DOI:10.19476/j.ysxb.1004.0609.2017.11.10

航空接头锻件低速等温模锻成形及其塑性变形微观机理

胡建良1,易幼平2,宋雷钧3,金 淼1,薄 宏4

(1. 燕山大学 机械工程学院,秦皇岛 066004;

2. 中南大学 高性能复杂制造国家重点实验室,长沙 410083;

3. 南京迪威尔高端制造股份有限公司,南京 210048;

4. 燕山大学 亚稳材料制备技术与科学国家重点实验室,秦皇岛 066004)

摘 要:采用低速等温模锻工艺制备7A85铝合金航空接头锻件,并对其在低速等温条件下塑性变形的微观机理进行分析。结果表明:低速等温模锻工艺有利于航空接头锻件的塑性成形,锻件成形质量良好,且锻件内部显微组织细小均匀。在低速等温变形条件下,晶界滑移是航空接头锻件塑性变形的主要机制,而扩散蠕变是晶界滑移的主要因素。基于空位扩散理论,建立7A85铝合金航空接头锻件在极低变形速度条件下的塑性变形本构方程,为低速等温锻造工艺提供理论指导。

关键词:航空接头锻件;低速等温模锻;晶界滑移;微观机理

文章编号:1004-0609(2017)-11-2260-07 中图分类号:TG316.3 文献标志码:A

航空制造业竞争特点是轻量化,由此驱动飞机结构件的设计制造向大型、整体、复杂、精密、优质方向发展,其制造技术已成为决定飞机性能、可靠性及经济性的重要因素[1-3]。复杂航空构件传统制造方式是对自由锻件进行机加工成形,这种制造工艺带来了残余应力过大、加工易变形、组织性能各向异性以及材料浪费严重等问题。而等温锻造工艺可消除冷模效应,大幅度降低材料变形抗力,提高成形过程中金属的流动性,同时最大程度地减小了锻件加工余量,甚至达到近净成形,十分适合复杂航空构件的精密成形,逐渐受到国内外学者的关注[4-7]。近年来,欧美国家已成功将整体模锻件应用于波音787飞机和空客A380飞机的重要承力构件[8-10]。单德彬等[11-12]对高强耐热镁合金多向转接头和稀土镁合金薄腹高筋支架等温成形过程进行了有限元模拟和实验研究,成功锻造出质量良好的模锻件。郭鸿镇等[13]研究了不同近等温锻造成形工艺条件下TC21钛合金的显微组织及拉伸性能。陈康华等[14-15]研究了7085铝合金等温模锻过程中的热变形温度和锻造速率参数对合金组织和性能的影响。然而对铝合金等温锻造工艺特别是低速等温锻造工艺的微观机理研究较少。本文作者以7A85铝合金航空接头为研究对象,采用低速等温模锻工艺,开展了锻件的精密模锻实验,分析了低速等温模锻工艺下锻件的塑性变形微观机理。

1 实验

图1所示为7A85铝合金航空接头锻件照片。此锻件外廓尺寸为550 mm×180 mm×174 mm,且为典型的筋高、壁薄结构件,最薄处只有20 mm。航空接头锻件材料为西南铝业(集团)有限责任公司提供的7A85铝合金,其名义化学成分如表1所列。航空接头的低速等温模锻实验在40 MN等温模锻液压机上进行,模具温度为450 ℃,坯料以10 ℃/min的速度从室温加热至450 ℃,并保温4 h。锻坯与模具的润滑剂为环保型水基润滑剂(二硫化钨+水+添加剂),润滑方式为喷雾润滑。

图1 7A85铝合金航空接头锻件照片

Fig. 1 Photo of designed 7A85 aluminum aviation forging

表1 7A85铝合金的化学成分

Table 1 Chemical composition of 7A85 aluminum (mass fraction,%)

2 结果与分析

2.1 航空接头低速等温模锻成形

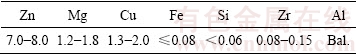

图2所示为航空接头低速等温模锻成形过程中实测的压力及速度曲线。从图2可以看出,锻压开始阶段,锻压速度为1 mm/s,坯料处于镦粗过程,载荷较小且增长十分平缓;当位移值达到65 mm左右时,此时锻压速度为0.1 mm/s,锻件成形压力开始急剧增大,进入闭式模锻过程,坯料在压应力作用下进行反挤,充填上下筋板;当位移值达到72 mm,锻压速度由0.05 mm/s降为0.002 mm/s,压力出现骤减,而后又剧烈增大。直到锻压结束时,航空接头低速等温模锻最大载荷约为32 MN。图3和图4所示分别为7A85铝合金航空接头的锻坯和终锻件。在低速等温模锻工艺条件下,航空接头锻件充填完整,金属流动平缓,未出现气泡、折边、分层、折叠、裂缝等缺陷。

图2 航空接头锻件低速等温锻造压力及速度曲线

Fig. 2 Plot of load and velocity versus stroke during isothermal forging

图3 航空接头锻坯结构示意图

Fig. 3 Schematic diagram of preform of aviation forging

图4 航空接头终锻件结构示意图

Fig. 4 Schematic diagram of aviation forging formed by isothermal forging

2.2 显微组织分析

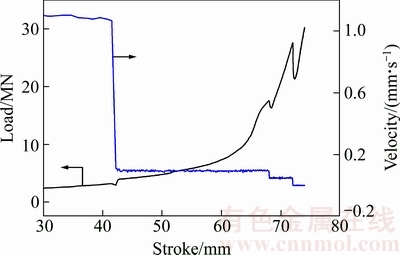

从航空接头锻件上选取一截面,如图4虚线框所示位置,在截面上选择4个部位对航空接头锻件进行金相分析,如图5所示。从航空接头锻件的金相图(见图6)可知,航空接头锻件a、c位置在锻压成形的开始阶段就基本完成变形,金属流动较平缓,没有出现条状晶粒分布。金属流动比较剧烈的部位为b、d位置,晶粒组织略呈线条状分布。锻件各个部位都均匀地发生了动态再结晶行为,其中a、b、c、d部位的平均晶粒直径分别为41、37、35和32 μm,晶粒组织细小均匀。实验结果表明在低速等温模锻工艺条件下,航空接头锻件具有较好的晶粒组织均匀性。

图5 航空接头锻件金相分析截面图

Fig. 5 Cross section of aviation forging for metallographic observation

图6 航空接头锻件金相图

Fig. 6 Optical micrographs for specimens taken from different locations of cross section of aviation forging

在航空接头锻件塑性变形开始阶段,合金内部存储的应变能达到动态再结晶所需要的能量时,内部发生动态再结晶行为。动态再结晶消耗了合金的畸变能,从而降低了位错密度。随着变形的继续,由于晶粒位向不同,各晶粒之间的变形不均匀,位向有利的晶粒发生滑移,晶界处有明显的晶界滑移带(见图7(a))。而位向不利的晶粒则受挤压,晶粒内部位错密度增大(见图7(b))。在低速等温条件下,如果锻件的局部应力集中大于晶体内部的临界切应力,晶界附近的位错则发生滑移-攀移运动,异号位错相互抵消,从而使合金内部的应力集中得以松弛,晶界滑移得以继续。晶界作为位错的源和井,晶界上的位错可以由晶内的位错滑移来相互抵消,同时晶内位错也可以通过滑移运动到晶界上(见图7(c))。

当变形速度降至最低速度时,晶界位错以滑移-攀移方式沿晶界运动,其滑移分量导致晶界滑移,攀移分量引起扩散蠕变[16]。扩散蠕变会导致晶界处出现无沉淀析出带,当位错沿晶界运动有大的攀移分量时,该晶界处的无沉淀析出带较宽。相反地,当位错运动具有较小攀移分量时,晶界处的无沉淀析出带较窄。而对于某些区域,晶界处没有析出相,这是由于位错攀移运动较剧烈,溶质原子和空位扩散明显,析出相难以形核长大。如图7(d)所示,航空接头锻件在晶界处出现无沉淀区,说明在极低变形速度条件下,锻件内部扩散蠕变运动剧烈,此时,晶界滑移速率则由位错攀移速度所控制[17-18]。

综上所述可知,航空接头锻件在低速等温变形条件下,内部均匀地发生动态再结晶行为,动态再结晶消耗了合金的崎变能,从而降低了位错密度,塑性变形得以继续进行。在低速等温变形条件下,晶界滑移是锻件变形的主要机制,而当变形速度将至最低速度时,扩散蠕变是促进锻件内部晶界滑移的主要因素,晶界滑移速率则由位错攀移速度所控制。

2.3 航空接头锻件极低变形速度条件下塑性变形微观机理分析

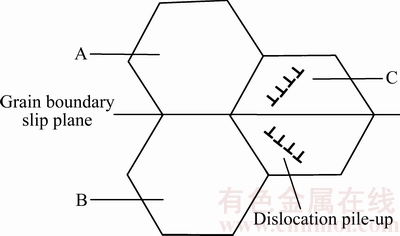

图8所示为锻件微观组织演变原理图,晶粒A和B沿着晶界滑移时,当遇到三角晶界处的阻挡晶粒C,其滑移运动被迫停止。在滑移运动受阻处容易引起应力集中,为了缓解这种晶内局部的应力集中,阻挡晶粒C内部激活位错,使晶粒内部的位错运动到晶界上。当内部应力达到临界值时,塞积在晶界处的位错就能发生攀移运动而消失,于是晶体内部局部内应力得到松弛,晶界的滑移运动得以继续发生。所以在极低变形速度条件下,航空接头锻件晶界滑移速率由位错攀移运动所制约。

图7 航空接头锻件的TEM像

Fig. 7 TEM images of aviation forging

图8 低速等温下锻件显微组织演变原理图

Fig. 8 Schematic diagram of microstructure evolution under isothermal low speed forging process

参考Mukherjee模型[19],晶界滑移速率由位错攀移速度控制,晶粒直径是位错攀移的距离,晶界滑移速率为

(1)

(1)

式中:L为晶界滑移距离;d为晶粒直径;t为位错攀移时间。

阻碍晶粒运动造成的应力集中使晶界处存在大量的空位,晶界空位浓度差是位错攀移的驱动力。设过饱和空位浓度为c,平衡空位浓度为c0,平衡空位浓度由可确定为

(2)

(2)

式中:uf为空位形成能,即增加一个空位所需增加的能量,相当于将一个原子移动所需的能量。A为常数,一般在1~10之间;k为Boltzmann常数;T为热力学温度。而晶界上的空位浓度c与作用在晶粒上的应力有关,具体表达式如下:

(3)

(3)

式中:σ为作用在晶粒上的应力;b为Burgers矢量。因此,晶界上的空位扩散方程为

(4)

(4)

式中:I为扩散通量;DV为空位扩散系数;Dgb=DVc0,为晶界扩散系数。

位错攀移速度和晶界上的空位扩散速度一致,不考虑方向性,可以得到位错攀移速度为

(5)

(5)

将空位浓度方程代入式(5)可得:

(6)

(6)

由于 的数量级比较小,因此根据泰勒展开公式可得:

的数量级比较小,因此根据泰勒展开公式可得:

(7)

(7)

所以位错攀移速度为

(8)

(8)

则位错攀移至消失处所需要的时间为

(9)

(9)

将式(9)代入式(1)可得晶界滑移速率为

(10)

(10)

式中:L为晶界滑移距离,可以近似为位错的Burgers矢量b,即L=b。当T=723 K时,晶界扩散系数Dgb为7.9×10-12 m2/s;Burgers矢量b为2.86×10-10 m[20];Boltzmann常数k为1.38×10-23 J/K;平均晶粒直接d为38×10-6 m。

在低速等温条件下,航空接头锻件塑性变形的主要机制为晶界滑移,因此,可以假定实际航空接头锻件宏观应变速率与晶界滑移速率成一定的协调关系,实际航空接头锻件宏观应变速率为

(11)

(11)

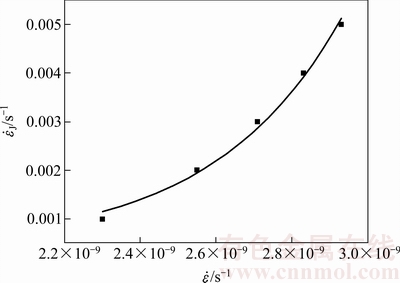

根据7A85铝合金稳态流变应力曲线[21]可以获得不同宏观应变速率条件下的应力数据,如表2所示。由于低速等温状态下,锻件处于稳定状态,铝合金应力可以近似为晶粒上的应力。将应力数据代入式(10),可以获得航空接头锻件宏观应变速率与晶界滑移速率关系图,如图9所示。航空接头锻件宏观应变速率和晶界滑移速率呈一定的指数函数关系,对图中的数据点进行拟合,可以获得锻件宏观应变速率与晶界滑移速率关系式:

(12)

(12)

因此,可以获得7A85铝合金航空接头锻件在极低变形速度条件下的塑性变形本构方程:

(13)

(13)

式中: 为航空接头锻件宏观应变速率;

为航空接头锻件宏观应变速率; 为晶界滑移速率;Dgb为晶界扩散系数;σ为作用在晶粒上的应力;b为Burgers矢量;d为晶粒直径;k为Boltzmann常数;T为热力学温度。

为晶界滑移速率;Dgb为晶界扩散系数;σ为作用在晶粒上的应力;b为Burgers矢量;d为晶粒直径;k为Boltzmann常数;T为热力学温度。

表2 不同宏观应变速率下7A85铝合金应力参数

Table 2 Strain rate and stress under different forming conditions

图9 锻件宏观应变速率与晶界滑移速率关系图

Fig. 9 Plot of strain rate versus sliding rate of grain boundary

3 结论

1) 通过低速等温模锻工艺制备了大型复杂航空接头锻件,锻件充填完整,内部未出现气泡、折边、分层、折叠、裂缝等缺陷,成形质量良好。航空锻件内部均匀地发生了动态再结晶行为,且晶粒组织细小均匀,具有较好的显微组织均匀性。

2) 航空接头锻件在低速等温变形条件下,晶界滑移是锻件塑性变形的主要机制。控制晶界滑移的微观过程比较复杂,其中扩散蠕变是促进锻件内部晶界滑移的主要因素。

3) 在极低变形速度条件下,航空锻件的晶界滑移速率则由位错攀移速度所控制,而位错攀移的驱动力是晶界的空位浓度差。因此,基于空位扩散理论,建立了7A85铝合金航空接头锻件在低速等温条件下的塑性变形本构方程,为低速等温锻造工艺提供理论指导。

REFERENCES

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[2] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775-5799.

[3] 杨 合, 李落星, 王渠东, 郭良刚. 轻合金成形领域科学技术发展研究[J]. 机械工程学报, 2010, 46(12): 31-42.

YANG He, LI Luo-xing, WANG Qu-dong, GUO Liang-gang. Research on the development of advanced forming for lightweight alloy materials area[J]. Journal of Mechanical Engineering , 2010, 46(12): 31-42.

[4] RAO K P, PRASAD Y, SURESH K. Materials modeling and simulation of isothermal forging of rolled AZ31B magnesium alloy: Anisotropy of flow[J]. Materials and Design, 2011, 32(8): 2545-2553.

[5] HU Jian-liang, YI You-ping, HUANG Shi-quan. Experimental study and microstructure analysis of aviation component by isothermal forging process[J]. Materials and Manufacturing Processes, 2015, 30(1): 79-84.

[6] SHAN De-bin, XU Wen-chen, HAN Xiu-zhu, HUANG Xiao-lei. Study on isothermal precision forging process of rare earth intensifying magnesium alloy[J]. Materials Science and Engineering B, 2012, 177(4): 1689-1702.

[7] 郭鸿镇, 姚泽坤, 虢迎光, 刘广义, 李园春. 等温精密锻造技术的研究进展[J]. 中国有色金属学报, 2010, 20(1): 570-576.

GUO Hong-zhen, YAO Ze-kun, GUO Ying-guang, LIU Guang-yi, LI Yuan-chun. Research progress of isothermal precision forging technology[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 570-576.

[8] HUDA Z, EDI P. Materials selection in design of structures and engines of supersonic aircrafts: A review[J]. Materials and Design, 2013, 46: 552-560.

[9] LIU W Y, ZHAO H, LI D, ZHANG Z Q, HUANG G J, LIU Q. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature[J]. Materials Science and Engineering A, 2014, 596: 176-182.

[10] CHAKRABARTI D J, LIU J, SAWTELL R R. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004, 28(3): 969-974.

[11] 徐文臣, 单德彬, 郭 斌, 韩修柱, 黄晓磊, 王 悦. 稀土镁合金薄腹高筋支架的等温锻造技术[J]. 塑性工程学报, 2014, 21(2): 7-12.

XU Wen-chen, SHAN De-bin, GUO Bin, HAN Xiu-zhu, HUANG Xiao-lei, WANG Yue. Isothermal forging rare element containing magnesium alloy bracket with thin web and high rib[J]. Journal of Journal of Plasticity Engineering, 2014, 21(2): 7-12.

[12] 张 浩, 张绪虎, 杜志惠, 单德彬, 王少华, 朱秉诚. 镁合金多向转接头等温成形数值模拟及实验研究[J]. 材料科学与工艺, 2013, 21(4): 123-126.

ZHANG Hao, ZHANG Xu-hu, DU Zhi-hui, SHAN De-bin, WANG Shao-hua, ZHU Bing-cheng. The numerical simulation and experiment study of multi-transfer-device by isothermal forming in magnesium alloy[J]. Materials Science and Technology, 2013, 21(4): 123-126.

[13] SHI Zhi-feng, GUO Hong-zhen, LIU Rui, WANG Xiao-chen, YAO Ze-kun. Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 72-79.

[14] 陈学海, 陈康华, 梁 信, 陈送义, 彭国胜. 热变形温度对7085铝合金组织和性能的影响[J]. 中国有色金属学报, 2011, 21(1): 88-94.

CHEN Xue-hai, CHEN Kang-hua, LIANG Xin, CHEN Song-yi, PENG Guo-sheng. Effects of hot deformation temperature on microstructure and properties of 7085 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2073-2082.

[15] 梁 信, 陈康华, 陈学海, 陈送义, 彭国胜. 等温锻造速率对7085铝合金组织与性能的影响[J].粉末冶金材料科学与工程, 2011, 16(2): 290-295.

LIANG Xin, CHEN Kang-hua, CHEN Xue-hai, CHEN Song-yi, PENG Guo-sheng. Effect of isothermal forging rate on microstructure and properties of 7085 aluminum alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(2): 290-295.

[16] 周泽鹏, 张 劲, 邓运来, 张新明. Al-Cu-Mg合金蠕变成形热处理工艺[J]. 中国有色金属学报, 2016, 26(8): 1607-1614.

ZHOU Ze-peng, ZHANG Jin, DENG Yun-lai, ZHANG Xin-ming. Creep forming heat treatment technology of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1607-1614.

[17] 孙 雪, 潘清林, 李梦佳, 史运嘉, 严 杰. Al-Mg-Sc-Zr合金冷轧板材的超塑性变形行为[J]. 中国有色金属学报, 2016, 26(2): 280-287.

SUN Xue, PAN Qing-lin, LI Meng-jia, SHI Yun-jia, YAN Jie. Superplastic deformation behavior of cold-rolled Al-Mg-Sc-Zr alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 280-287.

[18] LI Dong-feng, ZHANG Duan-zheng, LIU Sheng-dan, SHAN Zhao-jun, ZHANG Xin-ming, WANG Qin, HAN Su-qi. Dynamic recrystallization behavior of 7085 aluminum alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1491-1497.

[19] HOGE K G, MUKHERJEE A K. The temperature and strain rate dependence of the flow stress of tantalum[J]. Journal of Materials Science, 1977, 12(8): 1666-1672.

[20] 黄伯云, 李成功, 石力开. 中国材料工程大典(第4卷)[M].北京: 化学工业出版社, 2006: 110-115.

HUANG Bo-yun, LI Cheng-gong, SHI Li-kai. China materials engineering canon (Volume 17)[M]. Beijing: Chemical Industry Press, 2006: 110-115.

[21] 黄湘龙. 7A85铝合金航空接头等温锻造组织演变模拟与实验研究[D]. 长沙: 中南大学, 2012: 22-23.

HUANG Xiang-long. Microstructure evolution simulation and experimental study of 7A85 aluminum aviation joint forging by isothermal forging process[D]. Changsha: Central South University, 2012: 22-23.

Low speed isothermal forging and microcosmic mechanism analysis of plastic deformation of aviation joint forging

HU Jian-liang1, YI You-ping2, SONG Lei-jun3, JIN Miao1, BO Hong4

(1. College of Mechanical Engineering, Yanshan university, Qinhuangdao 066004, China;

2. State Key Laboratory of High Perfermance Complex Manufacturing, Central South University, Changsha 410083, China;

3. Nanjing Develop Advanced Manufacturing Co., Ltd., Nanjing 210048, China;

4. State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, Qinhuangdao 066004, China)

Abstract: The aviation forging of 7A85 aluminum alloy was prepared by the isothermal forging process with low speed, and the microcosmic mechanism of the plastic deformation was analyzed. The results show that the aviation forging is easily formed by using isothermal forging process with low speed, and the uniform microstructure is obtained. Grain boundary sliding is the main mechanism during the isothermal forging process with a low speed, and the diffusion creep is the main factor leading to the grain boundary sliding. Therefore, based on the vacancy diffusion theory, the plastic deformation constitutive equation of aviation forging under extremely low speed isothermal forging process is established in order to provide guidance for the low speed isothermal forging process.

Key words: aviation joint forging; low speed isothermal forging process; grain boundary sliding; microcosmic mechanism

Foundation item: Project(2010CB731701) supported by Key Project of Chinese National Programs for Fundamental Research and Development; Project(51401179) supported by National Natural Science Foundation of China; Project(E2015203116) supported by Natural Science Foundation of Hebei Province, China; Project(B980) supported by Doctor Foundation of Yanshan University, China

Received date: 2016-10-12; Accepted date: 2017-06-02

Corresponding author: YI You-ping; Tel: +86-731-88830294; E-mail: yyp@csu.edu.cn

(编辑 龙怀中)

基金项目:广国家重点基础研究发展计划资助项目(2010CB731701);国家自然科学基金资助项目(51401179);河北省自然科学基金资助项目(E2015203116);燕山大学博士基金资助项目(B980)

收稿日期:2016-10-12;修订日期:2017-06-02

通信作者:易幼平,教授,博士;电话:0731-88830294;E-mail:yyp@csu.edu.cn