旋流高梯度磁选机的原理及分选性能预测

卢东方,王毓华,何平波,孙伟,胡岳华

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:介绍旋流高梯度磁选机的基本结构,使用Fluent有限体积和ANSYS有限元分析软件分别对设备的流体力场、磁力场进行仿真分析,并对磁性和非磁颗粒的受力进行计算,预测该设备对某黑钨矿的分选效果。该磁选机磁系为电磁磁系,在有利于物料分散的离心力场中进行高梯度磁选是设备的主要特征。分选指标的预测结果表明:当原矿WO3品位为0.4%时,在低离心场强下,一次分选可得到品位大于20%,回收率大于50%的钨精矿;在高离心场强下,一次分选可得到回收率大于95%,品位大于1%的钨精矿。

关键词:磁选机;离心力场;磁力场;仿真;预测

中图分类号:TD457 文献标志码:A 文章编号:1672-7207(2014)01-0001-08

High-gradient magnetic separator with rotational flow field and predictions of its separation performance

LU Dongfang, WANG Yuhua, HE Pingbo, SUN Wei, HU Yuehua

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: The structure of high-gradient magnetic separator with the rotational flow field (HGMSRF) was described, the HGMSRF’s flow field and magnetic field were simulated by Fluent and ANSYS software, the forces on magnetic and non-magnetic particles were calculated, and magnetic separation of wolframite ore by HGMSRF was predicted. Electromagnetic system and high-gradient magnetic separation in centrifugal flow field are two important characteristics. The predictive results of reclaiming WO3 from wolframite ore by HGMSRF show that for a wolframite ore with a content of 0.4% WO3 as feed, a magnetic concentrate with WO3 grade of over 20% and recovery of over 50% are obtained by one time magnetic separation in week centrifugal force field, and a magnetic concentrate with WO3 grade of over 1% and recovery of over 90% are obtained by one time magnetic separation in strong centrifugal force field.

Key words: magnetic separator; centrifugal force field; magnetic field; simulation; prediction

我国拥有大量红铁矿、锰矿、黑钨矿等弱磁性矿物资源,浮选、磁选和重选是回收这类矿物的主要选矿方法[1],其中,浮选多适应于矿石性质较为简单的矿物,磁选和重选仍是回收矿石性质复杂的弱磁性矿物的主要手段,高梯度磁选机[2],如PEM84周期式高梯度磁选机[3]、SALA-HGMS480平环高梯度磁选机[4]、铁轮式高梯度磁选机和SLon-1000立环脉动高梯度磁选机[5]等利用其超高的磁场梯度,强化介质对弱磁性矿物的磁力,在选矿作业中尤其是粗选作业中大大提高了弱磁性矿物的回收率;离心机,如尼尔森选矿机[6]、法尔康选矿机[7]和SLon离心机[8]等利用高离心力场强化颗粒“重力”作用,以实现对密度大、粒度小的弱磁性矿物的捕收。虽然随着高性能的磁、重[9-10]设备的出现,弱磁性矿物的分选取得了一定进展,但仍存在几个方面问题:(1) 高梯度磁选设备物料分散性差、夹杂严重,严重影响磁精矿品质;(2) 高梯度磁选设备用于粗精矿精选作业,富集效率低,精选作业只能通过降低背景场强来实现,势必造成回收率的损失;(3) 离心机的强离心力场不仅增大了目的矿物的离心力,同时也增大了脉石矿物的离心力,而大多弱磁性矿物有易粉碎、易泥化的特点,相当部分颗粒粒度比脉石颗粒小,因此在离心机中无法实现良好分离;(4) 离心机虽然降低了目的矿物的粒度回收下限,但这必须以严格的分级为前提,对于微细粒级弱磁性矿石而言,严格分级往往是不现实的。本文作者设计的离心力和磁力场结合的新型复合力场设备-旋流高梯度磁选机,其原理是充分利用颗粒密度和比磁化系数的差异,实现矿物的高效分选,在结构上它吸收了离心设备的优点,分选腔中的旋转流场不仅提供了离心力场,还可避免分选过程中的机械夹杂,同时吸收高梯度磁选机[11]的优点,设备磁系在分选腔内壁磁介质上提供背景场强,强化对弱磁性矿物的选择性捕收。

1 旋流高梯度磁选机

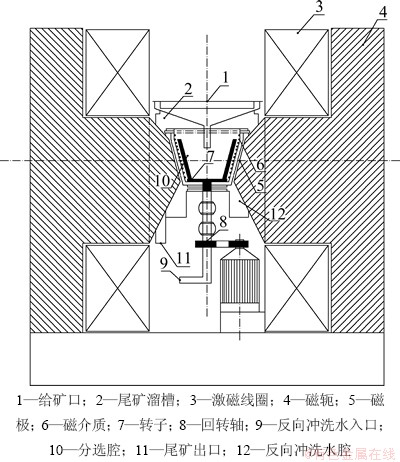

旋流高梯度磁选机主要由给矿口、尾矿溜槽、激磁线圈、铁轭、磁极、回转轴、分选腔、转子、水腔等组成,分选腔和转子为不导磁不锈钢材料,旋流高梯度磁选机结构见图1。分选腔中的转子由电动马达带动,转子旋转带动流体一起旋转,使分选腔中的物料受到离心力作用,由激磁线圈、磁极和铁轭所组成的磁系产生背景场强,使分选腔中的磁性物料受到介质的磁场力作用。

进行选矿作业时,首先打开激磁线圈冷却水阀门,然后打开电源,激磁线圈通过电流后,在分选腔产生背景磁场,开动转子旋转马达,转子在马达带动下高速旋转,开动反向冲洗水入口阀门,当尾矿出口有水流出后,开始给矿作业。在离心力、磁力和反向冲洗水的共同作用下,密度大的磁性颗粒在离心力和磁力复合力场作用下向分选腔内壁运动,运动过程中克服反向冲洗水的径向阻力,从而吸附在分选腔内壁上;密度小或比磁化系数小的颗粒则由于受到的离心力和磁力都较小,加上难以克服反向冲洗水的阻力,结果在矿浆的轴向流体力和离心力轴向分力共同作用下,带出分选腔,进入尾矿溜槽,最终成为尾矿,另外,由于分选腔为锥形部件,磁系在轴向可形成上弱下强的磁场,有利于磁性颗粒克服轴向流体力和离心力轴向分力。给矿作业完成后,按照停止反向冲洗水,关闭激磁电流,停止线圈冷却水,最后关闭马达电源的步骤操作,然后卸下分选腔,冲洗出分选腔中的物料,即为精矿。

图1 旋流高梯度磁选机结构

Fig. 1 Structure of high-gradient magnetic separator with rotational flow field

从旋流高梯度磁选机的结构和分选过程,可以看出其应用特点为:(1) 利用了颗粒物理性质的差异,即粒度、密度和比磁化系数的差异,磁力和离心力在同一方向上的叠加,增大了磁性颗粒与非磁性颗粒的受力差异,进而可提高不同性质物料的分选性。(2) 背景场强下,磁性颗粒的磁团聚相当于增大了磁性颗粒的粒径,有利于磁性颗粒在离心力作用下向分选腔内壁运动。(3) 可根据物料物理性质的差异,通过调节旋流高梯度磁选机的离心力和背景场强,调节颗粒所受力的比例,使不同颗粒的物理性质差异达到最大化利用。(4) 由于整个分选过程是在强紊动的离心力场中进行,因此夹杂现象会大大缓解,有利于精矿品位的提高。(5) 旋流高梯度磁选机具有大分选腔、可宽粒度范围分选的特点,因此堵塞现象不会出现。

2 设备力场仿真研究

为了对设备力场分布及特征进行详细表征,对设备力场进行基于有限体积分析软件Fluent的流场仿真[12-13]和基于有限元软件ANSYS的磁场仿真[14-15],根据仿真结果,对分选腔流场特性和磁场特性进行详细研究。

2.1 设备流体力场仿真研究

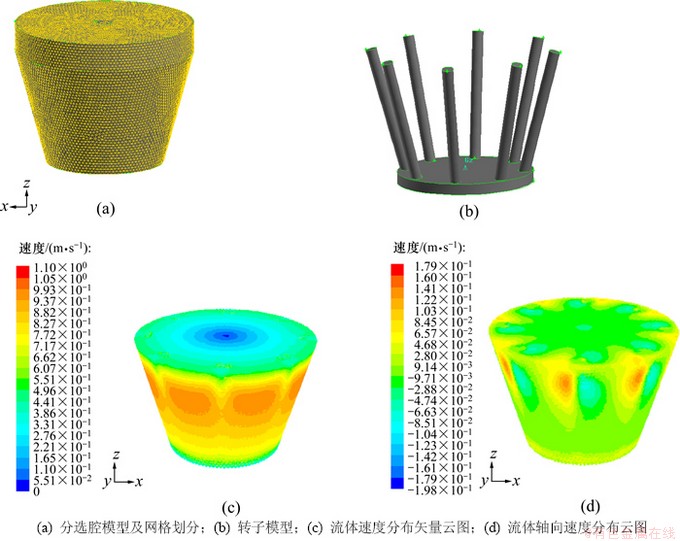

分选腔锥体高度为64 mm,柱体高度为16 mm,锥体内壁倾角为15°,锥体顶面直径为100 mm,底面直径为64.7 mm,转子转速为1 500 r/min。在Fluent前处理器Gambit中完成分选腔及转子模型的构建、网格的划分和边界定义;采用分离求解法的SIMPLE格式对模型进行了离散化处理;采用湍流模型和VOF模型对多相流流进行计算,最后使用Fluent自带的后处理模块将数据可视化,并进行分析。旋流高梯度磁选机流场仿真模型及仿真结果见图2。

由图2(c)可知:分选腔内流场有以下特征:(1) 分选腔内流体中心区速度小,近壁区速度大,在分选腔径向流体有从中心指向内壁的速度梯度,有利于不同物理性质的颗粒在径向上的分离;(2) 流体在分选腔锥体顶部的速度大、底部速度小,在分选腔轴向有从底部指向顶部的速度梯度,有利于颗粒在轴向上的分离。

由图2(d)可知:分选腔内流体的轴向速度分量在近壁区和顶部的出流区最大,随着距离分选腔顶部距离的减小,流体的轴向速度分量呈增大趋势,流体速度在分选腔轴向上存在一定的梯度,分选腔中流体在轴向的速度梯度会导致分选腔中颗粒在轴向的运动,随着距分选腔顶面距离的减小,流体的轴向速度呈增大趋势,因此,颗粒在靠近分选腔锥体顶部处受到的轴向力更大。

2.2 设备磁力场特性仿真研究

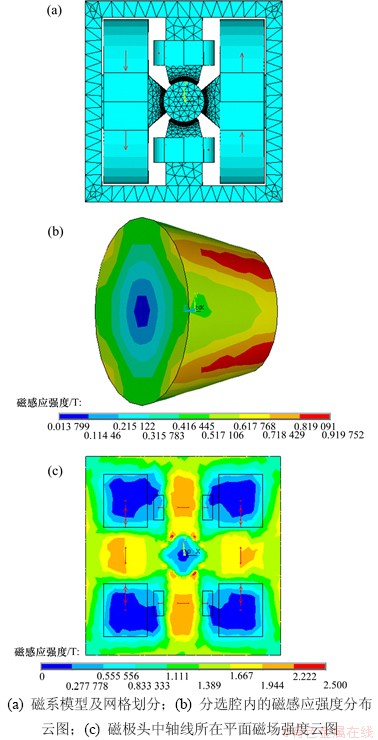

磁系模型参数: 磁极为四磁极N-S交替排列型;主磁极头四面收缩、副磁极头上下面收缩;主磁极磁包角为60°、副磁极磁包角为75°;主磁极每组90(10层×9匝)匝,副磁极10(2层×5匝)匝,励磁线圈共计200匝。激磁电流J=400 A,磁系总安匝数为8×104安匝,激磁功率为14.82 kW。采用ANSYS自带的前处理模块对模型进行构建和网格的自由划分;采用DOF约束荷载进行模型的静态3-D电磁场分析,最后采用后处理模块POST1对磁系和分选腔的磁感应强度进行分析。旋流高梯度磁选机磁场仿真模型及仿真结果见图3。

图2 旋流高梯度磁选机流场仿真模型及仿真结果

Fig. 2 Simulation model and results of flow field in HGMSRF

图3 旋流高梯度磁选机磁场仿真模型及仿真结果

Fig. 3 Simulation model and results of magnetic field in HGMSRF

从图3(b)可知:磁感应强度分布具有以下几个特征:(1) 磁感应强度在分选腔靠近内壁处强,中心弱;(2) 分选腔径向磁感应强度梯度靠近分选腔壁大,远离分选腔壁小;(3) 靠近分选腔底面上的磁感应强度大于分选腔顶部平面上的磁感应强度;(4) 沿分选腔母线上存在磁场梯度,靠近分选腔壁轴向上的磁场梯度大,靠近分选腔中心轴向上的磁场梯度小。

根据分选腔内的磁感应强度和梯度分布,磁性颗粒在分选腔内的受力有以下几个特点:(1) 随着颗粒距离分选腔内壁距离的减小,磁性颗粒受到的磁力增大;(2) 随着颗粒距离分选腔底面距离的增大,磁性颗粒受到的磁力减小;(3) 分选腔径向上的磁场梯度,导致颗粒受到磁力的作用向壁面径向运动;(4) 分选腔轴向上的磁场梯度,导致颗粒受到磁力的作用向底面轴向运动。

从图3(b)还可知:当激磁电流为400 A、磁系总安匝数为8×104安匝、激磁功率为14.82 kW时,分选腔内磁感应强度的最大值为0.92 T,最小值为0.45 T,对于弱磁性矿物精选而言已经可以满足分选要求。

3 颗粒受力分析

磁性颗粒在旋流高梯度磁选机分选过程中,会受到多种力的作用,如磁力、离心力、重力、重力场中的浮力、离心力场中的浮力和流体力等。下面以不同粒径的黑钨矿和石英的球形颗粒为例,计算它们所受到的力,为了直观,计算中所有变量的物理意义、单位(SI单位制)以及选取计算值如表1所示。

(1) 磁力。当半径为R,密度为ρ的颗粒在离心力和磁力作用下,运动至分选腔内壁处,吸附在截面积半径为R的磁介质上时,磁性颗粒受到磁介质的磁力为:

(1)

(1)

(2) 离心力。在旋流高梯度磁选机的分选过程中,转子高速旋转,矿浆随之做旋转运动,假设矿浆中的颗粒在离心力作用下达到分选腔内壁,随着流体的旋转做匀速圆周运动,在分选腔内壁且半径为R的球形矿粒所受的离心力为:

(2)

(2)

(3) 重力。

(3)

(3)

(4) 重力场的浮力。

(4)

(4)

(5) 离心力场的浮力。

(5)

(5)

(6) 轴向流体力。假设靠近分选腔内壁处的颗粒所受到的流体力符合斯托克斯公式,则

(6)

(6)

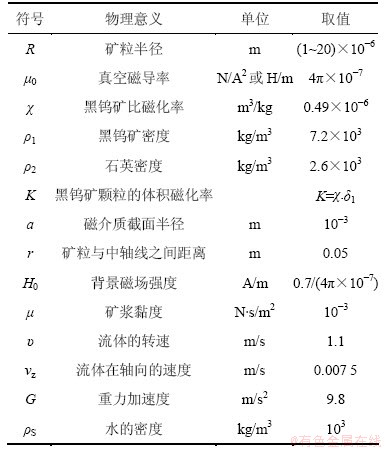

表1 颗粒受力计算过程中的原始数据

Table 1 Original data during calculating forces on particles

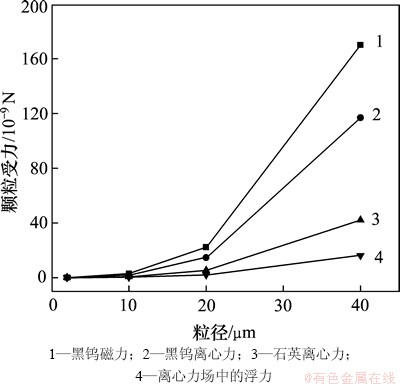

颗粒在分选腔径向所受的力主要有磁力、离心力和离心力场中的浮力3种,这3种力决定了颗粒在径向上运动轨迹和黑钨与石英的径向分选效率。当分选腔内某区域背景场强为0.7 T,流体转速为1.1 m/s时,颗粒所受径向力与粒径之间的关系见图4。

由图4可知:当颗粒粒径小于10 μm时,颗粒在分选腔中所受的径向力大小差别不大,因此黑钨和石英的分离难度大;当颗粒粒径大于10 μm时,黑钨矿所受的磁力成为影响其回收的第一要素,黑钨矿所受的离心力成为影响其回收的第二要素,随着粒径的变大,黑钨与石英之间的径向受力差异变大,离心力场中的浮力有助于增大两者受力比值,黑钨矿径向受力较石英大一个数量级,可预测当颗粒粒径大于10 μm时,黑钨矿和石英在径向可以实现良好的分离。

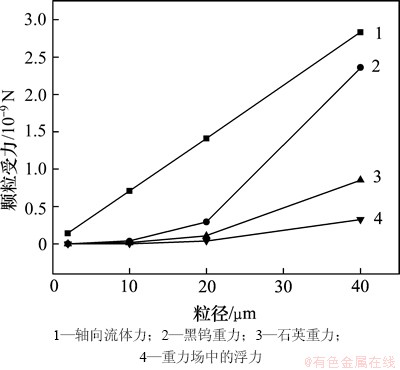

颗粒在分选腔轴向所受的力主要有轴向流体力、重力和重力场中的浮力3种,这3种力决定了颗粒在轴向上运动轨迹和黑钨与石英的轴向分离效率。当分选腔内某区域流体轴向速度为7.5×10-3 m/s,颗粒所受轴向力与粒径之间的关系见图5。

图4 颗粒所受的径向力与粒径之间的关系

Fig. 4 Relationship between radial forces and sizes on particles

图5 颗粒所受轴向力与粒径之间的关系

Fig. 5 Relationship between axial forces and sizes on particles

轴向流体力和浮力与颗粒所受重力的差值,决定了颗粒在轴向上的运动速度,差值小则颗粒轴向向上运动速度小,颗粒在分选腔中停留时间长,差值大则颗粒轴向向上运动速度快,在分选腔中停留时间短。从图5可知:随着颗粒粒径的增大,轴向流体力和浮力与颗粒所受重力的差值减小,黑钨所受轴向力差值减小幅度较石英的大,因此,黑钨在分选腔中可以停留更长的时间。颗粒粒径的增大有利于颗粒轴向分离和分选指标的提高,但当颗粒所受重力大于轴向流体力和浮力的合力时,颗粒无法沿轴向向上运动,分离则无法进行。

4 分选性能预测

以某地的黑钨矿(含WO3品位0.4%,磨矿细度(小于0.074 mm)70%)为研究对象,通过试验室型SLon高梯度磁选机和Falcon离心机的分选研究,获得了该物料分选指标与磁力场和离心力场之间的关系,同时根据理论公式构建了力场与精矿回收率和品位的理论模型,将获得的试验数据和理论公式导入1stopt数值分析软件,对试验数据进行迭代和拟合,求得回收率和品位模型中的参数值,最后利用理论模型对旋流高梯度磁选机分选指标进行预测,旋流高梯度磁选机处理本章研究对象黑钨矿时,精矿捕收率Rm和品位β的理论模型为:

(7)

(7)

优化算法:麦夸特法(Levenberg-Marquardt)+通 用全局优化法;计算结束原因:达到收敛判断标准;均方差:0.014 627 681 215 958 7;残差平方和:0.003 851 443 039 602 78;相关系数(R):0.961 585 508 361 928;相关系数之平方(R2):0.924 646 689 891 667;决定系数:0.924 471 106 938 126;卡方系数(Chi-Square):0.002 548 625 175 163 42;F统计(F-Statistic):196.333 074 379 843。

(8)

(8)

优化算法:麦夸特法(Levenberg-Marquardt)+通用全局优化法;计算结束原因:达到收敛判断标准;均方差:0.010 530 551 820 997;残差平方和:0.001 996 065 389 784 66;相关系数(R):0.983 148 274 091 723;相关系数之平方(R2):0.966 580 528 849 533;决定系数:0.966 522 973 792 752;卡方系数(Chi-Square):0.006 821 620 355 362 65;F统计(F-Statistic):462.762 812 492 215。

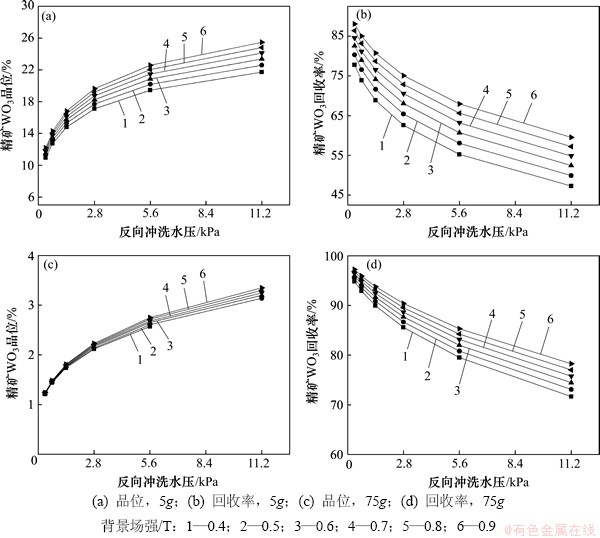

当磁介质直径为2 mm,离心加速度为5g和75g(为了考察低离心力场和高离心力场下2种情况)时,不同背景场强(0.4,0.5,0.6,0.7,0.8和0.9 T)下,改变反向冲洗水压,考察反向冲洗水压对分选指标的影响。不同反向冲洗水压对分选指标的预测见图6。

由图6可知:当背景场强和冲洗水水压固定时,随着颗粒的离心加速度的增大,精矿WO3品位下降,其原因是离心加速度的增大导致更多的脉石矿物进入精矿;当离心加速度和反向冲洗水压固定时,随着背景场强的提高有利于精矿WO3品位的提高,这是因为磁场力对黑钨矿有选择性,而对非磁性矿物无捕收作用。

从图6还可知:随着反向冲洗水压的增大,精矿WO3品位呈增大趋势,回收率呈减小趋势,在较低的离心场强中,反向冲洗水的增大,更加有利于精矿中WO3品位的提高。对原矿WO3品位0.4%的黑钨矿而言,当离心加速度为5g,背景场强为0.9 T,通过调节反向冲洗水压0.34~11.20 kPa,可得到WO3品位12.18%~25.47%(对应回收率为84.58%~54.87%)的钨精矿;当离心加速度为75g,背景场强为0.9 T,通过调节反向冲洗水压0.34~11.20 kPa,可得到WO3品位1.24%~3.35%(对应回收率为97.23%~78.27%)的钨精矿。因此,旋流高梯度磁选机,在高离心场强情况下,同时利用离心力场和磁力场对磁性颗粒比重和比磁化系数的作用,可以有效地提高精矿WO3回收率;在低离心力场分散矿浆的情况下,磁力场可实现对磁性颗粒的选择性捕收,进而大大提高精矿WO3品位。

图6 不同反向冲洗水压对分选指标影响的预测

Fig. 6 Prediction on effect of reverse washing water pressure on separation

5 结论

(1) 本文设计的旋流高梯度磁选机,其原理是充分利用颗粒密度和比磁化系数的差异,实现矿物的高效分选,在结构上它吸收了离心设备的优点,分选腔中的旋转流场不仅提供了离心力场,还可避免分选过程中的机械夹杂,同时吸收高梯度磁选机的优点,设备磁系在分选腔内壁磁介质上提供背景场强,强化对弱磁性矿物的选择性捕收。

(2) 旋流高梯度磁选机,在高离心场强情况下,同时利用离心力场和磁力场对磁性颗粒比重和比磁化系数的作用,可以有效地提高精矿WO3回收率;在低离心力场分散矿浆的情况下,磁力场中实现对磁性颗粒的选择性捕收,可有效提高精矿WO3品位。当原矿WO3品位为0.4%时,在低离心场强下,一次分选可得到品位大于20%,回收率大于50%的钨精矿;在高离心场强下,一次分选可得到回收率大于95%,品位大于1%的钨精矿。

(3) 旋流高梯度磁选机设计原理新颖,可根据物料性质灵活操作力场,是复合力场分选设备研发的一次全新尝试。

参考文献:

[1] 张家骏, 霍旭红. 物理选矿[M]. 北京: 煤炭工业出版社, 1992: 260-261.

ZHANG Jiajun, HUO Xuhong. Physical beneficiation[M]. Beijing: Coal Industry Press, 1992: 260-261.

[2] 孙时元. 最新中国选矿设备手册[M]. 北京: 机械工业出版社, 2006: 402-423.

SUN Shiyuan. Handle book of the latest mineral processing equipments of China[M]. Beijing: China Machine Press, 2006: 402-423.

[3] Kolm H H, Oberteuffer J A, Kelland D R. High-gradient magnetic separation[J]. Scientific American, 1975, 223(5): 46-54.

[4] 米夏夏. 斜环永磁高梯度磁选机的研制及应用[D]. 长沙: 中南大学资源加工与生物工程学院, 2010: 9-10.

MI Xiaxia. High-gradient permanent magnetic separator with inclined cylinder and its application[D]. Changsha: Central South University. School of Minerals Processing and Bioengineering, 2010: 9-10.

[5] WU Zeng, XIONG Dahe. The latest application of SLon vertical ring and pulsating high gradient magnetic separator[J]. Minerals Engineering, 2003, 16(6): 563-565.

[6] 陶有俊, Tao D, 赵跃民, 等. 采用Design-Expert设计进行优化Falcon分选试验[J]. 中国矿业大学学报, 2005, 34(3): 343-348.

TAO Yuejun, Tao D, ZHAO Yuemin, et al. Design and optimization of Falcon separation test using design-expert software[J] . Journal of China University of Mining & Technology, 2005, 34(3): 343-348.

[7] 张金钟, 姜良友, 吴振祥, 等. 尼尔森选矿机及其应用[J]. 有色矿山, 2003, 32(3): 28-37.

ZHANG Jinzhong, JIANG Liangyou, WU Zhenxiang, et al. Knelson concentrators and its application[J]. Nonferrous Mines, 2003, 32(3): 28-37.

[8] 陈禄政, 任南琪, 雄大和. Slon连续式离心机回收微细粒级铁矿物工业试验[J]. 金属矿山, 2007(1): 63-66.

CHEN Luzheng, REN Nanqi, XIONG Dahe. Industrial test on recovering micro-fine iron minerals by Slon continuous centrifugal separator[J]. Metal Mine, 2007(1): 63-66.

[9] 陈建生, 杨刚, 裘宝泉. 磁选机的现状和发展趋势[J]. 矿山机械, 2007, 37(17): 75-79.

CHEN Jiansheng, YANG Gang, QIU Baoquan. Current situation and development tendency of the magnetic separators[J]. Mining & Processing Equipment, 2007, 37(17): 75-79.

[10] 凌竞宏, Laplante A, 胡熙庚.国外离心选矿机的发展与应用[J]. 国外金属矿选矿, 1998, 35(5): 2-4.

LING Jinghong, Laplante A, HU Xigeng. Development and application of foreign centrifugal concentrators[J]. Metallic Ore Dressing Abroad, 1998, 35(5): 2-4.

[11] 刘树贻. 磁电选矿学[M]. 长沙: 中南工业大学出版社, 1993: 84-85.

LIU Shuyi. Magnetic and electricity dressing[M]. Changsha: Central South University of Technology Press, 1993: 84-85.

[12] 赵善彪, 张天孝, 问会青, 等. 基于Ansys的瓦形永磁体磁场分析[J]. 微电机, 2007, 40(10): 21-25.

ZHAO Shanbiao, ZHANG Tianxiao, WEN Huiqing, et al. Analysis on magnetic field of tegular permanent magnet with Ansys[J]. Micromotor, 2007, 40(10): 21-25.

[13] 王世山, 王德林, 李彦明. 大型有限元软件ANSYS在电磁领域的使用[J]. 高压电器, 2002, 38(3): 27-33.

WANG Shishan, WANG Delin, LI Yanming. Using software ANSYS to analyze electromagnetic process[J]. High Voltage Apparatus, 2002, 38(3): 27-33.

[14] Schafer M, Karasozen B, Uludag Y, et al. Numerical method for optimizing stirrer configurations[J]. Computers and Chemical Engineering, 2005, 30(2): 183-190.

[15] Scargiali F, D’Orazio A, Grisafi F, et al. Modelling and simulation of gas-liquid hydrodynamics in mechanically stirred tanks[J]. Chemical Engineering Research and Design, 2007, 85(5): 637-646.

(编辑 杨幼平)

收稿日期:2012-12-21;修回日期:2013-04-15

基金项目:国家“十二五”科技支撑项目(2012BAB10B05)

通信作者:胡岳华(1962-),男,湖南长沙人,博士生导师,教授,从事浮选溶液化学、选矿药剂、设备研发及生物选矿的研究;电话:0731-88830482;E-mail: hyhcsu@163.com