文章编号:1004-0609(2012)08-2340-07

微米孔径多孔铝的制备及性能

黄国涛1, 2,左孝青1,陆建生1,周 芸1

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 中国重汽济南卡车股份有限公司,济南 250116)

摘 要:为获得高强度的微米孔径多孔铝,通过真空-压力烧结-溶解工艺制备微米孔径多孔铝,对制备过程、微米孔径多孔铝的强度及渗透性能进行研究。结果表明:真空环境下的压力烧结可明显促进铝粉烧结,提高微米孔径多孔铝的抗弯强度;在压制压力500 MPa、烧结温度650 ℃、烧结时间2 h以及烧结压力150~200 MPa条件下可获得孔隙率44%~61%、平均孔径55~230 μm的多孔铝;随着孔隙率和平均孔径的提高,微米孔径多孔铝的相对渗透系数增大;与尺寸相同、孔结构相似的多孔不锈钢相比,微米孔径多孔铝具有较好的渗透性能和较高的耐压破坏比强度。

关键词:多孔铝;微米孔径;强度;渗透性

中图分类号:TF124;TF125.6 文献标志码:A

Fabrication and properties of micron cell porous Al

HUANG Guo-tao1, 2, ZUO Xiao-qing1, LU Jian-sheng1, ZHOU Yun1

(1. School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. CNHTC Jinan Truck Company, SINOTRUCK, Ji’nan 250116, China)

Abstract: Micron cell porous Al with high strength was fabricated by the vacuum-pressure sintering-dissolution processing. The preparation processing, strength and filtration property of the fabricated porous Al were studied. The results show that the sintering processing of Al powder under vacuum condition can be promoted evidently by applying a certain pressure to the sintered sample and result in a micron cell porous Al with high bending strength. Taking bending strength as the goal, the optimal processing parameters for fabricating micron cell porous Al with porosity 44%-61% and average cell diameter 55-230 μm were deduced experimentally as cold pressure 500 MPa, sintering temperature 650 ℃, sintering time 2 h and sintering pressure 150-200 MPa. With the increase of the porosity and average cell diameter, the relative permeability coefficient of porous Al increases. Compared with the porous stainless steel that has the same size and similar cell structure, the micron cell porous Al possesses a good filtration property and a higher specific compression collapsing strength.

Key words: porous Al; micron cell; strength; filtration property

微米孔径(10~200 μm)多孔金属在过滤分离、催化载体、电极材料等方面有广泛的应用[1-4]。目前,微米孔径金属过滤材料多以不锈钢[5]、钛[6]为主,成本较 高,而微米孔径多孔铝由于比强度高、成本低,可在一定环境下取代不锈钢、钛微米孔径金属材料。

目前,微米孔径多孔铝的制备方法主要是渗流铸造法[7]及烧结溶解法。在渗流铸造法中,当渗流前驱NaCl颗粒粒度小于100 μm时,由于微细孔的毛细作用使熔体渗流不充分,因此,渗流方法难以获得孔径小于100 μm的多孔铝。烧结溶解法的孔径适应范围宽,是制备微米孔径多孔铝的主流方法,在材料制备、孔结构及力学性能研究等方面已取得一定进展,如Surace等[8]研究了工艺参数对孔结构和压缩性能的影响、Goodall等[9]研究了孔形貌对力学性能的影响、Zhao等[10]研究了液相烧结的作用等。烧结溶解法制备多孔铝过程中,最大的问题是铝粉表面存在Al2O3膜,其化学性质十分稳定且耐高温,导致烧结困难、所制备产品强度低[11],而液相烧结会导致铝熔体的渗出[10]。因此,铝粉-NaCl颗粒混合体的烧结是微米孔径多孔铝获得广泛应用必须解决的瓶颈问题。

在烧结溶解法的基础上,本文作者采用真 空[12-13]-压力烧结-溶解的新方法制备微米孔径多孔铝,在烧结过程中引入烧结压力,解决铝粉/NaCl颗粒混合体烧结困难的问题,获得高强度的微米孔径多孔铝。对微米孔径多孔铝的真空-压力烧结-溶解制备、抗弯强度及渗透性能进行了研究,以期对微米孔径多孔铝的开发应用提供有益的参考。

1 实验

1.1 材料制备

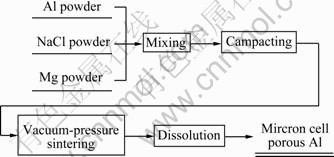

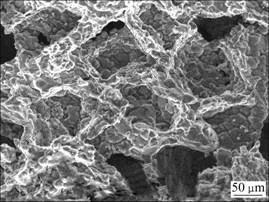

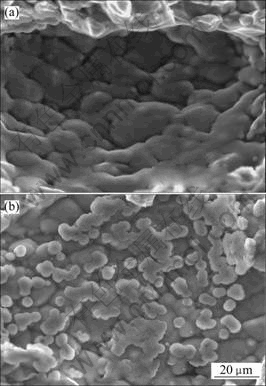

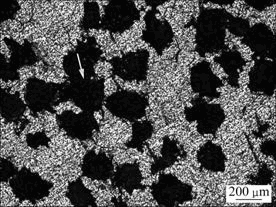

材料制备工艺如图1所示。采用雾化Al粉(55~75 μm)为基体材料;NaCl为造孔剂,经干燥破碎筛分成不同粒度(55~75 μm、75~96 μm、96~120 μm、120~150 μm和150~180 μm);Mg粉为助烧剂[10, 14]。将铝粉与NaCl按一定体积比配料,加入铝粉质量2%的Mg粉,在混料机中混合4 h,在300~600 MPa压力下压制成 D 36 mm×2 mm(渗透性能检测、耐压破坏强度检测规格)和30 mm×12 mm×6 mm(抗弯强度检测规格)的压坯,压坯装入特制的、可施压的模具中预加压(烧结压力,可在烧结过程中一直保持该压力),后置于真空(6×10-2 Pa)炉中随炉升温,在640~655 ℃烧结2 h后得到微米孔径多孔铝。图2所示为孔隙率55%、平均孔径110 μm的微米孔径多孔铝的SEM像。

1.2 测试方法

孔结构(孔隙率和平均孔径)采用孔结构分析软件BWJScan进行分析[15];孔微观形貌采用飞利浦XL30ESM-TMP扫描电镜进行观察;多孔铝抗弯强度采用AG-IS 10 kN力学试验机,按照《GB/T 5319—2002烧结金属材料(不包括硬质合金)横向断裂强度测定》方法进行测试;多孔铝耐压破坏强度采用多孔材料疲劳检测仪进行分析;多孔铝渗透系数采用FBP-Ⅲ型多孔材料性能检测仪,按照GB/T 5250—93方法进行测定。

图1 微米孔径多孔铝制备工艺流程图

Fig. 1 Fabricating process of micron cell porous Al

图2 孔隙率55%、平均孔径110 μm多孔铝的SEM像

Fig. 2 SEM image of micron cell porous Al with porosity of 55% and average pore diameter of 110 μm

2 结果与讨论

2.1 多孔铝的抗弯强度

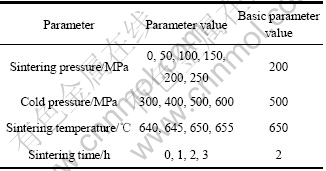

以抗弯强度为优化目标,对真空-压力烧结-溶解法制备多孔铝过程中的压制压力、烧结温度、烧结时间和烧结压力等工艺参数进行了实验研究,表1所列为实验参数表,当某个参数变化时,其他参数的取值为表中的基本参数,重点讨论了烧结压力对抗弯强度的影响,以获得优化的工艺参数配置。

2.1.1 烧结压力对抗弯强度的影响

对铝粉与NaCl颗粒的混合物进行冷压,可在一定程度上破坏铝粉表面的氧化膜,但所需压力大,而且过大压力会造成造孔剂的破碎变形。然而,当铝粉在接近熔融状态施加压力(烧结压力)时,可轻易破坏铝粉表面的氧化膜,产生金属间的接触而实现铝粉颗粒间的冶金结合,改善烧结试样的力学性能。

表1 多孔铝的制备实验参数

Table 1 Experimental parameters of porous Al fabrication

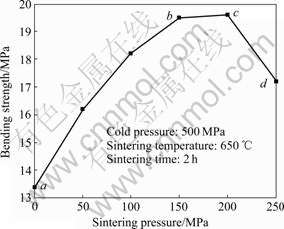

图3所示为烧结压力对抗弯强度的影响,未施加烧结压力时,抗弯强度较低(图3中点a),随烧结压力增大,抗弯强度增大,在烧结压力为150~200 MPa时,抗弯强度达到最大(图3中点b、c),进一步提高烧结压力到250 MPa时,抗弯强度大幅度下降(图3中点d)。

图3 烧结压力对抗弯强度的影响(试样孔隙率61%,平均孔径230 μm)

Fig. 3 Influence of sintering pressure on bending strength (samples with porosity of 61% and average pore diameter of 230 μm)

图4(a)所示为与图3中点b对应的多孔铝的微观组织,可见铝粉颗粒之间结合良好,无明显的空隙存在,烧结颈明显。图4(b)所示为与图3中点d对应的多孔铝的微观组织,可见其中有大量铝液在Al-NaCl界面溢出,形成了不连续的表面缺陷,并导致基体金属的缺失,这是烧结体力学性能下降的原因。与冷压真空溶解烧结法所制备试样的微观组织[12]对比,采用本工艺制备的多孔铝,铝粉颗粒之间的颗粒界面弱化, 空隙数量较少,烧结颈明显,这说明烧结压力对烧结过程有显著的促进作用。

图4 不同条件制备的多孔铝的SEM像

Fig. 4 SEM images of porous Al prepared by different processes: (a) Vacuum-pressure sintering-dissolution process at sintering pressure of 150 MPa; (b) Vacuum-pressure sintering- dissolution process at sintering pressure of 250 MPa

根据理想两球模型(见图5),烧结原动力为作用在烧结颈上的应力( ):

):

(1)

(1)

式中:γ为表面张力;ρ为烧结颈曲率半径,其中负号表示应力为方向向外的张力,其效果是使烧结颈长大。

施加烧结压力p后,两球在力的作用下相对移动(图5虚线),烧结颈曲率半径ρ减小,导致烧结原动力σ变大,使烧结颈的形成和长大更容易,促进了烧结过程。

图5 烧结两球模型

Fig. 5 Two ball model of sintering process

2.1.2 压制压力对抗弯强度的影响

图6所示为压制压力对抗弯强度的影响。由图6可知,随压制压力的增大,铝粉颗粒间的氧化膜破裂、结合充分,抗弯强度逐渐增大,在500 MPa时达到最大,之后逐渐下降,这是由于在压制压力600 MPa的情况下,造孔剂破碎,导致铝粉颗粒间应力松弛、孔形状变得不规则,抗弯强度下降。

图6 压制压力对抗弯强度的影响(试样孔隙率44%,平均孔径110 μm)

Fig. 6 Influence of cold pressure on bending strength (samples with porosity of 44% and average pore diameter of 110 μm)

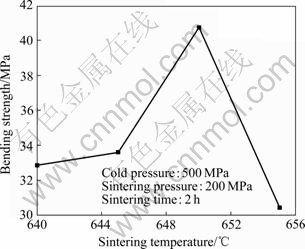

2.1.3 烧结温度对抗弯强度的影响

图7所示为烧结温度对抗弯强度的影响。由图7可知,随烧结温度的升高,试样内铝粉颗粒之间的烧结越来越充分,抗弯强度逐渐增大,并在650 ℃时达到最大,当烧结温度提高到655 ℃(接近铝的熔点)时,抗弯强度急剧下降,原因是在过高的烧结温度下,温度起伏导致铝熔化,熔融铝液溢出基体外部,造成孔缺陷及基体内部分金属基体缺失。

图7 烧结温度对抗弯强度的影响(试样孔隙率55%,平均孔径110 μm)

Fig. 7 Influence of sintering temperature on bending strength (samples with porosity of 55% and average pore diameter of 110 μm)

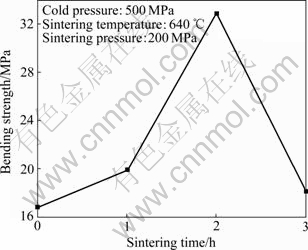

2.1.4 烧结时间对抗弯强度的影响

图8所示为烧结时间对抗弯强度的影响。由图8可知,随烧结时间的延长,多孔铝的抗弯强度增大,在2 h处达到最大,之后急剧下降。在未烧结试样中,颗粒之间的结合仅为机械结合,因此,抗弯强度很低。试样经烧结保温后,铝粉之间的冶金结合程度提高,抗弯强度随之增大。但烧结时间过长(高于2 h)时,由于烧结环境的温度起伏,也会导致部分铝熔化并溢出试样外,使抗弯强度降低。

图8 烧结时间对抗弯强度的影响(试样孔隙率55%,平均孔径110 μm)

Fig. 8 Influence of sintering time on bending strength (samples with porosity of 55% and average pore diameter of 110 μm)

2.2 孔结构

2.2.1 造孔剂体积含量对孔隙率的影响

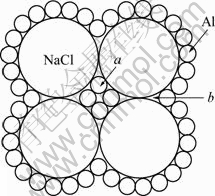

图9所示为造孔剂体积含量对孔隙率的影响。由图9可看出,随造孔剂含量的增大,孔隙率逐渐上升,且孔隙率稍高于造孔剂的体积含量。这是由于部分微细铝粉被造孔剂所包围,未能形成连续的金属基体(见图10 中a部位),水溶解时随造孔剂一起排出;此外,试样经压制、烧结后内部仍存在一定空隙(图10 中b部位),导致孔隙率稍高于造孔剂的体积含量。

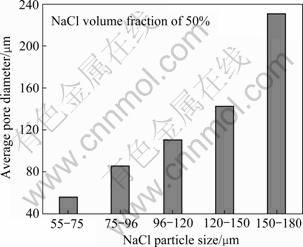

2.2.2 造孔剂粒度对平均孔径的影响

图11所示为造孔剂粒度对平均孔径的影响。由图11可知,随造孔剂粒度增大,平均孔径提高,当造孔剂粒度为150~180 μm时,平均孔径为230 μm、高于造孔剂粒度,这是由于当造孔剂粒度远比铝粉粒度大时,压制过程中容易产生大面积的造孔剂颗粒接触(见图12),使孔合并,导致平均孔径增大。

图9 造孔剂NaCl体积分数对孔隙率的影响

Fig. 9 Influence of NaCl volume fraction on porosity

图10 铝粉-NaCl结构示意图

Fig. 10 Sketch map of aluminum powder-NaCl structure

图11 造孔剂粒度对平均孔径的影响

Fig. 11 Influence of NaCl particle size on average pore diameter

图12 以孔径150~180 μm造孔剂颗粒制备的冷压样照片

Fig. 12 Photo of cold pressed sample by using 150-180 μm NaCl particles

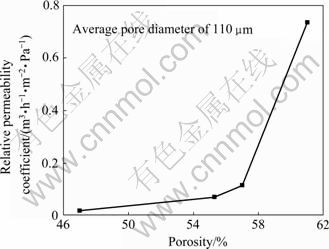

2.2.3 孔隙率对渗透性能的影响

孔隙率对渗透性能的影响如图13所示。由图13可见,相对渗透系数随孔隙率的增大而增大,因此,孔隙率越高,微米孔径多孔铝的渗透性能越好。

图13 孔隙率对相对渗透系数的影响

Fig. 13 Influence of porosity on relative permeability coefficient

2.2.4 平均孔径对渗透性能的影响

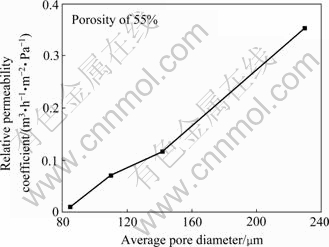

平均孔径对相对渗透系数的影响如图14所示。由图14可知,相对渗透系数随平均孔径的增大而增大,渗透性能提高,但平均孔径的增大意味着过滤精度的下降,因此,在实际应用时必须协调好二者的关系。

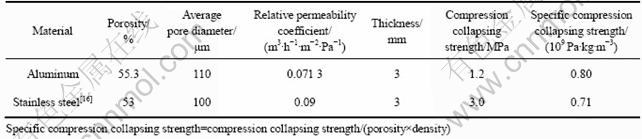

2.3 与多孔不锈钢的比较

过滤是多孔铝的主要应用目标,在保证过滤性能的前提下,所制备的微米孔径多孔铝对过滤环境的适应性是重点,而过滤材料一般是在一定压力下工作的,工程上通常采用耐压破坏强度[16]来衡量其抗压能力。

表2 多孔金属过滤材料的性能

Table 2 Properties of porous metal filtration materials

图14 平均孔径对相对渗透系数的影响

Fig. 14 Influence of average pore diameter on relative permeability coefficient

通过相似条件下与多孔不锈钢的性能对比(见表2)可见,微米孔径多孔铝具有与多孔不锈钢相当的渗透性能,满足作为过滤材料的要求;在耐压破坏强度方面,由于材料自身的限制,微米孔径多孔铝的耐压破坏强度较低,但其耐压破坏比强度超过了多孔不锈钢。因此,微米孔径多孔铝满足在低压(<1 MPa)过滤环境下的使用要求。

3 结论

1) 真空环境下的压力烧结可明显促进铝粉-NaCl压坯的烧结,以抗弯强度为优化目标,获得了制备微米孔径多孔铝的优化工艺参数如下:压制压力500 MPa,烧结温度650 ℃,烧结时间2 h,烧结压力150~200 MPa。

2) 微米孔径多孔铝的孔隙率稍高于造孔剂的体积含量,平均孔径在造孔剂粒度相对于铝粉粒度较大时大于造孔剂粒度;通过造孔剂粒度和含量的控制,成功制备出了孔隙率44%~61%、平均孔径55~230 μm的微米孔径多孔铝。

3) 随孔隙率和平均孔径提高,微米孔径多孔铝的相对渗透系数增大,渗透性能提高;与相似条件下的多孔不锈钢相比,微米孔径多孔铝具有较好的渗透性能和高的耐压破坏比强度。

REFERENCES

[1] Degischer H P, Kriszt B. Handbook of cellular metals: Production, processing, applications[M]. Verlag Gmbh Weinheim: wiley VCH, 2002: 27.

[2] 卢天健, 刘 涛, 邓子辰. 多孔金属材料多功能化设计的若干进展[J]. 力学与实践, 2008, 30(1): 1-9.

LU Tian-jian, LIU Tao, DENG Zi-chen. Multifunctional design of cellular metals: A review[J]. Mechanics and Engineering, 2008, 30(1): 1-9.

[3] 汤慧萍, 谈 萍, 奚正平, 汪强兵. 烧结金属多孔材料研究进展[J]. 稀有金属材料与工程, 2006, 35(z1): 428-432.

TANG Hui-ping, TAN Ping, XI Zheng-ping, WANG Qiang-bing. Research progress of sintered porous metal[J]. Rare Metal Materials and Engineering, 2006, 35(z1): 428-432.

[4] 汪强兵, 汤慧萍, 奚正平, 张 健, 李增峰. 煤气化技术用金属多孔材料研究进展[J]. 稀有金属材料与工程, 2006, 35(z1): 448-451.

WANG Qiang-bing, TANG Hui-ping, XI Zheng-ping, ZHANG Jian, LI Zeng-feng. The studies progress of the metal porous material using in the gasification technology[J]. Rare Metal Materials and Engineering, 2006, 35(z1): 448-451.

[5] Tang Hui-ping,Xi Zheng-ping,Dong Ling-feng. Preparation and application of porous stainless steel cone/tube in coal gasification engineering[J]. Rare Metal Materials and Engineering, 2009, 38(6): 947-950.

[6] LI Yan, GUO Zhi-meng, HAO Jun-jie, REN Shu-bin. Porosity and mechanical properties of porous titanium fabricated by gelcasting[J]. Rare Metals, 2008, 27(3): 282-286.

[7] 黄 可, 王 权, 何思渊, 王 辉, 何德坪. 小孔径通孔多孔铝合金的防风降噪性能[J]. 中国有色金属学报, 2009, 19(9): 1633.

HUANG Ke, WANG Quan, HE Si-yuan, WANG Hui, HE De-pin. Airflow noise attenuation capacity of porous Al alloy with small pore diameter[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1632-1635.

[8] Surace R, De Filippis L A C, Ludovico A D, Boghetich G. Influence of processing parameters on aluminium foam produced by space holder technique[J]. Materials and Design, 2009, 30: 1878-1885.

[9] Goodall R, Despois J F, Marmottant A, Salvo L, Mortensen A. The effect of preform processing on replicated aluminium foam structure and mechanical properties[J]. Scripta Materialia, 2006, 54: 2069-2073.

[10] ZHAO Yu-yuan, HAN Fu-sheng, FUNG T. Optimization of compaction and liquid-state sintering in sintering and dissolution process for manufacturing Al foams[J]. Materials Science and Engineering A, 2004, 364: 117-125.

[11] 宝鸡有色金属研究所. 粉末冶金多孔材料[M]. 北京: 冶金工业出版社, 1978.

Baoji Non-Ferrous Metals Institute. Power metallurgy porous materials[M]. Beijing: Metallurgical Industry Press, 1978.

[12] Jiang B, Zhao N Q, Shi C S, Du X W, Li J J, Man H C. A novel method for making open cell aluminum foams by powder sintering process[J]. Materials Letters, 2005, 59: 3333-3336.

[13] 赵乃琴, 赵万祥, 富东慧, 徐家富, 周福刚. 冷压-溶解-真空烧结法制备泡沫铝的工艺研究[J]. 金属热处理, 2005, 30(12): 20-23.

ZHAO Nai-qin, ZHAO Wan-xiang, FU Dong-hui, XU Jia-fu, ZHOU Fu-gang. Manufacturing aluminum foam by press-dissolution-vacuum sintering process[J]. Heat Treatment of Metals, 2005, 30(12): 20-23.

[14] Lumley R N, Sercombe T B, Schaffer G M. Surface oxide and the role of magnesium during the sintering of aluminum[J]. Metallurgical and Materials Transactions A, 1999, 30(2): 457-463.

[15] 左孝青, 廖明顺, 潘晓亮. VB和计算机图形学在多孔材料中的应用[J]. 金属热处理, 2006, 31(s): s98-s101.

ZUO Xiao-qing, LIAO Ming-shun, PAN Xiao-liang. Application of VB and computer graphics in cellular materials[J]. Heat Treatment of Metals, 2006, 31(s): s98-s101.

[16] http://www.ti-pm.cn.

(编辑 龙怀中)

基金项目:云南省应用基础研究重点项目(2010CC004);云南省人才培养项目(2006PY01-06);云南省国际合作项目(2006GH21)

收稿日期:2011-03-21;修订日期:2012-04-25

通信作者:左孝青, 教授,博士;电话:0871-6735058;E-mail: zxqdzhhm@hotmail.com