文章编号:1004-0609(2016)-09-1878-08

冷轧变形量对Al-Cu-Mg-Ag新型耐热铝合金抗腐蚀性能的影响

刘晓艳,王召朋,王佳琪,吴秀霞,高 飞

(河北工程大学 装备制造学院,邯郸 056038)

摘 要:采用晶间腐蚀和剥落腐蚀性能测试研究冷轧变形量(50%~90%)对Al-Cu-Mg-Ag耐热铝合金抗腐蚀性能的影响,结合金相显微分析和透射电子显微分析对其机理进行探讨。结果表明:增大冷轧变形量能够细化合金的再结晶晶粒,减小无沉淀析出带的宽度及其与基体的电位差。合金的抗晶间腐蚀性能主要由合金的晶界结构决定。增大冷轧变形量能够提高合金的抗晶间腐蚀性能。合金的抗剥落腐蚀性能由晶界结构和晶粒形貌决定。随着冷轧变形量的增大,合金的剥落腐蚀速率先增大后减小;冷轧变形量为50%的试样抗剥落腐蚀性能最佳。

关键词:Al-Cu-Mg-Ag铝合金;冷轧变形;腐蚀机理;无沉淀析出带;晶粒形貌

中图分类号:TG 174.3 文献标志码:A

Al-Cu-Mg系铝合金由于具有良好的耐热性能和较高的强度被广泛应用于航空工业。但该系铝合金主要用于100 ℃以下,温度超过100 ℃时,合金中的主要强化相θ′相发生粗化,合金的力学性能大幅度下降。近年来。一种含Ag的Al-Cu-Mg新型耐热铝合金得到学者们的广泛关注[1-3]。研究发现,在高铜镁比Al-Cu-Mg合金中添加微量Ag后,合金的时效析出序列发生改变,合金强化相由大量的θ′相和少量的S′相转变为大量的Ω相和少量的θ′相。Ω相具有良好的抗粗化能力,可以在200 ℃下长期存在而几乎不发生粗化[4]。Al-Cu-Mg-Ag合金作为一种新型耐热铝合金在航空航天领域有广阔的应用前景。

作为高强铝合金,2系合金普遍具有较高的腐蚀敏感性[5-8]。对其腐蚀性能的研究可为提高其综合使用性能提供依据。晶间腐蚀和剥落腐蚀是变形铝合金常见的两种腐蚀形式。前期研究结果[6]表明,热处理工艺对Al-Cu-Mg-Ag合金的腐蚀性能影响很大。其中晶界结构是决定合金电化学腐蚀性能的一个重要因素。Al-Cu-Mg-Ag合金PFZ、晶界平衡相(θ)和基体这3个不同结构的自腐蚀电位符合φMatrix>φθ>φPFZ。具有最低腐蚀电位的PFZ决定合金的耐蚀性。随时效时间的延长,晶界PFZ宽度逐渐增大,腐蚀通道加宽。另一方面,时效初期,PFZ中仍有大量的溶质原子,PFZ电位较高。随时效时间的延长,PFZ中越来越多的溶质原子参与晶界析出相的粗化,PFZ电位逐渐减小,其与基体的电位差逐渐增大。受以上两个因素的影响,Al-Cu-Mg-Ag合金的晶间腐蚀和剥落腐蚀敏感性随时效时间的延长逐渐增大。

剥落腐蚀和晶间腐蚀均属于电化学腐蚀,但剥落腐蚀除了受晶界结构的影响,还受晶粒形貌的影响。发生剥落腐蚀后,在晶界会产生一定的楔入力,随着腐蚀时间的延长,逐步导致合金鼓泡、剥落。变形合金中晶粒的纵横比,或者说晶粒的变形程度或再结晶程度,对合金剥落腐蚀性能影响很大。夏卿坤等[9]研究表明,晶粒纵横比越大,Al-Zn-Mg-Cu合金的剥落腐蚀敏感性越大。刘瑛等[10]在研究预变形对Al-Zn-Mg-Cu合金的剥落腐蚀性能的影响时也发现了这个现象。因此,对变形铝合金腐蚀性能进行研究时,晶界结构和晶粒形貌是两个研究重点内容。

研究表明,轧制变形量对铝合金的组织与性能影响很大[11-14]。目前未见有关于轧制变形量对Al-Cu- Mg-Ag组织与性能的影响的报道。为此,本文作者以Al-Cu-Mg-Ag新型耐热铝合金为研究对象,开展了冷轧变形量对合金组织与腐蚀性能的影响的研究,采用剥落腐蚀性能测试获得了冷轧变形量对合金腐蚀性能的影响规律,并结合金相显微分析和透射电子显微分析技术对其机理进行探讨。本研究可以为Al-Cu- Mg-Ag新型耐热铝合金的轧制工艺的优化和工程应用提供理论和实验依据。

1 实验

采用铸锭冶金的方法制备了Al-5.3Cu-0.8Mg- 0.5Ag-0.3Mn–0.15Zr合金。合金铸锭经500 ℃、24 h均匀化处理后进行铣面,然后在460 ℃下热轧至6 mm,经过400 ℃、2 h中间退火后进行冷轧。冷轧变形量为50%、80%、90%。将冷轧薄板于515 ℃下固溶处理1.5 h,最后对合金在185 ℃下进行时效处理。

取峰时效态合金进行晶间腐蚀和剥落腐蚀性能测试,试验标准和腐蚀等级评价均分别参照ASTM G110[15]和ASTM/G 34-01[16]。

采用TMVS-IS型电子显微硬度计对不同变形量的试样进行硬度测试。利用Olympus DSX500型全自动光学数码显微镜对试样的金相组织进行分析。TEM组织观察在ECNAI G2F30型电镜上进行。透射电镜试样采用离子减薄技术制备。

2 实验结果

2.1 时效硬化曲线分析

图1所示为不同冷轧变形量Al-Cu-Mg-Ag合金的时效硬化曲线。从图1中可以看出,不同冷轧变形量的Al-Cu-Mg-Ag合金均具有明显的时效硬化现象。冷轧变形量为50%试样的时效初期硬度随时效时间的延长迅速增大,时效4 h后,硬度达到峰值,为169 HV。随着变形量的增大,合金的峰值硬度明显增大,冷轧变形量为80%和90%的试样均在6 h后达到峰值,峰值硬度分别为175 HV和179HV。图1说明增大冷轧变形量能够提高Al-Cu-Mg-Ag合金的峰值硬度。

图1 不同冷轧变形量Al-Cu-Mg-Ag合金时效硬化曲线

Fig. 1 Aging hardening curves of Al-Cu-Mg-Ag alloy with different cold rolling deformation amounts

2.2 晶间腐蚀行为分析

图2所示为不同冷轧变形量Al-Cu-Mg-Ag合金在晶间腐蚀液中浸泡6 h后的截面照片。从图2中可以看出,不同变形量的合金均发生了不同程度的晶间腐蚀。冷轧变形量为50%的试样腐蚀深度较深(见图2(a)),并且有大量晶粒从基体中脱落(见图2(b))。随冷轧变形量的增大,合金的晶间腐蚀程度减轻。冷轧变形量为80%的试样,腐蚀深度减小(见图2(c)),并且表面整体腐蚀情况有所改善(见图2(d))。冷轧变形量为90%时,合金的腐蚀深度最小(见图2(e)),并且表面仅有少量粒子脱落(见图2(f))。

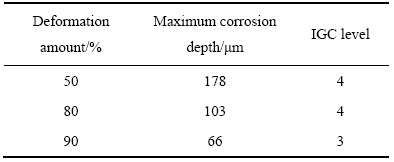

为了进一步比较不同变形量Al-Cu-Mg-Ag合金的晶间腐蚀情况,采用光学显微镜对合金的最大腐蚀深度进行定量测量,并根据试验标准对其进行腐蚀等级评价,其结果列于表1。冷轧变形量为50%合金的最大腐蚀深度为178 μm,腐蚀等级为4。随冷轧变形量的增大,合金的最大腐蚀深度逐渐减小,冷轧变形量为80%时,合金的最大腐蚀深度减小至103 μm。冷轧变形量为90%的合金最大腐蚀深度仅为66 μm,腐蚀等级为3。

晶间腐蚀性能测试结果表明,增大冷轧变形量能够提高Al-Cu-Mg-Ag合金抗晶间腐蚀性能。

2.3 剥落腐蚀行为分析

图3所示为不同冷轧变形量Al-Cu-Mg-Ag合金在剥落腐蚀液中浸泡不同时间后的宏观照片。从图3中可以看出,冷轧变形量对合金的剥落腐蚀行为影响很大。浸泡36 h后,3个不同变形量的试样均发生了不同程度的剥落腐蚀。变形量为50%的试样表面出现了鼓泡和少量的剥落(见图3(a))。变形量增大至为80%时,试样表面剥落面积增大,腐蚀程度加重(见图3(c))。变形量进一步增大至90%时,腐蚀程度略有减轻(见图3(e))。浸泡72 h后,3个试样的剥落腐蚀程度进一步加重(见图3(b)、(d)、(f))。其中变形量为80%的试样腐蚀程度最严重,表面呈粉状剥落(见图3(d))。

为了进一步比较冷轧变形量对Al-Cu-Mg-Ag合金剥落腐蚀行为的影响,根据ASTM标准对浸泡不同时间的试样进行腐蚀等级评价,结果列于表2(表中N代表没有明显的腐蚀;P代表点蚀;EA、EB、EC和ED均代表发生剥落腐蚀,且腐蚀逐渐加重;“-”和“+”分别代表腐蚀较轻或较严重)。从表2中可以看出,变形量对合金剥落腐蚀性能影响很大,其中变形量为80%的试样剥落腐蚀发展最快,合金的耐蚀性最差。

图2 不同冷轧变形量Al-Cu-Mg-Ag晶间腐蚀截面形貌

Fig. 2 Cross-section corrosion morphologies of Al-Cu-Mg-Ag with different cold rolling deformation amounts after IGC

表1 不同冷轧变形量Al-Cu-Mg-Ag合金晶间腐蚀结果

Table 1 IGC results of Al-Cu-Mg-Ag alloy with different cold rolling deformation amounts

2.4 金相组织分析

图4所示为冷轧态和固溶态Al-Cu-Mg-Ag合金的金相照片。从图4中可以看出,冷轧后,金相组织均为沿轧向分布的显微组织。冷轧变形量为50%的试样中可以观察到被沿轧向拉长的晶粒(见图4(a))。变形量越大,变形晶粒越细小。变形量为80%时,几乎只能观察到纤维组织,合金中仅有少量变形晶粒(见图4(c))。变形量为90%时,合金中仅有沿轧向分布的纤维组织(见图4(e))。固溶处理后,合金均发生了再结晶。再结晶晶粒尺寸随冷轧变形量的增大而逐渐减小(见图4(b)、(d)、(f))。

图3 不同冷轧变形量Al-Cu-Mg-Ag合金在剥落腐蚀液中浸泡不同时间后的宏观照片

Fig. 3 Macroscopic pictures of Al-Cu-Mg-Ag with different cold rolling deformation amount after immersion in EXCO solution for different time

表2 不同冷轧变形量和腐蚀时间下Al-Cu-Mg-Ag合金剥落腐蚀结果

Table 2 EXCO results of Al-Cu-Mg-Ag alloy at different cold rolling deformation amounts and corrosion times

2.5 透射电子显微组织分析

图5所示为峰时效态Al-Cu-Mg-Ag合金的TEM像。图5(a)、(c)、(e)沿近<110>α方向入射。从图5中可以看出,不同冷轧变形量Al-Cu-Mg-Ag合金中均析出了大量尺寸细小的Ω相,变形量对合金晶内析出相尺寸和数量影响不大(见图5(a)、(c)、(e)),而对晶界结构影响较大(见图5(b)、(d)、(f))。变形量为50%的试样,晶界析出相与晶内相比较为粗大,晶界附近出现了较宽的PFZ(见图5(b))。随冷轧变形量的增大,PFZ宽度逐渐减小。变形量增大至90%时,PFZ宽度非常小,晶界和晶内析出相的界线不明显(见图5(f))。

3 分析与讨论

由以上实验结果可以看出,冷轧变形量对Al-Cu-Mg-Ag合金晶间腐蚀和剥落腐蚀性能影响很大。铝合金晶间腐蚀和剥落腐蚀均属于电化学腐蚀,不同结构的腐蚀电位对其电化学腐蚀行为起关键作用。根据前期研究结果[6],时效态Al-Cu-Mg-Ag合金3个不同的结构为基体(Matrix)、晶界平衡相θ(Al2Cu)和PFZ,三者的腐蚀电位关系符合φMatrix>φθ>φPFZ。具有最低腐蚀电位的PFZ在电化学腐蚀中作为阳极优先被腐蚀,因此PFZ的结构是决定Al-Cu-Mg-Ag合金晶间腐蚀和剥落腐蚀性能的一个重要因素。

图4 不同冷轧变形量Al-Cu-Mg-Ag合金的金相组织

Fig. 4 OM microstructures of Al-Cu-Mg-Ag with different cold rolling deformation amounts

PFZ是由于晶界上粗大第二相的形核与长大形成的。与晶内相比,晶界析出相更粗大。一方面,这是由于晶界处空位较多,溶质原子易于通过空位扩散从基体中析出;另一方面,晶界具有一定的晶格畸变能,可为第二相的析出提供一定的能量。晶界粗大第二相的形核与长大均需要消耗晶界附近的溶质原子,使得晶界附近几乎没有第二相析出,在晶界附近形成一定宽度的无沉淀析出带(PFZ)。

从图4中可以看出,随冷轧变形量的增大,合金PFZ宽度逐渐减小。变形量越大,合金的再结晶晶粒越小,晶界越多,淬火后分布到每一个晶界的空位数量越少,晶界析出相依靠空位扩散进行形核与长大的优势与晶内析出相相比降低。因此,随冷轧变形量的增大,晶界析出相逐渐减少,消耗晶界附近的溶质原子减少,PFZ变窄,腐蚀通道变窄,Al-Cu-Mg-Ag合金的电化学腐蚀性能逐渐提高。PFZ内可能存在较多的溶质原子,会使PFZ电位升高,其与基体的电位差减小,也可能会导致合金的电化学腐蚀性能随冷轧变形量的增大而逐渐提高。

图5 不同冷轧变形量峰时效态Al-Cu-Mg-Ag合金的TEM像

Fig. 5 TEM images of peak-aged Al-Cu-Mg-Ag with different cold rolling deformation amounts

另一方面,晶粒形貌对合金的电化学腐蚀性能也有一定的影响。由图4可知,随冷轧变形量的增大,再结晶晶粒逐渐减小。变形量越大,冷轧态合金晶粒变形越严重,变形储能越大,在随后的固溶处理过程中,合金的再结晶驱动力越大,再结晶程度越大。变形量越大,冷轧态合金晶粒横纵比越大,固溶处理后,依附亚晶界形核的再结晶晶粒越小,合金内形成的微电池越多,从而降低合金的抗电化学腐蚀性能。

从Al-Cu-Mg-Ag合金晶间腐蚀实验结果中可以看出,随冷轧变形量的增大,合金的抗晶间腐蚀性能逐渐提高。说明晶界结构对Al-Cu-Mg-Ag合金的晶间腐蚀性能起主要作用。

对于剥落腐蚀,随冷轧变形量的增大,PFZ宽度越小,PFZ与基体的电位差越小,合金的抗剥落腐蚀性能逐渐提高。另一方面,随冷轧变形量的增大,再结晶晶粒逐渐减小,微电池数量增多,腐蚀后合金单位面积内的楔入力越大,合金更容易发生鼓泡和剥落。受以上两个因素的影响,Al-Cu-Mg-Ag合金的抗剥落腐蚀性能先降低后提高。冷轧变形量为50%试样的抗剥落腐蚀性能最好。

4 结论

1) 增大冷轧变形量,能够提高Al-Cu-Mg-Ag合金的峰时效硬度,细化合金再结晶晶粒,减小晶界PFZ宽度,而对合金晶内析出相影响不大。

2) PFZ宽度的减小能够提高合金的抗电化学腐蚀性能,细化再结晶晶粒能够使合金的微电池数量增多,降低合金的抗电化学腐蚀性能。受以上两个因素的影响,随着冷轧变形量的增大(50%~90%),Al-Cu-Mg-Ag合金的抗晶间腐蚀性能逐渐提高,抗剥落腐蚀性能先降低后提高,冷轧变形量为50%的试样抗剥落腐蚀性能最佳。

REFERRENCES

[1] BAI Song, ZHOU Xuan-wei, LIU Zhi-yi, YING Pu-you, LIU Meng, ZENG Su-min. Atom probe tomography study of Mg-dependent precipitation of Ω phase in initial aged Al-Cu-Mg-Ag alloys[J]. Materials Science and Engineering A, 2015, 637: 183-188.

[2] 刘晓艳, 潘清林, 陆智伦, 曹素芳, 何运斌, 李文斌. Al-Cu-Mg-Ag耐热铝合金高温蠕变行为[J]. 金属学报, 2011, 47(1): 61-68.

LIU Xiao-yan, PAN Qing-lin, LU Zhi-lun, CAO Su-fang, HE Yun-bin, LI Wen-bin. Creep behavior of Al-Cu-Mg-Ag heat-resistant alloy at elevated temperatures[J]. Acta Metallurgica Sinica, 2011, 47(1): 61-68.

[3] BAI Song, ZHOU Xuan-wei, LIU Zhi-yi, XIA Peng, LIU Meng, ZENG Su-min. Effects of Ag variations on the microstructures and mechanical properties of Al-Cu-Mg alloys at elevated temperatures[J]. Materials Science and Engineering A, 2014, 611: 69-76.

[4] HUTCHINSON C R, FAN X, PENNYCOOK S J, SHIFLETG J. On the origin of the high coarsening resistance of Ω plates in Al-Cu-Mg-Ag alloys[J]. Acta Materialia, 2001, 49(14): 2827-2841.

[5] LIU Xiao-yan, LI Meng-jie, GAO Fei, LIANG Shun-xing, ZHANG Xi-liang, CUI Hao-xuan. Effects of aging treatment on the intergranular corrosion behavior of Al-Cu-Mg-Ag alloy[J]. Journal of Alloys and Compounds, 2015, 639: 263-267.

[6] 齐 浩, 刘晓艳, 梁顺星, 张喜亮, 崔好选, 高 飞, 陈啟怀. Al-Cu-Mg-Ag 新型耐热铝合金的抗腐蚀性能[J]. 中国有色金属学报, 2015, 25(11): 3033-3039.

QI Hao, LIU Xiao-yan, LIANG Shun-xing, ZHANG Xi-liang, CUI Hao-xuan, GAO Fei, CHEN Qi-huai. Corrosion resistance of Al-Cu-Mg-Ag new heat-resistant Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3033-3039.

[7] LIN Y C, LIU Guan, CHEN Ming-song, HUANG Yuan-chun, CHEN Zhi-guo, MA Xiang, JIANG Yu-qiang, LI Jia. Corrosionresistance of a two-stage stress-agedAl-Cu-Mgalloy: Effects of stress-aging temperature[J]. Journal ofAlloysand Compounds,2016, 657: 855-865.

[8] LIN Y C, LIU Guan, CHEN Ming-song, ZHANG Jin-long, CHEN Zhi-guo, JIANG Yu-qiang, LI Jia. Corrosionresistance of a two-stage stress-agedAl-Cu-Mgalloy: Effects of external stress[J]. Journal of Alloys and Compounds, 2016, 661: 221- 230.

[9] 夏卿坤, 刘志义, 林亮华, 刘 煜, 许晓嫦, 陈 旭. 冷轧变形对Al-Zn-Mg-Cu铝合金剥落腐蚀性能的影响[J]. 材料热处理学报, 2012, 33(S2): 60-64.

XIA Qing-kun, LIU Zhi-yi, LIN Liang-hua, LIU Yu, XU Xiao-chang, CHENG Xu. Exfoliation corrosion behavior of an Al-Zn-Mg-Cu alloy during cold rolling[J]. Transactions of Materials and Heat Treatment, 2012, 33(S2): 60-64.

[10] 刘 瑛, 张新明, 周古昕, 刘 波, 李慧中, 高 慧, 李惠杰. 预变形量对2519铝合金抗剥落腐蚀性能的影响[J]. 材料热处理学报, 2006, 27(6): 61-65, 140.

LIU Ying, ZHANG Xin-ming, ZHOU Gu-xin, LIU Bo, LI Hui-zhong, GAO Hui, LI Hui-jie. Effect of predeformation amount on exfoliation corrosion resistance of 2519 aluminium alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 61-65, 140.

[11] WANG Xiao-feng, GUO Ming-xing, ZHANG Yan, XING Hui, LI Yong, LUO Jin-ru, ZHANG Ji-shan, ZHUANG Lin-zhong. The dependence of microstructure, texture evolution and mechanical properties of Al-Mg-Si-Cu alloy sheet on final cold rolling deformation[J]. Journal of Alloys and Compounds, 2016, 657: 906-916.

[12] 张新明, 张 翀, 刘胜胆, 朱航飞. 轧制变形量对7A55铝合金淬火敏感性的影响[J]. 中南大学学报(自然科学版), 2007, 38(4):589-594.

ZHANG Xin-ming, ZHANG Chong, LIU Sheng-dan, ZHU Hang-fei. Effect of rolling reduction on quench sensitivity of aluminium alloy 7A55[J]. Journal of Central South University (Science and Technology), 2007, 38(4): 589-594.

[13] WANG Bo, CHEN Xian-hua, PAN Fu-sheng, MAO Jian-jun, FANG Yong. Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2481-2489.

[14] 汪 波, 易丹青, 陈宇强, 王 斌, 李泽英. 2E12铝合金在冷轧和退火过程中织构和显微组织的演变[J]. 中国有色金属学报, 2013, 23(11): 3064-3074.

WANG Bo, YI Dan-qing, CHEN Yu-qiang, WANG Bin, LI Ze-ying. Evolution of texture and microstructure of 2E12 aluminum alloy during cold rolling and annealing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3064-3074.

[15] ASTM G110. Standard practice for evaluating intergranular corrosion resistance of heat treatable aluminum alloys by immersion in sodium chloride + hydrogen peroxide solution[S].

[16] ASTM G34-01. Standard test method for exfoliation corrosion susceptibility in 2XXX and 7XXX series aluminum alloys (EXCO Test)[S].

Effects of cold rolling deformation amount on corrosion resistance of Al-Cu-Mg-Ag new heat-resistant Al alloy

LIU Xiao-yan, WANG Zhao-peng, WANG Jia-qi, WU Xiu-xia, GAO Fei

(College of Equipment Manufacture, Hebei University of Engineering, Handan 056038, China)

Abstract: The effects of cold rolling deformation amount (50%-90%) on the corrosion resistance of Al-Cu-Mg-Ag heat-resistant Al alloy were investigated by intergranular corrosion (IGC) tests and exfoliation corrosion (EXCO) tests. The corrosion mechanism was researched by optical microscopy (OM) and transmission electron microcopy (TEM) analyses. The results show that with increasing the cold rolling deformation amount, the recrystallized grains are refined, the width of precipitation free zone (PFZ) and the potential difference between PFZ and the matrix decrease. The IGC resistance of the alloy is mainly determined by the microstructure of grain boundary, which is enhanced with increasing the cold rolling deformation amount. The EXCO resistance of the alloy is mainly determined by the microstructure of the grain boundary and the recrystallized grain morphology. The EXCO resistance of Al-Cu-Mg-Ag alloy decreases, and then increases with the increase of the cold rolling deformation amount. The alloy with deformation amount of 50% possesses the best EXCO resistance.

Key words: Al-Cu-Mg-Ag Al alloy; cold rolling deformation; corrosion mechanism; precipitation free zone; grain morphology

Foundation item: Project(E2013402056) supported by the Natural Science Foundation of Hebei Province, China; Project(QN2014002) supported by the Science and Technology Research Foundation of Hebei Education Department for Young Teachers University, China; Project(1321110085-4) supported by the Science and Development Projects of Handan City, China

Received date: 2016-03-11; Accepted date: 2016-06-18

Corresponding author: LIU Xiao-yan; Tel: +86-310-8577971; E-mail: x918y@126.com

(编辑 李艳红)

基金项目:河北省自然科学基金资助项目(E2013402056);河北省高等学校科学技术研究项目(QN2014002);邯郸市科学技术研究与发展计划项目(1321110085-4)

收稿日期:2016-03-11;修订日期:2016-06-18

通信作者:刘晓艳,副教授,博士;电话:0310-8577971;E-mail: x918y@126.com