DOI: 10.11817/j.ysxb.1004.0609.2021-37714

冷轧时效对新型Ti-Nb-Zr合金组织和性能的影响

贺 峰1, 2,杨双平1,曹继敏2,王 戈2

(1. 西安建筑科技大学 冶金工程学院,西安 710055;

2. 西安圣泰金属材料有限公司,西安 710018)

摘 要:利用X射线衍射仪(XRD)、光学显微镜(OM)、扫描电镜(SEM)、透射电镜(TEM)和拉伸测试等手段,研究形变热处理对新型β(Ti-25Nb-25Zr)钛合金组织演变和力学性能的影响。结果表明:由于合金具有较高的β稳定性,冷轧过程没有应力诱发α″相的形成,合金的变形机制以位错滑移为主。随着冷轧变形量的增加,加工硬化速率和弹性模量逐渐降低。经过相同的时效处理(300 ℃、2 h), 固溶态和冷轧态的合金相组成分别为β+等温ω和β+α相。冷轧产生的位错缺陷和晶界有效抑制ω相,促进了α相的析出。冷轧时效相比固溶时效能更好地得到较高的强度和理想的弹性模量,满足医用材料的性能要求。

关键词:Ti-25Nb-25Zr钛合金;冷轧变形;时效处理;组织演变;力学性能

文章编号:1004-0609(2021)-01-0042-07 中图分类号:TG146.2 文献标志码:A

引文格式:贺 峰, 杨双平, 曹继敏, 等. 冷轧时效对新型Ti-Nb-Zr合金组织和性能的影响[J]. 中国有色金属学报, 2021, 31(1): 42-48. DOI: 10.11817/j.ysxb.1004.0609.2021-37714

HE Feng, YANG Shuang-ping, CAO Ji-min, et al. Effect of cold rolling on microstructure and properties of Ti-Nb-Zr alloy by aging treatment[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(1): 42-48. DOI: 10.11817/j.ysxb.1004.0609.2021-37714

钛合金具有比强度高、弹性模量低、生物相容性好和耐腐蚀等优点,被广泛应用于生物医疗领域[1-2]。目前临床应用最多的α型(纯Ti)和α+β型(Ti-6Al-4V ELI)具有强度低,生物相容性差和弹性模量高等缺点[3-5],因此选择生物相容性好的Nb、Zr、Ta、Sn等元素设计的β钛合成为了热点[6]。目前,国外研究比较热的有NIINOMI课题组研究的Ti-29Nb-13Ta-4.6Zr合金和国内郝玉琳课题组研究的Ti-24Nb-4Zr-8Sn合金,作为生物医用钛合金,除了具备良好的生物相容性外,还必须具有较低的弹性模量和较高的强度[7-9]。Ti-25Nb-25Zr合金是根据d电子轨道理论设计的一种新型亚稳定钛合金,具有良好的生物相容性、较低的弹性模量和优异的冷加工性能,非常适合矫正支架、外科植入物等领域的应用。目前,Ti-25Nb-25Zr合金还处于实验室研究阶段,冷加工和热处理对合金的组织和性能的研究报道的比较少,限制了该合金的应用和发展。

目前,开发的新型低弹性模量β钛合金普遍具有较低的强度,为了能够满足医用材料的性能,必须对合金进行强化处理。β钛合强化的方式主要有固溶强化、析出强化、细晶强化和加工硬化强化等,形变热处理也是提高合金强度和塑性的常用办法。形变热处理改善钛合金力学性能的本质是改变了时效分解特征,使合金的弥散强化超过硬化强化,抑制再结晶和提高位错密度,使位错更加均匀分布。KARTHIKEYAN等[10]对Ti-5Ta- 1.8Nb合金的研究发现,冷轧组织对析出相的形貌有很重要的影响。张坤等[11]对TB8钛合金进行冷变形及时效处理表明冷变形可以使ω相的析出和分布更加均匀,有利于后续α相的形成和分布。XU等[12]对冷加工过程产生的位错缺陷在时效中会起到辅助形核作用,增加了形核率和相变速率。因此,本文将以新型的β钛合金Ti-25Nb-25Zr合金为研究对象,主要研究形变和热处理过程组织演变和力学性能的变化,为该合金的进一步应用奠定理论和实验基础。

1 实验

实验采用高纯度的海绵钛、海绵锆和铌条为原料,经过真空自耗电弧炉三次熔炼制备出Ti-25Nb-25Zr(质量分数,%)合金,化学成分如表1所示。铸锭在相变温度以上1100 ℃采用1600MN快锻机进行开坯锻造,表面打磨后在900 ℃进行热轧,得到d 10 mm的盘条,进行表面剥皮处理。在800 ℃进行固溶处理,在线材轧机上进行多道次冷轧处理,分别得到15%、30%、45%、60%、80%的冷轧试样,研究冷变形机理。固溶和冷轧30%试样分别在马弗炉中设定300 ℃、时效2 h,对比时效过程组织演变和力学性能。

对于不同状态的试样,采用金相显微镜和扫描电镜观察试样冷轧和时效后的晶粒形貌等,金相试样经V(HF):V(HNO3):V(H2O)为1:3:7腐蚀后进行观察。利用PhilipsPW1700 X射线衍射仪标定样品的相组成及残余应力的变化。采用Talos F200X透射电镜观察合金的微观组织、位错形态等,透射试样制备方法为机械减薄和离子减薄。用HV-10Z型维氏硬度测量仪测试合金的硬度,测试条件:载荷 98 N,加载时间15 s,每个试样取5个点计算平均值。采用WDW-100A型电子万能试验机测试合金力学性能和弹性模量,拉伸速度0.5 mm/min,弹性模量为应力和应变的比值。

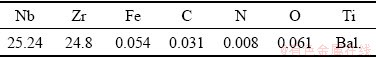

表1 Ti-25Nb-25Zr合金的化学成分

Table 1 Chemical composition of Ti-25Nb-25Zr (mass fraction, %)

2 结果与讨论

2.1 Ti-25Nb-25Zr合金的冷轧组织

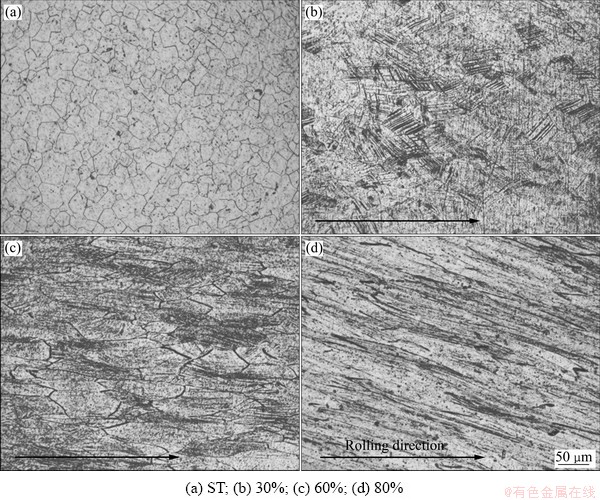

图1所示为冷轧前后Ti-25Nb-25Zr合金的显微组织的变化,在800 ℃、1 h固溶处理后,得到全为等轴的β组织,没有淬火ω和α″相的析出(见图1(a))。经过30%冷变形后,等轴的β组织被压扁拉长,在等轴的β晶粒内部出现了平行的黑色滑移带,交织分布(见图1(b)),此时,合金的变形是通过位错滑移和晶界滑动共同实现的。当变形量达到60%时,部分晶界开始破碎,晶粒被进一步的压扁、拉长,滑移带沿着轧制方向增多(见图1(c))。当变形量增大到80%时,原始晶粒和晶界已经模糊,无法看清,产生了大量的滑移带和扭曲的未结晶组织,滑移带沿着轧制方向成线性分布(见图1(d))。在变形量为80%的直径方向(见图2),可以看到细小纤维交织的大理石花纹状组织,BCC结构的合金经过大量的冷变形,内部出现了大量纳米晶格的扰动,形成了大量不连续的错层所导致的,这也与郭文渊等[13]和麻西群等[14]对Ti-Nb合金研究结果相同。

图1 Ti-25Nb-25Zr钛合金在不同冷轧变形量下的显微组织

Fig. 1 Microstructures of Ti-25Nb-25Zr alloy under different cold-rolled deformation

图2 Ti-25Nb-25Zr合金经80%冷轧横截面显微组织

Fig. 2 Cross sectional microstructure of alloy with 80% cold-deformation

图3 Ti-25Nb-25Zr合金经不同冷变形量的XRD谱

Fig. 3 XRD patterns of Ti-25Nb-25Zr alloy with different cold deformations

图3所示为Ti-25Nb-25Zr合金不同冷轧变形量的XRD谱。从图3中的图谱可以看出,由于合金含有大量的β稳定元素,合金经过固溶处理后,β相被完全保留至室温,没有出现淬火ω和α″相。冷轧后,合金也没有出现由于应力诱发的α″相。β钛合金冷变形过程中主要发生位错滑移、孪生和应力诱发马氏体相变,是否出现应力诱发马氏体相,取决于β相的稳定性,β稳定性越高,越不利于应力诱发α″相的出现[15]。

根据Morinaga的d电子轨道原理,采用两个参数(Md和Bo)来表征和控制钛合金的相稳定性和相关性能,Bo值越高,Md值越低,β相越稳定,合金以滑移变形为主[16]。通过计算,Ti-25Nb-25Zr合金的Bo=2.89,Md=2.53,具有较高的Bo值和较低的Md值,因此表现为较高的β稳定性,冷变形过程不会出现应力诱发的α″相,这也与XRD检测结果一致。冷轧变形后,Ti-25Nb-25Zr合金β相(110)面峰值逐渐减弱,而β相(200)面衍射峰逐渐增强,说明合金冷轧后发生了晶格畸变,晶体结构具有择优取向的趋势。随着变形量的增加,衍射峰明显宽化,这主要是因为冷轧变形过程纳米晶粒的产生,位错、晶界数量的增多,以及位错在滑移面上相互缠结造成应力集中导致晶格发生畸变。

2.2 Ti-25Nb-25Zr合金冷轧变形量对硬度和弹性模量的影响

图4所示为Ti-25Nb-25Zr合金硬度和弹性模量随冷轧变形量增加的曲线图。由图4中可以看出,随着冷轧变形量的增加,合金硬度逐渐增大,并且开始阶段增加的较快,当超过一定程度后,硬度的增长明显减缓,说明合金的硬化速率随冷加工变形量的持续增加而降低。当冷轧变形量为30%时,合金的硬度由固溶态的(197 HV)提高到(253 HV),而且增加的很快。主要原因是Ti-25Nb-25Zr合金含有很高的β稳定性,变形以滑移为主,位错沿着滑移面进行移动,位错的交互作用和完整的晶界对位错运动起到了阻滞作用,滑移无法延续到相邻晶粒,形成了交织的位错塞积群,导致合金硬化很明显。当冷轧变形量超过60%,合金的晶粒进一步细化且晶界开始破碎,宏观晶粒变形,呈纤维状,位错运动较易发生,降低了晶粒内部的位错密度,表现为合金的硬度增加的幅度比较缓慢,合金的硬度保持在(290 HV)左右,趋于稳定。

图4 Ti-25Nb-25Zr合金不同冷变形量的硬度和弹性模量

Fig. 4 Hardness and elastic modulus of Ti-25Nb-25Zr alloy under different cold-rolled deformations

图4还显示了Ti-25Nb-25Zr合金的弹性模量随冷轧变形量的变化。明显可以看出,冷轧态的弹性模量都高于固溶态的,且随着冷轧变形量的增加,逐渐降低。弹性模量使表征原子间结合力大小的物理量,对于合金材料,只有经过合金化后形成显著的第二相时,弹性模量才会发生明显的变化[17]。根据上面的研究发现Ti-25Nb-25Zr合金由于具有较高的稳定性,冷轧过程并没有第二相的产生,导致弹性模量的变化是由于冷轧过程形成微晶或纳米晶和冷轧织构的共同作用。冷轧产生的微晶或纳米晶,尺寸小,内部无缺陷,弹性变形为晶格常数的变化,导致合金的弹性模量增加。随着冷轧变形量的增加,合金产生了{001}  冷变形织构,

冷变形织构, 取向织构降低了合金该方向的弹性模量。因此,合金沿轧制方向弹性模量先增后降的变化趋势是由纳米结构和变形织构共同作用的结果。

取向织构降低了合金该方向的弹性模量。因此,合金沿轧制方向弹性模量先增后降的变化趋势是由纳米结构和变形织构共同作用的结果。

2.3 Ti-25Nb-25Zr合金的冷轧时效的组织

图5所示为固溶态和冷轧态的Ti-25Nb-25Zr合金经过300 ℃时效2 h的SEM像和TEM像。固溶态的合金在300 ℃时效2 h,β基体上分布着大量、弥散的白色椭球状的析出相。根据[110]β晶带轴的选区电子衍射结果,可以确定析出相为等温ω相,ω相实际是β稳定元素在α-Ti中的一种过饱和固溶体,常以较小的尺寸和非常高的颗粒密度共格析出。亚稳定β钛合金,在较低温度时效时,由于溶质原子扩散率低,亚稳定的α相很难在β基体上形核,而β→β+ω转化的速度比较快,在错配度较低的Ti-Nb合金中共格析出椭球状的ω相。随着时效的持续,ω相逐渐聚集长大,并且开始完成ω→α相的转变。而冷轧态的合金经过相同的时效制度后,β基体上析出了α强化相,晶界内的变形带依然存在。冷轧态合金在300 ℃时效2 h,位错缺陷依然存在,合金的选区电子衍射呈环状,表明温度太低,不足以引起晶粒的再结晶,晶粒尺寸依然非常细小。

图5 Ti-25Nb-25Zr钛合金固溶态和冷轧态300 ℃时效2 h的SEM像和TEM像

Fig. 5 SEM and TEM images of solution treated and cold-rolled alloys aged at 300℃ for 2 h

根据时效原理,固溶态合金的位错等晶体缺陷的数量少,相变过程仅依靠微区成分的差异来实现,形核数量较少,且过程需要的时间较长。等温ω相的析出是通过1/2[111]全位错分解得到的1/3[111]、1/6[111]和1/12[111]的不全位错运动来实现[18]。这说明阻碍位错运动的因素能抑制ω相的生成。晶界和位错缺陷能阻碍位错运动,从而抑制了ω相的形成。与ω相形核机制不同,α相易于在晶界和位错处形核,因此冷轧产生大量的位错缺陷、滑移带和晶界为α相提供了形核位置和能量,从有效促进α相的析出,起到了很好的强化作用。

2.4 Ti-25Nb-25Zr合金的冷轧时效对力学性能和弹性模量的影响

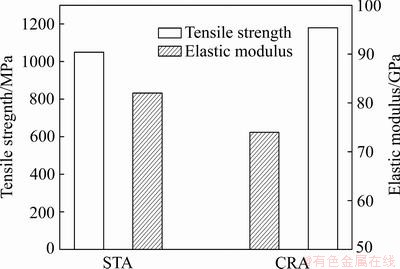

图6所示为固溶态和冷轧态的Ti-25Nb-25Zr合金经过300 ℃时效2 h的强度和弹性模量。从图6中可以看出,冷轧时效态的合金相比固溶时效态具有更高的抗拉强度和较低的弹性模量。合金300 ℃时效2 h,固溶态的合金主要由ω相组成,由于ω相的硬度和弹性模量很高,脆性极大(δ→0),固能显著提高合金的强度和弹性模量,而大大降低塑性。ω相对合金力学性能的影响程度与其体积分数有很大的关系,当ω相的体积分数超过80%,合金即无宏观塑性[19]。故合金中一旦出现ω相,位错不能在其中移动,导致合金强度、硬度和弹性模量将大大升高,而塑性和韧性急剧降低,时效过程应该避免ω相的析出。冷轧之后,合金中产生大量的位错缺陷和晶界,时效过程抑制了ω相的形成并促进了α相析出,此时合金的强化机制主要由细晶强化和α相的弥散强化共同作用,相比固溶时效试样具有更高的强度。但是,钛合金中β、α和ω相的弹性模量依次增加[20],冷轧时效析出的α相相比ω相具有较低的弹性模量。因此,冷轧时效相比固溶时效能更好地得到合金高强度和低弹性模量的匹配,满足医用材料的性能要求。

图6 Ti-25Nb-25Zr合金固溶时效和冷轧时效的力学性能

Fig. 6 Mechanical properties of Ti-25Nb-25Zr alloy under STA and CRA

3 结论

1) Ti-25Nb-25Zr合金具有较高的β稳定性,冷轧过程没有应力诱发α″马氏体相变,变形机制主要以位错滑移为主。合金的硬化速率和弹性模量随冷变形量的增加而降低。

2) 固溶态和冷轧态的合金经300 ℃时效2 h,合金的相组成分别为β+等温ω和β+α相。冷轧产生的位错缺陷和晶界有效抑制ω相,促进了α相的析出。冷轧时效相比固溶时效能更好地得到合金高强度和低弹性模量的匹配,满足医用材料的性能要求。

REFERENCES

[1] RACK H J, QAZI J I. Titanium alloy for biomedical applications[J]. Materials Science and Engineering C, 2006, 26: 1269-1277.

[2] 赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010, 29(5): 1-8.

ZHAO Yong-qing. Current situation and development trend of titanium alloy[J]. Materials China, 2010, 29(5): 1-8.

[3] LAN Chun-bo, WU Yu, GUO Li-li, et al. Microstructure, texture evolution and mechanical properties of cold Ti-32.5Nb-6.8Zr-2.7Sn biomedical beta titanium alloy[J]. Journal of Materials Science & Technology, 2018, 34(5): 788-792.

[4] TANE M, AKITA S, NAKANO T, et al. Peculiar elastic behavior of Ti-Nb-Ta-Zr single crystals[J]. Acta Materialia, 2008, 56(12): 2856-2863.

[5] SAKAGUCHI N, NIINOMI M, AKAHORI T, et al. Relationships between tensile deformation behavior and microstructure in Ti-Nb-Ta-Zr system alloys[J]. Materials Science and Engineering C, 2005, 25(3): 363-369.

[6] WANG Li-qiang, LU Wei-jie, QIN Ji-ning, et al. Micro structure and mechanical properties of cold-rolled TiNbTaZr biomedical β titanium alloy[J]. Materials Science and Engineering A, 2008, 490: 421-426.

[7] NIINOMI M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy Ti-29Nb-13Ta-4.6Zr[J]. Biomaterials, 2003(24): 2673-2683.

[8] 张思倩, 李述军, 郝玉琳, 等. Ti-24Nb-4Zr-8Sn合金疲劳缺口敏感性[J]. 中国有色金属学报, 2010, 20(1): 518-522.

ZHANG Si-qian, LI Shu-jun, HAO Yu-lin, et al. Fatigue notch sensitivity of Ti-24Nb-4Zr-8Sn alloy[J]. The Chinese Journal of Nonferrous Metals, 2010,20(1):518-522.

[9] WANG Xing, ZHANG Li-gang, GUO Zi-yi, et al. Study of low-modulus biomedical β Ti-Nb-Zr alloys based on single-crystal elastic constants modeling[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 62: 310-314.

[10] KARTHIKEYAN T, DASGUPTA A, KHATIRKAR R, et al. Effect of cooling rate on transformation texture and variant selection during β→α transformation in Ti-5Ta-1.8Nb alloy[J]. Materials Science and Engineering A, 2010, 528(2): 549-553.

[11] 张 坤, 董洪波, 姜智勇, 等. 冷变形及时效工艺对TB8钛合金组织及性能影响的研究[J]. 稀有金属, 2019, 43(9): 904-910.

ZHANG Kun, DONG Hong-bo, JIANG Zhi-yong, et al. Effect of cold-deformation and aging process on microstructure and properties of TB8 titanium alloy[J]. Chinese Journal of Rare Metals, 2019, 43(9): 904-910.

[12] XU Tie-wei, LI Jin-shan, ZHANG Feng-shou, et al. Microstructure evolution during cold-deformation and aging response after annealing of TB8 titanium alloy[J]. Rare Metal Materials and Engineering, 2016, 45(3): 575-578.

[13] GUO W Y, XING H, SUN J, et al. Evolution of microstructure and texture during recrystallization of the cold-swaged Ti-Nb-Ta-Zr-0 alloy[J]. Metallurgical and Materials Transactions A, 2008, 39(3): 672-678.

[14] 麻西群, 于振涛, 程 军, 等. 镜架用Ti-25Nb-15Zr合金的力学性能及组织[J]. 稀有金属材料与工程, 2014, 43: 182-185.

MA Xi-qun, YU Zhen-tao, CHEN Jun, et al. Mechanical properties and microstructures of Ti-25Nb-15Zr alloy for spectacle frame[J]. Rare Metal Materials and Engineering, 2014, 43: 182-185.

[15] SADEGHPOUR S, ABBASI S M, MORAKABATI M. Deformation-induced martensitic transformation in a new metastable β titanium alloy[J]. Journal of Alloy and Compounds, 2015, 650: 22-25.

[16] MATSUMOTO H, WATANABE S, HANADA S. Microstructures and mechanical properties of metastable β TiNbSn alloys cold rolled and heat treated[J]. Journal of Alloys and Compounds, 2007, 439: 146-149.

[17] 张志辉, 王希哲, 商顺利, 等. 加工工艺对高弹高强钛合金弹性模量的影响[J]. 稀有金属, 2001, 25(1): 19-22.

ZHANG Zhi-hui, WANG Xi-zhe, SHAG Shun-li, et al. Influence of processing on elastic modulus for a titanium alloy with high strength and high elastic modulus[J]. Chinese Journal of Rare Metals, 2001, 25(1): 19-22.

[18] 胡 亮, 郭 顺, 孟庆坤, 等. 热-机械处理对亚稳β钛合金微观组织和力学性能的影响[J]. 稀有金属材料与工程, 2015, 44(1): 146-151.

HU Liang, GUO Shun, MENG Qing-kun, et al. Effect of thermo-mechanical treatment on microstructure and mechanical property in metastable β titanium alloys[J]. Rare Metal Materials and Engineering, 2015, 44(1): 146-151.

[19] 廉才浩, 易丹青, 刘会群, 等. 新型β钛合金Ti-25Nb-10Ta-1Zr-0.2Fe的固溶时效行为[J]. 稀有金属材料与工程, 2011, 40(9): 1633-1637.

LIAN Cai-hao, YI Dan-qing, LIU Hui-qun, et al. Aging response of Ti-25Nb-10Ta-1Zr-0.2Fe alloys for biomedical application[J]. Rare Metal Materials and Engineering, 2011, 40(9): 1633-1637.

[20] 李 群, 王 清, 李晓娜, 等. 三元β-Ti-Mo-Zr(Sn)合金析出相对弹性模量和力学性能的影 响[J]. 金属学报, 2013, 49(9): 1143-1147.

LI Qun, WANG Qing, LI Xiao-na, et al. Influences of phase precipitations of ternary β-Ti-Mo-Zr(Sn) alloys on Young’s modulus and mechanical properties[J]. Acta Metallurgica Sinica, 2013, 49(9): 1143-1147.

Effect of cold rolling on microstructure and properties of Ti-Nb-Zr alloy by aging treatment

HE Feng1, 2, YANG Shuang-ping1, CAO Ji-min2, WANG Ge2

(1. School of Metallurgical Engineering, Xi’an University of Architecture & Technology, Xi’an 710055, China;

2. Xi’an Seatell Metal Materials Co., Ltd., Xi’an 710018, China)

Abstract: The effects of thermo-mechanical treatment on microstructure and mechanical properties of Ti-25Nb-25Zr alloy were investigated by X-ray diffraction (XRD), optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM) and tension tests. The results show that the alloy exhibits excellent phase stability that no stress-induced α″ phase transition occurs during cold rolling and the plastic deformation mechanisms are related to dislocation slipping. With the increase of the cold deformation, the hardness and elastic modulus decrease gradually. It’s found that the phase composition of aging products for the solution treated and the cold-rolled alloys are β+ω and β+α phases at 300 ℃ for 2 h. The cold deformation produces much more dislocation defects and grain boundaries inhibits the nucleation of the ω phase, while α phase tends to nucleate at the dislocations and grain boundaries to promote the precipitation of α phase. Compared with solution and aging, the aging treatment after cold deformation has high strength and ideal elastic modulus can satisfy the requirements for dental implant.

Key words: Ti-25Nb-25Zr alloy; cold-rolling deformation; aging treatment; microstructure evolution; mechanical properties

Foundation item: Project(2019JLP-15) supported by the Joint Venture Foundation of Department of Science and Technology of Shaanxi Province, China

Received date: 2020-03-17; Accepted date: 2020-07-13

Corresponding author: YANG Shuang-ping; Tel: +86-13186143532; E-mail: Yang_sping@163.com

(编辑 王 超)

基金项目:陕西省科技厅企业联合项目(2019JLP-15)

收稿日期:2020-03-17;修订日期:2020-07-13

通信作者:杨双平,教授,博士;电话:13186143532,E-mail: Yang_sping@163.com