文章编号:1004-0609(2015)10-2688-07

双级时效对7085铝合金组织和性能的影响

陈送义1, 2,陈康华2,董朋轩2, 叶升平2,黄兰萍2,阳代军3

(1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 首都航天机械公司,北京 100076)

摘 要:采用硬度、电导率、力学拉伸、慢应变速率拉伸试验及透射电镜等测试分析方法,研究双级时效对7085铝合金组织和性能的影响。结果表明:预时效热处理主要析出相为GP 区和η′相,预时效时间对合金硬度和电导率的影响较小。随着第二级时效时间的延长,合金的抗拉强度和屈服强度先增大后减小,电导率和抗应力腐蚀性能提高,晶界析出相由连续分布变为非连续分布。第二级时效温度越高,合金强度随时效时间的延长,降低得越显著。采用(110 ℃, 6 h)+(160 ℃, 12 h)双级时效热处理,合金的抗拉强度、屈服强度、伸长率及电导率分别为515 MPa、487MPa、11.7%、38%(IACS)。

关键词:7085铝合金;双级时效;显微组织;性能

中图分类号:TG 146.4 文献标志码:A

Effect of two-step aging on microstructure and properties of 7085 aluminum alloy

CHEN Song-yi1, 2, CHEN Kang-hua2, DONG Peng-xuan2, YE Sheng-ping2, HUANG Lan-ping2 , YANG Dai-jun3

(1. Light Alloy Research Institute,Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Capital Aerospace Machinery Company, Beijing 100076, China)

Abstract: The effect of two-step aging treatment on microstructure and properties of 7085 aluminum alloy was investigated by hardness, conductivity, mechanical testing, slow strain rate testing and transmission electron microscopy. The results show that the GP zones and η′ phase are the mainly precipitation phases of pre-aging, and the pre-aging time is less impact on the hardness and electrical conductivity. The strength after two-step aging process first increases, and then decreases, while the ability of stress corrosion resistance increases with the extension of the second step of aging time. With the size of grain boundary precipitates coarsening, and the distribution of grain boundary precipitates from continuous to non-continuous. The strength of the alloy significantly decreases with the increases of the second step aging temperature. The optimal of the two-step aging process is (110 ℃, 6 h)+(160 ℃, 12 h), the tensile strength, yield strength, elongation and conductivity of alloy are 515 MPa, 487 MPa, 11.7%, 38%(IACS), respectively.

Key words: 7085 aluminum alloy; two-step aging; microstructure; property

Al-Zn-Mg-Cu系铝合金具有高强度、低密度等特点,被广泛应用于航空航天领域[1-3]。7085铝合金是Alcoa公司开发的具有高淬透性、高强、高损伤容限的新一代厚截面超高强铝合金。目前,7085铝合金锻件已成功用于波音787飞机和空客A380飞机的翼梁、起落架等重要承力构件[4-5]。

为了进一步提高7085高强铝合金的综合性能,研究人员从合金元素、热变形行为、固溶和时效热处理工艺等方面进行了大量研究,如加入微合金元素Sc,能够提高合金强度和断裂韧性[6];适当提高Mg元素含量同时降低Cu元素含量,在获得较高强度的同时降低淬火敏感性[7-8];需要调控第二相的析出降低变形流变应力[9];变形温度较低引起固溶过程再结晶,降低合金耐应力腐蚀性能[10];采用部分重固溶能够提高合金耐腐蚀性能但牺牲了强度[11];回归再时效能够同时提高合金的强韧耐蚀性[12-13]。有研究表明[14-17],精确调控时效析出相能够显著提高7xxx系铝合金综合性能。与7150、7055合金等高Cu含量(2.0%~2.6%,质量分数)超高强合金相比,7085铝合金为高Zn、低Mg和低Cu(1.3%~1.9%,质量分数)含量,其时效析出动力学其演变规律将发生改变。目前,优化时效工艺参数、精确调控时效析出相和深入研究双级时效对7085铝合金组织和性能的影响是7085铝合金材料获得高性能急需解决的问题。

本文作者通过研究双级时效对7085铝合金锻件显微组织和性能的影响,为优化时效热处理工艺提供参考。

1 实验

实验材料为国内某厂生产的7085铝合金锻造板材,合金成分为7.5Zn,1.6Mg,1.5Cu,0.12Zr,0.06Fe,0.02Si,Al余量(质量分数,%)。板材经过(470 ℃, 1 h)固溶处理,随后进行不同的时效。时效工艺为:预时效温度110 ℃,时效时间6~24 h;第二级时效温度150~170 ℃,时效时间 0~24 h。

采用HBRVU-187.5型布洛维硬度计测量不同时效状态的硬度,试样加载力为294 N,实验值为5个点的平均值。采用7501型涡流电导仪测量合金不同状态的电导率。在Instron3369型电子拉伸机上进行拉伸实验,测定合金的强度和伸长率,拉伸速率为 2 mm/min, 工作段标距为25 mm、厚度为2 mm的方形试样。用工作段标距为25 mm、厚度为2 mm的方形试样在西安力创公司生产的应力腐蚀试验机上进行慢应变速率拉伸试验(SSRT),试样安装后施加一定的载荷以消除夹具间隙,应变速率为6.67×10-6 s-1,试验腐蚀溶液为含3%(质量分数)NaCl+0.5 mL H2O2的水溶液。

采用JEM-2100F型透射电镜观察合金的显微组织。样品采用电解双喷减薄方法制备。电解液为硝酸甲醇混合溶液,其中硝酸和甲醇的体积比为3:7,温度控制在-25 ℃以下,工作电压为12~15 V,电流为60~80 mA。

2 结果与分析

2.1 预时效对7085铝合金组织的影响

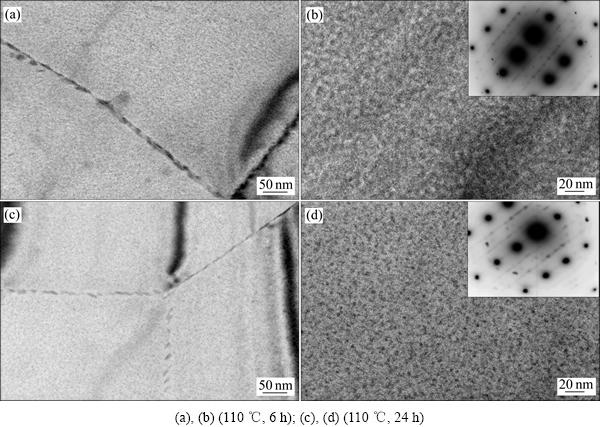

图1 预时效对7085铝合金显微组织的影响

Fig. 1 Effect of pre-ageing on microstructures of 7085 Al alloy

7085铝合金经不同预时效处理的显微组织如图1所示。合金经(110 ℃, 6 h(预时效处理,晶界析出相沿晶界连续分布(见图1(a)),晶内析出相尺寸较小(见图1(b))。预时效延长至(110 ℃, 24 h),晶界析出相仍然沿晶界连续分布(见图1(c));晶内析出相发生长大,尺寸达到3~5 nm(见图1(d))。对比两种预时效处理后的衍射斑点可以发现:在沿<112>衍射条件下,经(110 ℃, 6 h)时效处理的试样在2/3{220}处, 出现与{111}平行的芒线;在 1/3{311}和 2/3{311}处出现 GPI 的衍射;同时,在 1/2{311}处出现 GPII区衍射斑点;在 1/3{220}和 2/3{220}处, 出现η′相衍射花样。以上结果表明:合金经110 ℃、6 h预时效后,主要析出相为 GP 区和少量η′相(见图1(b))。合金经110 ℃、24 h 预时效处理,在 1/3{220}和 2/3{220}处的衍射变强, 表明η′相体积分数增加,主要析出相为GP区和大量η′相(见图1(d))。

2.2 预时效对7085铝合金硬度和电导率的影响

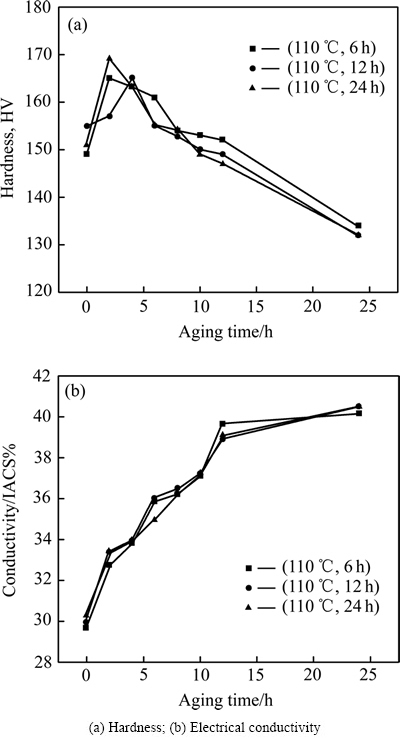

图2 预时效对7085铝合金硬度和电导率的影响(第二级时效温度为160 ℃)

Fig. 2 Effect of pre-ageing time on hardness and electrical conductivity of 7085 Al alloy (Second ageing temperature 160 ℃)

图2所示为合金经110 ℃预时效不同时间并在160 ℃进行第二级时效的硬度和电导率。从图2中可以看出,不管何种预时效时间条件下,随着第二级时效时间延长,合金的硬度先升高后降低,电导率持续升高。对比不同预时效时间发现,预时效时间对合金的硬度和电导率影响较小,表明在此温度条件下,预时效时间对合金第二级时效析出动力学影响较小。在后续的研究过程中,将采用(110 ℃, 6 h)作为预时效 工艺。

2.3 双级时效对7085铝合金锻件组织的影响

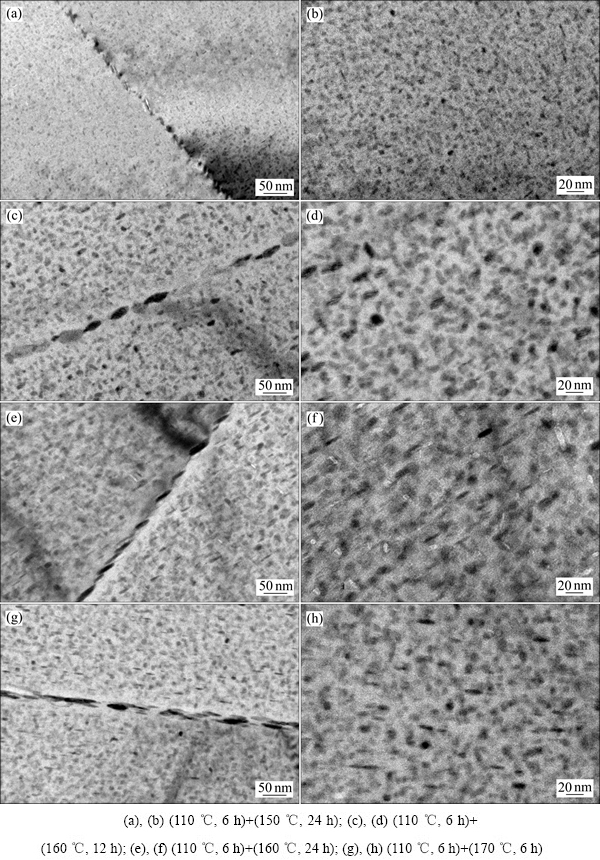

7085铝合金锻件经不同双级时效处理后的显微组织如图3所示。经(110 ℃, 6 h)+(150 ℃, 24 h)处理后,合金晶界析出相细小且不连续分布,其尺寸为13~20 nm,晶界析出相间距为9~15 nm(见图3(a));晶内析出相均匀而细小,其尺寸为4~8 nm(见图3(b))。合金经(110 ℃, 6 h)+(160 ℃, 12 h)处理后,显微组织发生明显变化,晶界析出相进一步不连续分布和粗化,其尺寸为30~35 nm,晶界析出相间距为20~25 nm(见图3(c));晶内析出相数量减少且尺寸粗化,晶内析出相为两种不同形状的粒子:椭条状析出相(长为20 nm、宽为8 nm)和球状析出相(尺寸为6.~10 nm)(见图3(d))。当经(110 ℃, 6 h)+(160 ℃, 24 h)处理后,合金晶界析出相进一步粗化,尺寸为40~45 nm,晶界析出相间距为23~28 nm(见图3(e));晶内椭条状析出相数量增加而球状析出相数量减少(见图3(f))。合金采用 (110 ℃, 6 h)+(170 ℃, 6 h)时效处理后,晶界析出相尺寸达到40~45 nm,晶界析出相间距为10~20 nm(见图3(g));晶内析出相由椭球状析出相和球状析出相组成,其尺寸分别为长15 nm、宽5 nm,球状析出相尺寸为5~8 nm(见图3(h))。

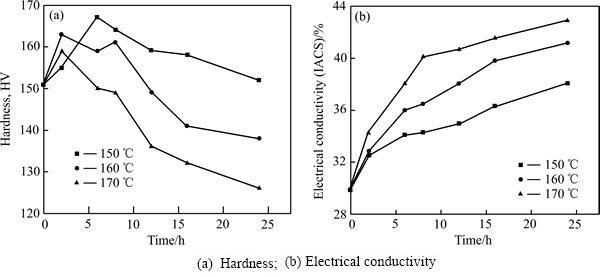

2.4 双级时效对7085铝合金硬度和电导率的影响

合金经(110 ℃, 6 h)预处理并在不同温度进行第二级时效的硬度和电导率如图4所示。在相同第二级时效温度条件下,随着时效时间的延长,合金的硬度先升高后降低。第二级时效温度越高,合金的硬度降低幅度越明显(见图4(a))。同时,随着第二级时效温度的升高,合金的电导率随之提高。在相同的第二级时效温度下,随着第二级时效时间延长,合金的电导率也随之提高(见图4(b))。但是第二级时效温度对电导率的影响较大,第二级时效温度为170 ℃的电导率提高幅度显著高于第二级时效温度为150 ℃的。对比时效对硬度和电导率的复合影响,可以发现,在时效温度为150~170 ℃,时效时间为0~24 h时,(110 ℃, 6 h)+(160 ℃, 12 h)能够同时获得较高的硬度(150 HV)和电导率(38%(IACS))。

图3 双级时效对7085铝合金显微组织的影响

Fig. 3 Effect of two-step aging on microstructures of 7085 Al alloy

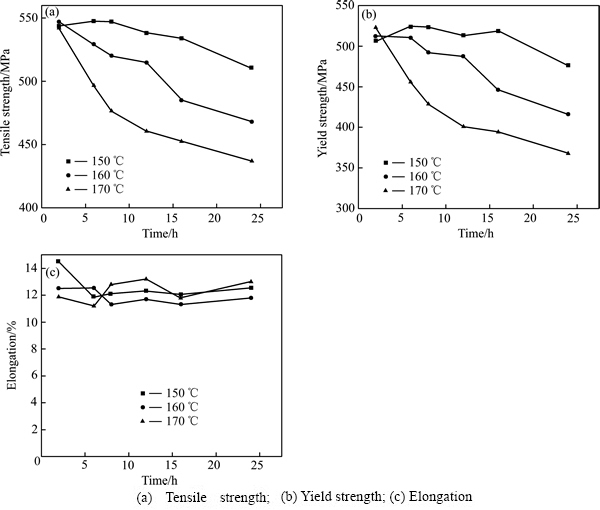

2.5 双级时效对7085铝合金锻件力学性能的影响

7085合金经(110 ℃, 6 h)预时效并在不同温度进行第二级时效的力学性能如图5所示。在相同第二级时效温度情况下,随着时效时间的延长,合金抗拉强度和屈服强度都先升高后降低,而伸长率变化不大,均大于10%。随着第二级时效温度的提高和时效时间的延长,合金抗拉强度和屈服强度降低越显著。第二级时效温度为150 ℃,时效时间从2 h到24 h,合金的抗拉强度和屈服强度分别从544和507 MPa降低到511 MPa和476 MPa,降低幅度为6.07%和6.11%;当第二级时效温度为160 ℃时,时效时间从2 h延长到24 h,合金的抗拉强度和屈服强度降低幅度分别为14.2%和18.6%;第二级时效温度为170 ℃,时效时间从2 h延长到24 h,合金的抗拉强度和屈服强度降低幅度分别达到19.2%和29.6%。

图4 双级时效对7085合金硬度和电导率的影响(第一级时效为(110 ℃, 6 h))

Fig. 4 Effect of two-step aging on hardness and conductivity of 7085 Al alloy (First ageing (110 ℃, 6 h))

图5 经(110 ℃, 6 h)处理后双级时效对7085铝合金力学性能的影响

Fig. 5 Effect of two-step aging on tensile properties of 7085 Al alloy after (110 ℃, 6 h) treatment

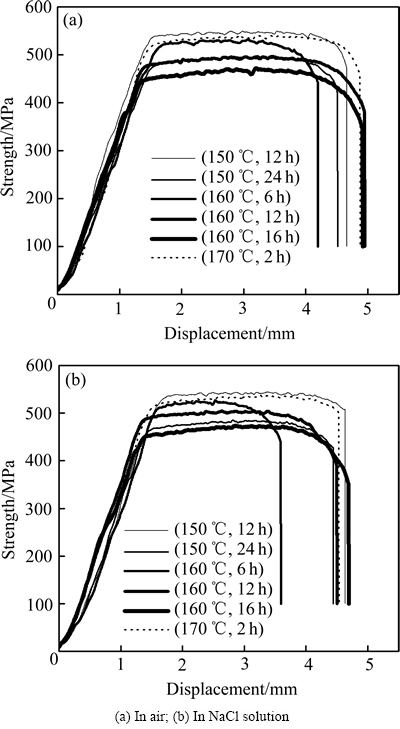

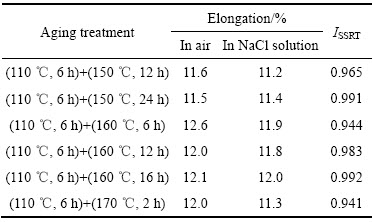

2.6 双级时效对7085铝合金锻件应力腐蚀性能的影响

图6所示为经过不同双级时效处理后的合金在空气和腐蚀溶液中的慢应变速率拉伸曲线。从图6中可以看出,在同一时效温度情况下,随着时效时间的延长,合金强度随之降低。时效温度越高,合金的抗拉强度降低越明显。与空气中的拉伸曲线对比,在NaCl腐蚀溶液中,经过不同时效处理的合金抗拉强度降低同时位移减小。为了更好地对比双级时效处理对合金应力腐蚀的影响,采用应力腐蚀因子ISSRT表示合金的抗应力腐蚀能力,应力腐蚀敏感因子越接近1,其抗应力腐蚀性能越好,其表达式为ISSRT=ηsol/ηair(其中ηsol表示合金试样在腐蚀溶液中的伸长率;ηair表示合金试样在空气中的伸长率)。表1所列为合金不同双级时效处理后的慢应变速率应力腐蚀敏感因子,可以发现第二级时效时间温度越高和时效时间越长,合金的抗应力腐蚀性能越好。经(110 ℃, 6 h)+(160 ℃, 16 h)时效处理后,合金的应力腐蚀敏感性最低。

图6 第一级时效为(110 ℃, 6 h)时7085铝合金经不同双级时效的慢应变速率拉伸曲线

Fig. 6 Tensile curves of 7085 Al alloy at slow strain rate with different two-step aging treatments after (110 ℃, 6 h) treatment

表1 7085合金不同双级时效的慢应变速率应力腐蚀敏感因子

Table 1 Slow strain rate testing results of AA7085 with various two-step aging treatments

3 分析与讨论

超高强铝合金在时效过程中析出相发生一系列演变,其析出序列一般为SSS→GP区→η′→η。其中GP区与基体共格,η′与基体半共格,η与基体不共格。时效沉淀析出相的特征要考虑合金成分、时效方式(时效温度、时效时间)等一系列过程的影响,每一个步骤或者工艺的改变将对析出相的动力学产生显著影响。有研究表明[18-19],Cu元素的加入增加了GP区的稳定性,即提高析出相回溶的临界尺寸和温度范围,但析出相的序列不会发生改变。7085铝合金为高Zn、低Mg和低Cu(1.3%~1.9%,质量分数)合金。经过110 ℃预时效处理,晶内析出细小的GP区,在晶界析出连续分布的晶界析出相(见图1)。随着第二级时效温度的提高或者时间延长,在热激活的作用下,晶内析出相的数量减少和尺寸加大,并从GP+η′相转变为η+η′相,甚至转变为η相(见图3)。而晶界由于聚集各种缺陷,形核的自由能较小,析出相优先在晶界析出和长大,随着时效温度的提高或者时效时间的延长,晶界析出相分布由连续分布转变为非连续分布,晶粒尺寸进一步粗化(见图3)。

超高强铝合金的力学性能与晶内时效析出相的种类、数量、大小和分布密切相关。合金经不同时效处理后,析出相种类发生变化。经过双级时效处理后,合金的力学性能随着时效温度提高和时效时间延长而先稍微升高后显著降低。其主要原因由于经110 ℃、6 h的预时效,析出相主要为GP区+η′,然后在150~ 170 ℃的第二级时效过程中,随时效时间延长,析出相由GP区逐渐转变成GP区+η′、η+η′和η,且析出相的数量逐渐减少而尺寸逐步粗化,引起合金力学性能先升高后降低(见图5)。

随着双级时效的第二级时效温度提高和时效时间延长,合金抗应力腐蚀性能增强(见图6和表1)。有研究表明[19],晶界析出相尺寸越粗大和间距越大,晶界析出相的Cu含量越高,合金的抗应力腐蚀性能越好。因此,晶界析出相的Cu含量随着时效温度升高而升高。同时,由于随着第二级时效温度提高和时效时间延长,晶界析出相尺寸进一步粗化且更加不连续,在两者的作用下,合金的抗应力腐蚀性能提高。

4 结论

1) 在双级时效过程中,预时效主要析出相为GP 区和η′相,预时效时间对合金的硬度和电导率影响较小。

2) 在双级时效过程中,随着第二级时效时间的延长,合金的抗拉强度和屈服强度先增大后减小,抗应力腐蚀能力提高,晶界析出相粗化并由连续分布变为非连续分布,无沉淀析出带变宽。第二级时效温度越高,合金抗拉强度和屈服强度随时效时间的延长降低得越显著。

3) 采用(110 ℃, 6 h)+(160 ℃, 12 h)双级时效热处理,合金的抗拉强度、屈服强度、伸长率及电导率分别为515 MPa、487 MPa、11.7 %和38%(IACS)。

REFERENCES

[1] JAMES T S, JOHN L, WARREN H H Jr. Aluminum alloys for aero-structures[J]. Advanced Materials and Process, 1997, 152(4): 17-20.

[2] HEINZ A, HASZLER A, KEIDEL C. Recent development in aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(3): 102-107.

[3] JOHN L. Advanced aluminum and hybrid aero-structure for future aircraft[J]. Materials Science Forum, 2006, 519/521: 1233-1238.

[4] KARABIN M E, BARLAT F, SCHULTZ R W. Numerical and experimental study of the cold expansion process in 7085 plate using a modified split sleeve[J]. Journal of Materials Processing Technology, 2007, 189(1/3): 45-57.

[5] CHAKRABARTI D J,LIU J, SAWTELL R R, VENEMAV G B. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004, 28: 969-974.

[6] 肖代红, 巢 宏, 陈康华, 黄伯云. 微量Sc对AA7085铝合金组织与性能的影响[J]. 中国有色金属学报, 2008, 18(12): 2145-2150.

XIAO Dai-Hong, CHAO Hong, CHEN Kang-hua, HUANG Bai-yun. Effect of Sc addition on microstructure and properties of AA7085 alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2145-2150.

[7] 熊柏青, 李锡武, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 新型高强韧低淬火敏感性Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr合金[J]. 中国有色金属学报, 2009, 19(9): 1539-1547.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Novel Al-7.5Zn- 1.65Mg-1.4Cu-0.12Zr alloys with high strength high toughness and low quench sensitivity[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1539-1547.

[8] LI Xi-wu, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, LIU Hong-wei. Effect of one-step aging on microstructure and properties of a novel Al-Zn-Mg-Cu-Zr alloy[J]. Science in China Series E: Technological Sciences, 2009, 52(1): 67-71.

[9] CHEN Song-yi, CHEN Kang-hua, CHEN Xue-hai, CENG Qing-hua. Effect of heat treatment on hot deformation behavior and microstructure evolution of 7085 aluminum alloy[J]. Journal of Alloys and Compounds, 2012, 537(10): 338-345.

[10] CHEN Song-yi, CHEN Kang-hua, JIA Le, PENG Guo-sheng. Effect of hot deformation conditions on the grain structure and property of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 329-334.

[11] 肖代红, 陈康华, 罗伟红. 固溶热处理对AA7085铝合金组织与性能的影响[J]. 稀有金属材料与工程, 2010, 39(3): 494-497.

XIAO Dai-Hong, CHEN Kang-hua, LOU Wei-Hong. Effect of solution heat treatment on microstructure and properties of AA7085 aluminum alloys[J]. Rare Metal Materials and Engineering, 2010, 39(3): 494-497.

[12] CHEN Song-yi, CHEN Kang-hua, JIA Le, DONG Peng-xuan. Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy[J]. Materials and Design, 2012, 35(3): 93-98.

[13] CHEN Song-yi, CHEN Kang-hua, DONG Peng-xuan, YE Sheng-ping, HUANG Lan-ping. Effect of heat treatment on stress corrosion cracking, fracture toughness and strength of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2320-2325.

[14] LIN Jing-chie, LIAO Hsueh-lung, JEHNG Wern-dare, CHANG Chih-horng, LEE Sheng-long. Effect of heat treatment on the tensile strength and SCC-resistance of AA7050 in an alkaline saline solution[J]. Corrosion Science, 2006, 48(10): 3139-3156.

[15] OLIVEIRA A F Jr, de BARROS M C, CARDOSO K R, TRAVESSA D N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys[J]. Materials Science and Engineering A, 2004, 379(1/2): 321-326.

[16] KNIGHT S P, BIRBILIS N, MUDDLE B C. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2010, 52(12): 4073-4080.

[17] WANG D, NI D R, MA Z Y. Effect of pre-strain and two-step aging on microstructure and stress corrosion cracking of 7050 alloy[J]. Materials Science and Engineering A, 2008, 494(1/2): 360-366.

[18] CHINH N Q, LENDVAI J, PING D H. The effect of Cu on mechanical and precipitation properties of Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2004, 378(1): 52-60.

[19] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2012CB619502,2010CB731701);国家重大科研仪器设备研制专项(51327902);湖南省自然科学基金资助项目(12JJ6040);国家自然科学基金资助项目(51201186);高性能复杂制造国家重点实验室开放课题(HPCM-201403)

收稿日期:2015-01-12;修订日期:2015-07-22

通信作者:陈送义,博士;电话:0731-88830714;E-mail: sychen08@csu.edu.cn