文章编号:1004-0609(2013)S1-s0765-06

La对Ti-44Al-6Nb合金组织及性能的影响

陈瑞润1,马志坤1, 2,董书琳1,丁宏升1,郭景杰1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 中国人民解放军装甲兵技术学院 坦克维修教研室,长春 130117)

摘 要:采用La对Ti-44Al-6Nb进行合金化处理,La元素的含量分别为0、0.3%、0.6%、0.9%和1.2%(摩尔分数)。对熔炼后的钮扣锭的表面质量、宏观组织、微观组织、压缩性能和断口形貌进行观察和分析。结果表明:La对表面质量影响较大,含量较高时,表面有起皮现象,表面质量被恶化;La元素的添加能够细化晶粒,但是含量不同,细化效果有较大区别,含量为0.3%和0.9%时细化效果较好,晶粒最小可达到0.1 mm。压缩试验表明:La添加后强度和塑性均有较大程度的提高,压缩率最大可提高100%左右;晶粒细化和晶界强化是提高性能的主要原因。

关键词:La;钛-铝合金;压缩性能;晶粒细化;析出强化

中图分类号:TF804.3 文献标志码:A

Effect of La on microstructure and mechanical property of Ti-44Al-6Nb alloy

CHEN Rui-run1, MA Zhi-kun1, 2, DONG Shu-lin1, DING Hong-sheng1, GUO Jing-jie1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Department of Tank Repair, People’s Liberation Army Armored Force Engineering Institute, Changchun 130117, China)

Abstract: Different contents (0, 0.3%, 0.6%, 0.9%, 1.2%, mole fraction) of La were added into Ti-44Al-6Nb alloys to prepare ingots. The surface quality, macrostructure, microstructure, compressive properties and fracture surface of the ingots were studied. The results show that La has bad influence on the surface quality, especially when the content is higher. La can refine the grains of the ingots, whereas, the refining effect is different for different La contents, it is better when the contents are 0.3% and 0.5%, and the smallest grain can reach 0.1 mm. The compressive testing results show that La can improve the strength and ductility, the compression ratio can be improved by about 100%, which is owing to grain refining and boundary and grain-boundary strengthening.

Key words: La; Ti-Al alloy; compressive property; grain refining; precipitation strength

钛铝基合金具有低密度、高熔点、高强度等特点,广泛应用于航空航天工业。TiAl基合金同时具有良好的抗腐蚀性、较高的高温强度等优良性能,被作为能代替铁合金和镍基合金的材料大力发展。TiAl基合金的微观组织状态对力学性能有重要影响,全片层微观组织是潜在的喷气发动机叶片、涡轮盘和汽车发动机进排气阀材料[1-5]。在此基础上,通过合金化法可以进一步提高钛铝基合金的综合性能。目前,科学研究和工程实际中利用Nb元素对TiAl系合金进行合金化最为广泛,Nb本身具有较高的熔点,它可有效地提高TiAl基合金的室温塑性、熔点及有序化温度, 提高高温抗氧化性能,使合金突破800 ℃的高温氧化使用门槛,高铌钛铝基合金的使用温度通常达到900 ℃以上,Nb的添加不会破坏钛铝基合金低密度的优点[6-12]。本文作者在高铌钛铝合金Ti44Al6Nb(摩尔分数,%)中添加不同含量的稀土元素La,研究La元素对高铌钛铝基合金组织和性能的影响, 以期进一步提高和改善高铌钛铝合金的使用性能。

1 实验

实验用原料为海绵钛(纯度≥99.98%)、高纯铝块(纯度≥99.98%)、铝铌中间合金(43.1%Al-54.13%Nb,质量分数)和高纯镧(纯度≥99.9%)。按摩尔比计算,各称取40 g,按照Ti-44Al-6Nb-xLa(x=0, 0.3%, 0.6%, 0.9%, 1.2%,摩尔分数,下同),采用WK-Ⅱ型非自耗电弧炉将其制备成纽扣锭,该设备由抽真空系统、电源控制柜、熔炼系统和冷却系统组成,制备前先抽取真空,再充入高纯氩气作为保护气体,为确保成分均匀,每个纽扣锭均进行3次以上熔化。利用数码相机、Olympus金相显微镜和扫描电镜对纽扣锭进行形貌观察,利用X射线衍射对试样表面进行组织结构分析,采用的腐蚀液为5% HF + 5% HNO3 + 90% H2O(体积分数)。对不同成分试样进行压缩断裂实验,试样尺寸为d 4 mm × 6 mm,研究不同La含量对Ti44Al6Nb合金组织及性能的影响。采用扫描电镜观察断口形貌。

2 结果与讨论

2.1 La对Ti-44Al-6Nb合金锭表面质量的影响

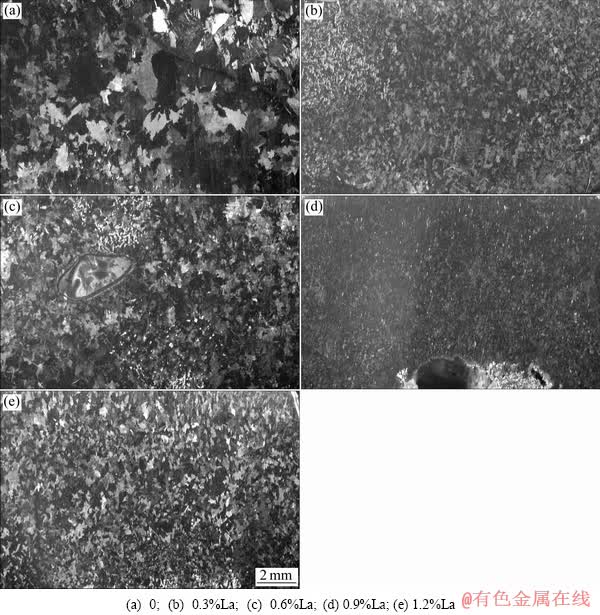

图1所示为不同La含量时锭的表面质量。从图1中可以看出,La的加入会使铸锭表面质量变差,随着La含量的增加,铸锭表面质量变差,甚至出现起皮现象,严重恶化了铸锭的表面质量。

图1 不同La含量时锭的表面质量

Fig. 1 Surface quality of ingots with different La contents

2.2 La对Ti-44Al-6Nb宏观组织的影响

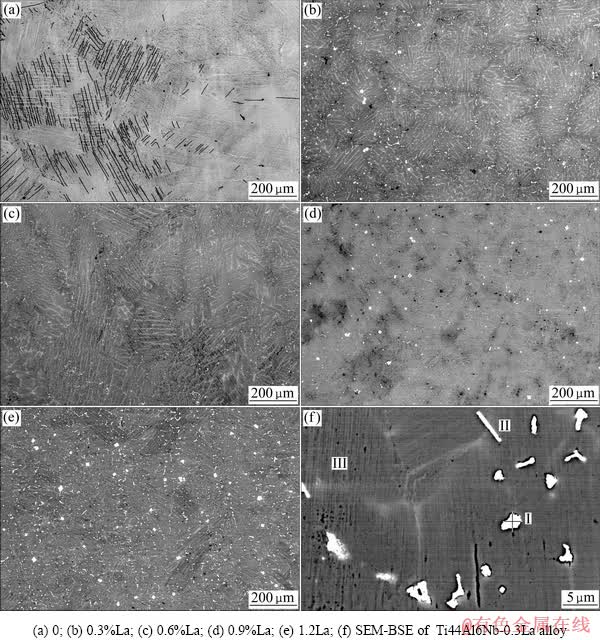

图2所示为不同La含量铸锭的宏观组织。由图2可以看出, La元素的添加可使晶粒细化,其中图2(b)和2(d)对应的组织最为细化,当La添加至0.9%时,晶粒尺寸减小到约0.1 mm。La的添加对合金的补缩能力造成影响,图2(d)中可观察到有较大缩孔出现。

加入稀土元素La可降低液态金属的相界上表面张力,生成晶核所要求的能量起伏较小,提高均匀形核的形核率。同时稀土金属特别活泼,和氧元素有很大的亲合力,容易与氧结合生成氧化物,促使非均匀形核。稀土氧化物等超微质点的熔点很高,这些质点聚集在固液界面前沿会阻碍晶体的继续生长,并阻碍晶界移动,使晶体的长大线速度降低,阻止晶体长大,从而可细化晶粒,改善TiAl 合金的性能。

2.3 La对Ti-44Al-6Nb微观组织的影响

图3所示为添加不同含量的La元素后的微观组织。由图3可以看出,随着La元素含量的增加,晶粒尺寸减小,白色的析出物增多。Ti44Al6Nb-0.3La在高倍下可以观察到析出物主要呈块状和杆状。取Ⅰ、Ⅱ、Ⅲ 3点(Ⅰ—块状析出物,Ⅱ—杆状析出物,Ⅲ—基体)进行能谱分析,结果如表1所列。

参考研究过渡金属时所采用的电子特性理论,引出BO(键级)和Md(电子能级)两个参量,令tan θ=BO/Md≈固溶强化/析出强化,tan θ=1表明合金元素加入后其固溶强化效果和析出强化效果相当,tan θ值越大,表明固溶作用越强;tan θ值越小,则说明析出强化作用越强。由于周期表中稀土元素La与Ti、Al、Nb的距离较远,原子的核外电子排布差别也较大,导致tan θ值较小(tan θ<1),说明La元素的析出强化效果较明显,实验结果也验证了这一点。

2.4 La对Ti-44Al-6Nb压缩性能的影响及断口形貌

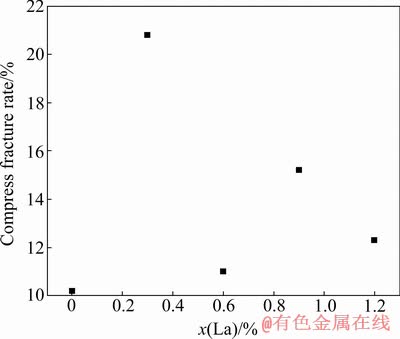

图4所示为5个试样压缩试验的压缩率。由图4可以看出,随着La元素的添加试样的抗压强度和压缩率均有提高,当添加量为0.3%和0.9%(摩尔分数)时,断裂压缩率较大,这和前面观察到的组织所反映的晶粒大小正好相关,即小的晶粒尺寸对应于较大的断裂压缩率,而5组实验的断裂应力基本保持在1 500~1 700 MPa范围内。相比于拉伸实验,在压缩实验条件下,即使是脆性材料也往往会表现出相对较高的应变率。La元素的加入可降低堆垛层错能,促进全位错分解和孪晶生成,同时也可降低超点阵结构中的APB(反向畴界)能,促进APB和超位错的产生,这些都有益于金属间化合物材料的塑性提高。但是,在TiAl基合金中,La元素属析出强化机制的合金元素,故随其含量的增加,La化合物大量析出(有资料表明为LaAl或LaAl3[13]),这些析出物均为硬脆相,压缩试验下易被压溃。因此,虽可使TiAl基合金的硬度和抗压强度等性能在一定范围内保持或小幅提高,但是大量加入后塑性将受到很大影响。

图2 不同La含量时锭的宏观组织

Fig. 2 Macrostructures of ingots with different La contents

图3 不同La含量合金的微观组织

Fig. 3 Microstructures of ingots with different La contents

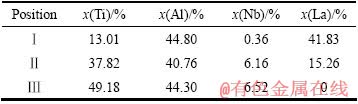

表1 图3(f)中3点位置的SEM-EDS结果

Table 1 SEM-EDS results of three points in Fig. 2(b)

图4 La元素含量对断裂压缩率的影响

Fig. 4 Influence of La content on compress fracture rate

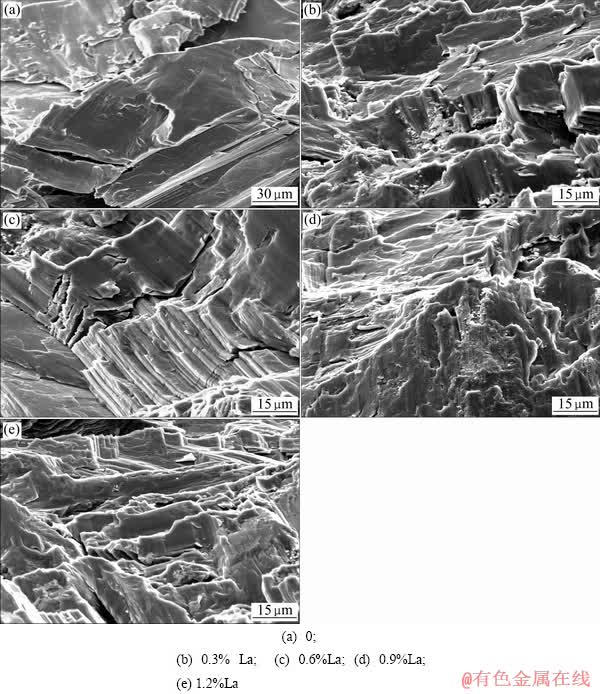

图5 不同La含量试样压缩断口形貌

Fig. 5 Fracture morphologies of compress sample with different La contents

图5所示为不同La含量下的压缩断口形貌。由图5可以看出,5种不同La含量的试样均显示出了明显的脆性断裂断口形貌,由于大量的含La脆性相析出,图5(e)中可观察到明显的析出物局部碎化现象。

3 结论

1) La的添加将恶化铸锭表面质量,随其含量的增加,表面质量逐渐恶化,甚至出现起皮现象。

2) La可有效细化Ti-44Al-6Nb晶粒,当La的添加量为0.9%(摩尔分数)时,晶粒尺寸可减小到约0.1 mm。

3) 在TiAl基合金中,La元素可起到析出强化作用,当添加量为0.3%(摩尔分数)时,断裂压缩率最高约为20.8%,提高了约100%;而断裂应力基本保持在1 500~1 700 MPa范围内。

REFERENCES

[1] HU D, WICKINS J F M M, HARDING R A. Microstructure and tensile properties of investment cast Ti-46Al-8Nb-1B alloy [J]. Scripta Materialia, 2002, 47: 273-278.

[2] WANG Y H, LIN J P, HE Y H. Microstructural characteristics of Ti-45Al-8.5Nb/TiB2 composites by powder metallurgy [J]. Journal of Alloys and Compounds, 2009, 468: 505-511.

[3] 肖志霞, 郑立静, 杨莉莉, 闫 洁, 张 虎. 温度梯度对定向凝固TiAl基合金片层取向的影响[J]. 金属学报, 2010, 10: 1223-1229.

XIAO Zhi-hong, ZHENG Li-jing, YANG Li-li, YAN Jie, ZHANG Hu. The effection of temperature gradient on TiAl-based alloy lamellar orientation by directionally solidification [J]. Acta Metallurgica Sinica, 2010, 10: 1223-1229.

[4] 孔凡涛, 张树志, 陈玉勇. Ti-46Al-3Cr-4Nb-Y合金的高温变形及加工图[J]. 中国有色金属学报, 2010, 20(S1): s233-s236.

KONG Fan-tao, ZHANG Shu-zhi, CHEN Yu-yong. Hot deformation and processing map of Ti-46Al-3Cr-4Nb-Y [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s233-s236.

[5] 王 刚, 徐 磊, 崔玉友, 杨 锐. Ti-47Al-2Cr-2Nb-0.2W-0.15B合金合金板材的制备及其拉伸性能[J]. 中国有色金属学报, 2010, 20(S1): s274-s277.

WANG Gang, XU Lei, CUI Yu-you, YANG Rui. Fabrication and tensile property of Ti-47Al-2Cr-2Nb-0.2W-0.15B alloy sheets [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s274-s277.

[6] HUANG Lan, LIAN P K, LIU C T, LIU Yong, HUANG Jin-song Microstructural evolution of (TiAl)+Nb+W+B alloy [J]. Transformations of Nonferrous Metals Society of China, 2011, 21(10): 2192-2198.

[7] WU Y, HWANG S K. Microstructural refinement and improvement of mechanical properties and oxidation resistance in EPM TiAl-based intermetallics with yttrium addition [J]. Acta Materialia, 2002, 50: 1479-1493.

[8] PILONE D, FELL F. Isothermal oxidation behaviour of TiAl-Cr-Nb-B alloys produced by induction melting [J]. Intermetallics, 2012, 26: 36-39.

[9] LIN J P, ZHAO L L, LI G Y, ZHANG L Q, SONG X P, YE F, CHEN G L. Effect of Nb on oxidation behavior of high Nb containing TiAl alloys [J]. Intermetallics, 2011, 19: 131-136.

[10] ZHOU Y, WANG J Q, ZHANG B, KE W, HAN E H. High-temperature fatigue property of Ti46Al8Nb alloy with the fully lamellar microstructure [J]. Intermetallics, 2012, 24: 7-14.

[11] LEE H N, JOHNSON D R, INUI H, HO M H, WEE D M, YAMAGUCHI M. A composition window in the TiAl-Mo-Si system suitable for lamellar structure control through seeding and directional solidification [J]. Materials Science and Engineering A, 2002, 329/331: 19-24.

[12] 尹 权, 黄泽文. 热暴露对Ti-44Al-4Nb-4Hf-1B 合金显微结构和力学性能的影响[J]. 中国有色金属学报, 2011, 20(12): 3050-3056.

YIN Quan, HUANG Ze-wen. Effect of long-term thermal exposure on microstructure and mechanical properties of Ti-44Al-4Nb-4Hf-1B alloy [J]. The Chinese Journal of Nonferrous Metals, 2011, 20(12): 3050-3056.

[13] 蒋淑英, 李世春. La-Al化合物价电子结构对铝合金性能的影响[J]. 材料热处理学报, 2013, 34(7): 31-35.

JIANG Shu-ying, LI Shi-chun. Effect of valence electron structure of La-Al compounds on aluminum alloy properties [J]. Transaction of Materials and Heat Treatment, 2013, 34(7): 31- 35.

(编辑 李向群)

基金项目:国家重点基础研究发展计划资助项目(2011CB605504);教育部新世纪优秀人才(NCET-12-0153);国家自然科学金资助项目(51274076)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:陈瑞润,教授,博士;电话:0451-86413931;E-mail: ruirunchen@hit.edu.cn