轧机工作辊振动在线监测的新方法

来源期刊:中南大学学报(自然科学版)2004年第4期

论文作者:李建平 张希林 段吉安

文章页码:613 - 617

关键词:轧机;垂直振动;状态监测

Key words:rolling mill; vertical vibration; vibration monitoring

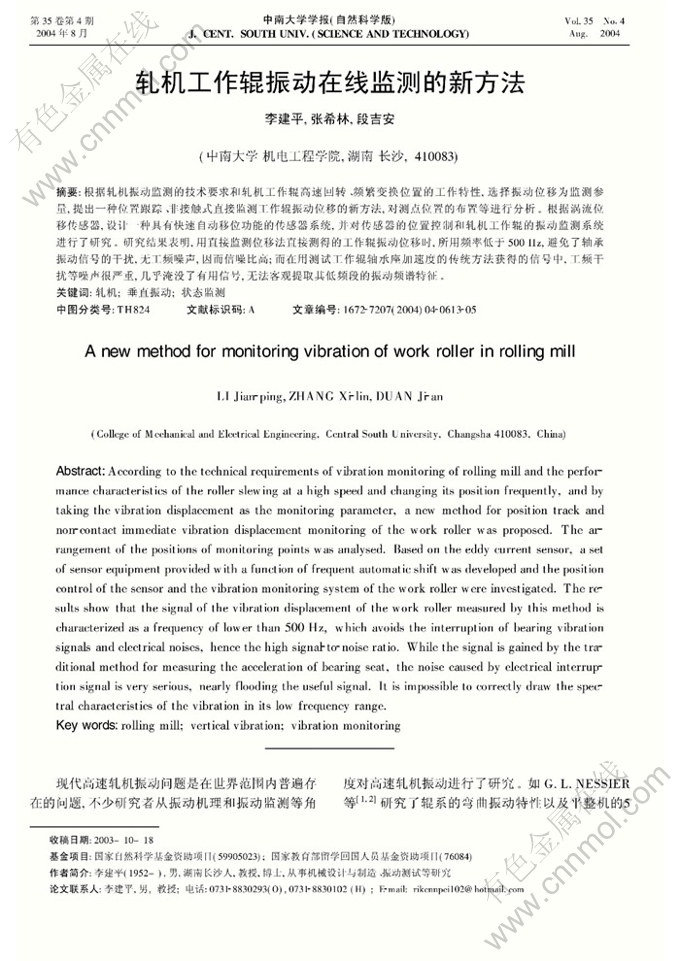

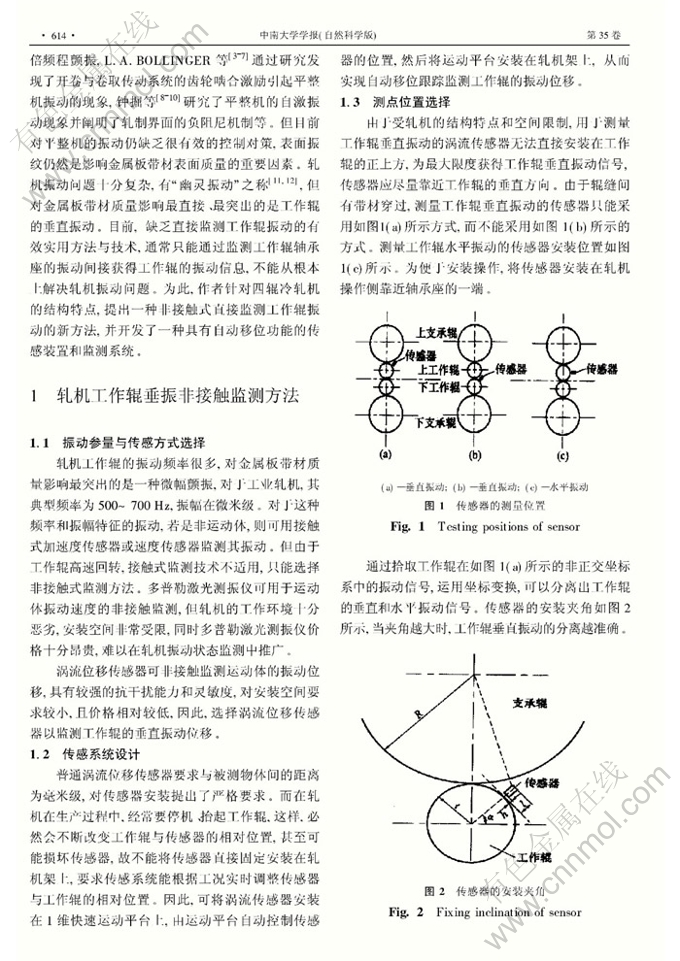

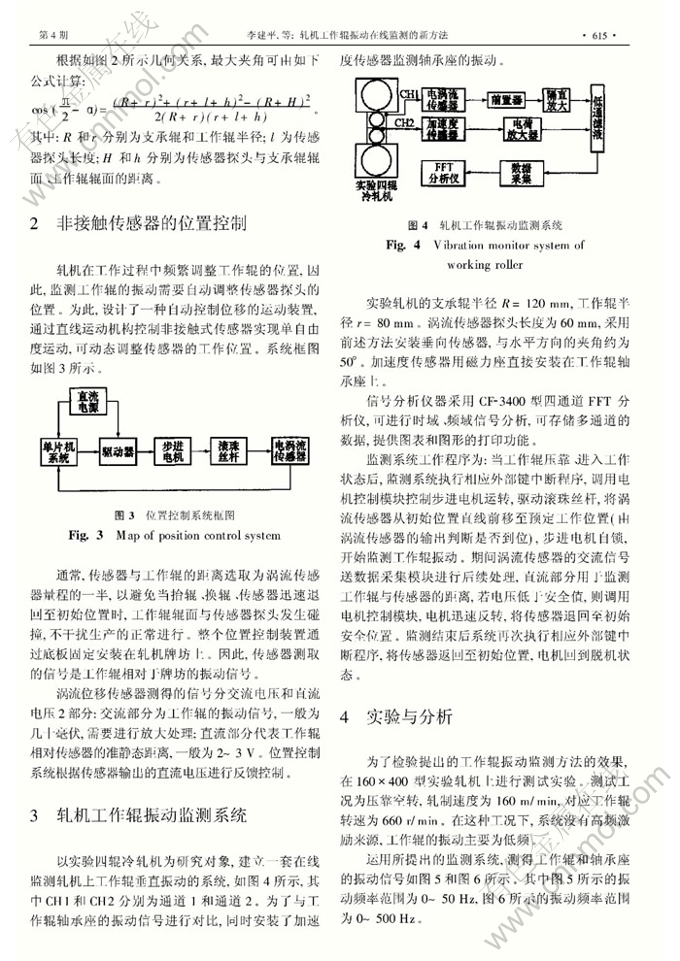

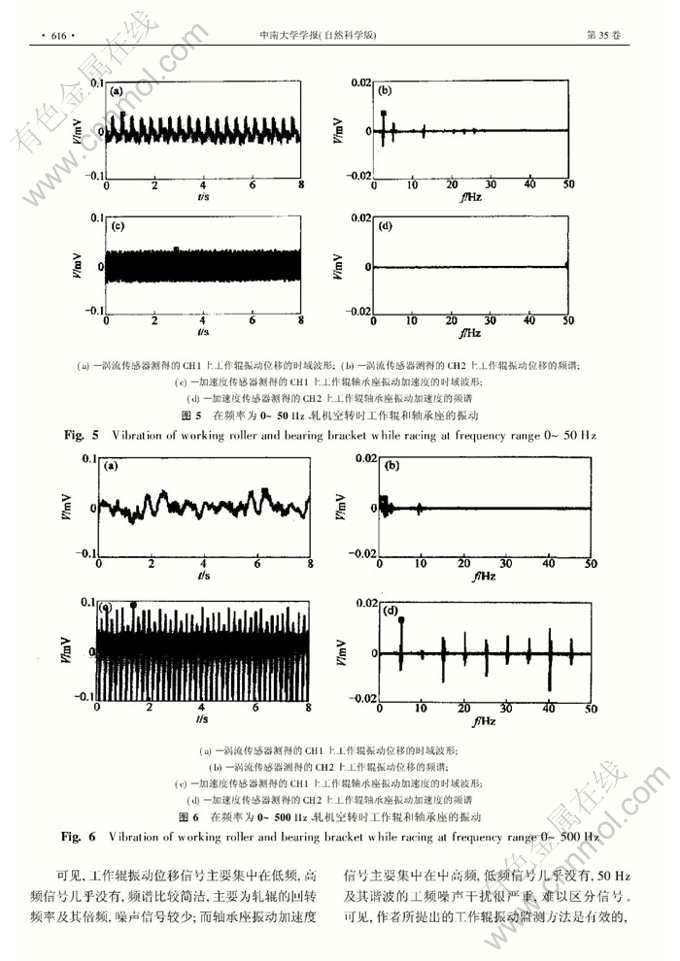

摘 要:根据轧机振动监测的技术要求和轧机工作辊高速回转、频繁变换位置的工作特性,选择振动位移为监测参量,提出一种位置跟踪、非接触式直接监测工作辊振动位移的新方法,对测点位置的布置等进行分析。根据涡流位移传感器,设计一种具有快速自动移位功能的传感器系统,并对传感器的位置控制和轧机工作辊的振动监测系统进行了研究。研究结果表明,用直接监测位移法直接测得的工作辊振动位移时,所用频率低于500 Hz,避免了轴承振动信号的干扰,无工频噪声,因而信噪比高;而在用测试工作辊轴承座加速度的传统方法获得的信号中,工频干扰等噪声很严重,几乎淹没了有用信号,无法客观提取其低频段的振动频谱特征。

Abstract: According to the technical requirements of vibration monitoring of rolling mill and the performance characteristics of the roller slewing at a high speed and changing its position frequently, and by taking the vibration displacement as the monitoring parameter, a new method for position track and non-contact immediate vibration displacement monitoring of the work roller was proposed. The arrangement of the positions of monitoring points was analysed. Based on the eddy current sensor, a set of sensor equipment provided with a function of frequent automatic shift was developed and the position control of the sensor and the vibration monitoring system of the work roller were investigated. The results show that the signal of the vibration displacement of the work roller measured by this method is characterized as a frequency of lower than 500 Hz, which avoids the interruption of bearing vibration signals and electrical noises, hence the high signal-to-noise ratio. While the signal is gained by the traditional method for measuring the acceleration of bearing seat, the noise caused by electrical interruption signal is very serious, nearly flooding the useful signal. It is impossible to correctly draw the spectral characteristics of the vibration in its low frequency range.