文章编号:1004-0609(2016)-05-0947-10

预时效工艺对7020铝合金显微组织和应力腐蚀性能的影响

杨 涛1, 3,叶凌英2, 3,单朝军2, 3,王绍玲2, 3,邓运来2, 3,张新明1, 2, 3

(1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:7020铝合金经470 ℃固溶1 h后分别进行自然时效0 h、168 h以及65 ℃预时效72 h、168 h,再进行(90 ℃,8 h)+(160 ℃,14 h)双级时效。采用室温拉伸、慢应变速率拉伸(SSRT)、扫描电镜(SEM)、透射电镜(TEM)研究预时效工艺对7020铝合金的常温拉伸性能、抗应力腐蚀性能与显微组织的影响。结果表明:经65 ℃、168 h预时效处理后,合金具有最高的抗拉强度Rm=397.4 MPa和最好的抗应力腐蚀性能ISSRT=-0.003; 65 ℃、72 h预时处理效和自然时效168 h后合金的抗拉强度和抗应力腐蚀性能相当,Rm、ISSRT分别为387.6 MPa、0.034和392.0 MPa、0.036;而直接双级时效合金的抗拉强度和抗应力腐蚀性能最差,Rm、ISSRT为368.9 MPa、0.038。晶内析出相η′(MgZn2)的尺寸随预时效时间的延长而减小,晶界析出相η(MgZn2)的断续分布程度随预时效时间延长而增大。

关键词:7020铝合金;预时效;拉伸性能;慢应变速率拉伸;显微组织

中图分类号:TG146.2 文献标志码:A

7020铝合金属于Al-Zn-Mg(7xxx)系可热处理强化中强铝合金,因其具有较轻质量、较高强度、较好的导热导电性、易成型及可焊接性等优良性能而作为理想轻量化材料应用在轨道交通结构件中。但该合金材料在服役过程中存在有应力腐蚀开裂现象,其影响抗应力腐蚀性能机理研究备受学者们所重视。因而开展有关在保证该合金材料强度的同时改善其抗应力腐蚀性能的研究成为7020铝合金的研究热点之一。

一般而言,7xxx系铝合金材料常用的热处理工艺为固溶-淬火-时效强化。时效处理作为该系列合金材料在服役前的最后一道热处理工序,可以调控合金材料的微观结构以满足最终综合性能要求[1-2]。在时效过程中,时效强化相在晶内均匀、弥散析出能够使合金材料获得高强度,析出相于晶界以一定尺寸断续分布则有利于合金材料获得很好的抗应力腐蚀性能。文献[3-6]报道,7xxx系铝合金已开发多种时效工艺:T6 (峰值时效)时效制度可以满足材料的高强度需求,但晶界处的连续析出时效相会使材料极易出现应力腐蚀现象,应力腐蚀抗性差; T7x (过时效)时效制度可以提高合金材料的抗应力腐蚀性能,但是必须以牺牲材料的强度为前提;采用回归再时效制度能够很好满足合金材料对强度与抗应力腐蚀性能的要求;也有学者探索出一种将正常T6时效制度打断成二次时效制度,在此峰时效中间插入一级温度较低的二次时效(即T6I6),T6I6时效制度能够同时兼顾该系列铝合金材料的强度、抗腐蚀性能和断裂韧性等。

近年来,我国高铁发展迅猛,对国产质轻性能优越的铝合金材料需求迫切。有关在日本高速列车上应用的成分相近的Al-Zn-Mg合金型材所采用的热处理方法与制度,并没有文献详尽报道,只在有关日系JIS标准里涉及了热处理T5态应该达到的性能指标。目前,国内有关成分相近Al-Zn-Mg合金的时效热处理报道主要有自然时效、单级时效、双级时效、T6I6和RRA等时效制度[7-12]。总体说来,对于该Al-Zn-Mg合金型材的有关时效热处理制度对其组织与应力腐蚀性能的影响机理尚缺乏比较系统与充分的认识。通过对比工厂生产工艺,本文作者在传统双级人工时效前引入65 ℃短时间预时效(工业上7020铝合金型材挤压成型后先自然停放3~7 d后再进行后续人工时效处理),采用室温拉伸性能测试、慢应变速率拉伸性能测试、扫描电镜分析、透射电镜分析等实验研究该热处理工艺对7020铝合金的应力腐蚀性能与显微组织的影响机理,以期为优化该合金热处理制度和实际生产提供理论依据。

1 实验

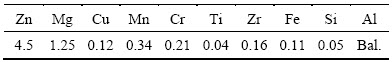

实验所用材料为应用于轨道列车车体7020铝合金挤压型材10 mm厚肋板,其化学成分见表1。热处理制度为470 ℃、1 h固溶热处理,经室温水淬火(转移时间小于3 s)后先进行自然时效0 h、168 h(实测温度25 ℃)和65 ℃预时效72 h、168 h,再进行(90 ℃、8 h)+(160 ℃、14 h)双级人工时效。室温拉伸性能测试试样是按国标GB/T228.1-2010金属材料《金属拉伸试样实验标准》规定进行线加工制作,试样从挤压型材上沿挤压方向切取,试样平行区标距长度为40 mm,平行区宽度为10 mm,厚度为3 mm,经过相应的时效处理后在CRIMS拉伸机上进行室温拉伸实验,拉伸速率为2 mm/min。选取3个拉伸数据的平均值作为实验有效结果。

慢应变速率拉伸性能测试试样平行区标距长30 mm,宽5 mm,厚3 mm,在WDML-1型慢应变速率拉伸机上进行,应变速率为1×10-6 s-1。慢应变速率拉伸试样分为参考组试样和实验组试样两组,每组取3个试样的平均值作为实验有效结果。实验前用1000号水磨砂纸打磨试样后用乙醇清洗并吹干,参考组试样在空气中进行,实验组试样在3.5%NaCl溶液中进行。所有慢应变速率拉伸实验均在室温条件下进行。使用FEI Quanta-200型扫描电子显微镜(SEM)对慢应变速率拉伸断口进行形貌观察,对于在3.5%NaCl(质量分数)溶液中进行慢应变速率拉伸的试样,先用酒精清洗断口。透射电镜组织分析(TEM)是在TECNAIG 220型透射电镜上进行,加速电压为200 kV。TEM薄片试样先采用机械减薄至0.1 mm以下后在MTP-1型双喷电解减薄仪上减薄制备,电解液配比为30%HNO3+70%CH3OH(体积分数),温度控制在-30 ℃左右。

表1 实验所用7020铝合金的化学成分

Table 1 Chemical composition of investigated 7020 aluminum alloy (mass fraction, %)

2 实验结果

2.1 常温拉伸性能

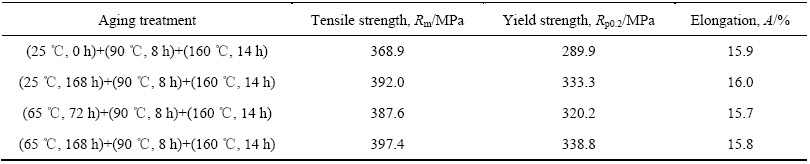

表2所列为7020铝合金先进行自然时效0 h、168 h和65 ℃预时效72 h、168 h后经过(90 ℃、8 h)+(160 ℃,14 h)双级人工时效处理的常温拉伸力学性能。从表2可以看出,在后续相同双级人工时效处理条件下,合金经65 ℃预时效168 h后的力学性能均最佳,Rm、Rp0.2分别为397.4 MPa、338.8 MPa,伸长率为15.8%;65 ℃预时效72 h后的力学性能比65 ℃预时效168 h的低,其Rm、Rp0.2分别为387.6 MPa、320.2 MPa,伸长率为15.7%。而直接双级人工时效后的力学性能最低,伸长率与65 ℃预时效72 h、168 h处理后的相当。合金经自然时效168 h后的Rm、Rp0.2分别为392.2 MPa、333.3 MPa,伸长率为16.0%。

通过对比表2中先进行自然时效0 h、168 h,65 ℃预时效72 h、168 h再经(90 ℃、8 h)+(160 ℃、14 h)双级人工时效后的综合性能可知,在伸长率相当的情况下进行65 ℃预时效可以获得相对更好的抗拉强度与屈服强度,当把65 ℃预时效时间延长至168 h时,其强度可接近400 MPa。尤其是对65 ℃预时效72 h+双级人工时效和自然时效168 h+双级人工时效进行对比后,在伸长率相当的情况下可以采用65 ℃预时效72 h加速时效处理来获得与自然时效168 h后相同双级人工时效后相当的强度。

2.2 慢应变速率拉伸性能

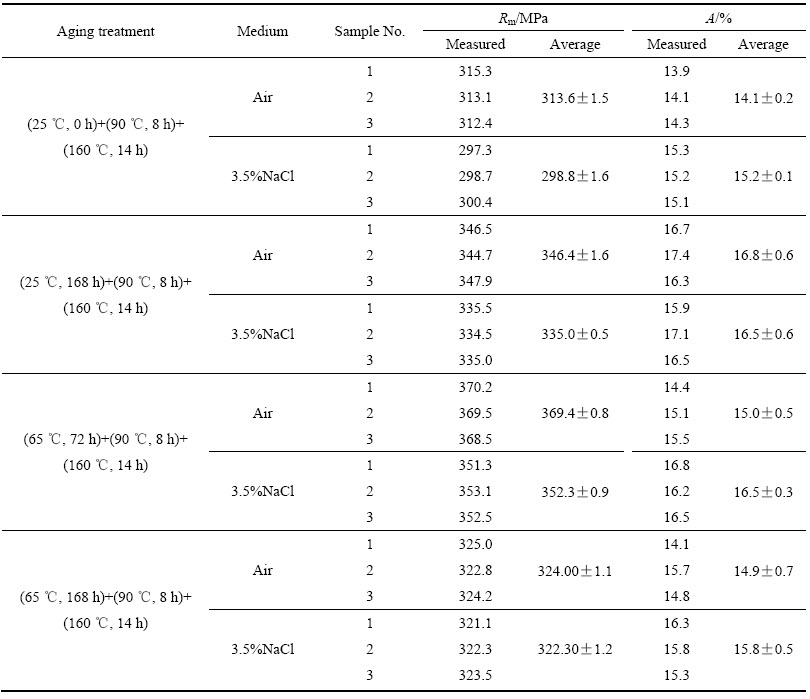

表3所示为合金试样先经65 ℃预时效72 h、168 h不同时间和自然时效0 h、168 h后再经(90 ℃、8 h)+(160 ℃、14 h)双级人工时效处理后在空气和3.5%NaCl腐蚀溶液中的慢应变速率拉伸性能。从表3中可以看出,合金试样经过自然时效0 h、168 h和65 ℃预时效72 h、168 h后,再经过后续双级人工时效处理,在3.5%NaCl腐蚀液中进行的慢应变速率拉伸性能比以室温空气为腐蚀介质的慢应变速率拉伸性能相对低。

表2 7020铝合金的常温拉伸性能

Table 2 Tensile properties of investigated 7020 aluminum alloy

对比合金试样在3.5%NaCl腐蚀液、空气中的实验结果表明:试样直接双级人工时效后,其在3.5%NaCl腐蚀液中的强度比空气中的下降4.72%,而伸长率增加约7.80%。试样自然时效168 h后在3.5%NaCl腐蚀液中的强度比空气中的下降约3.29%,伸长率却下降约1.79%;试样经65 ℃预时效72 h后在3.5%NaCl腐蚀液中的强度比空气中的下降4.63%,而伸长率增加约10.00%。经65 ℃预时效168 h后在3.5%NaCl腐蚀液中的强度比空气中下降约0.52%,而伸长率增加约6.04%。通过对比实验结果还可以看出,试样在双级人工时效前经过不同预时效工艺处理后的伸长率相当,但是65 ℃预时效后的慢应变速率拉伸性能还是要优于直接双级时效和自然时效168 h后的性能。这表明进行65 ℃预时效结合双级人工时效工艺可以在一定程度上提高合金的抗应力腐蚀性能。

根据国标HB7232-1995,可以采用应力腐蚀指数来表示合金材料的抗应力腐蚀性能的高低。其中应力腐蚀指数计算公式如下:

ISSRT=1-[σfwx(1+δfw)]/[σfAx(1+δfA)] (1)

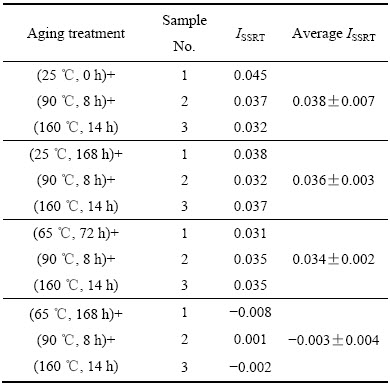

式中:σfw和δfw分别为拉伸试样在3.5%NaCl腐蚀液中拉伸时的抗拉强度和伸长率;σfA 和δfA为拉伸试样在空气中拉伸时的抗拉强度和伸长率。由式(1)可以看出,ISSRT是将慢应变速率拉伸后的各项力学系性能指标进行了数学处理,它比单一的慢应变速率拉伸力学性能指标更能反映材料的应力腐蚀敏感性。应力腐蚀指数ISSRT越小,代表该材料在腐蚀环境下与常规环境下性能差别越小,即该材料的抗应力腐蚀性能越好。计算得到不同时效制度的应力腐蚀指数如表4所列。

表3 7020铝合金的慢应变速率拉伸性能

Table 3 Slow strain rate tensile properties of investigated 7020 aluminum alloy

从表4可得出,合金直接进行双级人工时效处理后的应力腐蚀指数最大,ISSRT=0.038,经自然时效168 h处理后,合金的应力腐蚀指数ISSRT=0.036次之;经65 ℃预时效168 h处理后,合金的应力腐蚀指数最小,为-0.003。65 ℃预时效72 h处理后的应力腐蚀指数比自然时效168 h处理后,合金的应力腐蚀指数ISSRT=0.036,小约5.56%,由此可以看出,65 ℃预时效(72 h、168 h) 结合双级人工时效在慢应变速率拉伸过程中强度下降不大的情况下较其显著提高了材料的抗应力腐蚀性能。在强度损失和伸长率变化相差不是很大的同时,65 ℃预时效72 h+双级人工时效制度的性能是优于自然时效168 h+双级人工时效制度的,它能在一定程度上显著提高合金材料的应力腐蚀抗性。65 ℃预时效168 h+双级人工时效的应力腐蚀抗性更是优于65 ℃预时效72 h+双级人工时效处理后的应力腐蚀抗性。

表4 7020铝合金在不同时效制度下应力腐蚀指数表

Table 4 Stress corrosion index of 7020 aluminum alloy at different aging treatments

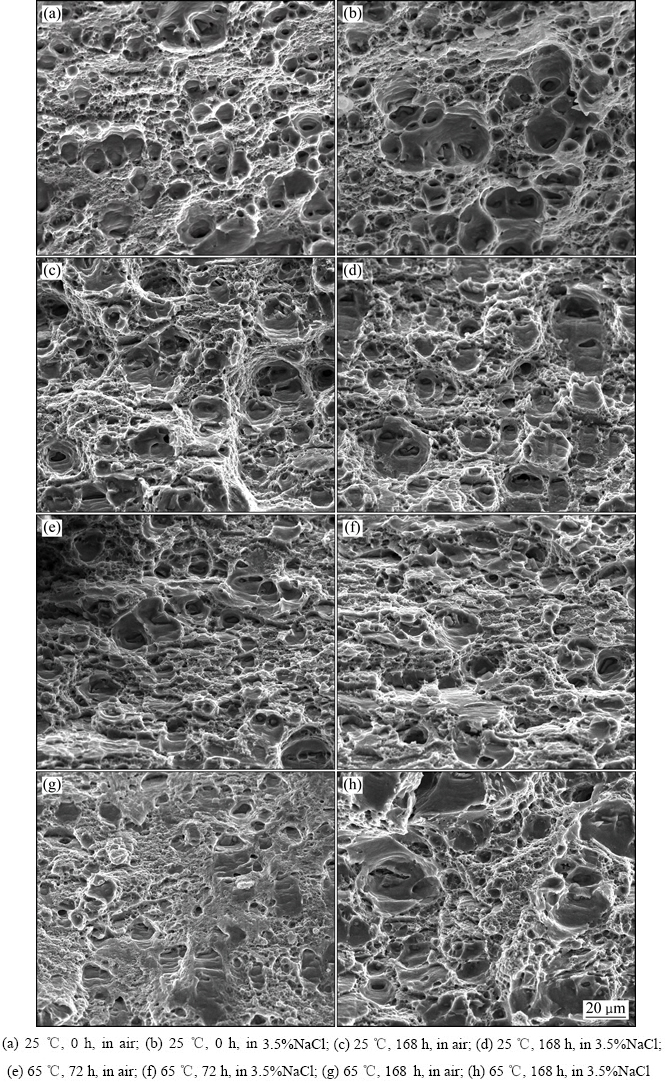

2.3 慢应变速率拉伸断口形貌观察与分析

图1所示为合金试样在自然时效0 h、168 h和经65 ℃预时效72 h、168 h后再经(90 ℃、8 h)+(160 ℃、14 h)双级人工时效处理后在空气和3.5%NaCl腐蚀介质中的慢应变速率拉伸断口形貌。由图1(a)~(h)中可以看出,在不同时效处理状态下,合金试样在经过不同介质中的慢应变速率拉伸断口形貌存在一定的差别,但是拉伸断口主要是围绕晶内的析出相粒子形成,为穿晶韧窝断裂方式,在断口都有一定数量的大大小小的韧窝。通过对比图1 (a)~(h),可以发现图1(a)、(b)相对图1(c)~(h)韧窝较深且相对细小。从图1(h)、(g)可以发现,在空气和3.5%NaCl腐蚀介质中的慢应变速率拉伸断口存在差别,相对图1(g)而言,图1(h)中韧窝相对较多较深。

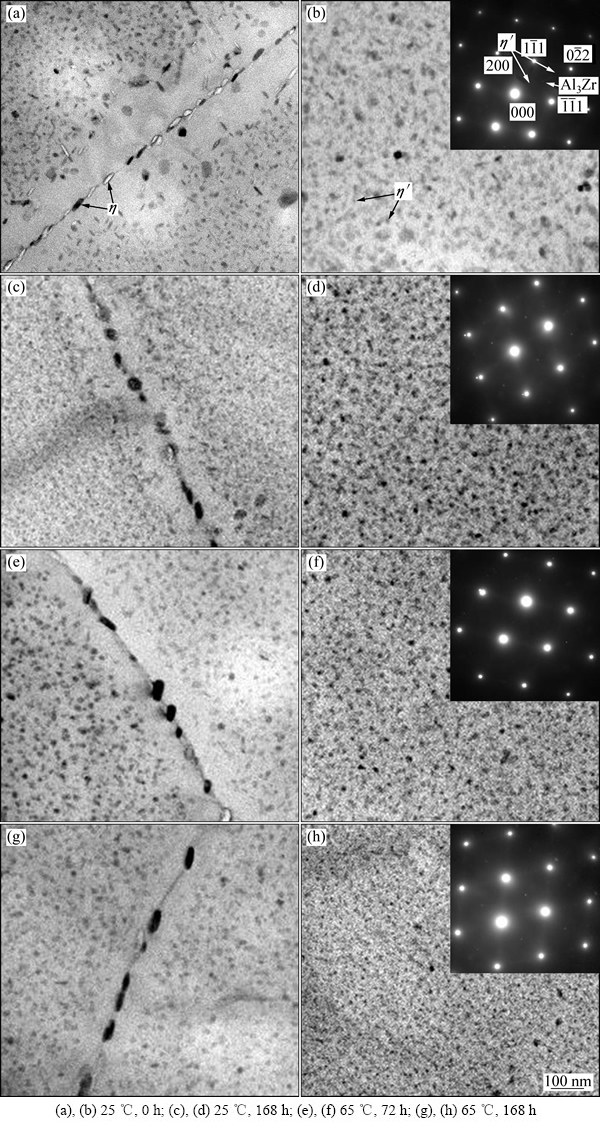

2.4 透射电镜显微组织分析

图2所示为7020铝合金经过不同时效制度后晶内、晶界析出相的形貌。从图2可以看出,在后续双级人工时效工艺(90 ℃、8 h)+(160 ℃、14 h)相同条件下,前期65 ℃预时效72 h、168 h以及自然时效0 h、168 h (实验室实测温度为25 ℃)的长短对合金在时效过程中的析出相的析出数量、弥散分布程度与尺寸有很大影响。

根据图2中[110]Al衍射斑点以及TEM像可知,析出相主要为η′(MgZn2)相,同时有少量的η(MgZn2)相,1/2{200}和1/2{0 2}斑点对应Al3Zr粒子。经过65 ℃预时效72 h、168 h和自然时效168 h后再结合双级人工时效(90 ℃、8 h)+(160 ℃、14 h)处理后,从图2可以看出预时效时间越长,经后续双级时效后晶内析出相越细小弥散分布。对比图2(b)、(d)、(f)、(h)中的晶内析出相分布情况,图2(h)中析出相分布最为细小弥散分布。图2(f)所示为65 ℃预时效72 h+双级人工时效后的晶内析出相分布情况,其晶内析出相的弥散程度较弱于图2(h)中的。图2(d)所示为自然时效168 h后经双级人工时效的晶内析出相分布情况,很明显其弥散程度弱于图2(f)和(h)。而图2(b)为固溶淬火后直接双级人工时效后晶内析出相的分布情况,从该图中可以看出析出相有一定程度的长大,尺寸较图2(d)、(f)、(h)中的大。晶内析出相的这种弥散分布程度上从微观上揭示了合金经过不同时效工艺处理,其强度存在一定差别的原因。图2(h)中所示的析出相最为细小弥散分布,说明其强度在这几个时效制度中是最好的,这是因为在65 ℃预时效168 h过程中细小密集的GP区在刚固溶淬火完具有很高过饱和固溶度的基体内形核析出,为后期更高温度的双级时效处理在组织上作了准备,尤其在160 ℃温度下临界尺寸下的GP区重新回溶,η′相以低温时效过程中形核长大到一定尺寸GP区作为核心形核、长大,由于65 ℃预时效168 h过程中形核析出大量的GP区,所以后期所析出的η′相数量多、细小弥散分布。

2}斑点对应Al3Zr粒子。经过65 ℃预时效72 h、168 h和自然时效168 h后再结合双级人工时效(90 ℃、8 h)+(160 ℃、14 h)处理后,从图2可以看出预时效时间越长,经后续双级时效后晶内析出相越细小弥散分布。对比图2(b)、(d)、(f)、(h)中的晶内析出相分布情况,图2(h)中析出相分布最为细小弥散分布。图2(f)所示为65 ℃预时效72 h+双级人工时效后的晶内析出相分布情况,其晶内析出相的弥散程度较弱于图2(h)中的。图2(d)所示为自然时效168 h后经双级人工时效的晶内析出相分布情况,很明显其弥散程度弱于图2(f)和(h)。而图2(b)为固溶淬火后直接双级人工时效后晶内析出相的分布情况,从该图中可以看出析出相有一定程度的长大,尺寸较图2(d)、(f)、(h)中的大。晶内析出相的这种弥散分布程度上从微观上揭示了合金经过不同时效工艺处理,其强度存在一定差别的原因。图2(h)中所示的析出相最为细小弥散分布,说明其强度在这几个时效制度中是最好的,这是因为在65 ℃预时效168 h过程中细小密集的GP区在刚固溶淬火完具有很高过饱和固溶度的基体内形核析出,为后期更高温度的双级时效处理在组织上作了准备,尤其在160 ℃温度下临界尺寸下的GP区重新回溶,η′相以低温时效过程中形核长大到一定尺寸GP区作为核心形核、长大,由于65 ℃预时效168 h过程中形核析出大量的GP区,所以后期所析出的η′相数量多、细小弥散分布。

图1 7020铝合金经470 ℃、1 h固溶后经过不同预时效工艺处理再经(90 ℃,8 h)+(160 ℃,14 h)双级时效的慢应变速率拉伸断口SEM像

Fig. 1 Slow strain rate tensile fractural SEM images of 7020 aluminum alloy through (470 ℃, 1 h) solution heat-treated, and different pre-aging process followed by two-step aging ((90 ℃, 8 h)+(160 ℃, 14 h))

图2 7020铝合金经470 ℃、1 h固溶后经过不同预时效工艺处理再经(90 ℃、8 h)+(160 ℃、14 h)双级时效后的TEM像

Fig. 2 TEM images of 7020 aluminum alloy through (470 ℃, 1 h) solution heat-treated, and different pre-aging process followed by two-step aging ((90 ℃, 8 h)+(160 ℃, 14 h))

对比图2(a)、(c)、(e)、(g)发现,经过前期不同预时效处理,再经后续双级人工时效处理后在晶界处析出相主要为盘片状η′(MgZn2)相,呈现为断续分布状态,其长轴尺寸长度随时效制度和时效程度而定。图2(a)所示为固溶淬火后直接双级人工时效处理,其晶界无沉淀析出带(PFZ)平均宽度最宽,约为210 nm,而图2(c)、(e)、(g)中所示的PFZ宽度明显比图2(a)中的窄得多,分别为135 nm、100 nm、80 nm。在2(a)中所示析出物在晶界的断续分布程度不是很明显,基本呈现为连续分布,这对材料的抗应力腐蚀性能会产生不利的影响。图2(c)所示为经自然时效168 h处理后的带晶界透射电镜显微照片,相对图2(a)中的PFZ宽度而言,其PFZ宽度随前期自然时效时间的延长而呈变窄趋势,析出物在晶界的断续分布程度随前期自然时效时间的延长而增大,析出物的这种分布情况有利于合金获得一定的抗应力腐蚀性。图2(e)、(g)所示为经65 ℃预时效72 h、168 h处理后的晶界析出物分布情况,其PFZ宽度的变化趋势和自然时效后的基本一致,但是在晶界处的断续分布程度很明显与自然时效后相同人工时效的不同,在65 ℃下随着预时效时间的延长,析出相的断续分布程度增大。经65 ℃预时效处理后的晶界析出相的断续分布程度最明显,有利于合金材料获得很好的抗应力腐蚀性能。

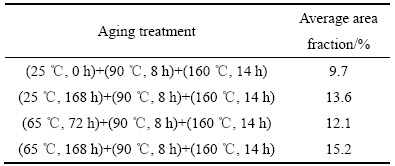

利用分析软件Image Pro Plus对合金材料经过不同时效处理后的晶内析出相进行初步统计,每组取5次统计数据的平均值,其结果如表5所列。从表5可以看出,固溶后直接双级人工时效后晶内析出相的平均面积百分数最低,为9.7%;65 ℃、72 h预时效处理后,晶内析出相平均面积百分数为与自然时效168 h后的相差不大,分别为12.1%、13.6%;65 ℃、168 h预时效处理后,晶内析出相平均面积百分数在4种时效制度中最高,为15.2%。这与表2中的常温拉伸力学性能结果相一致。

表5 合金在不同时效制度下晶内析出物面积分数

Table 5 Average area fraction of intragranular precipitates of investigated alloy under different aging treatments

3 分析与讨论

3.1 预时效工艺对合金常温拉伸性能与微观组织的影响

Al-Zn-Mg(7xxx)系铝合金在固溶淬火后形成的过饱和固溶体在室温条件下是不稳定的,在适宜的温度条件下将发生第二相的脱溶过程(即所谓时效过程),并在不同的脱溶阶段会形成原子偏聚区、亚稳相和稳定的第二相等。一般而言,7xxx铝合金的强化机制主要是沉淀析出强化。Al-Zn-Mg(7xxx)系铝合金在时效过程中的时效析出序列为[13-14]:过饱和固溶体(Supersaturated solid solution)→GP区(GPⅠand GPⅡzones)→亚稳相(η′-MgZn2)→稳定相(η-MgZn2)。合金材料强度的高低在很大程度上是取决于时效过程中晶内析出相的尺寸大小、数量以及弥散分布程度。当固溶淬火后,在进行自然时效和65 ℃预时效条件下晶内主要析出大量的GP区。在此低温下时效时间越长,GP区数量越多,当在后续相对更高温度的双级时效条件之下(90 ℃、8 h),临界尺寸下的GP区原子会部分重新固溶,临界尺寸之上的GP区有所长大。当进行更高温度160 ℃时效时,临界尺寸之上的GP区将作为析出强化相(据图2知主要为η′相和少量的η相)的形核核心[15],GP区回溶后所形成的过饱和原子将再次以时效析出相析出。由此,低温时效时温度与时效时间的长短将决定GP区的数量,在双级时效前时效温度由25 ℃提高到65 ℃,GP区数量越多,后期晶内形核析出的η′相数量越多,η′相时效结束后在晶内呈现为弥散分布。

据图2(b)、(d)、(f)、(h)可知,在后续双级时效制度相同的情况,双级时效前的时效温度和时效时间的长短对合金的析出相的数量尺寸、分布状态及力学性能起决定性作用。在合金材料的时效过程中,其时效驱动力与温度有很大关系。65 ℃预时效温度比自然时效温度稍高,在相同时效时间条件下,在65 ℃预时效过程中具备比自然时效更充分的动力学条件,能有数量更多的GP区形核,为后续时效做组织准备。后续双级时效过程中时效析出相就能以前期预时效时析出的GP区晶核为形核核心形核析出,由于双级人工时效前的时效时间充分,存在大量的GP区,在更高温度条件下可加大时效析出过程,使析出相从基体中脱溶析出更为彻底,达到析出相细小弥散分布的效果,在160 ℃下时效,当时间不是很长以至于不会使过时效程度不至于太大的情况下,这些析出相尺寸保持在某一范围,析出相的这种弥散、大量细小分布有利于合金材料获得高的强度,从而使材料具有更好的综合性能。

在后续相同(90 ℃、8 h)+(160 ℃、14 h)双级人工时效下,相对于固溶后直接进行双级时效和先自然时效168 h再经双级时效而言(见图2(b)、(d)),进行65 ℃预时效168 h后的晶内析出相更加细小弥散分布(见图2(h)),使合金具有较之于固溶淬火后直接双级人工时效和自然时效168 h处理后更高的强度。从晶内析出相的尺寸大小、数量及弥散分布程度可知(见图2(b)、(d)、(f)、(h)),经65℃预时效72h处理后,晶内的分布弥散程度弱于图2(d)、(h)中所示的,但优于图2(b)中所示的,在合金强度上优于直接双级人工时效后的强度而次于自然时效、65 ℃预时效、168 h后的强度。

3.2 时效工艺对合金慢应变速率拉伸性能的影响

近30余年来,很多国内外学者对7xxx系铝合金材料的抗应力腐蚀开裂机理进行了大量的研究,但是由于影响合金材料的应力腐蚀开裂的因素不唯一和材料的服役环境的复杂性等,以及7xxx铝合金的抗应力腐蚀性能与材料的化学成分、时效热处理制度都有很大关系,有关的腐蚀作用机理尚未达成统一认识,目前比较熟知的主要有氢致破裂理论、阳级溶解理论等[16-18]。一般而言,对于给定组分的铝合金材料,其抗应力腐蚀性能是与其强度呈负相关性,但是合金在时效过程中时效析出相在晶界、晶内的析出数量、分布情况以及形貌对材料的抗应力腐蚀性能具有很重要的影响[19]。由于铝基体(Matrix)、时效析出相和溶质贫化区(SDZ)之间存在电级电位差,在腐蚀过程中电化学行为差异很大,导致晶界比晶粒内部更易腐蚀[20]。

在通常情况下,在晶内主要是析出GP区和η′相及一定数量的η相;而晶界析出相主要是η相,同时,在晶界存在一定宽度的无沉淀析出带(PFZ)。根据时效强化机理,晶内析出物η′相析出数量多、尺寸细小弥散,则合金材料的强化效应愈加显著,材料强度也越高;而抗应力腐蚀性能与晶界析出相尺寸和无沉淀析出区的宽度有关,在晶界处析出相的尺寸和间距越大,则抗应力腐蚀性能愈好,晶界无沉淀析出带的宽度在一定情况下有利于合金材料获得好的抗应力腐蚀性能。因为在应力腐蚀过程中晶界析出物作为阳级先溶解,而晶界析出相间距越大则应力腐蚀开裂的阻力越大,同时氢原子在粗大晶界析出相上富集并形成分子氢逸出可以降低晶界氢含量从而抑制氢脆[16-17]。在应力和腐蚀介质共同作用下,晶界析出相在合金材料的腐蚀过程中作为阳级会优先溶解导致应力腐蚀开裂现象,因此,晶界析出相断续分布则材料应力腐蚀开裂的阻力越大,抗应力腐蚀性能愈佳,析出相在晶界连续分布则会加速在应力腐蚀条件下的析出相溶解,导致应力腐蚀开裂现象过早出现对材料抗应力腐蚀性能的提高产生不利影响。在晶界析出的粗大相尺寸大、断续分布和一定的晶界无沉淀析出带宽度有利于吸收氢原子形成分子氢逸出以降低晶界的氢含量来起到抑制氢脆的作用。因此,要提高7020铝合金材料的抗应力腐蚀性能,可以通过调控热处理工艺参数改变晶内、晶界的析出相和晶界无沉淀析出带(PFZ)的分布特征来使合金材料获得较好的综合性能。

合金试样经固溶淬火后再直接双级人工时效和经过自然时效168 h后再进行双级热人工时效(见图2(a)、(c)),晶界析出相呈连续分布状态,在慢应变速率拉伸过程中,这些连续分布的晶界析出相在腐蚀介质和应力共同作用下充当腐蚀电位阳级,为腐蚀电流提供了腐蚀通道,从而导致合金材料在该状态下很容易受到应力腐蚀影响以至于出现应力腐蚀开裂现象。而图2(e)、(g)所示为合金材料经65 ℃预时效72 h、168 h处理后,其晶界析出相与图2(a)、(g)中所示的差异很大,呈断续分布状态。在慢应变速率拉伸过程中,这样的大尺寸析出相不连续分布能破坏腐蚀通道以提高合金材料的抗应力腐蚀性能。

在自然时效和65 ℃预时效长达168 h的过程中,晶内会时效析出大量的GP区,从后续双级时效后的显微TEM可以得知,65 ℃预时效168 h过程中析出的GP区更多。经过双级时效的第一级90 ℃、8 h短时间过度后远小于临界尺寸的GP区原子回溶,再次析出部分GP区,临界尺寸附近及其以上有所稍微长大。进入高温160 ℃后,所有临界尺寸以下GP区发生回溶以补充基体合金中的Zn、Mg元素在该时效过程中进行η′相形核、生长,原有组织中临界尺寸附近及其以上的GP区将作为时效析出相η′相的形核核心,临界尺寸以上的GP区越多,在终时效160℃时效过程中时效析出相η′相形核核心越多,最后,析出相η′相在晶内细小弥散分布,在晶界析出相η相发生一定的生长、粗化呈现连续或断续分布,使得合金材料具有较高的强度和一定的抗应力腐蚀性能。

经过自然时效和65 ℃预时效不同时间后再经行双级人工时效后,结合图2、表2和表3可知,采用在传统人工时效前进行65 ℃短时间预时效,使得合金材料晶内更加细小弥散分布,晶界析出相断续分布,保证合金材料具有较高的强度和很好的抗应力腐蚀性能。同时通过对比可以看出,65 ℃预时效结合双级人工时效工艺显著地提高合金的应力腐蚀抗性。

4 结论

1) 后续(90 ℃、8 h)+(160 ℃、14 h)双级时效相同条件下,经65 ℃预时效168 h处理后,合金的力学性能比固溶淬火后直接双级时效的性能优越,Rm、Rp0.2、A分别为397.4 MPa、338.8 MPa、15.8%和368.9 MPa、289.9 MPa、15.9%;经65 ℃预时效72 h处理,合金的最终性能与自然时效168 h后的相当,Rm、Rp0.2、A分别为387.6 MPa、320.2 MPa、15.7%和392.0 MPa、333.3 MPa、16.0%。

2) 经65 ℃预时效168 h处理后合金具有最好的抗应力腐蚀性能,ISSRT为-0.003;65 ℃预时效72 h与自然时效168 h处理后的抗应力腐蚀性能相当,ISSRT分别为0.034和0.036;直接双级时效处理后的抗拉强度和抗应力腐蚀性最差,ISSRT为0.038。

3) 直接双级时效处理后合金晶界析出物η相连续分布,晶内析出相尺寸最大、晶内析出相平均面积分数9.7%。经自然时效168 h后晶界析出物呈现不连续分布,晶内析出相平均面积分数13.6%;65 ℃预时效(72 h、168 h)后的晶界析出相呈现断续分布且断续分布程度随预时效时间延长而增大,晶内析出相η′相随预时效时间的延长更加细小弥散;晶内析出相平均面积分数分别为12.1%和15.2%。

REFERENCES

[1] WANG D, NI D R, MA Z Y. Effect of pre-strain and two-step aging on microstructure and stress corrosion cracking of 7050 alloy[J]. Materials Science and Engineering A, 2008, 494(1): 360-366.

[2] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[3] HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, KE Bin, XIN Xing. Effects of pre-stretching and ageing on the strength and fracture toughness of aluminum alloy 7050[J]. Materials Science and Engineering A, 2011, 528(10/11): 3714-3721.

[4] 宋丰轩, 张新明, 刘胜胆, 韩念梅, 花 隆. 时效对7050铝合金预拉伸板抗腐蚀性能的影响[J]. 中国有色金属学报, 2013, 23(3): 645-651.

SONG Feng-xuan, ZHANG Xin-ming, LIU Sheng-dan, HAN Nian-mei, HUA Long. Effect of aging on corrosion resistance of 7050 aluminum alloy pre-stretching plate[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 645-651.

[5] 韩念梅, 张新明, 刘胜胆, 黄乐瑜, 辛 星, 何道广. 回归再时效对7050铝合金强度和断裂韧性的影响[J]. 中国有色金属学报, 2012, 22(7): 1871-1882.

HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, HUANG Le-yu, XIN Xing, HE Dao-guang. Effects of retrogression and reaging on strength and fracture toughness of aluminum alloy 7050[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1871-1882.

[6] 冯 迪, 张新明, 邓运来, 刘胜胆, 吴泽政, 郭奕文. 预时效温度及回归加热速率对7055铝合金组织及性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1141-1150.

FENG Di, ZHANG Xin-ming, DENG Yun-lai, LIU Sheng-dan, WU Ze-zheng, GUO Yi-wen. Effect of pre-ageing temperature and retrogression heating rate on microstructure and properties of 7055 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1141-1150.

[7] 曾世宝, 叶凌英, 刘胜胆, 邬沛卿, 单朝军, 邓运来, 张新明. 均匀化升温速率对7N01铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2014, 24(9): 2228-2234.

ZENG Shi-bao, YE Ling-ying, LIU Sheng-dan, WU Pei-qing, SHAN Chao-jun, DENG Yun-lai, ZHANG Xin-ming. Effect of homogenization heating rate on microstructure and mechanical properties of 7N01 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2228-2234.

[8] 张建波, 张永安, 何振波, 金龙兵, 朱宝宏, 李志辉. 自然时效对7N01铝合金组织和性能的影响[J]. 稀有金属, 2012, 36(2): 191-195.

ZANG Jian-bo, ZANG Yong-an, HE Zhen-bo, JIN Long-bing, Zhu Bao-hong, Li Zhi-hui. Influence on microstructure and mechanical properties of 7N01 aluminum alloy under natural aging treatment[J]. The Chinese Journal of Rare Metals, 2012, 36(2): 191-195.

[9] 宋 涛, 高家诚, 乔丽英, 高安江. 7N01铝合金120℃单级时效的组织和性能[J]. 材料热处理学报, 2011, 32(7): 104-109.

SONG Tao, GAO Jia-cheng, QIAO Li-ying, GAO An-jiang. The microstructure and properties of 7N01 aluminum under single aging treatment at 120 ℃[J]. The Transaction of Materials and Heat Treatment, 2011, 32(7): 104-109.

[10] 付 高, 邓运来, 王亚风, 戴青松, 张新明. 微量元素含量对Al-Zn-Mg合金组织与性能的影响[J]. 中国有色金属学报, 2015, 25(10): 2632-2641.

FU Gao, DENG Yun-lai, WANG Ya-feng, DAI Qing-song, ZHANG Xin-ming. Effects of microelement content on microstructure and properties of Al-Zn-Mg aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2632-2641.

[11] 吴翼贻, 黄清添, 林昆民. AA7005铝合金抗应力腐蚀制程之研究[J]. 金属热处理, 2005, 30(z1): 8-12.

WU Yi-yi, HUANG Qing-tian, LIN Kun-ming. A study on the stress corrosion resistance processes of AA 7005 aluminum alloy[J]. Heat Treatment of Metal, 2005, 30(z1): 8-12.

[12] 邬沛卿. 热处理制度对7N01铝合金性能的影响[D]. 长沙: 中南大学, 2014: 34-55.

WU Pei-qing. Effect of heat treatments on the properties of 7N01 aluminum alloy[D]. Changsha: Central South University, 2014: 34-55.

[13] SHARMA M, AMATEAU M F, EDEN T J. Hardening mechanisms of spray formed Al-Zn-Mg-Cu alloys with scandium and other elemental additions[J]. Journal of Alloys and Compounds, 2006, 416(1/2): 135-142.

[14] WATERLOO G, HANSEN V, GJONNES J, SKJERVOID S R. Effect of predeformation and preaging at room temperature in Al-Zn-Mg-(Cu, Zr) alloys[J]. Materials Science and Engineering A, 2001, 303(1/2): 226-233.

[15] STILLER K, WARREN P J, HANSEN V, ANGENETE J, GJONNES J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 ℃ and 150 ℃[J]. Materials Science and Engineering A, 1999, 270(1): 55-63.

[16] GRUHL W, METALLKD Z. Stress corrosion cracking of high strength aluminium alloys[J]. Materials Science and Engineering A, 1984, 75(1): 819-826.

[17] 刘继华, 李 荻, 朱国伟, 刘培英. 7075铝合金应力腐蚀敏感的SSRT和电化学测试研究[J]. 腐蚀与防护, 2005, 26(1): 6-9.

LIU Ji-hua, LI Di, ZHU Guo-wei, LIU Pei-ying. Stress corrosion susceptibility of 7075 aluminium alloy studied by SSRT and electrochemical tests[J]. Corrosion & Protection, 2005, 26(1): 6-9.

[18] 陈小明, 宋仁国. 7000系铝合金应力腐蚀开裂的研究进展[J]. 腐蚀科学与防护技术, 2010, 22(2): 120-123.

CHEN Xiao-ming, SONG Ren-guo. Progress in research on stress corrosion cracking of 7000 series aluminium alloys[J]. Corrosion Science and Protection Technology, 2010, 22(2): 120-123.

[19] RINGER S P, HONO K. Microstructural evolution and age hardening in aluminium alloys: Atom probe field-ion microscopy and transmission electron microscopy studies[J]. Materials characterization, 2000, 44(1/2): 101-131.

[20] 苏景新, 张 昭, 曹发和, 张鉴清, 曹楚南. 铝合金的晶间腐蚀与剥蚀[J]. 中国腐蚀与防护学报, 2005, 25(3): 187-192.

SU Jing-xin, ZHANG Zhao, CAO Fa-he, ZHANG Jian-qing, CAO Chu-nan. Review on the intergranular corrosion and exfoliation corrosion of aluminum alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(3): 187-192.

Effect of pre-aging on microstructure andstress corrosion resistance of 7020 aluminum alloy

YANG Tao1, 3, YE Ling-ying2, 3, SHAN Zhao-jun2, 3, WANG Shao-ling2, 3, DENG Yun-lai2, 3, ZHANG Xin-ming1, 2, 3

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Material Science and Engineering, Central South University, Changsha 410083, China;

3. Key Laboratory of Nonferrous Materials Science and Engineering,

Ministry of Education, Central South University, Changsha 410083, China)

Abstract: After solution heat treatment at 470℃ for 1h, the alloys were natural aged for 0 h or 168 h and pre-aged at 65 ℃ for 72 h or 168 h, respectively. And then, the two-step aging ((90 ℃, 8 h)+(160 ℃, 14 h)) was conducted on these alloys. The effect of pre-ageing treatment on the tensile properties, resistances to stress corrosion and microstructures of 7020 aluminum alloy was investigated by tensile test, slow strain rate tensile (SSRT) test, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). 7020 aluminum alloy aged at 65 ℃ for 168 h pre-ageing treatment has the highest tensile property Rm of 397.4 MPa as well as the best stress corrosion resistance ISSRT of -0.003. The tensile property and stress corrosion resistance of alloy pre-ageing treatment at 65 ℃ for 72 h are 387.6 MPa and 0.034. And it is comparable of that of natural aging 168h, with Rm of 392.0 MPa and ISSRT of 0.036. While the tensile property and stress corrosion resistance of alloy by direct two-step aging are the worst, with Rm of 368.9 MPa and ISSRT of 0.038. With the increase of the pre-aging time, the size of intragranular precipitates η′(MgZn2) inside grains decreases, the intermittent distribution degree of precipitates intragranular precipitates η′(MgZn2) inside grains decreases and the intermittent distribution degree of precipitates η(MgZn2) at the grain boundaries increases.

Key words: 7020 aluminum alloy; pre-aging; tensile property; slow strain rate tensile; microstructure

Foundation item: Project (2012CB619500) supported by the National Basic Research Development Program of China

Received date: 2015-07-08; Accepted date: 2016-01-11

Corresponding author: YE Ling-ying; Tel: +86-13607435545;E-mail:30575421@qq.com

(编辑 龙怀中)

基金项目:国家重点基础研究计划资助项目(2012CB619500)

收稿日期:2015-07-08;修订日期:2016-01-11

通信作者:叶凌英,副教授,博士;电话:13607435545;E-mail:30575421@qq.com