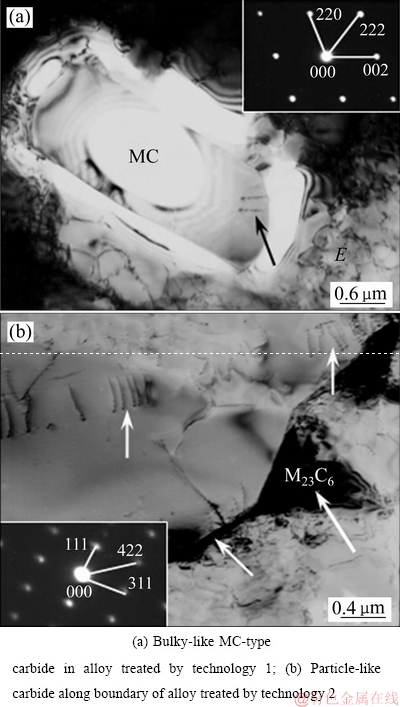

不同工艺热处理合金经780 ℃和700 MPa条件下蠕变断裂后,在近碳化物区域的TEM像如图7所示。经1230 ℃固溶处理合金蠕变127 h断裂后的形貌如图7(a)所示,可以看出,合金中粗大碳化物的长约6 μm,宽约2 μm;该碳化物的选区电子衍射及指数标定如图7(a)的右上侧插图所示,由此可鉴定出该相为MC型碳化物。蠕变后期合金的形变量较大,促使大量位错在基体中滑移,该粗大MC碳化物可阻碍位错滑移,故大量位错塞积于近碳化物区域,如图中区域E所示,大量位错的塞积可引起应力集中,致使位错剪切该碳化物相,如图中箭头标注所示。

图7 不同状态合金蠕变断裂后,碳化物的形貌及选区电子衍射

Fig. 7 Carbides configuration and SAD patterns in different stated alloys after crept up to fracture

经1260 ℃固溶处理合金蠕变339 h断裂后的形貌示如图7(b)所示,可以看出,蠕变后期,有位错列剪切进入 相,如图中箭头所示。合金中的晶界如图7(b)中细小倾斜箭头所示,尺寸约为0.8 μm的类粒状碳化物位于晶界处,其选区电子衍射及指数标定,如图7(b)的左下侧插图所示,由此可鉴定出该相为(Cr, W)23C6碳化物,该碳化物可阻碍位错运动,抑制晶界的滑移。与图7(a)相比,在近碳化物区域的位错密度较小,故可引起的应力集中值较小。

相,如图中箭头所示。合金中的晶界如图7(b)中细小倾斜箭头所示,尺寸约为0.8 μm的类粒状碳化物位于晶界处,其选区电子衍射及指数标定,如图7(b)的左下侧插图所示,由此可鉴定出该相为(Cr, W)23C6碳化物,该碳化物可阻碍位错运动,抑制晶界的滑移。与图7(a)相比,在近碳化物区域的位错密度较小,故可引起的应力集中值较小。

2.4 蠕变期间裂纹的萌生与扩展

经1230 ℃固溶及时效处理合金在780 ℃和700 MPa条件下蠕变不同时间的组织形貌,如图8所示。合金蠕变80 h时,在近粗大碳化物区域的组织形貌如图8(a)所示,可以看出,粗大碳化物呈条状形态,如图中箭头所示,与该碳化物相邻的区域为 相,且在化学腐蚀期间已被溶解,呈现空洞形态。该粗大碳化物位于枝晶间区域,其相邻的立方

相,且在化学腐蚀期间已被溶解,呈现空洞形态。该粗大碳化物位于枝晶间区域,其相邻的立方 相较为粗大,尺寸约为1.5~2.0 μm,在远离碳化物的枝晶干区域,立方

相较为粗大,尺寸约为1.5~2.0 μm,在远离碳化物的枝晶干区域,立方 相尺寸较为细小,如图8(a)的区域H所示。

相尺寸较为细小,如图8(a)的区域H所示。

在样品的另一区域存在团聚态类粒状碳化物,其形貌如图8(b)中箭头所示,其粗大和细小 相分别存在于枝晶间与枝晶干区域。与细小粒状碳化物相比,蠕变后期,在近粗大碳化物区域易于产生应力集中,故该区域易于发生裂纹的萌生与扩展。合金蠕变127 h断裂后的表面形貌,如图8(c)所示,施加应力轴的方向如图中双箭头标注所示。可以看出,粗大碳化物的排列方向与应力轴垂直,裂纹在与应力轴垂直的界面处萌生,并沿与碳化物相邻的界面扩展,如图中箭头标注所示。

相分别存在于枝晶间与枝晶干区域。与细小粒状碳化物相比,蠕变后期,在近粗大碳化物区域易于产生应力集中,故该区域易于发生裂纹的萌生与扩展。合金蠕变127 h断裂后的表面形貌,如图8(c)所示,施加应力轴的方向如图中双箭头标注所示。可以看出,粗大碳化物的排列方向与应力轴垂直,裂纹在与应力轴垂直的界面处萌生,并沿与碳化物相邻的界面扩展,如图中箭头标注所示。

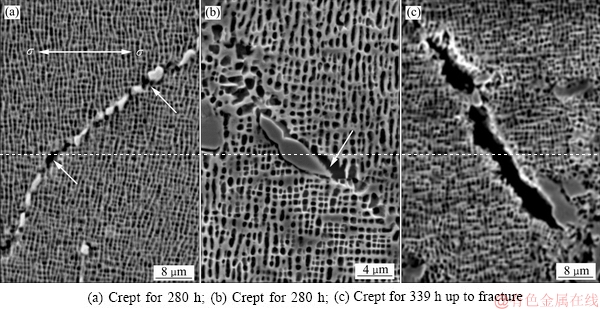

经1260 ℃固溶及时效处理后,合金在780 ℃和700 MPa条件下蠕变至后期,样品表面发生裂纹萌生与扩展的形貌如图9所示,施加应力的方向如图中双箭头标注所示。合金蠕变280 h已经进入加速阶段,应变量达5.5%,如图4所示。样品中大部分 相仍保持完整的立方体形态,如图9(a)所示。由于合金蠕变期间的应变较大,可激活大量位错在基体中滑移,当蠕变位错滑移至晶界受阻,可塞积于近晶界区域,并引起应力集中。当应力集中值大于晶界的结合强度时,首先在晶界处发生裂纹的萌生[15]。其中,在近类粒状碳化物区域、且与应力轴成45°角方向的晶界区域发生裂纹的萌生,在近粒状碳化物区域细小裂纹的形态,如图9(a)中箭头所示。样品的另一区域,在近粗大碳化物区域发生裂纹的萌生,其中,在碳化物与基体界面处裂纹的形貌,如图9(b)中箭头所示。

相仍保持完整的立方体形态,如图9(a)所示。由于合金蠕变期间的应变较大,可激活大量位错在基体中滑移,当蠕变位错滑移至晶界受阻,可塞积于近晶界区域,并引起应力集中。当应力集中值大于晶界的结合强度时,首先在晶界处发生裂纹的萌生[15]。其中,在近类粒状碳化物区域、且与应力轴成45°角方向的晶界区域发生裂纹的萌生,在近粒状碳化物区域细小裂纹的形态,如图9(a)中箭头所示。样品的另一区域,在近粗大碳化物区域发生裂纹的萌生,其中,在碳化物与基体界面处裂纹的形貌,如图9(b)中箭头所示。

随蠕变进行,微裂纹逐渐沿晶界扩展,并有新的裂纹萌生于晶界,致使合金的应变量增大,当多个萌生于晶界的微裂纹同时沿晶界扩展时,使相邻的微孔洞或微裂纹相互连通,形成大裂纹,当多个裂纹发生扩展直至相互连接时,发生合金的蠕变断裂。该合金经780 ℃和700 MPa条件下蠕变339 h 断裂后,在倾斜晶界区域发生多个裂纹扩展,形成的大裂纹形貌如图9(c)所示。这表明在蠕变期间,裂纹易于在枝晶间区域沿与应力轴约成45°角的倾斜晶界处发生裂纹的萌生与扩展;且沿晶界发生裂纹的萌生与扩展直至蠕变断裂是合金在蠕变后期的断裂机制。由此可知,与基体相比,晶界仍是合金中蠕变强度较低的薄弱区域,且样品中裂纹易于沿倾斜晶界发生萌生与扩展,其中,撕裂后的断口呈现非光滑锯齿状形态,为裂纹沿晶界扩展时所遇阻力较大所致。

图8 工艺1热处理合金经780 ℃和700 MPa蠕变不同时间的组织形貌

Fig. 8 After heat treated by technology 1, surface morphology of sample crept for different times at 780 ℃ and 700 MPa

图9 经工艺2热处理合金经780 ℃和700 MPa蠕变不同时间的形貌

Fig. 9 Surface morphology of sample crept for different times at 780℃ and 700 MPa

3 讨论

定向凝固合金的主要强化机制是第二相强化和固溶强化,且合金中含有W、Cr、Mo、Ta等难熔元素。一方面,难熔元素具有高的熔点及较低的扩散系数;另一方面,一些难熔元素是碳化物形成元素,在热处理期间可以促使合金中析出M6C、M23C6和MC型碳化物。由于不同碳化物具有不同的形态和尺寸,故对合金的力学及蠕变性能有不同的影响。当大量细小粒状碳化物在晶内和沿晶界析出、并均匀分布时,可阻碍位错运动、抑制晶界滑移,大幅度提高合金的蠕变抗力,如图3(c)所示。但当粗大块状碳化物存在于晶界区域,蠕变期间在近碳化物区域易于产生应力集中,促使裂纹在碳化物/基体界面处发生裂纹的萌生与扩展如图8(c)所示,则可降低合金的蠕变抗力,成为影响合金蠕变强度的薄弱环节。

关于碳化物形态对合金蠕变抗力影响的研究表明,当粒状碳化物沿晶界不连续分布时,如图9(a)所示,其粒状碳化物的钉扎作用可抑制晶界滑移,增加位错运动的阻力,提高合金的蠕变强度。其碳化物抑制晶界滑移的抗力( )可表示为

)可表示为

(2)

(2)

式中:L为晶界碳化物的平均间距;G为剪切模量;d为粒状碳化物的平均尺寸;b为柏氏矢量;f为粒状碳化物的体积分数。此式表明,随碳化物尺寸和沿晶界分布距离的减小,粒状碳化物体积分数的增加,晶界滑移的阻力增大。

合金经工艺 1 热处理后,由于固溶温度较低,元素扩散较不充分,MC型碳化物分解不完全,故经随后的时效处理后,合金中仍存在粗大MC型碳化物,如图2(b)所示。合金中较大尺寸的碳化物主要分布于枝晶间区域,其中,粗大碳化物的存在割裂了基体之间力的传递,与基体界面的结合力较弱,易于产生应力集中,故有损于合金的强度和蠕变抗力。再则,合金在高温蠕变期间,由于碳化物与基体之间的热膨胀系数不同,两者之间的界面可产生较大的热应力,故蠕变期间碳化物易与基体分离,成为裂纹的萌生源,或致使裂纹沿碳化物与基体的界面扩展。因此,蠕变期间粗大碳化物的存在,其不利作用增大。

在高温固溶处理期间,合金中的元素得到充分扩散,并致使粗大块状碳化物发生分解,转变成网状形态,或转变成粒状形态。同时,有粒状碳化物沿晶界不连续析出,如图9(a)所示,可阻碍位错运动,抑制晶界滑移,故可大幅度提高合金的蠕变抗力。因此,与工艺 1热处理合金相比较,高温固溶处理合金具有较好的蠕变抗力和较长的蠕变寿命。

4 结论

1) 铸态DZ125合金中存有块状MC型碳化物,热处理期间,合金中MC型碳化物可发生分解和形态演化,转变成粒状M23C6型碳化物。随固溶温度提高、时间延长,元素得到充分扩散,碳化物分解及发生形态演化的几率增加,并使细小粒状碳化物沿晶界不连续析出。

2) 与工艺1热处理的合金相比,经工艺2热处理的合金在近780 ℃具有良好的蠕变抗力。其中,立方 相以共格方式嵌镶在

相以共格方式嵌镶在 基体中,并均匀分布在枝晶干和枝晶间区域。其中,沿晶界析出的细小粒状碳化物可抑制晶界滑移,阻碍位错运动,是使合金具有较好蠕变抗力的原因之一。

基体中,并均匀分布在枝晶干和枝晶间区域。其中,沿晶界析出的细小粒状碳化物可抑制晶界滑移,阻碍位错运动,是使合金具有较好蠕变抗力的原因之一。

3) 在近780 ℃蠕变后期,合金中裂纹首先在晶界处萌生,并沿晶界扩展,且不同形态晶界具有不同的损伤特征,其中与应力轴呈45°角的晶界承受较大的剪切应力。裂纹在沿应力轴呈45°角的晶界处萌生与扩展,直至断裂是合金的蠕变断裂机制。

REFERENCES

[1] HENDERSON P J, MCLEAN M. Creep transients in the deformation of anisotropic nickel-base alloys[J]. Acta Metallurgica, 1982, 30(6): 1121-1131.

[2] 张 璞, 侯 华, 赵宇宏, 靳玉春, 赵宇辉, 眭怀明. 基于CAFE模型的镍基合金定向凝固过程显微组织模拟[J]. 中国有色金属学报, 2016, 26(4): 783-789.

ZHANG Pu, HOU Hua, ZHAO Yu-hong, LE Yu-cun, ZHAO Yu-hui, GUI Huai-ming. Microstructure simulation during directional solidifiation of nickel-based alloy based on CAFE model[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 783-789.

[3] 孟凡国, 董建新, 张麦仓, 姚志浩. 镍基耐蚀合金028 平衡相的析出行为[J]. 中国有色金属学报, 2014, 24(2): 432-420.

MENG Fan- guo, DONG Jian -xin, ZHANG Mai- cang, YAO Zhi-hao. Precipitationbehaviorofequilibrium phases in nickel basedcorrosionresistantalloy 028[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 432-420.

[4] CHEN Q Z, JONES C N, KNOWLES D M. Effect of alloying chemistry on MC carbide morphology in modified RR2072 and RR2086 SX superalloy[J]. Scripta Materialia, 2002, 47(10): 669-675.

[5] 田 宁, 田素贵, 张宝帅, 于慧臣, 李秋阳. 应力时效对 DZ125 镍基合金组织 演化及蠕变抗力的影响[J]. 中国有色金属学报, 2018, 28(3): 536-546.

TIAN Ning, TIAN Su-gui1, ZHANG Bao-shuai, YU Hui-chen, LI Qiu-yang. Effect of stress aging on microstructure evolution and creep resistance of DZ125 nickel-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(3): 536-546.

[6] 柴国明, 陈希春, 郭汉杰. FGH96 高温合金中一次碳化物形成规律[J]. 中国有色金属学报, 2012, 22(8): 2205-2213.

CHAI Guo-ming, CHEN Xi-cun, GUO Han-jie. Formation mechanism of primary carbides in FGH96 superalloy[J]. The Chinese Journal of Nonferrous Metals,2012, 22(8): 2205-2213.

[7] LIU Lin, SOMMER F. Effect of solidification conditions on MC carbides in a nickel-base superalloy in IN738LC[J]. Scripta Metallurgica et Materialia, 1994, 30(5): 587-591.

[8] 唐中杰, 郭铁明, 寇 生, 付 迎, 金 硕. 镍基高温合金K4169中夹杂物的特征及形成机理[J]. 中国有色金属学报, 2015, 25(9): 2404-2412.

TANG Zhong-jie, GUO Tie-ming, KOU Sheng-zhong, FU Ying, JIN Suo. Feature and formation mechanism of inclusions in K4169 Ni-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2404-2412.

[9] 田素贵, 谢 君, 周晓明. FGH95镍基合金的蠕变行为及影响因素[J]. 稀有金属材料与工程2011, 40(5): 807-812.

TIAN Su-gui, XIE Jun, ZHOU Xiao-ming, Creep behavior and influencing factors of FGH95 nickel base superalloy[J]. Rare Metal Materials and Engineering, 2011, 40(5): 807-812.

[10] YIN Feng-shi, SUN Xiao-feng, YUAN Chao, GUAN Heng-rong, HU Zhuang-qi. Effect of melt superheating on the morphology of MC carbide in a cast Ni-base superalloy M963[J]. Journal of Wuhan University of Technology, 2002, 17(3): 42-45.

[11] 张小彬, 刘常升, 吕俊英. 镍基高温合金长期时效过程中第二相的析出[J]. 东北大学学报(自然科学版), 2005, 26(4): 253-256.

ZHANG Xiao-bin, LIU Chang-sheng, Lü Jun-ying, Secondarily precipitated phases of a Ni-based superalloy during durable thermal treatment[J] Journal of Northeastern University (Natural Science), 2005, 26(4): 253-256.

[12] 刘建涛, 张义文, 陶 宇, 张 莹, 迟 悦. 预处理过程中FGH96合金粉末中碳化物演变[J]. 材料热处理学报, 2012, 33(5): 53-58.

LIU Jian-tao, ZHANG Yi-wen, TAO Yu, ZHANG Ying, CHI Yue. Carbides evolution of FGH96 PM superalloy powders during pre-heat treatment[J]. Transactions of Materials and Heat Treatment, 2012, 33(5): 53-58.

[13] APPA R G, SRINIVAS M, SARMA D S. Effect of oxygen content of powder on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718[J]. Materials Science and Engineering A, 2006, 435/436(8): 84-99.

[14] 胥国华, 焦兰英, 张北江, 秦鹤勇, 赵光普. 固溶冷却速度对GH4586合金组织及850 ℃拉伸性能的影响[J]. 材料热处理学报, 2006, 27(2): 47-49.

XU Guo-hua, JIAO Lan-ying, ZHANG Bei-jiang, QIN He-yong, ZHAO Gguan-pu. Effect of cooling rate after solid solution on microstructure and tensile properties of GH4586 superalloy at 850 ℃[J]. Transactions of Materials and Heat Treatment, 2006, 27(2): 47-49.

[15] 丁 智, 张 军, 王常帅, 苏海军, 刘 林, 傅恒志. DZ125镍基高温合金高温持久断裂后的位错组态[J]. 金属学报, 2011, 47(1): 47-52.

DING Zhi, ZHANG Jun, WANG Chang-shuai, SU Hai-jun, LIU Lin, FU Heng-zhi. Dislocation configuration in DZ125 Ni-based superalloy after high temperature stress rupture[J]. Acta Metallurgica Sinica, 2011, 47(1): 47-52.

[16] 侯介山, 丛陪娟, 周兰章, 秦学智, 王 勇, 李谷松. Hf 对抗热腐蚀镍基高温合金微观组织和力学性能的影响[J]. 中国有色金属学报, 2011, 21(5): 945-954.

HOU Jie-shan, CONG Pei-juan, ZHOU Lan-zhang, QIN Xue-zhi WANG Yong, LI Gu-snong. Effect of Hf on microstructure and mechanical behavior of hot corrosion resistant Ni-based superalloys[J]. The Chinese Journal of Nonferrous metals, 2011, 21(5): 945-954.

[17] LEE H S, KIM D H, KIM D S, YOO K B. Microstructural changes by heat treatment for single crystal superalloy exposed at high temperature[J]. Journal of Alloys and Compounds, 2013, 561: 135-141.

[18] BOR H Y, CHAO C G, MA C Y. The influence of magnesium on carbide characteristics and creep behavior of the MAR-M247[J]. Scripta Materialia, 1998, 38(2): 329-334.

Configuration evolution of carbides and its influence on creep property of nickel-based superalloy

TIAN Ning1, TIAN Su-gui1, 2, YU Hui-chen3, ZHAO Guo-qi1, YAN Hua-jin1, MENG Xian-lin1, 2

(1. School of Mechanical Engineering, Guizhou University of Engineering Science, Bijie 551700, China;

2. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110178, China;

3. Aviation Key Laboratory of Science and Technology on Materials Testing and Evaluation, AVIC Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: By means of heat treatment at different regimes, creep properties measurements and microstructure observations, an investigation has been made into the influence of solution temperature on the carbides configuration evolution and creep properties of a directionally solidified nickel-based superalloy. The results show that the thicker bulk-like MC-type carbide is distributed in the as-cast DZ125 superalloy. And the decomposition and configuration evolution of the MC-type carbide occur gradually, during heat treatment, to transform into the particle-like M23C6-type carbides. As the solution temperature enhances and time prolongs, the probability of the MC-type carbide occurring decomposition and morphology evolution increase, which may promote significant amount of particle-like M23C6-type carbide precipitating along the grain boundary of alloy. Compared with the alloy solution treated by lower temperature, the alloy solution treated at higher temperature displays a better creep resistance at a temperature near 780 ℃. Wherein, the fine γ′ precipitates embedded coherent in the matrix phase are homogeneously distributed in the dendrite/ inter-dendrite regions, and some M23C6-type carbide particles along the grain boundaries may restrain the slipping of boundary, which is thought to be the main reasons of alloy having better creep resistance. At the latter stage of creep at a temperature near 780 ℃, the bigger shearing stress applying in the boundaries at about 45° angles relative to the stress axis results in the initiation and propagation of the micro-cracks along the ones up to fracture, which is thought to be fracture mechanism of the alloy during creep.

Key words: directional solidification nickel-based alloy; solution temperature; microstructure; carbide; creep; initiation and propagation of crack

Foundation item: Project(QJHRCTD [2015]73) supported by Guizhou Innovation Team, China; Project(QKHLH[2015]7583) supported by Guizhou Science and Technology Cooperation Program, China; Project(YKHZG201701) supported by Guizhou University of Engineering Science, China

Received date: 2017-12-18; Accepted date: 2018-09-18

Corresponding author: TIAN Su-gui; Tel: +86-13889121677 ; E-mail: tiansugui2003@163.com

(编辑 何学锋)

基金项目:贵州省创新团队项目(黔教合人才团队字[2015]73);贵州省科技合作项目(黔科合LH字[2015]7583);贵州工程应用技术学院高层次人才启动基金资助项目(院科合字G2017001号)

收稿日期:2017-12-18;修订日期:2018-09-18

通信作者:田素贵,教授,博士;电话:13889121677;E-mail:tiansugui2003@163.com