DOI: 10.11817/j.issn.1672-7207.2015.04.012

水基纳米WS2等温模锻润滑剂的制备与应用

石琛1, 2, 3,毛大恒2, 3,杨续跃1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

3. 中南大学 机电工程学院,湖南 长沙,410083)

摘要:为了制备出适于等温模锻的水基纳米WS2润滑剂,从润湿性、稳定性和润滑性能方面进行系列组分配比实验,并将制备的水基纳米WS2润滑剂应用于7085铝合金的等温模锻试验。研究结果表明:水基纳米WS2润滑剂各组分的最佳质量分数为8.0% PAO6+2.0%复合表面活性剂+9.0%纳米WS2+81.0%水,其中复合表面活性剂为Span-80,Tween-80和OP-10按43:43:14的质量比复配而成;在等温模锻试验中,水基纳米WS2润滑剂在高温模具表面成膜致密,颗粒分布均匀,模锻时所需锻压力较低,脱模时所需脱模力较低,且无黏模、飞边和裂纹现象,综合应用效果优于水基石墨润滑剂和油基石墨润滑剂。

关键词:WS2;纳米;等温模锻;制备

中图分类号:TG356.16 文献标志码:A 文章编号:1672-7207(2015)04-1253-07

Preparation of water-based nano-WS2 isothermal forging lubricant and its application

SHI Chen1, 2, 3, MAO Daheng2, 3, YANG Xuyue1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance and Complex Manufacturing,

Central South University, Changsha 410083, China;

3. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: In order to prepare water-based nano-WS2 lubricant for isothermal forging, a series of experiments on wettability, stability and lubricating property were done to determine the optimum parametric mixed batch, and then the water-based nano-WS2 lubricant prepared was applied to isothermal forging of 7085 aluminium alloy. The results show that the optimum mass fraction of water-based nano-WS2 lubricant is PAO6 8.0%, compound surfactants 2.0%, nano-WS2 9.0% and water 81.0%, thereinto the mass ratio of compound surfactant is 43:43:14. During the isothermal forging experiment, water-based nano-WS2 lubricant forms film on the surface of hot mould, where the nano-particles are distributed evenly, and that can reduce the forging pressure and demoulding force, eliminate the phenomena of mold sticking, fins and cracks. The comprehensive application effect of water-based nano-WS2 lubricant is better than that of water-based graphitic lubricant or oil-based graphitic lubricant.

Key words: WS2; nanometer; isothermal forging; preparation

等温模锻是在使模具和工件保持等温的情况下以较慢的成形速度来实现模锻成形的方法,由于工件在高温下以较低的应变速率变形,变形材料能够充分再结晶,从而可以克服加工硬化的影响[1-3],因此,非常适于成形加工结构复杂、强度高的零件。在模锻成形过程中,摩擦会阻碍金属流动,使锻压载荷升高,消耗变形能,导致工件组织不均匀,模膛充型不满,并降低模具使用寿命[4-5],所以,必须使用润滑剂。目前,市场上针对热模锻的润滑剂类型单一,主要为石墨系润滑剂[6-7]。石墨具有良好的高温润滑性能,但石墨是热的良导体,其隔热保温性能较差,而且石墨在金属表面的附着性能较差,这些都制约着石墨润滑剂在等温模锻中的应用。WS2(二硫化钨)是一种结构类似于石墨的层片状固体润滑材料,具有优良的耐高温、抗极压性能,对金属表面的吸附能力良好,而且热导率较低。WS2最早被应用于美国水手号太空飞船关键部位的润滑[8-9],笔者近年来将其用于制备高温极压润滑 脂[10-11]、节能型发动机润滑油[12-13],取得了良好的应用效果。本文拟研究制备一种适于等温模锻的水基纳米WS2润滑剂,并将其应用于高强铝合金的等温模锻工艺中,以期获得一种节能环保的等温模锻润滑剂。

1 实验

1.1 实验材料

1.1.1 基础油

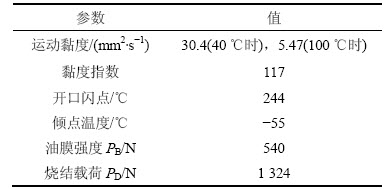

选用黏温性能优良的聚α烯烃PAO6作为基础油,其性能参数如表1所示。

1.1.2 表面活性剂

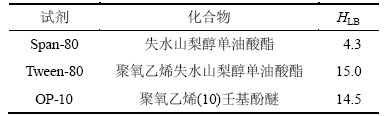

将基础油均匀分散在水中并形成乳化液,需要采用表面活性剂进行乳化,非离子型表面活性剂具有乳化效率高、对水质无要求等优点[14-15]。本文选用亲水性强的OP-10和Tween-80与亲油性强的Span-80进行复配,以获得能稳定储存的乳化液。表2所示为3种非离子型表面活性剂的HLB (亲水亲油平衡值)。

表1 基础油的性能参数

Table 1 Performance parameters of base oil

1.1.3 纳米WS2

本文所用纳米WS2颗粒采用多能场复合湿式粉碎法细化微米级WS2颗粒制备。纳米WS2呈层片状结构,粒度分布在40~300 nm之间,平均粒度为59 nm。

1.1.4 比对润滑剂

为了考察制备的水基纳米WS2润滑剂的应用效果,选购目前常用的模锻润滑剂(油基石墨润滑剂、水基石墨润滑剂)进行对比分析。

表2 试验用表面活性剂的HLB

Table 2 HLB of surfactant

1.2 实验过程

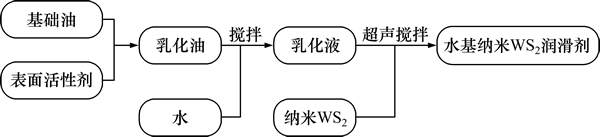

水基纳米WS2润滑剂的制备过程如图1所示。

水基纳米WS2润滑剂制备成功后,在40 MN等温模锻液压机进行等温模锻应用试验,所用模具材料为5CrNiMo,锻件材料为7085铝合金,锻件变形量为20%~78%。试验过程为下料—模具预热—喷涂润滑剂—工件加热保温—锻压—出模,润滑剂喷涂温度为120~150 ℃,厚度为0.1~0.2 mm,锻压成形温度为480 ℃,保温时间为5 min,最大成型载荷为3.5×107 N。

1.3 测试方法

在JY-82接触角测定仪上测得润湿角;采用吊环法,在JZHY2-180界面张力仪上测定表面张力;采用MRS-10A型四球摩擦试验机进行摩擦学性能测试试验。试验用钢球为国家Ⅱ级标准GCr15轴承钢球,直径为12.7 mm,硬度(HRC)为59~61;油滴粒径在激光衍射粒度仪上测得;实验中用于搅拌分散处理的超声波发生器,频率为20 kHz,功率为500 W。

图1 水基纳米WS2润滑剂的制备流程

Fig. 1 Preparation flow diagram of water-based nano-WS2 lubricant

2 结果分析与讨论

2.1 水基纳米WS2润滑剂的制备

2.1.1 复合表面活性剂配比

HLB(亲水亲油平衡值)是衡量表面活性剂分子中亲水基团与亲油基团的平衡关系和判别表面活性剂的亲油或亲水程度的量,基础油的乳化所需的HLB 应与所用表面活性剂的HLB 相匹配才能获得稳定的乳化液,其过高或过低会导致表面活性剂完全溶于水相或油相中,很少存在于界面上,难以达到降低界面张力的效果,造成表面析油明显,油水分层速度较快,无法形成稳定的乳化液。

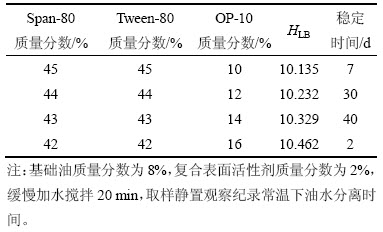

表3所示为Span-80,Tween-80和OP-10进行复配得到不同HLB后乳化液的储存稳定性比较,其中,复合后的HLB 由如下公式计算得出[16]:

式中:HLBi为混合体系中单一表面活性剂的HLB;ωi为表面活性剂在混合物中所占的质量分数。从表3可看出:当HLB 为10.135时,PAO6基础油虽然可以被乳化,但乳化液稳定时间较短;当HLB 增加到10.232和10.329时,乳化液稳定时间显著提高;当HLB 为10.329时,稳定时间达到40 d,说明此时乳化效果最好;当HLB 继续增加到10.462时,乳化液在较短时间内出现油水分离现象,稳定时间明显下降。

表3 不同HLB 下乳化液储存稳定性能

Table 3 Stability performance of O/W emulsified liquids with different HLB

根据上述分析可知:乳化PAO6基础油所需的较优HLB 为10.329,此时Span-80,Tween-80和OP-10的复配质量比为43:43:14。

2.1.2 复合表面活性剂添加量

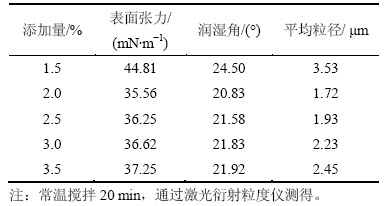

润湿性和稳定性是乳化液的重要性能,也是保障乳化液润滑功能的基础。润湿性可通过润湿角和表面张力衡量,稳定性可通过油滴平均粒径评定。

不同复合表面活性剂添加量下乳化液的表面张力、润湿角和油滴平均粒径见表4。从表4可以看出:随着复合表面活性剂添加量的增加,乳化液的表面张力、润湿角和油滴平均粒径均下降,但达到最小值后又略微增加,其中当质量分数为2.0%时,乳化液表面张力、润湿角和平均粒径达到最小,其值分别为35.56 mN/m,20.83°和1.72 μm。这可能是因为当复合表面活性剂添加量较少时,表面活性剂在界面膜的吸附强度不高,油滴粒径较粗大,形成乳化液稳定性差;当表面活性剂添加量达到最佳值时,油水界面膜强度得到增强,乳化液的稳定时间延长,表面张力和润湿角也达到最小值;而当继续增加表面活性剂的用量时,油滴粒径开始逐渐增加,说明过量的表面活性剂造成絮凝,不利于乳化液的稳定。

表4 不同复合表面活性剂添加量的乳化液的润湿性和稳定性

Table 4 Wettability and stability of O/W emulsified liquids with different compound surfactant contents

综合上述分析可知:当复合表面活性剂的质量分数为2.0%时,乳化液具有最佳的润湿稳定性能。

2.1.3 乳化油添加量

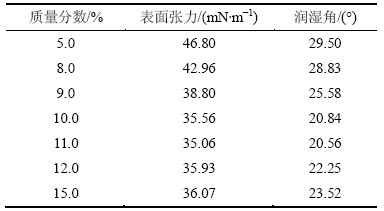

乳化油添加量是决定乳化液稳定性和润滑性能的关键因素,一般而言,乳化油添加量越小,乳化液的冷却效果越好,但过低的乳化油添加量可能对润滑剂在模具表面铺展成膜不利,润滑效果也会随之下降[16-18]。

表5所示为不同乳化油添加量的乳化液表面张力和润湿角。由表5可知:随着乳化油质量分数的增加,乳化液的表面张力和润湿角呈现先降低后增加的变化趋势;当乳化油质量添加量为11.0%时达到最小值,说明在该浓度下乳化液铺展润湿性能最好,而当乳化液油质量分数为10.0%时的表面张力和润湿角与11.0%相差不大。

表5 不同乳化油添加量乳化液的表面张力和润湿角

Table 5 Surface tension and wetting angle of O/W emulsified liquids with different emulsified oil content

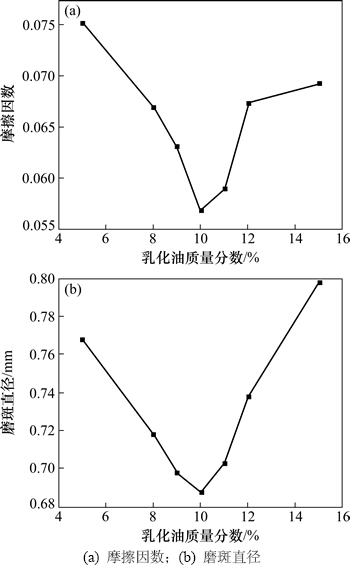

图2所示为乳化液的润滑性能随乳化油添加量的变化曲线。由图2可知:随着乳化油添加量的增加,乳化液摩擦因数和磨斑直径都存在先减后增的趋势;当乳化油质量分数为10.0%时达到最小值,且与质量分数为11.0%时相比相差较大。

图2 乳化液润滑性能随乳化油添加量的变化曲线

Fig. 2 Lubricating performance variation of O/W emulsified liquids with emulsified oil content

综合考虑润湿性能与润滑性能,最终确定乳化油的质量分数为10.0%。

2.1.4 纳米WS2添加量

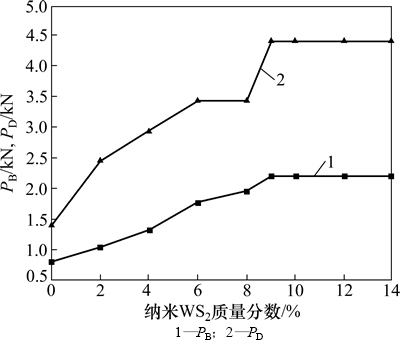

图3所示为乳化液的油膜强度(PB)与烧结载荷(PD)随纳米WS2添加量的变化曲线。从图3可看出:乳化液的PB和PD均随纳米WS2颗粒质量分数的增大而增大,当增大到一定值后保持恒定;当纳米WS2质量分数为9.0%时,乳化液的PB和PD达到最大值,分别为2.207 kN和4.410 kN,较原乳化液提高了1.75和2.5倍,表明添加纳米WS2后乳化液的的极压性能得到显著提高。这主要是因为随着纳米WS2添加量的增加,摩擦副表面的纳米WS2吸附膜越致密完整,在短时间内需要更大的负载才能使润滑膜破裂或导致摩擦表面烧结。

图3 极压性能随纳米WS2添加量的变化曲线

Fig. 3 Extreme pressure property variation of O/W emulsified liquids with nano-WS2 content

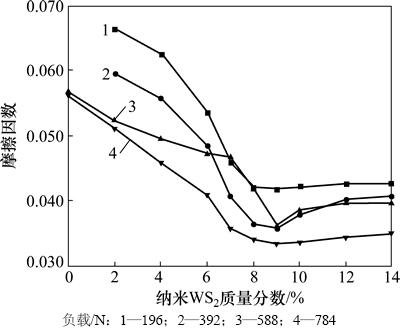

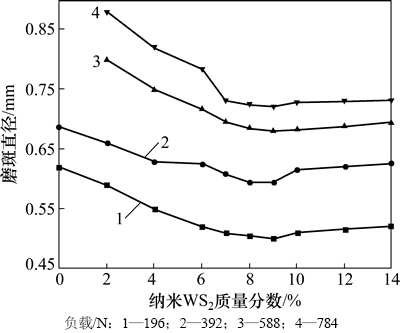

图4和图5所示分别为不同负载下纳米WS2添加量对乳化液减摩性能、抗磨性能的影响曲线。从图4和图5可以看出:在不同负载下,乳化液的平均摩擦因数、磨斑直径均随着纳米WS2添加量的增加而出现先降低后升高的趋势,但在高载荷下的降低幅度比低载荷下的降低幅度大,而当质量分数为9.0%时都达到最小值。这是因为在低载荷下摩擦副间同时存在流体摩擦和边界摩擦,乳化液中吸附于摩擦副表面的极性基团起减摩抗磨作用,阻碍了纳米WS2膜的形成。当极性基团的化学吸附膜因磨损破裂时,在摩擦热作用下,纳米WS2的活性得到提高,并逐步在摩擦副新生表面生成纳米WS2吸附膜;随着纳米WS2添加量的增加,吸附膜越致密完整,润滑效果也越好,在高载荷下边界摩擦占据主导地位,摩擦生热较快,纳米WS2颗粒活性较高。减摩抗磨主要依靠纳米WS2在摩擦副表面形成的吸附层来实现。润滑性能随纳米WS2添加量的增加而显著提高。但当纳米WS2质量分数超过9.0%时,过量的纳米WS2碰撞聚集而导致乳化液润滑性能下降。

图4 摩擦因数随纳米WS2添加量的变化曲线

Fig. 4 Relationship between friction coefficient of O/W emulsified liquids and nano-WS2 content

图5 磨斑直径随纳米WS2添加量的变化曲线

Fig. 5 Relationship between wear scar diameter of O/W emulsified liquids and nano-WS2 content

综上可知:纳米WS2质量分数为9.0%时对乳化液润滑性能的改善效果最明显。

2.1.5 水基纳米WS2润滑剂的制备

通过上述试验得到水基纳米WS2润滑剂各组分的最佳质量分数配比为8.00% PAO6+2.00%复合表面活性剂(0.86% Span-80+0.86% Tween-80+0.28% OP-10)+ 9.00%纳米WS2+81.00%水。将表面活性剂、基础油混合制成乳化油后加入水中搅拌得到乳化液,再加入纳米WS2颗粒,经500 W功率超声波分散处理120 s后,制备出水基纳米WS2润滑剂。

2.2 水基纳米WS2润滑剂在等温模锻中的应用

2.2.1 成膜性能分析

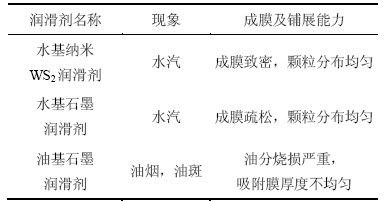

表6所示为模锻润滑剂在热模具表面成膜的试验结果。从表6可以看出:在试验工况下,水基纳米WS2润滑剂在模具表面形成的吸附膜成膜致密,颗粒分布均匀;而水基石墨以疏松态附着在模具表面;油基石墨喷涂后,由于基础油的闪点较低,油分烧损严重,并在模具表面形成油斑。由此可见:水基纳米WS2在模具表面的附着性能比水基石墨的优,而且在模锻过程中不产生油烟、油斑,环保性能比油基石墨的优。

表6 模锻润滑剂在热模具表面成膜性能

Table 6 Film-forming property of isothermal forging lubricant on surface of hot mould

2.2.2 对锻压力的影响分析

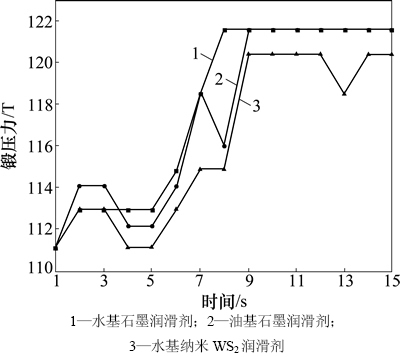

为考察不同模锻润滑剂对锻压力的影响,进行多次等温模锻试验。试验中,速度变化率为0.01 mm/s2,记录凸模压下速度从1.45 mm/s匀速下降至1.30 mm/s时锻压力的变化。

图6所示为等温模锻锻压力随时间变化曲线。由图6可知:在相同锻压速度下,使用水基纳米WS2润滑剂的锻压力比水基石墨、油基石墨的锻压力要低1.2×104 N,且在整个锻压过程中其变化最平稳,这说明在相同压力下,经水基纳米WS2润滑剂润滑的金属表面流动性优于水基石墨或油基石墨。随着锻压的进行,锻压力都存在增加的趋势,最终保持在一个稳定的锻压力,说明随着水基中水分的蒸发和油基中油分的烧损,起润滑和隔离模具与工件的只有固体润滑颗粒。

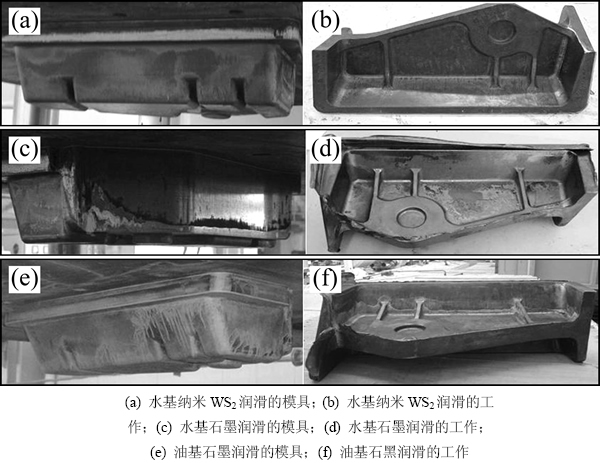

2.2.3 对脱模的影响分析

锻压结束时,使用水基纳米WS2润滑剂所需脱模力较低,无黏模、飞边和裂纹现象;而水基石墨和油基石墨润滑剂在模具和工件表面成膜不均匀,拐角和凹槽底部无石墨覆盖,有飞边现象发生(见图7)。这是因为纳米WS2颗粒在模具表面成膜均匀(图7(a)),强度较高,而且吸附膜可随着锻件的成形在新生表面迁移铺展,锻件表面光滑,无充型不满现象,肋板和拐角处均得到有效润滑;水基石墨和油基石墨在模具和工件表面成膜不均匀,锻压后拐角和筋深处石墨吸附膜被挤出(图7(c)和(e)),不能对新生表面实现完全覆盖,虽有一定隔离模具与工件的效果,但无法对边角及筋深处实现有效润滑,容易引起黏膜现象发生,影响模具和工件表面质量。

图6 模锻锻压力随时间的变化曲线

Fig. 6 Relationship between forging pressure and time

图7 等温模锻后模具与锻件的实物照片

Fig. 7 Photos of moulds and forge pieces after isothermal forging experiment

3 结论

1) 非离子型表面活性剂Span-80,Tween-80和OP-10以质量比43:43:14复配对PAO6基础油的乳化效果最优。当复配后的表面活性剂质量分数为2.0%时,乳化液具有最佳的润湿稳定性能;当乳化油的质量分数为10.0%时,制备的乳化液具有良好的润湿性能与润滑性能。

2) 纳米WS2可显著改善乳化液的润滑性能,且当质量分数为9.0%时,乳化液的极压、抗磨减磨性能最佳。

3) 水基纳米WS2润滑剂在模具表面成膜致密,颗粒分布均匀,模锻时所需锻压力较低,脱模时所需脱模力较低,且无黏模、飞边和裂纹现象,综合应用效果比水基石墨润滑剂和油基石墨润滑剂的优。

参考文献:

[1] 肖亚庆. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2005: 13-27.

XIAO Yaqing. User manual of aluminum processing technology[M]. Beijing: Metallurgical Industry Press, 2005: 13-27.

[2] Hyoji Y, Katsuhisa T. Precision forging of aluminum and steel[J]. Journal of Materials Processing Technology, 2000, 98(2): 196-204.

[3] 梁信, 陈康华, 陈学海, 等. 等温自由锻温度对7085铝合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2012, 43(3): 900-905.

LIANG Xin, CHEN Kanghua, CHEN Xuehai, et al. Effects of isothermal free forging temperature on microstructure and properties of 7085 aluminum alloy[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 900-905.

[4] 赵振铎, 邵明志, 张召铎, 等. 金属塑形成形中的摩擦与润滑[M]. 北京: 化学工业出版社, 2004: 106-132.

ZHAO Zhenduo, SHAO Mingzhi, ZHANG Zhaoduo, et al. Friction and lubrication of metal plastic forming[M]. Beijing: Chemical Industry Press, 2004: 106-132.

[5] 张玉勋, 易幼平, 李云, 等. 铝合金机轮轮毂锻造流线仿真与实验研究[J]. 中南大学学报(自然科学版), 2011, 42(7): 1967-1972.

ZHANG Yuxun, YI Youping, LI Yun, et al. Simulation and experiment research on forging flow lines for aluminum alloy wheel-hub[J]. Journal of Central South University (Science and Technology), 2011, 42(7): 1967-1972.

[6] 周强, 徐瑞清. 石墨材料的润滑性能及其开发应用[J]. 新型碳材料, 1997, 12(3): 11-16.

ZHOU Qiang, XU Ruiqing. Lubricating properties and application of graphite material[J]. New Carbon Materials, 1997, 12(3): 11-16.

[7] 李伟华, 董选普, 陈晓君, 等. 铝合金热模锻润滑机理研究与应用[J]. 锻压技术, 2010, 35(3): 175-178.

LI Weihua, DONG Xuanpu, CHEN Xiaojun, et al. Research and application of lubrication mechanism alloy hot die forging[J]. Forging & Stamping Technology, 2010, 35(3): 175-178.

[8] Rapoport L, Leshchinsky V, Lapsker I, et al. Tribological properties of WS2 nanoparticles under mixed lubrication[J]. Wear, 2003, 255(7/8/9/10/11/12): 785-793.

[9] Greemberg R, Halperin G, Etsin I, et al. The effect of WS2 nanoparticles on friction reduction in various lubrication regimes[J]. Tribology Letters, 2004, 17(2): 179-186.

[10] 毛大恒, 石琛, 俸颢, 等. 高温润滑脂中WS2亚微米粒子的摩擦学性能研究[J]. 摩擦学学报, 2010, 30(1): 68-74.

MAO Daheng, SHI Chen, FENG Hao, et al. Tribological performance of high temperature grease containing WS2 submicron particles[J]. Tribology, 2010, 30(1): 68-74.

[11] MAO Daheng, FENG Hao, SUN Xiaoya. Preparation of hyperthermal lithium complex grease[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(6): 1361-1366.

[12] SHI Chen, MAO Daheng, FENG Hao. Preparation of tungsten disulfide motor oil and its tribological characteristics[J]. Journal of Central South University of Technology, 2007, 14(5): 673-678.

[13] SHI Chen, MAO Daheng, ZHOU Ming. Dispersion effect and Auto-reconditioning performances of nanometer WS2 Particles in green lubricant[J]. Bulletin of Materials Science, 2010, 33(5): 529-534.

[14] 李玲. 表面活性剂与纳米技术[M]. 北京: 化学工业出版社, 2004: 16-30.

LI Ling. Surfactant and nanotechnology[M]. Beijing: Metallurgical Industry Press, 2004: 16-30.

[15] 任俊, 沈键, 卢寿慈. 颗粒分散科学与技术[M]. 北京: 化学工业出版社, 2005: 38-40.

REN Jun, SHENG Jian, LU Shouci. Particle dispersion science and technology[M]. Beijing: Metallurgical Industry Press, 2005: 38-40.

[16] 任智, 陈志荣, 吕德伟. 非离子活性剂乳液稳定性HLB规则研究[J]. 浙江大学学报(工学版), 2001, 35(5): 471-478.

REN Zhi, CHEN Zhirong, L Dewei. Studies on the HLB rule for non-ionic surfactant[J]. Journal of Zhejiang University (Engineering Science), 2001, 35(5): 471-478.

Dewei. Studies on the HLB rule for non-ionic surfactant[J]. Journal of Zhejiang University (Engineering Science), 2001, 35(5): 471-478.

[17] 黄伟九, 李芬芳, 董浚修, 等. 乳液润滑剂表面张力与组分相关性研究[J]. 润滑与密封, 2000, 25(2): 47-49.

HUANG Weijiu, LI Fenfang, DONG Junxiu, et al. Study on the relativity between surface tension and the composition of emulsion[J]. Lubrication Engineering, 2000, 25(2): 47-49.

[18] 白振华, 陈浩, 王瑞, 等. 乳化液性能对磨擦系数影响机理及工程实用模型的研究[J]. 燕山大学学报, 2014, 38(1): 16-21.

BAI Zhenhua, CHEN Hao, WANG Rui, et al. Study of relationship between performance of emulsion and friction coefficient and its practical model in cold tandem mill[J]. Journal of Yanshan University, 2014, 38(1): 16-21.

(编辑 陈灿华)

收稿日期:2014-05-06;修回日期:2014-07-21

基金项目(Foundation item):国家自然科学基金资助项目(51205416);教育部博士点专项基金资助项目(20110162120086);中南大学博士后基金资助项目(2011)(Project (51205416) supported by the National Natural Science Foundation of China; Project (20110162120086) supported by the Special Fund of Ministry of Education; Project (2011) supported by the Post Doctoral Foundation of Central South University)

通信作者:石琛,博士,讲师,从事纳米润滑减摩研究;E-mail:shichen@csu.edu.cn