片状TA15钛合金在热变形过程中的动态球化动力学

来源期刊:中国有色金属学报(英文版)2011年第9期

论文作者:吴成宝 杨合 樊晓光 孙志超

文章页码:1963 - 1969

关键词:TA15合金;动态球化;动力学;应变;动力学速率

Key words:TA15 titanium alloy; dynamic globularization; kinetics; strain; kinetics rate

摘 要:通过等温热压缩实验定量地研究片层TA15钛合金在860~940℃,应变速率0.01~10 s-1范围内的动态球化动力学。研究发现TA15钛合金的动态球化动力学和动力学速率对热变形参数很敏感。动态球化率随应变的增加、温度的升高和应变速率的降低而增大,且应变的变化规律遵循动力学Avrami模型曲线。通过模型预测球化开始应变和完全球化所需要的应变分别为0.34~0.59和3.40~6.80。动态球化动力学速率随着应变的增加呈现先增大后减小的趋势。球化动力学速率的峰值对应的球化率为20%~33%,且随着温度的升高和应变速率的降低而增大。

Abstract:

The dynamic globularization kinetics of TA15 (Ti-6Al-2Zr-1Mo-1V) titanium alloy with a colony α microstructure during deformation at temperature range of 860-940℃ and strain rate range of 0.01-10 s-1 was quantitatively studied through isothermal compression tests. It is found that the dynamic globularization kinetics and the kinetics rate of TA15 are sensitive to deformation parameters. The dynamic globularized fraction increases with increasing strain, temperature but decreasing strain rate. The variation of globularized fraction with strain approximately follows an Avrami type equation. Using the Avrami type equation, the initiation and completion strains for dynamic globularization of TA15 were predicted to be 0.34-0.59 and 3.40-6.80. The kinetics rate of dynamic globularization increases with strain at first, then decreases. The peak value of kinetics rate, which corresponds to 20%-33% globularization fraction, increases with increasing temperature and decreasing strain rate.

WU Cheng-bao, YANG He, FAN Xiao-guang, SUN Zhi-chao

State Key Laboratory of Solidification Processing, School of Materials Science and Engineering,

Northwestern Polytechnical University, Xi’an 710072, China

Received 7 September 2010; accepted 5 January 2011

Abstract: The dynamic globularization kinetics of TA15 (Ti-6Al-2Zr-1Mo-1V) titanium alloy with a colony α microstructure during deformation at temperature range of 860-940 °C and strain rate range of 0.01-10 s-1 was quantitatively studied through isothermal compression tests. It is found that the dynamic globularization kinetics and the kinetics rate of TA15 are sensitive to deformation parameters. The dynamic globularized fraction increases with increasing strain, temperature but decreasing strain rate. The variation of globularized fraction with strain approximately follows an Avrami type equation. Using the Avrami type equation, the initiation and completion strains for dynamic globularization of TA15 were predicted to be 0.34-0.59 and 3.40-6.80. The kinetics rate of dynamic globularization increases with strain at first, then decreases. The peak value of kinetics rate, which corresponds to 20%-33% globularization fraction, increases with increasing temperature and decreasing strain rate.

Key words: TA15 titanium alloy; dynamic globularization; kinetics; strain; kinetics rate

1 Introduction

TA15 (Ti-6Al-2Zr-1Mo-1V) titanium alloy is an important titanium alloy extensively used in aircraft industry. It is a near α titanium alloy which was developed as BT20 titanium alloy by the former USSR in 1964 [1-2]. TA15 alloy has been widely used because of its attractive properties such as high specific strength, thermal stability, and welding ability.

The colony microstructure usually exists in as-cast or beta-processed two-phase titanium alloys, and it breaks up or globularizes during deformation and subsequent annealing in the α/β phase field. Globularization process is very important to the acquirement of desired microstructure for final forming. Therefore, it has received considerable attention [3-7].

Many studies have been carried out on dynamic globularization of two-phase titanium alloys. SEMIATIN et al [8-9] observed the dynamic globularization and the effect of initial microstructure on dynamic globularization of Ti-6Al-4V alloy with colony α structure occurring at strain rate lower than 0.01 s-1, and found that strains around the order of 0.75-1.0 and 2-2.5 are required respectively for initiation and completion of dynamic globularization. POTHS et al [10] studied the effect of strain-path reversal on the kinetics of dynamic globularization of Ti-6Al-4V. SONG et al [11] studied the dynamic globularization kinetics of TC11 alloy, and found that the globularization fraction increases with strain in sigmoid way. WANG et al [12] had a study on the dynamic globularization kinetics during hot working of Ti-17 alloy with initially lamellar microstructure, and indicated the influence of deformation conditions on the dynamic globularization kinetics, kinetics rate and strains for initiation and completion of dynamic globularization. To be summarized, the dynamic globularization kinetics are different for different titanium alloys because of chemical compositions difference. It is clear that the TA15 alloy is extensively used in important structural parts of airplanes and the equiaxed microstructure is usually required in the structural parts, so we need to convert lamellar microstructure (associated with as-cast or beta-processed TA15 titanium alloys) to equiaxed microstructure. Studying dynamic globularization kinetics of TA15 plays a key role in this conversion and development of desired microstructure for final forming or service of structural parts. To date, there is little systematic work focusing on dynamic globularization kinetics for TA15 alloy during hot working in two-phase field.

In the present work, we quantitatively studied the dynamic globularization kinetics of TA15 alloy with a colony α structure during hot deformation in two-phase field. The results can be references of processing parameters selection to meet the requirement of fine microstructure and excellent mechanical properties in hot forming of TA15 component parts in aircraft industry.

2 Experimental

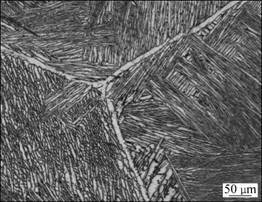

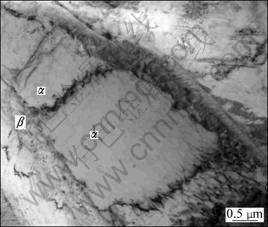

The chemical compositions of TA15 alloy in this study are as follows (mass fraction, %): 6.06 Al, 2.08 Mo, 1.32 V, 1.86 Zr, 0.09 Fe, 0.08 Si, 0.05 C, 0.07 O, and balance Ti. The β transus temperature of the alloy was measured to be about 990 °C by metallographic observations. The original wrought bars were heated to 1 020 °C, held for 30 min and cooled in furnace. The initial microstructure of the heat treated material is given in Fig. 1. The microstructure shows a colony structure consisting of lamellar α in prior β coarse grains (average grain size of about 500 μm), a grain boundary α layer (in thickness of 7 μm) and continuous β layers between the colony α lamellae (in thickness of 4 μm), which has a typical microstructure characteristic before cogging process in α/β phase field.

Fig. 1 Initial microstructure of TA15 alloy

Compression specimens (8 mm in diameter and 12 mm in height) machined from the heat treated bars were subjected to 30%-70% isothermal hot compression tests on a Gleeble 3 500 thermal simulator in the temperature range of 860-940 °C and strain rate range of 0.01-10 s-1. The specimens were heated to compression temperature at heating rate of 5 °C/s, and homogenized for 3 min before deformation. After hot compression, the specimens were quenched immediately in water, to preserve the hot-deformed structures.

The deformed specimens were sectioned parallel to the compression axis for microstructural analysis. The samples for optical metallographic examination were made by mechanically polished and etched with a solution consisting of 7% HF, 13% HNO3 and 80% H2O. Because of the inhomogeneous deformation and non-uniform strain distribution in the compressed specimens, FEM was applied to calculate the local effective strains of six selected fields in every specimen for microstructure observation. Globularization behavior of the α lamellae was then quantified using moderate magnification optical photographs by a quantitative metallographic image analysis system (Image-pro plus 5.0) considering α phase with the aspect ratio (length/width) lower than 2.5 as a globular.

3 Results and discussion

3.1 Characterization of dynamic globularization kinetics

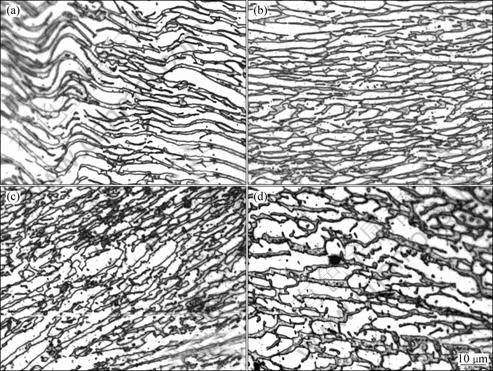

Figure 2 shows the deformed microstructures of TA15 alloy with strain of 2.0 at different temperatures and strain rates. It can be found that the microstructure in Fig. 2(a) contains a small amount of kinked lamellae and a little of globular or equiaxed morphology at a low temperature (860 °C) and high strain rate (1 s-1). Micrographs in Figs. 2(c) and (d) show the effect of strain rate on dynamic globularization development of the lamellar structure. Compared with the microstructure at higher strain rate (Fig. 2(c)), the lamellae break up and transform to globular or equiaxed α phase more remarkably at a lower strain rate (Fig. 2(d)). A larger fraction of lamellae have globularized at higher temperature of 940 °C and lower strain rate of 0.01 s-1 (Fig. 2(d)).

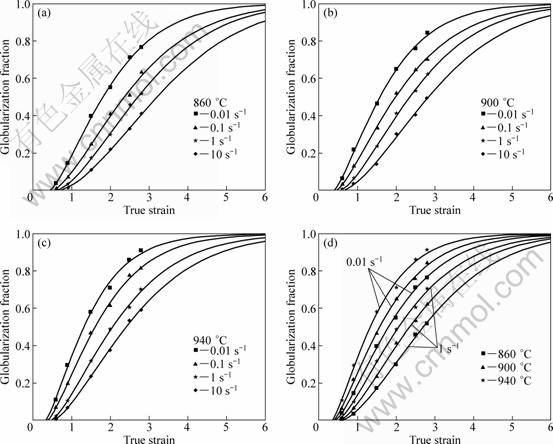

Using Image-pro plus 5.0, the dynamic globularized fraction was quantitatively measured under different hot working conditions for TA15 alloy with a colony microstructure, which is plotted as a function of the effective strain in Fig. 3. It suggests that the dynamic globularization initiates after a critical strain reaches and the globularization fraction is very sensitive to the deformation parameters.

SONG et al [11] found that the dynamic globularization fraction of TC11 alloy increases with strain in a sigmoid way. It can be found in Fig. 3 that the globularization behavior of TA15 is very similar to that of TC11. So an Avrami type equation can be used to describe the globularized fraction of TA15.

fDg=1-exp[-k(ε-εc)n] (1)

where fDg is the volume fraction of dynamic globularized α, εc is the critical strain for initiation of dynamic globularization, n is the Avrami exponent, and k is the kinetic constant and temperature-dependent factor. Hereinto, εc, n and k are fitting parameters.

Fig. 2 Optical micrographs of structure developed in TA15 alloy specimens: (a) 860 °C, 1 s-1; (b) 860 °C, 0.01 s-1; (c) 940 °C, 1 s-1; (d) 940 °C, 0.01 s-1

Fig. 3 Measurements of dynamic globularized fraction versus strain for TA15 alloy samples under different deformation conditions (Dot—Experimentally measured data; Line—Fitted result using Eq. (1))

The predicted results using Eq. (1) are consistent with the experimental results, as shown in Fig. 3. Therefore, it may be reasonable to describe the dynamic globularization kinetics of TA15 with Avrami type Eq. (1). The kinetic constant k ranges from 0.14 to 0.71 under the current experimental conditions, and it increases with increasing temperature and decreasing strain rate. The value of n varies between 1.29 and 1.68. However, it decreases with increasing temperature and decreasing strain rate.

The data of the critical strain εc for initiation of globularization and the strain needed for full globularization εf are then predicted respectively using the fitting curves in Fig. 3. A detailed analysis is carried out in the later section.

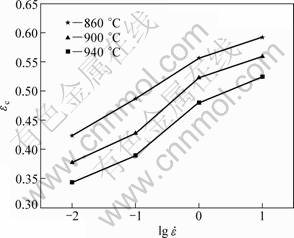

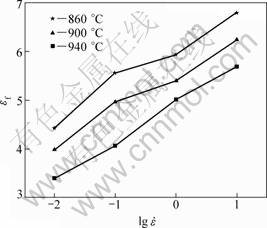

3.2 Analysis of strain εc and εf

It is found that a critical strain between 0.34-0.59 is needed for the initiation of dynamic globularization under all deformation conditions (Fig. 4). As shown in Fig. 4, the critical strain εc increases with decreasing temperature and increasing strain rate. The conversion of lamellar microstructure to globularization α was extensively studied [13-16]. WANG et al [12] revealed that the globularization may consist of two events: breakup of lamellae and formation of globules. It is shown in Fig. 5 that the lamella can break up into separated α grains through intense shearing or the penetration of the β phase along the interfaces. The breakup of the lamellae begins at the formation of intraphase boundary in the lamellae, which is likely to occur at kinks or shearing band of lamellae, so that a certain amount of strain must be needed for formation of intraphase boundary [8]. The breakup of lamellae is determined by the dislocation glide, which is related to strain magnitude. Migration of the interfaces to form a globular shape occurs through diffusional processes driven by the urge to minimize the interfacial energy or the surface tension [13].

Fig. 4 Predicted values of εc for initiation of dynamic globularization at different deformation conditions

Fig. 5 TEM observation of conversion of α lamella to equiaxed or globularized α (at strain of 0.90, temperature of 900 °C, strain rate of 0.1 s-1)

As we know, dynamic globularized α results from three main sources: short lamellae with Feret ratio less than 2.50 from direct separation, broken-up lamellae with Feret ratio more than 2.50 (followed by termination migration to minimize the surface tension), unbroken-up severing lamellae (followed by the diffusion of interface alloy elements to minimize the interfacial energy) [12]. The migration and diffusion of interface are affected by the thermal activation. Thus, the critical strain εc also depends on the thermal activation. At a low temperature or high strain rate, the dynamic globularized α mainly derives from the short lamellae with Feret ratio less than 2.50 from direct broke-up, because the diffusion rate is slow at low temperature and the diffusion time is not sufficient. At a higher temperature or lower strain rate, the diffusion process is very intense. As a result, the inconspicuous intraphase boundaries divide the lamellae into short lamellae or globularized α. Moreover, the volume fraction of prior α lamellae increases at lower temperature, so more lamellae consume the strains. Accordingly, the critical strain becomes large. From the above analyses, it can be concluded that the critical strain of dynamic globularization of TA15 is observably dependent on the temperature and strain rate.

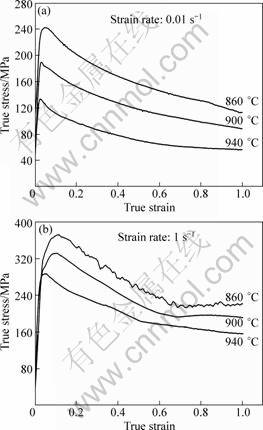

The critical strain (0.34-0.59) for dynamic globularization is much higher than the peak strain (0.02-0.10) on the flow stress curves of TA15 (Fig. 6). SONG et al [11] and WANG et al [12] also discovered the similar phenomenon in TC11 and Ti-17 alloys, and suggested that the dynamic globularization is controlled by dislocation glide not by dislocation density. SESHACHARYULU et al [14] suggested that the dynamic globularization process is a type of DRX, because it also includes two completive processes (rate of nucleation and rate of migration). Unlike the DRX, the nucleation of new interfaces appeared in dynamic globularization instead of new grains. McQUEEN et al [17] considered that the type of microstructural change involving a reduction in Feret ratio of the lamellae can be interpreted in terms of geometric recrystallization. Because the imposed strain is consumed by the kink, rotation of lamellae and the forming of intraphase boundaries or subgrain boundaries, the critical strain of dynamic globularization is higher than the peak strain. These microstructural features can be observed in the former micrographs (Fig. 2).

Fig. 6 Stress—strain curves of TA15 alloy with colony microstructure

The values of the strain εf (3.40–6.80) to complete fully dynamic globularization (corresponding to 95% dynamic globularization) under different conditions are calculated using Avrami type Eq. (1) and shown in Fig. 7. Like the critical strain εc, the strain εf also increases with decreasing temperature and increasing strain rate. This phenomenon is similar to that of Ti-17 alloy [12]. Based on these characteristics, it may be concluded that the completion of dynamic globularization is also dependent on the diffusional processes. Because the diffusion process is limited at a lower temperature or higher strain rate, a great amount of broken-up lamellae with Feret ratio more than 2.5 and unbroken-up lamellae with intraphase boundaries can not complete globularization. By comparing Fig. 2(b) (860 °C, 0.01 s-1) with Fig. 2(d) (940 °C, 0.01 s-1), it can be found that most lamellae break up into equiaxed lamellae after deformation with large strain at lower temperature. However, the globularized degree of α phase is evidently lower than that at high temperature. By comparing Fig. 2(c) (940 °C, 1 s-1) with 2(d) (940 °C, 0.01 s-1), it is concluded that the high strain rate also restricts the dynamic globularization of TA15 alloy.

Fig. 7 Predicted values of εf to complete full globularization under different deformation conditions

Moreover, the predicted strain εc and εf of TA15 alloy are higher than those of Ti-6Al-4V [8], TC11 alloy [11] and Ti-17 [12]. The differences are mainly due to the large thickness and α phase content of the lamellae in TA15 alloy with rich α alloying elements. The study of SHELL et al [9] and WEISS et al [13] indicated that completing separation and dynamic globularization kinetics of α lamellae are dependent on the lamellae thickness in initial microstructure of titanium alloys. Relatively, the initiation and completion of globularization require larger strain within thicker lamellae because the development of interfaces is more difficult and the penetration depth is larger within thicker lamellae. Therefore, compared with Ti-6Al-4V [8], TC11 alloy [11] and Ti-17 [12], the kinetics rate is lower and higher strain is needed for the initiation and competition of dynamic globularization in TA15 alloy with a colony α structure.

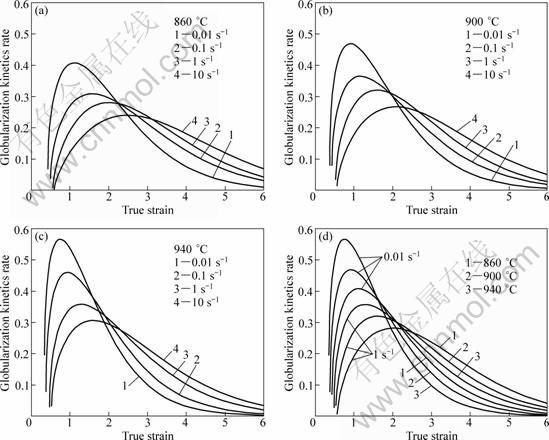

3.3 Analysis of dynamic globularization kinetics rate

Seen from Fig. 3, the evolution of globularization fraction versus strain shows significant dependence on deformation conditions. Because the strain rates are constant in the compression processes, the dynamic globularization kinetics rate can be defined as:

![]() (2)

(2)

The variation of kinetics rate with strain is given in Fig. 8. The curves of the dynamic globularization kinetics rate have single peak value at a strain corresponding to 20%-33% globularization. In DRX process, the similar phenomenon has also been found, which is considered a result of competition between the new grain nucleation rate and grain growth rate. However, new grain nucleation is excluded during dynamic gobularization. So the increase of dynamic globularization kinetics rate at early stage is mainly because of the breakup of abundant lamellae, while the decrease of the kinetics rate after a certain strain may be due to the reduction of aspect ratio of lamellae after certain amount of globularization, which makes the continued fragmentation of lamellae more difficult [12]. In addition, another reason for the decreasing kinetics rate considered by SONG et al [11] is that more strain is consumed by the boundary gliding of globularized grains because of easier deformation ability of globularized grains than lamellae.

Fig. 8 Calculated kinetics rate as function of strain at different conditions

It is noted that the dynamic globularization kinetics rate increases with decreasing strain rate and increasing temperature, and the maximal value of the kinetics rate is higher at higher temperature and lower strain rate (Fig. 8). These indicate that the diffusional process plays an important role in globularization process [12]. As the final step for dynamic globularization of the lamellae, the migration rate of intraphase boundary limits the kinetics rate of dynamic globularization. WANG et al [12] also discovered similar rules in Ti-17 alloy.

4 Conclusions

1) The dynamic globularization kinetics of TA15 alloy is sensitive to deformation parameters and it increases with strain in an Avrami type sigmoid way.

2) The strains for initiation and completion of dynamic globularization are predicted to be 0.34-0.59 and 3.40-6.80, respectively. They both increase with increasing temperature and decreasing strain rate.

3) The kinetic rate of dynamic globularization reaches the maximum at a strain corresponding to 20%-33% globularization, then decreases with strain. This is attributed to the decreased fraction of prior lamellae and the difficulty in subsequent breakup of lamellae with reduced aspect ratio at large strains.

4) The peak value of the kinetics rate is higher at higher temperature and lower strain rate. The kinetics rate of dynamic globularization increases with increasing temperature and decreasing strain rate because the kinetic rate is limited by the rate of intraphase boundary migration.

References

[1] XU Wen-cheng, SHAN De-bin, YANG Guo-ping, LU Yan. Flow behavior and microstructure evolution during hot compression of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(s3): s2066-s2071.

[2] ZHU Jing-chuan, WANG Yang, LIU Yong, LAI Zhong-hong, ZHAN Jia-jun. Influence of deformation parameters on microstructure and mechanical properties of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(s1): s490-s494.

[3] CHEN Hui-qin, CAO Chun-xiao, GUO Ling, LIN Hai. Globularization mechanisms during hot deformation processes of TC11 alloy with lamellar structure [J]. Rare Metal Materials and Engineering, 2009, 38(3): 421-425. (in Chinese)

[4] CHEN Hui-qin, CAO Chun-xiao, GUO Ling, LIN Hai. Hot deformation globularization kinetic processes of TC11 titanium alloy with lamellar structure [J]. Journal of Aeronautical Materials, 2009, 29(1): 37-42. (in Chinese)

[5] ZHOU Jun, ZENG Wei-dong, SHU Ying, ZHOU Yi-gang. Study on globularization of lamellar α structure in TC17 titanium alloy during hot deformation using processing map [J]. Rare Metal Materials and Engineering, 2006, 35(2): 265-269. (in Chinese)

[6] WANJARA P, JAHAZI M, MONAJATI H, YUE S. Influence of thermomechanical processing on microstructural evolution in near-α alloy IMI834 [J]. Materials Science and Engineering A, 2006, 416: 300-311.

[7] PARK C H, KO Y G, LEE C S, PARK K T, SHIN D H, LEE H S. High-temperature deformation behavior of ELI grade Ti-6Al-4V alloy with martensite microstructure [J]. Materials Science Forum, 2007, 365: 551-552.

[8] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure [J]. Materials Science and Engineering A, 1999, 263: 257-271.

[9] SHELL E B, SEMIATIN S L. Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti-6Al-4V [J]. Metallurgical Transactions A, 1999, 30: 3219-3229.

[10] POTHS R M, AGNELLA G, WYNNE B P, RAINFORTH W M, SEMIATIN S L, BEYNON J H. Effect of strain reversal on the dynamic spheroidization of Ti-6Al-4V during hot deformation [J]. Metallurgical Transactions A, 2004, 35: 2993-3001.

[11] SONG H W, ZHANG S H, CHENG M. Dynamic globularization kinetics during hot working of a two phase titanium alloy with a colony alpha microstructure [J]. Journal of Alloys and Compounds, 2009, 480: 922-927.

[12] WANG K X, ZENG W D, ZHAO Y Q, LAI Y J, ZHOU Y G. Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure [J]. Materials Science and Engineering A, 2010, 527: 2559-2566.

[13] WEISS I, FROES F H, EYLON D, WELSCH G E. Modification of alpha morphology in Ti-6Al-4V by thermomechanical processing [J]. Metallurgical Transactions A, 1986, 17: 1935-1947.

[14] SESHACHARYULU T, MEDEIROS S C, MORGAN J T, MALAS W G, FRAZIER W G, PRASAD Y V R K. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti-6Al-4V [J]. Materials Science and Engineering A, 2000, 279: 289-299.

[15] DING R, GUO Z X, WILSON A. Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing [J]. Materials Science and Engineering A, 2002, 327: 233-245.

[16] SHARMA G, RAMANUJAN R V, TIWARI G P. Instability mechanisms in lamellar microstructures [J]. Acta Materialia, 2000, 48: 875-889.

[17] McQUEEN H J, SOLBERG J K, RYUM N, NES E. Influence of ultra-high strains at elevated temperatures on the microstructure of aluminium [J]. Philosophical Magazine A, 1989, 60: 473-485.

吴成宝,杨 合,樊晓光,孙志超

西北工业大学 材料学院,凝固技术国家重点实验室,西安 710072

摘 要:通过等温热压缩实验定量地研究片层TA15钛合金在860~940 °C,应变速率0.01~10 s-1范围内的动态球化动力学。研究发现TA15钛合金的动态球化动力学和动力学速率对热变形参数很敏感。动态球化率随应变的增加、温度的升高和应变速率的降低而增大,且应变的变化规律遵循动力学Avrami模型曲线。通过模型预测球化开始应变和完全球化所需要的应变分别为0.34~0.59和3.40~6.80。动态球化动力学速率随着应变的增加呈现先增大后减小的趋势。球化动力学速率的峰值对应的球化率为20%~33%,且随着温度的升高和应变速率的降低而增大。

关键词:TA15合金;动态球化;动力学;应变;动力学速率

(Edited by YUAN Sai-qian)

Foundation item: Project (50935007) supported by the National Natural Science Foundation of China; Project (2010CB731701) supported by the National Basic Research Program of China

Corresponding author: YANG He; Tel/Fax: +86-29-88495632; E-mail: yanghe@nwpu.edu.cn

DOI: 10.1016/S1003-6326(11)60957-6