DOI:10.19476/j.ysxb.1004.0609.2017.11.11

Mo含量对镍基合金力学及摩擦学性能的影响

杨素兰1, 2,马 勤1,王文珍2,贾均红1, 2

(1. 兰州理工大学 材料科学与工程学院 省部共建有色金属先进加工与再利用国家重点实验室, 兰州 730050

2. 中国科学院 兰州化学物理研究所 固体润滑国家重点实验室,兰州 730000)

摘 要:利用粉末冶金的方法制备不同Mo含量的镍基合金。考察其室温至1000 ℃的力学性能及室温至900 ℃下的摩擦磨损性能,分析磨损表面形貌,阐明Mo含量对Ni基合金力学和摩擦学性能的影响及其机理,优化Mo元素的含量。结果表明:Mo含量(质量分数)为5%时可以改善镍基合金的拉伸、压缩等力学性能和摩擦学性能;XRD、SEM及 Raman分析表明在500 ℃以上时,磨痕表面形成由NiO、NiMoO4等组成的摩擦层,有效地改善了Ni基合金在高温下的摩擦学性能。

关键词:粉末冶金;镍基合金;钼;摩擦磨损

文章编号:1004-0609(2017)-11-2267-09 中图分类号:TQ127.1 文献标志码:A

航空、航天、核工程等现代高新技术的迅速发展,对极端苛刻工况条件下服役的材料的润滑性能和强度提出了迫切需求[1-2]。以先进发动机为代表的高温部件,它们不仅要求材料具有较高的力学性能,而且要求材料在宽温域(RT~1000 ℃)内具有良好的摩擦学性能[3-4]。

目前研究的宽温域润滑材料多以镍为基体,以金属氧化物(Cr2O3,Al2O3)、合金元素等为强化相[5],通过不同温域润滑剂复配[6]或通过摩擦化学反应自生成润滑剂[7]来实现宽温域的连续润滑,例如DELLACORTE等[8]研究的 PS300、PS304、PS310和PS400 采用Ag和BaF2/CaF2共晶复配实现低温至650℃的润滑;李诗卓等[9-10]研制的Ni-Cu-Re、Co-Cu-Re合金通过生成铼的氧化物和铼酸盐取得了300~800℃下的润滑。但之前有关宽温域润滑材料的力学性能设计及力学性能的考察较少。

镍基合金因在500 ℃以上具有较高的力学性能、较好的抗氧化性能、良好的耐磨损性能以及能固溶大量合金元素而不生成有害相等而成为极佳的基体合 金[2, 11]。在镍基合金中Al、Cr、Mo、W、Ta、Re等是常用的强化元素,其中Al元素与Ni结合生成Ni3Al相,它具备高温时溶解,低温时再析出的特征,可以起沉淀强化的作用[12-14],Cr、Mo、W、Ta等元素在Ni基合金中可以起固溶强化的作用,Cr在高温条件下生成的Cr2O3可以起抗磨作用[15],Mo可起固溶强化的作用,并且其在高温条件下生成的氧化物(如MoO3)及由于摩擦化学反应生成的氧化物钼酸盐(如Ag2MoO4、Ag2Mo2O7)都具有优良的高温润滑作用[16-17],Mo元素既能提高材料的力学性能,又对摩擦学性能有益,因而其作用日益受到人们的重视。

但是关于Mo含量变化对Ni基合金摩擦学性能的研究较少。本文作者以Ni为基体,添加Cr、Mo、Al为强化元素,采用粉末冶金(高能球磨+真空热压烧结)方法制备不同Mo含量的Ni基合金,考察Mo含量对Ni基合金的力学及摩擦学性能的影响,并阐明其机理。其中各元素含量的选择及其依据如下:Cr、Al的含量(质量分数)分别为5%,这是因为Cr虽能起固溶强化的作用,但其含量过高会导致有害相生成,对性能不利;而Al是γ′相形成元素,在Ni基高温合金真正起强化作用的是γ/γ′界面,因此Al含量不宜过高,辛成来等[11]考察了5%和10%的Al对Ni基合金力学和摩擦学性能的影响,表明Al含量的升高降低了合金的抗压强度,因此本研究中Al含量选择为5%。而Mo含量过高易生成有害相,因而在先进的高温合金中,Mo含量最高一般不超过6%,并且呈逐渐下降的趋势,因此本研究选择Mo含量为0、5%、10%,考察Mo含量变化对NiCrMoAl合金力学性能及摩擦学性能的影响。

1 实验

实验所用的原材料为市售的Ni粉(60 μm)、Al粉(45 μm)、Cr粉(45 μm)、Mo粉(45 μm),粉末纯度均在99.5%以上。将上述粉末按照表1所示质量分数加入球磨罐中,放入Fritsch Pulverisette 5高能球磨机中球磨,球磨参数为:球料比为10:1,并加入5 mL甲醇作为球磨介质,转速为250 r/min,转30 min停30 min,球磨时间为20 h。

将球磨后的合金粉末装入石墨磨具(内径为24 mm)中,以一定压力冷压后放入ZT-45-20Y真空热压烧结炉中进行烧结,烧结工艺为:升温速率10 ℃/min,烧结压力为20~30 MPa,在1100~1150 ℃保温保压0.5 h,之后随炉冷却,保温时的真空度在10-2 Pa以下,将烧结后的试样切割成不同尺寸,用碳化硅砂纸打磨并抛光,并用丙酮超声处理待用。

试样的密度采用Archimedes原理测试;利用MH-5维式硬度仪测量材料的硬度(加载力为300 g,保压时间为5 s);用SANS-CMT5205电子万能试验机测试材料的抗压和抗拉强度,试验温度分别为室温、400、600、800和1000 ℃,压缩速率为0.3 mm/min,拉伸速率为屈服前0.1 mm/min、屈服后1 mm/min。

采用UMT-3高温摩擦试验机测试不同Mo含量的Ni基合金的摩擦因数,摩擦方式采用旋转式,上试样是Al2O3球,下试样为Ni基合金。摩擦测试温度分别为室温、300、500、700、900 ℃,旋转速度为0.1 m/s(200 r/min),载荷为20 N,摩擦持续时间为60 min。磨损体积ΔV(单位为mm3)采用如下公式计算:

ΔV=2πRS (1)

式中:S为磨损横截面积,在Nano Map 500LS接触式三维轮廓仪测定,mm2;R为磨痕半径,mm。

磨损率ω(单位为mm3/Nm)的计算公式为

ω=ΔV/(NL) (2)

式中:L为滑动距离,m;N为载荷,N。

为了减小实验误差,所有的试验结果均取3次试验的平均值。用X’PERT PRO型X射线衍射仪(XRD Cu Kα)分析试样烧结前后的物相变化,用TESCA-MIRA3型扫描电子显微镜(SEM)分析试样烧结之后的微观组织形貌及磨损表面形貌,采用拉曼光谱(Raman)仪测定磨损表面物相组成。

2 结果与讨论

2.1 材料的物相组成及力学性能

不同Mo含量的Ni基合金烧结前后的XRD谱如图1所示。可以看出,烧结前Cr、Al等元素基本固溶进Ni基体中,随着Mo含量的升高,Mo峰增强(见图1(a))。烧结后,3种合金中均有Al2O3生成,且在Mo含量为10%的NCA10M合金中,形成了Mo2C陶瓷相(见图1(b)),说明Mo和石墨模具在烧结的过程中发生了固相反应,这与LIU等[7, 18]及KRISHNAM等[19]的研究一致。

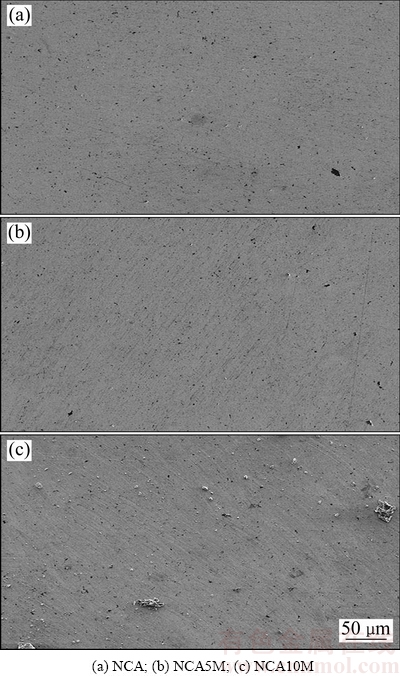

图2所示为3种合金烧结之后的表面形貌。可以看出,3种合金都具有较致密、均匀的组织结构,且表面主要由灰色和少量的白色相组成。EDS分析表明灰色相富含Ni,为Ni基合金;少量白色相富含Al、O,为Al2O3;NCA10M合金中有新相析出,EDS分析表明此相中含大量的C,结合XRD结果分析可知此相为Mo2C。烧结过程中Mo2C的固相反应式如下:

Mo+C→Mo2C (3)

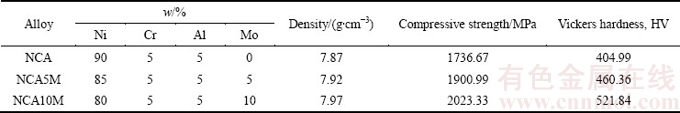

不同Mo含量Ni基合金的密度、硬度、室温抗压强度如表1所列,随着Mo含量的增加,Ni基合金的密度、硬度、抗压强度均增大,其原因是Mo起强化作用。

表1 不同Mo含量的镍基合金的组成及力学性能

Table 1 Composition and mechanical properties of Ni-based alloy with different Mo contents

图1 不同Mo含量的Ni基合金烧结前后的XRD谱

Fig. 1 XRD patterns of Ni-based alloys with different Mo contents

图2 不同Mo含量的Ni基合金SEM像

Fig. 2 SEM morphologies of Ni-based alloys with different Mo contents

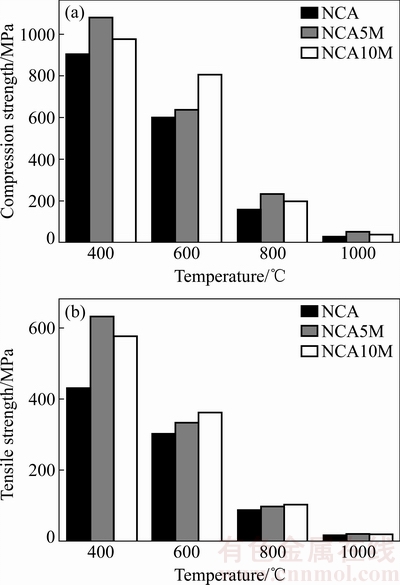

图3 Ni基合金在高温下的抗压和抗拉强度

Fig. 3 Compressive strength (a) and tensile strength (b) of Ni-based alloys at high temperatures

图3所示为添加了不同Mo含量的NCA、NCA5M和NCA10M合金在400、600、800和1000 ℃条件下的抗压和抗拉强度。可以看出,NCA5M合金的抗压、抗拉强度较好(600 ℃除外);600 ℃时,NCA10M合金的抗压、抗拉强度高于NCA5M的,其原因可能是碳化物在中温起强化作用,具体机制仍有待于进一步研究。

2.2 Mo含量对材料摩擦学性能的影响

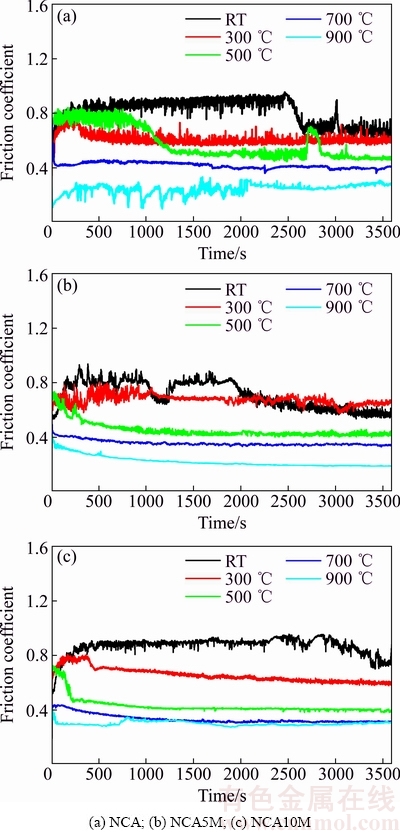

不同Mo含量的Ni基合金在室温~900 ℃的摩擦因数和磨损率示于图4和5,可以看出随着温度的升高,Ni基合金的平均摩擦因数和磨损率均呈降低趋势。并且NCA5M合金的摩擦因数和磨损率均较低,在900 ℃时的摩擦因数低至0.22(图4(a)和5(b))。

图4 不同Mo含量的Ni基合金在不同温度下的摩擦因数和磨损率

Fig. 4 Tribological properties of Ni-based alloys with different Mo contents at different temperatures

图5 不同Mo含量的Ni基合金在不同温度下的摩擦因数随时间变化的曲线

Fig. 5 Curves of friction coefficient vs time of Ni-based alloys with different Mo contents from room temperature to 900 ℃

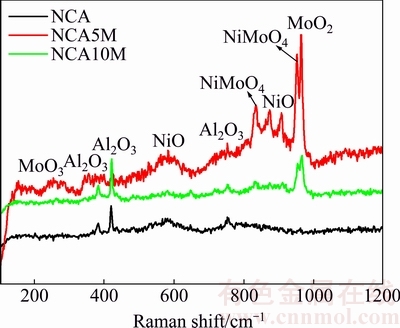

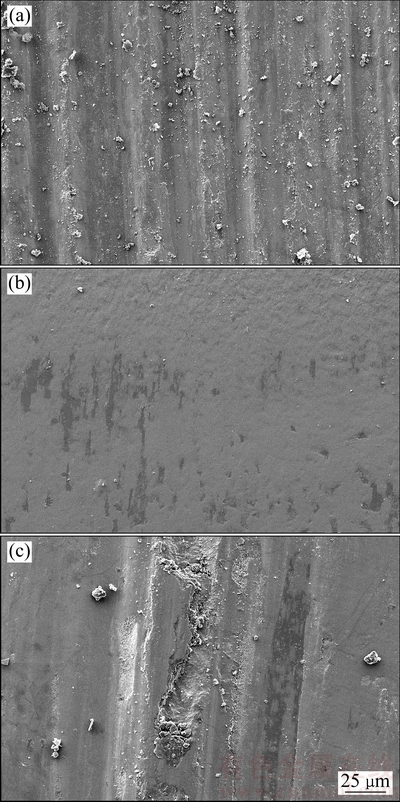

图6所示为镍基合金在不同温度条件下的磨损形貌。可以看出:室温时,3种合金磨损表面均形成了磨屑和少量犁沟(见图6(a1)、(b1)和(c1))。这是试样与对偶材料磨粒磨损所导致的,表明此温度时的磨损机理主要是磨粒磨损,导致摩擦因数高,磨损严重。300 ℃时,3种合金磨损表面由少量磨屑和较深的犁沟组成(见图6(a2)、(b2)和(c2)),表明此时的磨损机理仍以磨粒磨损为主。对3种合金磨损表面拉曼分析可知(见图7),此温度下有少量的NiO生成,NiO可起一定的润滑作用[20],使得合金的摩擦学性能稍有提高。随着温度进一步升高至500 ℃,NCA5M和NCA10M合金磨损表面主要由较浅犁沟组成(见图6(b3)和(c3)),磨损较轻;而NCA合金的磨损表面由大量磨屑和剥落坑组成(见图6(a3)),表明NCA合金此时的磨损机理以磨粒磨损为主。拉曼分析表明,NCA合金在磨痕内外均有NiO生成,表明此温度下的NiO是氧化生成的,并非由摩擦化学反应生成;而NCA5M和NCA10M合金表面不仅有NiO,还有NiMoO4、MoO2和MoO3等润滑相,并且磨痕内MoO2、MoO3和NiMoO4拉曼峰的强度大于磨痕外的,表明摩擦可以促使MoO2、MoO3 和NiMoO4的生成,由此导致NCA5M和NCA10M合金的磨损率和摩擦因数较NCA的低。700 ℃时,NCA合金和NCA10M合金的磨损表面相似,都是由犁沟和少量的分层坑组成(见图6(a4)和(c4)),此时的磨损机理以磨粒磨损和疲劳磨损为主。而NCA5M合金的磨损表面由一层不连续的摩擦层组成(见图6(b4)),结合拉曼分析可知:NCA合金摩擦表面有NiO、MoO2和MoO3 生成,而NCA10M合金与NCA5M合金磨痕表面物相组成相似,都是由NiO、Mo的氧化物及 NiMoO4组成,但NCA5M合金中NiO、MoO2 、NiMoO4等的拉曼峰更强,表明在摩擦化学反应过程中生成的氧化物和钼酸盐更多,形成了不连续的润滑膜,使得NCA5M合金的摩擦学性能优于其他两种合金。900 ℃时,NCA合金和NCA5M合金的摩擦表面都较为平整,

NCA合金磨痕表面形成一层不连续的摩擦层,对偶球摩擦表面有较深的犁沟和很多细小的颗粒组成(见图9(a));而NCA5M合金磨痕表面形成了一层连续的摩擦层,对偶球摩擦表面比较光滑(见图9(b)),且检测出了较多的NiO、MoO2、MoO3、NiMoO4等物质(见图8),表明在摩擦过程中形成了转移膜,阻碍了材料与对偶球的直接接触,因而其摩擦因数和磨损率最低;NCA10M合金表面形成了较浅的犁沟和数量较多的凹坑,此时的磨损机理以疲劳磨损为主,而对偶球摩擦表面出现了大量的磨屑和剥落坑(见图9(c)),且此时形成的转移膜较少,故其摩擦因数较NCA5M的高。由于NCA10M合金中生成了Mo2C相,Mo2C陶瓷相的钉扎作用导致摩擦化学反应过程中生成的NiO、MoO2、MoO3和NiMoO4等润滑相不能连续成膜,未能有效地阻碍摩擦对偶间的直接接触,导致摩擦因数较高。因此,Mo含量过高对材料的摩擦学性能不利。

图6 NCA、NCA5M和NCA10M合金在不同温度条件下的磨损形貌

Fig. 6 SEM morphologies of worn surfaces of NCA (a1-a5), NCA5M (b1-b5) and NCA10M (c1-c5) alloys at different temperatures

综上所述,NCA5M合金具有宽温域内较高的力学性能和高温下良好的摩擦学性能,但中低温下的摩擦学性能较差,加入低温润滑剂(如Ag、MoS2等)以及高温强化相(如Al2O3、Y2O3等),有望得到宽温域内机械性能和摩擦学性能优化统一的材料,目前该部分研究工作仍在进行中。

图7 NCA、NCA5M和NCA10M合金在不同温度下的磨痕内外Raman谱

Fig. 7 Raman spectra of NCA (a1-a5), NCA5M (b1-b5) and NCA10M (c1-c5) alloys after test at different temperatures

图8 900 ℃对偶材料摩擦表面的Raman谱

Fig. 8 Raman spectra of worn surfaces of mating materials at 900 ℃

图9 900 ℃对偶材料表面形貌

Fig. 9 SEM morphologies of worn surfaces of mating material NCA (a), NCA5M (b) and NCA10M (c) of Ni-based alloys at 900 ℃

3 结论

1) 通过粉末冶金的方法制备了组织均匀的不同Mo含量的Ni基合金,NCA10M合金在烧结过程中形成了Mo2C陶瓷相。

2) 随着Mo含量的升高,合金的密度、硬度及室温压缩性能提高,除600 ℃外NCA5M合金的力学性能优于NCA和NCA10M合金的,但其在500 ℃及以下温度的摩擦学性能仍较差。

3)含Mo合金在高温(500 ℃及以上)摩擦过程中形成了含有NiO、NiMoO4、MoO2、MoO3等的润滑膜,降低了合金的摩擦因数和磨损率。NCA5M合金在宽温域内具有较高的力学性能和良好的摩擦学性能。

致谢:感谢中国科学院金属研究所蔡静博士对本研究样品高温力学性能的检测。

REFERENCES

[1] 王常川, 王日初, 彭超群, 冯 艳, 韦小凤. Ni-20Cr/hBN自润滑材料的高温氧化行为[J]. 中国有色金属学报, 2013, 23(2): 356-361.

WANG Chang-chun, WANG Ri-chu, PENG Chao-qun, FENG Yan, WEI Xiao-feng. High temperature oxidation behaviours of Ni20Cr/hBN self-lubricating composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 356-361.

[2] 奚小波, 缪 宏, 金亦富, 郑再象, 呈吉林, 张瑞宏. Ni-Co-Mn合金的电镀工艺优化及与金刚石复合镀的摩擦磨损性能[J]. 中国有色金属学报, 2015, 25(9): 2523-2530.

XI Xiao-bo, MIAO Hong, JIN Yi-fu, ZHENG Zai-xiang, CHENG Ji-lin, ZHANG Rui-hong.Electroplating process optimization of Ni-Co-Mn alloy and tribological wear performance of composition plating with diamond[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2523-2530.

[3] JOHN P J, ZABINSKI J S. Sulfate based coatings for use as high temperature lubricants[J]. Tribology Letters, 1999, 7(1): 31-37.

[4] VOEVODIN A A, ZABINSKI J S. Nanocomposite and nanostructured tribological materials for space applications[J]. Composites Science and Technology, 2005, 65(5): 741-748.

[5] HE Long, TAN Ye-fa, TAN Hua, ZHOU Chun-hua,GAO Li. Tribological properties of nanostructured Al2O3-40%TiO2 multiphase ceramic particles reinforced Ni-based alloy composite coatings[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2618-2627.

[6] LI Jian-liang, XIONG Dang-sheng, HUANG Zhong-jia, KONG Jian, DAI Ji-hui. Effect of Ag and CeO2 on friction and wear properties of Ni-base composite at high temperature[J]. Wear, 2009, 267(1/4): 576-584.

[7] LIU Er-yong, WANG Wen-zhen, GAO Yi-min, JIA Jun-hong. Tribological properties of Ni-based self-lubricating composites with addition of silver and molybdenum disulfide[J]. Tribology Internationl, 2013, 57(4): 235-241.

[8] DELLACORTE C, LASKOWSKI J A. Tribological Evaluation of PS300: A new chrome oxide-based solid lubricant coating sliding against Al2O3 from 25 ℃ to 650 ℃[J]. Tribology Transactions, 1996, 40(1): 163-167.

[9] 李诗卓, 姜晓霞, 尹付成, PETERSON M B. CALABRESE S J. Ni-Cu-Re高温自润滑合金的研究[J]. 材料科学进展, 1989, 3(6): 481-486.

LI Shi-zhuo, JIANG Xiao-xia, YIN Fu-cheng, PETERSON M B, CALABRESE S J. On self-lubricating behavior of Ni-Cu-Re alloy at elevated temperature[J]. Material Science Progress, 1989, 3(6): 481-486.

[10] 姜晓霞, 李诗卓, PETERSON M B, CALABRESE S J. Co-Cu-Re高温自润滑合金的研究[J]. 材料科学进展, 1989, 3(6): 487-493.

JIANG Xiao-xia, LI Shi-zhuo, PETERSON M B, CALABRESE S J. On self-lubricating behavior of Co-Cu-Re alloy at elevated temperature[J]. Material Science Progress, 1989, 3(6): 487-493.

[11] 辛成来, 王文珍, 马 勤, 国洪建. Co含量对一种Ni-Co-Al粉末高温合金摩擦学性能的影响[J]. 材料研究学报, 2014, 28(7): 490-496.

XIN Cheng-lai, WANG Wen-zhen, MA Qin, GUO Hong-jian. Effect of Co content on tribological behavior of Ni-Co-Al P/M superalloy[J]. Chinese Journal of Materials Research, 2014, 28(7): 490-496.

[12] 谢锡善, 董建新, 付书红, 张麦仓. γ′和γ″相强化的Ni-Fe基高温合金GH4169的研究与发展[J]. 金属学报, 2010, 46(11): 1289-1302.

XIE Xi-shan, DONG Jian-xin, FU Shu-hong, ZHANG Mai-cang. Research and development of γ″ and γ′ strengthened Ni-Fe based superalloy GH4169[J]. Acta Metallurgica Sinica, 2010, 46(11): 1289-1302.

[13] 王常川, 王日初, 彭超群, 冯 艳, 韦小凤. 金属基固体自润滑复合材料的研究进展[J]. 中国有色金属学报, 2012, 22(7): 1945-1955.

WANG Chang-chuan, WANG Ri-chu, PENG Chao-qun, FENG Yan, WEI Xiao-feng. Research progress of metallic solid self-lubricating composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1945-1955.

[14] LU Yan-li, LU Guang-ming, JIA De-wei, CHEN Zheng. Phase-field study on competition precipitation process of Ni-Al-V alloy [J]. Transations of Nonferrous Metals Society of China, 2015, 25(2): 544-551.

[15] ZHANG Wen-ting, DU Ling-zhong, LAN Hao, HUANG Chuan-bin, ZHANG Wei-gang. Wear behavior of a NiCr/AgVO3 self-lubricating composite[J]. Acta Metallurgica Sinica, 2013, 26(4): 435-440.

[16] LIU Er-yong, WANG Wen-zhen, GAO Yi-min, JIA Jun-hong. Tribological properties of adaptive Ni-Based composites with addition of lubricious Ag2MoO4 at elevated temperatures[J]. Tribology Letters, 2012, 47(1): 21-30.

[17] WANG Jian-yi, SHAN Yu, GUO Hong-jian, LI Bo, WANG Wen-zhen, JIA Jun-hong. Friction and wear characteristics of hot-pressed NiCr–Mo/MoO3/Ag self-lubrication composites at elevated temperatures up to 900 ℃[J]. Tribology Letters, 2015, 59(3): 1-16.

[18] LIU Er-yong, GAO Yi-min, BAI Ya-ping, YI Ge-wen, WANG Wen-zhen, ZENG Zhi-xiang, JIA Jun-hong. Tribological properties of self-lubricating NiAl/Mo-based composites containing AgVO3 nanowires[J]. Materials Characterization, 2014, 97(97): 116-124.

[19] KRISHNAM P, KAUFMAN M J. Development and characterization of interface coatings in molybdenum-reinforced NiAl matrix composites[J]. Metallurgical and Materials Transactions A, 1994, 25(10): 2111-2116.

[20] PETERSON M B, CALABRESE S J, LI Shi-zhuo, JIANG Xiao-xia. Friction of alloys at high temperature[J]. Journal of Materials Science and Technology, 1994, 10(5): 313-320.

Effect of molybdenum content on mechanical and tribological properties of nickel- base alloy

YANG Su-lan1,2, MA Qin1, WANG Wen-zhen2, JIA Jun-hong2

(1. State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China;

2. State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou 730000, China)

Abstract: Ni-based alloys with different Mo contents were prepared by the powder metallurgy. The mechanical properties from RT to 1000 ℃ and the tribological properties from RT to 900 ℃ were investigated, and the wear surfaces morphologies were analyzed. The effect of Mo content on the mechanical and tribological properties and the mechanism were elucidated. The results show that the mechanical properties and tribological properties of Ni-based alloy can be improved when the molybdenum content is 5%. The worn surfaces examined by XRD, SEM and Raman indicate that the tribo-layers consist of NiO and NiMoO4 at temperature above 500 ℃, which is responsible for the reduced friction coefficient and wear rate of Ni-based alloy at high temperatures.

Key words: powder metallurgy; Ni-based alloy; Mo; friction and wear

Foundation item: Projects(51471180, 51675508) supported by National Natural Science Foundation of China

Received date: 2016-10-25; Accepted date: 2017-06-12

Corresponding author: MA Qin; Tel: +86-18809311515; E-mail: maq0931@126.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51471180, 51675508)

收稿日期:2016-10-25;修订日期:2017-06-12

通信作者:马 勤,教授,博士;电话:18809311515;E-mail: maq0931@126.com