文章编号: 1004-0609(2005)08-1262-05

铝液充型过程水模拟计算机可视化技术

赵忠兴1, 2, 王松涛2, 闻绍玲2, 翟玉春1

(1. 东北大学 材料与冶金学院, 沈阳 110006; 2. 沈阳理工大学 材料科学与工程学院, 沈阳 110168)

摘 要: 采用可视观察方法研究了铝液充型过程的二维流动状态, 并与水模拟实验进行了对比分析, 通过调整水粘度来保证水模拟过程与铝液充型过程的相似性。 以PIV技术为基础, 运用数字视频处理中的运动补偿技术, 选用NCCF准则和三步搜索法对低压铸造浇注系统水模拟充型过程的内部二维流场进行了计算和分析; 运用边缘检测及提取技术, 选用Roberts边缘检测算子对低压铸造浇注系统水模拟充型过程的二维表面流场进行了计算和分析, 实现了水模拟过程的量化分析。

关键词: 铝液充型; 水模拟; 粒子图像测速技术; 流场; 计算机可视化

中图分类号: TG244.1

文献标识码: A

Computer video technology of water simulation for

aluminum liquid filling process

ZHAO Zhong-xing1, 2, WANG Song-tao2, WEN Shao-ling2, ZHAI Yu-chun1

(1. College of Materials and Metallurgy, Northeastern University, Shenyang 110006, China;

2. College of Materials Science and Engineering,Shenyang Ligong University, Shenyang 110168, China)

Abstract: The two-dimension flowing state of aluminum liquid filling process was studied by video observation and was contrasted with water simulation experiment, which ensure water simulation comparability with aluminum liquid filling process by changing water viscosity. On PIV technology, the inside two-dimension fluid field of water simulation filling process for low-die casting gating was calculated and analyzed by movement compensate technology in digital video processing and NCCF rule. On edge inspecting and picking-up technology, the two-dimension surface fluid field of water simulation filling process for low-die casting gating was calculated and analyzed by Roberts edge inspect arithmetic operators. It realizes the quantity analyses of water simulation process.

Key words: aluminum liquid filling; water simulation; particle image velocimetry technology(PIV); fluid field; computer video

铝液充型过程是复杂的高温、 动态、 瞬时的流动过程, 在这个过程中极易产生氧化、 飞溅、 卷气等一系列化学和物理变化, 对铸件内部缺陷的产生有着重要的影响。 直接观察铝液的充型状态难度较大, 在对铝液充型过程的研究中, 较成熟的技术是计算机数值模拟[1, 2]和物理模拟。 水模拟技术是常用的物理模拟研究方法, 但传统的水模拟技术只能实现对流动状态的定性分析, 研究过程局限于流动过程的显示和对流动趋势的判断[ 3-5], 很难进行场定量分析, 这种非量化的研究方法限制了水模拟技术的发展。

随着近代计算机图像处理技术以及激光技术的发展, 上世纪末快速发展起来的PIV(particle image velocimetry)技术是在流场显示的基础上, 利用计算机图形图像学高速有效的算法, 对液体流场图像进行定量化研究, 使流动可视化研究发生从定性到定量的转变。 在国外很多研究者采用该技术开展了了铝液充型状态水模拟过程的定量分析, 为水模拟的发展奠定了基础[6-10], 而国内在该领域的研究只处于起步阶段。 本文作者通过直接观察和记录铝液在浇注系统内的流动状态与水模拟实验的对比, 研究水模拟技术的相似准则, 采用PIV技术, 对水模拟过程的二维流场进行可视化研究。

1 铝液实际充型状态与水模拟的对比分析

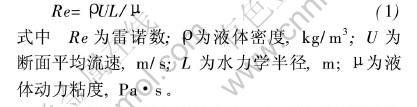

水模拟技术的理论基础是粘性流体运动的相似定律, 满足模型的几何相似和流体的力学相似, 即在几何相似的流场中使无量纲参数St(Strouhal number)、 Eu(Euler number)、 Re(Reynolds number)、 Fr(Frouds number)相等[11], 在几何相似的条件下, 可以满足St、 Eu、 Fr数的相等, 对于Re数, 由下式可推导出保证Re相等的条件是调整ρ/μ的比值, 使ρ(铝液)/μ(铝液)=ρ(水)/μ(水)相等, 即可保证水模拟过程与铝液流动状态的相似。

但在铝液实际充型过程中, 由于铸型的激冷作用, 铝液的温度不断下降, 而ρ、 μ均为温度的函数, 对铝液实际流动过程ρ/μ比值的控制有一定的难度。 为了保证水模拟实验与铝液实际充型过程的相似性, 调整水的粘度, 在同一尺寸的铸型和模型内, 保证铝液流动过程与水流动过程的一致性。

1.1 铝液实际充型过程的实验

采用树脂砂型, 石英玻璃板作为观察窗, 浇注温度730℃, 铝液流动状态如图1所示。

图1 不同时刻铝液流动状态

Fig.1 Aluminum flowing state on different time

1.2 水模拟实验

调整水的粘度, 加入0.215%聚丙烯酰胺使水溶液的粘度为6.537(Pa·s×10-3), 水溶液在模型中的流动状态如图2所示。

图2 不同时刻水溶液流动状态

Fig.2 Water solution flowing state on different time

由图1、 2的实验结果分析, 根据合金的种类及浇注参数, 调整水的粘度, 使水模拟过程中水的流动状态与铝液的流动状态具有相似性, 为水模拟实验提供了可信性。

2 PIV技术基本原理及图像处理算法

2.1 PIV技术基本原理

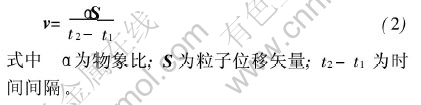

PIV技术是一种流场显示技术[12], 其基本原理为: 在被测流体中放入随动性较好的某种示踪粒子, 将要研究的区域用激光片光源照亮, 通过某种记录设备, 将要研究流场的流动过程记录下来, 然后通过图形图像学中的相关技术, 找出同一粒子在两幅图像上的位置, 根据下式就可以计算出要求的速度矢量:

2.2 水模拟充型内部速度场的图像处理算法

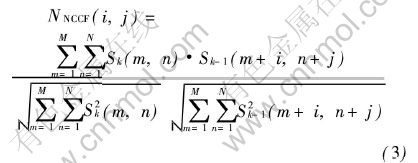

PIV技术的关键在于建立检测粒子图像位移的算法。 本文对铸造充型过程中的速度场进行研究, 液体流动速度较快, 而且粒子数量较多, 所以基于BICC算法的PIV技术[13]和对应于低粒子密度图像的四帧—PTV算法等都是不合适的。 综合考虑计算速度以及精度的要求, 决定采用数字视频处理中用到的运动补偿技术[14, 15]。

运动补偿技术通常包括如下一些处理: 1)从图像中分割出运动目标; 2)对运动目标进行估值; 3)用位移估值进行补偿预测; 4)对预测信息进行编码。 这里主要用到了1)和2)。 在具体实现上, 采用目前通用的块匹配技术实现目标的估值。 选用对噪声有自免疫能力但运算量较大的归一化二维互相关函数NCCF(normalized 2-D cross-correlation function)进行运算。

NCCF准则的定义为

搜索策略采用了速度较快的三步搜索法[15] 。

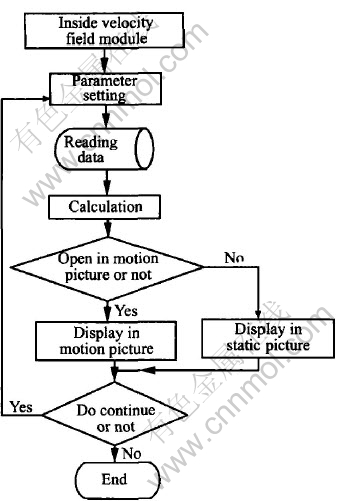

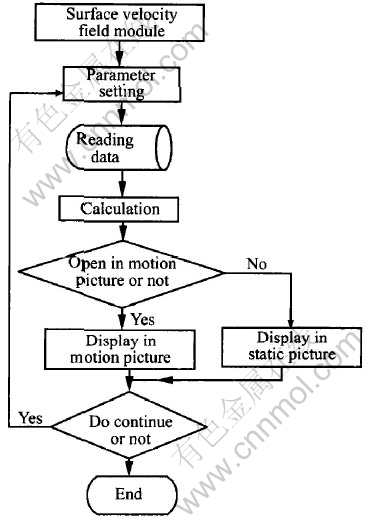

对获取的数据按图3的流程图作相应处理, 就可以以数字的方式重建整个自由表面流动场, 精确的重现整个流动过程。

图3 内部速度场模块

Fig.3 Inside velocity field module

2.3 水模拟充型表面速度场的图像处理算法

获取自由表面流动场过程中的最关键技术就是边缘检测及提取技术。 当通过PIV技术获取到液体充型过程的原始数据, 并以静态图片的形式保存下来后, 通过边缘检测及提取技术可以获取到液体充型的自由表面曲线, 为下一步的计算提供数据。

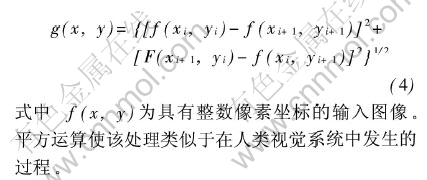

边缘检测及提取技术是根据物体边缘灰度不连续所反映的。 经典的边缘提取方法是考察图像的每个像素在某邻域内灰度的变化, 利用边缘临近一阶或二阶方向导数变化规律检测边缘。 这种方法称为边缘检测局部算子法。 在这里用了Roberts边缘检测算子[16], 可表示为:

经过这种运算后再做相应的轮廓提取操作就能得到合适的轮廓数据。 对获取的数据按图4所示的流程图作相应处理, 就可以以数字的方式重建整个自由表面流动场, 精确的重现整个流动过程。

图4 表面速度场模

Fig.4 Surface velocity field module

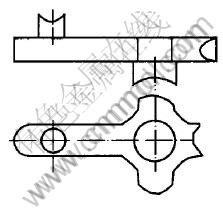

图5 浇注系统简图

Fig.5 Gating sketch

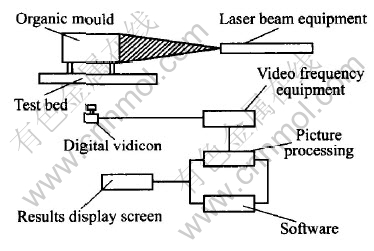

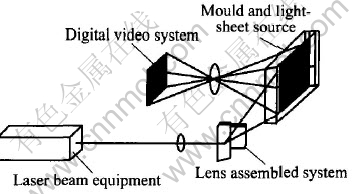

图6 图片获取及处理系统框图

Fig.6 Frame drawing of capturing picture and dealed system

图7 激光片光源光路系统

Fig.7 Light route system on laser light-sheet source

3 水模拟计算机可视化

水模拟模型采用有机玻璃制作, 模拟介质为室温水, 示踪粒子采用粒度75μm铝粉, 采用低压铸造轮毂类铸件进行水模拟实验, 浇注系统如图5所示。 单升液管, 横浇道及内浇口各四个。 图片获取及处理系统框图见图6, 激光片光源光路系统如图7所示。

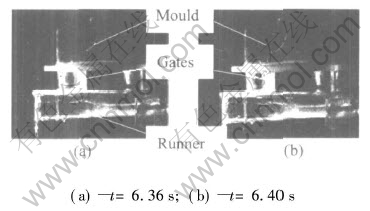

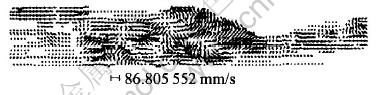

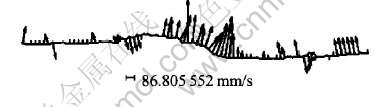

低压铸造的工艺参数为: 升液时间10s, 升液流量3.8m3/h, 气体分压0.2MPa。 浇注系统内相邻两幅图片的流动状态如图8所示; 浇注系统液体内部速度场计算结果如图9所示, 表面速度场计算结果如图10所示。

图8 横浇道内液体流动状态

Fig.8 Liquid flowing state in runner

图9 横浇道内液体内部速度场

Fig.9 Inside velocity field of liquid flowing in runner

(t=6.40s)

图10 横浇道内液体表面速度场

Fig.10 Surface velocity field of liquid flowing in runner

(t=6.40s)

低压铸造浇注系统内液体的充型过程相对平稳, 但由于横浇道端部的阻流作用, 在升液管和内浇口之间的横浇道内, 液体内部的流动依然存在一定的波动, 这在对水模拟充型过程的观察(图8)和采用PIV技术所计算的水模拟流场(图9和10)都反映了这一规律, 从而验证了PIV技术在水模拟流场测试中的可行性。

水模拟充型流场的建立及量化分析, 实现了水模拟技术由定性分析向定量分析的转变, 从理论上建立合理的相似准则, 水模拟充型流场可以实现对计算机数值模拟充型流场的补充及验证, 对铸造工艺设计的合理性进行指导, 有效地预测和避免铸造缺陷的产生。

REFERENCES

[1] 李依依, 李殿中, 黄成江, 等. 材料制备的计算机模拟[J]. 中国有色金属学报, 2004, 14(S1): 138-146.

LI Yi-yi, LI Dian-zhong, HUANG Cheng-jiang, et al. Computer simulation on materials processing[J]. The Chinese Journal of Nonferrous Metal, 2004, 14(S1): 138-146.

[2] 闻星火, 康进武, 熊守美, 等. 低压铸造铝合金轮毂充型与凝固模拟[J]. 中国有色金属学报, 1999, 9(3): 123-128.

WEN Xing-huo, KANG Jin-wu, XIONG Shou-mei, et al. Mould filling and solidification simulation of low pressure die casting aluminum wheel casting[J]. The Chinese Journal of Nonferrous Metal, 1999, 9(3): 123-128.

[3] 蔡临宁, 麻向军, 杨秉俭, 等. 铸型型腔充填过程的准三维水模拟试验[J]. 西安交通大学学报, 1999, 33(5): 84-87.

CAI Lin-ning, MA Xiang-jun, YANG Bing-jian, et al. Mold filling process examined using water as substitute[J]. Journal of Xian Jiao Tong University, 1999 , 33(5): 84-87.

[4] 贾良荣, 熊守美, 冯伟明, 等. 压力铸造充型过程流动与传热的数值模拟研究[J]. 清华大学学报(自然科学版), 2001, 41(2): 8-11.

JIA Liang-rong, XIONG Shou-mei, FENG Wei-ming, et al. Numerical simulation of fluid flow and heat transfer during mold filling for die casting[J]. J Tsinghua Univ(Sci &Tech) , 2001, 41(2): 8-11.

[5] 薛寒松, 李华基, 王勇勤. 薄壁件差压铸造的充型特点及影响因素[J]. 重庆大学学报, 2002, 25(10): 20-22.

XUE Han-song, LI Hua-ji, WANG Yong-qin. Characteristics of filling process and factors of differential pressure cast for thin wall casting[J]. Journal of Chongqing University, 2002, 25(10): 20-22.

[6] Ian Hamill, Tracy Lucas. Computational fluid dynamics modeling of dundishes and continuous casting moulds[A]. Fluid Flow Phenomeno in Metals Processing[C]. Warrendale, PA: The Minerals, Metals and Materials Society, 1999, 279-286.

[7] Jones W K, Xu D, Evans J W. Recent results on modeling of metal delivery systems used in EM and DC casting of aluminum[A]. Fluid Flow Phenomeno in Metals Processing[C]. Warrendale, PA: The Minerals, Metals and Materials Society, 1999. 295-305.

[8] Tol R V, Katgerman L, van den Akker H E A. Experimental and numerical investigations of mould filling of thin wall horizontal aluminium casting[J]. Materials Science Forum, 2000, 329-330: 461-466.

[9] DONG Xu, Kinzy W, Jr Evans J W. The use of particle image velocimetry in the physical modeling of flow in electromagnetic or direct-chill casting of aluminum(partⅠ): development of the physical model[J]. Metall Mater Trans B, 1998, B29(6): 1281-1288.

[10] DONG Xu, Kinzy W, Jr Evans J W. The use of particle image velocimetry in the physical modeling of flow in electromagnetic or direct-chill casting of aluminum(part Ⅱ): results of the physical model, in-cluding bag geometry, blockage, and nozzle placement[J]. Metall Mater Trans B, 1998, B29(6): 1289-1295.

[11] 张兆顺, 崔桂香. 流体力学[M]. 北京: 清华大学出版社, 1999. 254-259.

ZHANG Zhao-shun, CUI Gui-xiang. Hydrodynamics[M]. Beijing: Tsinghua University Press, 1999. 254-259.

[12] Okuno T, Sugii Y, Nishio S. Image measurement of flow field using physics-based dynamic model[J]. Meas Sci Technol, 2000, 11: 667-676.

[13] 阮晓东, 宋向群, 山本富士夫. 基于BICC算法的PIV技术[J]. 实验力学, 1998, 13(4): 514-519.

RUAN Xiao-dong, SONG Xian-gun, Fujio Yamam oto. PIV technique and BICC algorithm[J]. Journal of Experimental Mechanics, 1998, 13(4): 514-519.

[14] 王世刚, 陈贺新. 运动图像矢量匹配运动补偿压缩算法[J]. 长春邮电学院学报, 2001, 19(2): 15-22.

WANG Shi-gang, CHEN He-xin. A vector matching algorithm of motion compensation for moving picture[J]. Journal of Changchun Post and Telecommunication Institute, 2001, 19(2): 15-22.

[15] 孙琥知, 许志祥. 运动补偿快速算法的探讨[J]. 上海大学学报(自然科学版). 1997, 3(6): 643-649.

SUN Hu-zhi, XU Zhi-xiang. A study on the fast algorithm of motion compensation[J]. Journal of Shanghai University (Natural Science),1997, 3(6): 643-649.

[16] 欧珊瑚, 王倩丽, 朱哲瑜. Visual C++.NET数字图像处理技术与应用[M]. 北京: 清华大学出版社, 2004. 397-401.

OU Shan-hu, WANG Qian-li, ZHU Zhe-yu. Visual C++.NET Digital Video Processing Technology and Application[M]. Beijing: Tsinghua University Press, 2004. 397-401.

收稿日期: 2005-01-16;

修订日期: 2005-06-20

作者简介: 赵忠兴(1963-), 男, 教授.

通讯作者: 赵忠兴, 教授; 电话: 024-24680920; E-mail: zzx_teacher@163.com

(编辑 陈爱华)