文章编号:1004-0609(2008)11-2030-06

磁热处理对La-Mg-Ni-Co合金微结构与电化学性能的影响

赵显久1,李 谦1,林根文1,周国治1, 2

(1. 上海大学 上海市现代冶金及材料制备重点实验室,上海 200072;

2. 北京科技大学 冶金与生态工程学院,北京 100083)

摘 要:考察La0.67Mg0.33Ni2.5Co0.5合金分别在铸态、热处理及磁热处理3种状态下的微结构及其电化学性能。通过XRD衍射及SEM分析贮氢合金的物相组成和电极合金循环后的形貌,研究Co部分替代Ni以及有无外加磁场下热处理对合金微结构与电化学性能的作用规律。结果表明:经Co部分取代的La-Mg-Ni铸态合金经过50次循环后,放电容量保持率从64.46%提高到74.80%;经磁热处理后,La0.67Mg0.33Ni2.5Co0.5合金的最大放电容量为324.80 mA?h/g,较常规热处理合金的容量提高了10.59%,放电容量保持率为83.07%,其放电平台更为宽广且平坦;磁热处理的引入进一步降低贮氢合金电极的极化电阻,改善合金电极动力学性能。

关键词:La-Mg-Ni型贮氢合金;磁热处理;微结构;电化学性能

中图分类号:TG139.7 文献标识码:A

Effects of magnetic-heat treatment on microstructure and electrochemical properties of La-Mg-Ni-Co alloys

ZHAO Xian-jiu1, LI Qian1, LIN Gen-wen1, CHOU Kuo-chih1, 2

(1. Shanghai Key Laboratory of Modern Metallurgy and Materials Processing, Shanghai University,

Shanghai 200072, China;

2. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: The microstructure and electrochemical performances of La0.67Mg0.33Ni2.5Co0.5 hydrogen storage alloys treated by casting, heat treatment and magnetic-heat treatment were studied. The influence of the substitution of Co for Ni and heat treatment with and without magnetic field on the structures and electrochemical performances of La-Mg-Ni alloys were investigated by XRD and SEM. The results show that the retention of discharge capacity of as-cast La0.67Mg0.33Ni2.5Co0.5 alloy increases from 64.46% to 74.80% for as-cast La0.67Mg0.33Ni3.0 after 50 cycles. The maximum discharge capacity of La0.67Mg0.33Ni2.5Co0.5 alloy heat treated under magnetic field is 324.8 mA?h/g, which is larger by 10.59% than that of La0.67Mg0.33Ni2.5Co0.5 alloy after conventional heat treatment. The retention of discharge capacity of the former is 83.07%. The discharge voltage platform of La0.67Mg0.33Ni2.5Co0.5 alloy after magnetic-heat treatment is more broadened and flatter. The magnetic-heat treatment reduces the polarization resistance and improves the electrochemical kinetic properties of alloy electrode.

Key words: La-Mg-Ni-based hydrogen storage alloys; magnetic-heat treatment; microstructure; electrochemical properties

近年来,许多发达国家开始立法禁止使用污染环境的Ni-Cd电池,这为具有高能量密度、耐过充和无污染的Ni/MH电池提供了发展良机。稀土系AB5型贮氢合金作为电池负极材料已得到商业化应用,但仍然存在容量低和循环性能差等问题。R-Mg-Ni基(R为稀土或Ca)AB3型电极合金,由于其具有相对较低的成本和较高的贮氢容量,引起国内外学者的广泛关 注[1]。

KADIR等[2?3]发现该类合金具有PuNi3型结构。唐睿等[4]研究La1.3CaMg0.7Ni9最大放电容量可到395 mA?h/g。KOHNO等[5]研究了La0.7Mg0.3Ni2.8Co0.5合金电极的电化学性能。结果表明,最大放电容量可为410 mA?h/g,在前30次循环中保持较好的稳定性。PAN等[6]对La0.7Mg0.3(Ni0.85Co0.15)x(x=3.15~3.8)合金电极的研究发现,该体系中的合金最大放电容量达到了398.4 mA?h/g,经过50次循环后,合金的容量保持率为52.71%。张羊换等[7]发现铸态La2Mg(Ni0.85Co0.15)9合金最大容量为386.2 mA?h/g,经过50次循环合金的容量保持率为73.25%。因而,该系贮氢合金当前存在的主要问题是循环性能差。元素取代是改善贮氢电极合金循环性能的一个重要手段。LIAO等[8]研究了Cu、Fe、Mn和Co等金属元素取代对合金结构和电化学性能的影响。结果表明:元素取代后,合金都保持着PuNi3型主相结构,Co、Cu和Mn金属取代可以提高其循环性能,但合金最大放电容量有所降低。热处理也是改善合金电化学性能的有效方法之一,它可以使合金成分更均匀,晶格应力减少[9],从而提高贮氢合金电极的活化性能及高倍率放电性能[10]。

最近,磁场在贮氢合金制备过程中的应用取得了一定效果。VARIN等[11]利用磁场改变球磨过程中磨球的能量,制备出性能较好的镁基贮氢合金。PAN等[12]及马建新等[13]对合金La0.9Sm0.1Ni2.0Co3.0进行了磁处理后,发现其最大放电容量从热处理合金的 198.5 mA?h/g增加到磁处理合金的225.6 mA?h/g。本课题组[14]在外加磁场条件下运用氢化燃烧成功合成了Mg2FeH6,它在1 000 s内可吸氢6.75%(质量分数)。

本文作者考察Co部分取代AB3型La-Mg-Ni贮氢合金中的Ni后对其电化学性能的影响。并对比研究热处理和磁热处理两种不同处理方式对合金相结构与电化学性能的影响,通过研究合金微结构和组织形貌,探讨磁热处理改善La0.67Mg0.33Ni2.5Co0.5合金电化学性能的原因。

1 实验

La0.67Mg0.33Ni3.0和La0.67Mg0.33Ni2.5Co0.5按照化学计量比各自配料70 g,原料为纯度均在99.5%以上的单质元素,分别在真空感应炉中熔炼。采用电感偶合等离子体发射光谱仪对熔炼合金进行成分测试,验证其配比是否与名义设计成分相符。将熔炼好的La0.67Mg0.33Ni2.5Co0.5合金取两份,一份在850 ℃下热处理8 h;另一份在850 ℃外加磁场下(磁感应强度为1T)磁热处理4 h。

合金经机械粉碎过孔径75 μm的筛后,取其粉末0.1 g与0.4 g的羟基镍粉混合。然后,采用压样机冷压成直径为10 mm,厚度为2.0 mm的小圆片作为电池负极待用。烧结式Ni(OH)2作为正极,电解液为6 mol/L KOH溶液,在DC?5型电池测试充放仪上测试合金电极的性能。活化时,首先将电极在100 mA/g的电流密度下充电5 h,停10 min,再在同样的电流密度下放电,截止电压1 V。经多次充放循环后,负极达到最高放电容量时,即可视其完全活化。在相同的充放电制度下,进行循环特性的测试。合金电极完全活化后,在放电深度(Depth of discharge,DOD)为50%的状态下静置一段时间,待电极电位稳定后,利用电化学工作站(法国HCP-803)进行线性极化及交流阻抗(EIS)测试。线性极化扫描速度为1 mV/s,扫描范围为?5~5 mV(相对于开路电位)。交流阻抗速度为0.1 mV/s,频率为1 mHz~10 kHz。

采用X射线衍射分析仪(D/max 2550型)测试合金的微结构。测试条件:Cu Kα靶,管压40 kV,电流200 mA,扫描范围为20°~80°,速度为10 (°)/min。利用Jade 5.0软件分析XRD结果,判断合金的相组成,并计算晶格常数。

2 结果与分析

2.1 物相分析

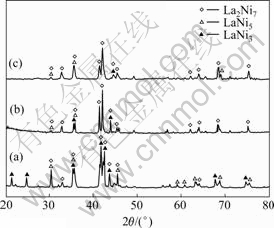

图1所示为Co部分取代Ni前后两种铸态合金的X射线衍射谱。其中La0.67Mg0.33Ni3.0的主相为LaNi5和(La, Mg)2Ni7以及少量的(La, Mg)Ni3。La0.67Mg0.33- Ni2.5Co0.5合金的主相仍为(La, Mg)2Ni7和(La, Mg)Ni5及少量的(La, Mg)Ni3,说明少量的Ni被Co取代后,合金的晶体结构和相组成没有变化。

图1 Co部分取代Ni前后La0.67Mg0.33Ni3.0合金的XRD谱

Fig.1 XRD patterns of La0.67Mg0.33Ni3.0 alloys before and after partially substitution Ni with Co: (a) As-cast La0.67Mg0.33Ni3.0; (b) As-cast La0.67Mg0.33Ni2.5Co0.5

图2所示为La0.67Mg0.33Ni2.5Co0.5在不同状态下(铸态、热处理后和磁热处理)的XRD谱。由图2可知,La0.67Mg0.33Ni2.5Co0.5在850 ℃下热处理及同等温度的磁热处理后,合金的(La, Mg)Ni3衍射峰明显降低,说明合金中的(La, Mg)Ni3相逐步向主相(La, Mg)2Ni7转变。在热处理后的合金中,(La, Mg)Ni3相的小角度衍射峰明显减少,经磁热处理后,2θ在35°以下衍射峰消失。表1所列为几个不同状态合金的(La, Mg)2Ni7主相的晶胞参数。由表1可知,热处理及磁热处理后,主相的晶胞体积变大,且磁热处理后的晶胞体积大于热处理的晶胞体积。晶胞体积的增加使单位晶胞容纳氢原子的数目增加。以上研究表明,磁热处理较之传统的热处理方法能较明显地影响合金的微结构。

图2 La0.67Mg0.33Ni2.5Co0.5在不同状态下的XRD谱

Fig.2 XRD patterns of La0.67Mg0.33Ni2.5Co0.5 alloys under different states: (a) As-cast La0.67Mg0.33Ni2.5Co0.5; (b) La0.67Mg0.33Ni2.5Co0.5, 850 ℃; (c) La0.67Mg0.33Ni2.5Co0.5, 850 ℃, 1 T

表1 合金主相的晶格参数和晶胞体积

Table 1 Lattice parameters and cell volumes of main phases of (La, Mg)2Ni7 of alloys

2.2 组织结构和形貌分析

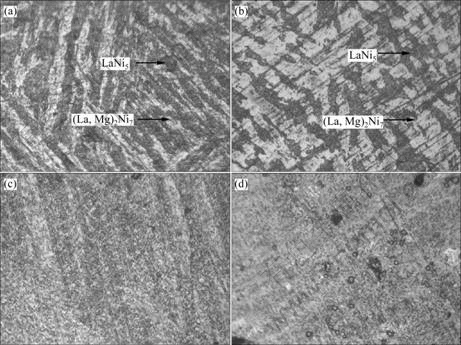

图3所示为合金的显微组织。由图3(a)和(b)可知,铸态合金La0.67Mg0.33Ni3.0和La0.67Mg0.33Ni2.5Co0.5的组织都较粗大,呈板条状,合金的成分均匀性较差。结合能谱分析发现:两种铸态合金表面颜色较暗的区域为LaNi5相,颜色较亮的区域为对应的(La, Mg)2Ni7相。Co部分取代Ni后,合金的相组成没有发生变化,这与XRD分析结果一致。由于(La, Mg)Ni3相含量较少,故未能观察到。由图3可看出,热处理和经磁热处理后的合金组织呈弥散分布,合金成分趋于均匀,这将有利于提高合金充放电性能和循环性能。

图3 合金的显微组织

Fig.3 Microstructures of alloys: (a) As-cast La0.67Mg0.33Ni3.0; (b) As-cast La0.67Mg0.33Ni2.5Co0.5; (c) La0.67Mg0.33Ni2.5Co0.5 after heat treatment; (d) La0.67Mg0.33Ni2.5Co0.5 after magnetic-heat treatment

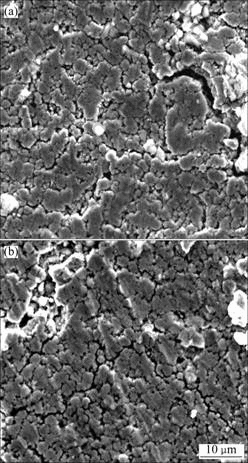

图4所示为在热处理和磁热处理后La0.67Mg0.33- Ni2.5Co0.5合金经50次充放电循环后的SEM像。由图4可知,经磁热处理合金的裂纹少于经热处理合金的。可能由于在合金的组分中,Ni及Co是铁磁性物质,经磁化处理后的合金保持一定程度的剩磁,使得合金粉与导电剂间能保持良好的接触,这有助于改善合金在碱液中的抗腐蚀能力及合金的吸放氢动力学性能。磁热处理后,合金的微结构发生了改变,组织和成分更加均匀,因此,合金电极表现出较好的电化学性能。

图4 热处理和磁热处理后La0.67Mg0.33Ni2.5Co0.5合金经50次充放电循环后的SEM像

Fig.4 SEM images of La0.67Mg0.33Ni2.5Co0.5 alloy after 50 cycles: (a) Heat treatment; (b) Magnetic-heat treatment

2.3 合金的电化学性能分析

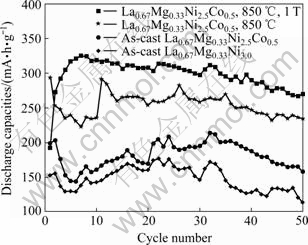

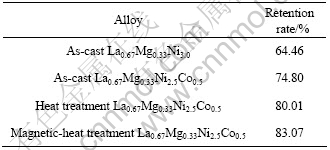

图5所示为铸态合金La0.67Mg0.33Ni3.0及不同状态下的La0.67Mg0.33Ni2.5Co0.5合金的放电曲线。表2所列为合金经50个循环后的容量保持率。由图5可知,铸态合金La0.67Mg0.33Ni3.0和La0.67Mg0.33Ni2.5Co0.5合金的放电容量相差不大。合金充放电循环50次后,两者的容量保持率分别为64.46%和74.80%,这说明Co部分取代Ni,对合金容量保持率有一定改善作用;La0.67Mg0.33Ni2.5Co0.5合金经热处理后,其放电容量较铸态合金的大,最大电化学放电容量为293.7 mA?h/g,经充放电循环50次后,合金容量保持率提高到80.01%;经磁热处理后,最大放电容量为324.8 mA?h/g,较热处理的最大放电容量提高了10.59%,经50次循环后,合金容量保持率为83.07%。综上所述,引入磁热处理方法的确能改善La0.67Mg0.33Ni2.5Co0.5合金电极电化学性能,主要原因是由于磁热处理更能促进合金主相的增加和成分均匀化。从活化次数上看,磁热处理的合金经过7次循环才能达到最大放电容量,而铸态及热处理的合金在一两次即可活化。磁热处理的合金活化次数增加的原因在于Co和Ni是铁磁性物质,经磁热处理后,合金中保持一定的剩磁,合金粉具有较好的团聚特性。合金在活化过程中,合金去除表面氧化层,颗粒粉化后裸露出新鲜的合金表面,由于合金颗粒的磁性使得这一过程变得缓慢乃至困难,从而造成合金的活化性能较低。但合金一旦完成活化,反而由于合金的不易粉化特性,提高了合金的循环稳定性能。

图5 铸态合金La0.67Mg0.33Ni3.0和La0.67Mg0.33Ni2.5Co0.5在不同状态下合金的放电曲线

Fig.5 Discharge curves of as-cast La0.67Mg0.33Ni3.0 and La0.67Mg0.33Ni2.5Co0.5 alloys under different states

表2 合金经50个循环后的容量保持率

Table 2 Retention rate of alloys after 50 cycles

图6所示为不同状态的La0.67Mg0.33Ni2.5Co0.5合金及铸态La0.67Mg0.33Ni3.0合金的放电平台特性曲线。合金的放电平台宽度很大程度上取决于其放电容量,放电平台的平坦性取决于合金均匀性及表面的电催化活性。由图6可知,La0.67Mg0.33Ni3.0和La0.67Mg0.33Ni2.5Co0.5两种合金在铸态条件下的放电平台长度相差不大,这与放电循环曲线中两者的放电容量相差不大的结论相一致。La0.67Mg0.33Ni2.5Co0.5合金经热处理后,放电平台长度增加,较铸态La0.67Mg0.33Ni2.5Co0.5的放电平台平缓,说明热处理后的合金成分偏析减少。磁热处理合金放电平台较热处理合金更为平坦和宽广,从XRD结果及合金金相照片可看出,磁热处理的合金成分更为均匀。

图6 铸态合金La0.67Mg0.33Ni3.0及La0.67Mg0.33Ni2.5Co0.5在不同状态下的放电平台特性曲线

Fig.6 Characteristics curves of discharge voltage platform of as-cast La0.67Mg0.33Ni3.0 and La0.67Mg0.33Ni2.5Co0.5 alloys under different states

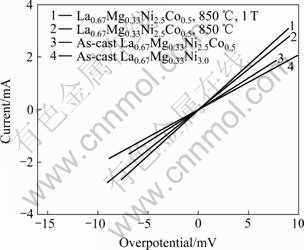

图7所示为铸态合金La0.67Mg0.33Ni3.0和不同状态下的La0.67Mg0.33Ni2.5Co0.5合金在298 K放电深度为50%时的线性极化曲线。斜率越大表示极化电阻(RD)越小。由图7可知,Co部分取代Ni后,RD略有降低;经热处理及磁热处理的La0.67Mg0.33Ni2.5Co0.5合金的RD较铸态La0.67Mg0.33Ni2.5Co0.5合金的明显降低了,表明铸态合金经热处理和磁热处理后,合金电极的电化学极化电阻变小,电催化活性变好,这也一定程度上解释了合金电极放电容量增加的原因。

图7 铸态合金La0.67Mg3.3Ni3.0及不同状态下La0.67Mg0.33- Ni2.5Co0.5合金在298 K放电深度为50%时的线性极化曲线

Fig.7 Linear polarization curves of as-cast La0.67Mg3.3Ni3.0 and La0.67Mg0.33Ni2.5Co0.5 alloys under different states at 50%DOD and 298 K

图8所示为铸态La0.67Mg0.33Ni3.0合金及不同状态下的La0.67Mg0.33Ni2.5Co0.5合金在298 K放电深度为50%时的交流阻抗谱。根据KURIYAMA等[15]的EIS模型分析,高频区半圆弧对应电极片和集流体之间的电阻,中频区半圆弧对应电荷转移反应的极化电阻,低频区直线对应Warburg阻抗。由图8可知,Co部分取代后,阻抗图谱两个半圆仅仅是高频区半圆弧对应电极片和集流体之间的电阻略有降低,电荷转移反应的极化电阻变化不大。取代后的合金经热处理后,合金的半圆弧明显减小,这与线性极化的结果一致。进一步说明合金经热处理后,尤其是经过磁热处理后,电极合金的电催化活性得到明显的改善,合金具有较好的反应动力学特征。

图8 铸态合金La0.67Mg3.3Ni3.0及不同状态下La0.67Mg0.33- Ni2.5Co0.5合金在298 K放电深度为50%时的线性极化曲线

Fig.8 Linear polarization curves of as-cast La0.67Mg3.3Ni3.0 and La0.67Mg0.33Ni2.5Co0.5 alloys under different states at 50%DOD and 298 K

REFERENCES

[1] 张羊换, 任慧平, 李保卫, 董小平, 赵小龙, 王新林. La0.7Mg0.3Ni2.55?xCo0.45Alx(x=0~0.4)贮氢合金的循环稳定性[J]. 中国有色金属学报, 2006, 16(8): 1320?1325.

ZHANG Yang-huan, REN Hui-ping, LI Bao-wei, DOND Xiao-ping, ZHAO Xiao-long, WANG Xin-lin. Cycling stability of La0.7Mg0.3Ni2.55?xCo0.45Alx(x=0?0.4) hydrogen storage alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1320?1325.

[2] KADIR K, SAKAI T, UEHARA I. Synthesis and structure determination of a new series of hydrogen storage alloys; RMg2Ni9(R=La, Ce, Pr, Nd, Sm and Gd) built form MgNi2 Laves type layer alternating with AB5 layers[J]. J Alloys Compd, 1997, 257(1/2): 115?121.

[3] KADIR K, SAKAI T, UEHARA I. Structural investigation and hydrogen capacity of YMg2Ni9 and (Y0.5Ca0.5)(MgCa)Ni9: new phases in the AB2C9 system isostructural with LaMg2Ni9[J]. J Alloys Compd, 1999, 287(1/2): 264?270.

[4] 唐 睿, 张朝晖, 刘丽琴, 朱杰武, 柳永宁. La1.3CaMg0.7Ni9储氢合金[J]. 中国有色金属学报, 2004, 14(1): 51?54.

TANG Rui, ZHANG Zhao-hui, LIU Li-qin, ZHU Jie-wu, LIU Yong-ning. La1.3CaMg0.7Ni9 hydrogen storage alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 51?54.

[5] KOHNO T, YOSHIDA H, KAWASHIMA F, INABA T, SAKAI I, YAMAMOTO M, KANDA M. Hydrogen storage properties of new ternary system alloys: La2MgNi9, La5Mg2Ni23, La3MgNi14[J]. J Alloys Compd, 2000, 311(2): L5?L7.

[6] PAN Hong-ge, LIU Yong-feng, GAO Ming-xia, ZHU Yun-feng, LEI Yong-quan, WNG Qi-dong. An investigation on the structural and electrochemical properties of La0.7Mg0.3- (Ni0.85Co0.15)x(x=3.15?3.80) hydrogen storage electrode alloys[J]. J Alloys Compd, 2003, 351(1/2): 228?234.

[7] 张羊换, 董小平, 王国清, 郭世海, 任江远, 王新林. 铸态及快淬态La-Mg-Ni系(PuNi3型)贮氢合金的循环稳定性[J].中国有色金属学报, 2005, 15(5): 705?710.

ZHANG Yang-huan, DONG Xiao-ping, WANG Guo-qing, GUO Shi-hai, REN Jiang-yuan. WANG Xin-lin. Cycling stability of La-Mg-Ni system (PuNi3 type)hydrogen storage alloys prepared by casting and rapid quenching[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 705?710.

[8] LIAO B, LEI Y Q, CHEN L X. A study on the structure and electrochemical properties of La2Mg (Ni 0.95 M0.05)9(M = Co, Mn, Fe, Al, Cu, Sn) hydrogen storage electrode alloys[J]. J Alloys Compd, 2004, 376(1/2): 186?195.

[9] 靳红梅, 李国勋, 王瑞坤, 王超群, 张昭良, 孙丽虹. 热处理对La0.9Nd0.1(NiCoMnAl)5电极性能的影响[J]. 电源技术, 1997, 21(2): 58?76.

JIN Hong-mei, LI Guo-xun, WANG Rui-kun, WANG Chao-qun, ZHANG Zhao-liang, SUN Li-hong. Effect of heat treatment on the performance of La0.9Nd0.1(NiCoMnAl)5 electrode[J]. Chinese Journal of Power Sources, 1997, 21(2): 58?76.

[10] 黄 兵, 史鹏飞. 热处理对贮氢合金电极性能的影响[J]. 电池, 2005, 35(3): 171?172.

HUANG Bing, SHI Peng-fei. Effect of heat treatment on the performance of hydrogen storage alloy electrode[J]. Battery Bimonthly, 2005, 35(3): 171?172.

[11] VARIN R A, LI S, CALKA A. Environmental degradation by hydrolysis of nanostructured β-MgH2 hydride synthesized by controlled reactive mechanical milling(CRMM) of Mg[J]. J Alloys Compd, 2004, 376(1/2): 222?231.

[12] PAN Hong-ge, MA Jian-xin, ZHU Yun-feng, LI Shou-quan, CHEN Chang-pin, WANG Qi-dong. Effect of magnetization treatment on the electrochemical properties of La0.9Sm0.1- Ni2.0Co3.0 electrode alloy[J]. J Alloys Compd, 2001, 327(1/2): 136?140.

[13] 马建新, 潘洪革, 朱云峰, 李寿权, 陈长聘. 一种改善贮氢电极合金电化学性能的新方法[J]. 金属学报, 2001, 37(1): 57?60.

MA Jian-xin, PAN Hong-ge, ZHU Yun-feng, LI Shou-quan, CHEN Chang-pin. A novel method to improve the electrochemical properties of hydrogen storage electrode alloy[J]. Acta Metallurgica Sinica, 2001, 37(1): 57?60.

[14] LI Qian, LIU Jing, CHOU Kuo-chih, LIN Gen-wen, XU Kuang-di. Synthesis and dehydrogenation behavior of Mg-Fe-H system prepared under an external magnetic field[J]. J Alloys Compd, 2008, 466(1/2): 146?152.

[15] KURIYAMA N, SAKAI T, MIYAMURA H, UEHARA I, ISHIKAWA H, IWASAKI T. Electrochemical impedance and deterioration behavior of metal hydride electrodes[J]. J Alloys Compd, 1993, 202(1/2): 183?187.

基金项目:上海市科委西部开发科技合作资助项目(065258036);上海市青年科技启明星计划资助项目(06QA14021);全国博士学位论文作者专项资助项目(200746)

收稿日期:2008-02-22;修订日期:2008-07-08

通讯作者:李 谦,副研究员,博士;电话:021-56338065;E-mail: shuliqian@shu.edu.cn

(编辑 李艳红)