DOI: 10.11817/j.issn.1672-7207.2021.04.011

航空湿式离合器接合过程中摩擦副间瞬态流场特性分析

鲍和云1,许同晶1,谭武中2,陆凤霞1,孔维地1

(1. 南京航空航天大学 直升机传动技术重点实验室,江苏 南京,210016;

2. 中国航发湖南动力机械研究所 直升机传动技术重点实验室,湖南 株洲,412002)

摘要:以航空湿式离合器为研究对象,通过数值仿真得出摩擦片输出转速曲线和对偶钢片轴向移动曲线,采用最小二乘法拟合出输出转速曲线公式和钢片轴向移动公式,获得接合过程中时变的摩擦片输出转速和钢片轴向移动位移。基于计算流体动力学(CFD)方法,运用Fluent仿真技术,采用动网格方法,对轴心供油冷却方式下摩擦副的不同接合时间下的瞬态流场进行仿真分析,研究该润滑方式下瞬态油液的速度分布规律和压力分布规律。研究结果表明:摩擦副半径越大处,油液流速越大,润滑油在油液离心力的作用下,高速排出,部分油液不断被搅动,再次进入摩擦副片间润滑摩擦副;在该轴心润滑方式下,随着接合时间增大,油液所受的油膜承载力越大,油压分布越均匀,接合面的油压几乎呈对称分布,润滑效果好。

关键词:航空湿式离合器;轴心供油冷却;摩擦副;瞬态流场;CFD

中图分类号:TH133.4 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)04-1138-11

Analysis of transient flow field characteristics between friction pairs during engagement of aviation wet clutch

BAO Heyun1, XU Tongjing1, TAN Wuzhong2, LU Fengxia1, KONG Weidi1

(1. National Key Laboratory of Science and Technology on Helicopter Transmission, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. National Key Laboratory of Science and Technology on Helicopter Transmission, AECC Hunan Aviation Powerplant Research Institute, Zhuzhou 412002, China)

Abstract: A numerical model was developed to analyze the transient flow field characteristics of the wet clutch. The output speed curve of the friction plate and the axial movement curve of the steel plate were obtained and the formulas were gotten by the least square fitting method. The transient flow field of the friction pair of the axial oil supply cooling mode at different engagement times were simulated and analyzed based on the computational fluid dynamics(CFD) method, using fluent simulation technology and the dynamic grid method. The speed distribution law and pressure distribution law of the transient oil were studied. The results show that the greater radius of the friction pair is, the greater the flow rate of the oil will be. The lubricating oil is discharged at a high speed under the action of the centrifugal force of the oil, and part of the oil is continuously agitated to lubricate. As the engaging time increases, the bearing capacity of the oil film becomes larger and the oil pressure distribution becomes more uniform. The oil pressure on the joint surface is almost symmetrically distributed with good lubrication effect.

Key words: aviation wet clutch; axial oil cooling; friction pair; transient flow field; CFD

航空湿式离合器结构紧凑,传递功率大,功率密度高,对润滑冷却要求苛刻。航空湿式离合器摩擦副的运动不仅包括钢片向摩擦片轴向移动挤压油膜的过程,而且包括摩擦片、钢片的相对转动剪切油膜以实现动力传递的过程。接合过程中摩擦副间的油液被不断挤出,润滑油起到润滑冷却的作用,油液的流动是一个复杂的过程,摩擦副间油液的速度分布与压力分布对摩擦副的润滑效果至关重要,因此,研究离合器摩擦副接合过程中油液的瞬态流场特性,具有重要的理论意义和工程应用价值。

国内外学者主要是利用CFD软件对离合器的流场特性进行模拟分析,并采用试验对摩擦副间多相流的流态进行验证。CHO等[1]进行了湿式离合器挤压油膜过程的瞬态模拟,发现边界条件的施加对挤压油膜仿真模拟有很大的影响;TAKAGI等[2]利用CFD软件对湿式离合器摩擦副间的润滑油液两相流的流态进行模拟,并对其进行实验研究;TERZI等[3]采用试验和CFD仿真方法对湿式离合器润滑分布进行优化以减少摩擦片上的热应力,利用CFD软件模拟预测摩擦副间的润滑流量分布规律,并利用快速成像试验技术捕获了摩擦副间的多相流流态以进行对比验证。ZHENG等[4]对油液的两相流态分布进行模拟,对高速旋转的湿式离合器摩擦副间的润滑油-空气的两相流动特性进行分析,并分析了不同的转速和油槽数量对润滑油和空气的流动特性的影响。

PAHLOVY等[5]为了最大限度地减小换挡传动损失,提出了1个阻力矩模型来预测湿式离合器在脱开时在不同转速、摩擦副间隙、摩擦片尺寸和油温下的变化规律。ZHANG等[6]考虑了摩擦片与钢板之间的耦合运动,建立了流固耦合模型,分析了3种不同润滑流量下的摩擦副的冲击特性。熊钊等[7]对高速旋转的湿式离合器摩擦副间的润滑油-空气的两相流动特性进行分析,获得了湿式离合器摩擦副间润滑油和空气的流场分布特性,并分析了不同的转速和油槽数量对润滑油和空气的流动特性的影响。冯珊珊[8]建立了车辆传动系统高速工况的摩擦副油膜的传热模型,针对接合过程中的润滑油和空气的两相流现象,对摩擦副进行了润滑油和空气的流场分析。陈荣[9]基于Fluent软件,对3种不同油槽结构的湿式摩擦副间润滑油的速度分布、温度分布与压力分布特性进行了仿真与分析,对比论证了不同油槽结构摩擦片的散热情况。

王小虎[10]在Fluent软件中对比分析了湿式离合器常用的飞溅冷却、强制循环冷却液冷却和轴心供油冷却这3种供油冷却方式的油路结构的冷却散热效果。王清[11]根据摩擦片和钢片的瞬态运动方程,采用动网格技术对脱开过程中离合器的油液进行了动态仿真,获得了脱开过程油液的流动特性及各片间油层厚度的分布情况。童耀文[12]基于油膜的空化效应和N-S方程,建立了摩擦副间油液的流场数值模型,研究了不同输入转速、初始摩擦副间隙、供给流量等因素对润滑油油液和空气的流动影响规律。郭广超等[13]对径向槽摩擦副间复杂多相流的流场进行了数值模拟,研究了空化效应下油槽数量和转速对油膜压力分布的影响。尹文超等[14]开展了径向槽、Y型槽和太阳射线槽3种摩擦片油槽构型对油流状态的影响研究,对不同油槽结构对油液的出口速度和油液形态的影响进行了仿真分析。鲍和云等[15]采用RNG k-ε湍流模型、流体体积(VOF)模型和动网格模型,对浸油润滑齿轮箱内部流场进行了动态数值模拟,分析了齿轮转速、浸油深度及滑油黏度等对齿轮箱中的油液分布、速度场和压力场的影响。

国内外学者利用CFD流场仿真软件对离合器摩擦副间的油液进行了较多的仿真分析,但很少根据摩擦副接合过程中的运动特性对摩擦副接合过程中的瞬态流场进行分析,亦未见动态模拟离合器接合过程中摩擦副间油液的流动规律的研究。本文作者数值仿真出摩擦片输出转速曲线和对偶钢片轴向移动曲线,采用最小二乘法拟合出输出转速曲线公式和钢片轴向移动公式,获得接合过程中时变的摩擦片输出转速和钢片轴向移动位移。基于计算流体动力学(CFD)方法,运用Fluent仿真技术和动网格方法,对在轴心供油冷却方式和不同接合时间下摩擦副的瞬态流场进行仿真分析,研究接合过程中该润滑方式下油液的瞬态速度分布规律和压力分布规律。

1 数值计算理论

1.1 控制方程

航空湿式离合器接合过程中,摩擦副间内充满润滑油,油液不断从油槽处被挤出。其油液的流动是一个复杂的过程,但对于一切流体而言,都应遵循质量守恒定律、动量守恒定律和能量守恒定律[16]。

(1)

(1)

(2)

(2)

(3)

(3)

式中:ρ为流体微元密度,kg/m3;t为时间,s;U为速度向量,m/s;▽为散度;p为压强,Pa;Sm为外部体积力,N/m3;ui为流体速度沿坐标轴分量,m/s;τ为应力张量;i表示x,y和z坐标方向;T为流体微元温度,K;k为流体热传导率,W/(m·K);cp为流体比定压热容,J/(kg·K);ST为黏性耗散项,W。

1.2 湍流模型

航空湿式离合器转速高、功率大,本文的流场仿真工况参数如下:外径为190 mm,输入转速为314 rad/s(2 000 r/min),运动黏度为40 mm2/s。经计算,本文的雷诺数为70 846.25,摩擦副内的润滑油流态为湍流流动。Realizable k-ε模型适合于湍流发展充分的复杂剪切流动,Realizable k-ε模型方程[17]为:

(4)

(4)

(5)

(5)

,

, ,

, (6)

(6)

式中:Gk为由流体的平均流动速度梯度产生的湍流动能,m2/s2;Gb为由浮力产生的湍流动能,m2/s2;YM为在可压缩湍流中过渡扩散产生的波动幅值;C1ε和C2为定值;σk和σε分别为k和ε的湍流普朗特数;Sk和Sε为用户定义的源项,kg/(m2·s2)。

1.3 动网格理论

为真实反映摩擦片边界的变转速转动以及钢片接合过程中的动态轴向移动,本文采用动网格模型。采用弹簧光顺模型处理边界附近变形网格,基本原理为将节点之间的连接视为理想弹簧,通过计算平衡方程对节点位置进行更新[18]。弹簧力与节点位置更新的计算方法为:

(7)

(7)

(8)

(8)

式中: 和

和 分别为节点i和节点j的位移,m;ni为节点i相连的节点数量;kij为节点i与节点j之间的弹簧刚度,N/m;上标n+1和n分别表示下一时间步节点位置与当前时间步节点位置。

分别为节点i和节点j的位移,m;ni为节点i相连的节点数量;kij为节点i与节点j之间的弹簧刚度,N/m;上标n+1和n分别表示下一时间步节点位置与当前时间步节点位置。

当钢片和摩擦片计算域边界位移过大时,采用弹簧光顺法会使网格质量下降,出现负体积,导致迭代计算终止。Fluent采用网格重构法对网格进行重新划分:根据网格畸变率和网格尺寸两项指标对网格进行质量识别,将畸变率大和尺寸变化大的网格集中汇合,对其重新划分网格,对新的网格质量再次进行识别,若无法满足要求,则再次对局部重新划分[19]。

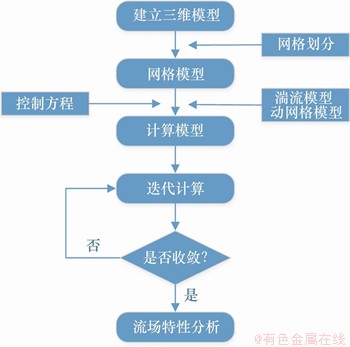

本文计算分析的流程图如图1所示。

图1 计算分析流程图

Fig. 1 Flow chart of calculation and analysis

2 摩擦副流场前处理

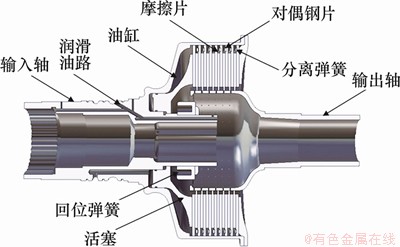

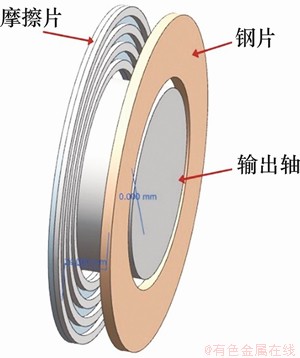

航空摩擦离合器工作原理为:液压油和润滑油分别从不同的油道进入输入轴,对活塞施加压力和轴承处进行润滑,当液压油施压时,回位弹簧受力压缩,挤压钢片,通过力传递,向右靠拢,离合器处于接合状态;当液压油从控制油道泄压时,回位弹簧的弹力让活塞复位,钢片与摩擦片之间的分离弹簧促使摩擦片分离,如图2所示。

图2 湿式摩擦离合器结构图

Fig. 2 Structure drawing of wet friction clutch

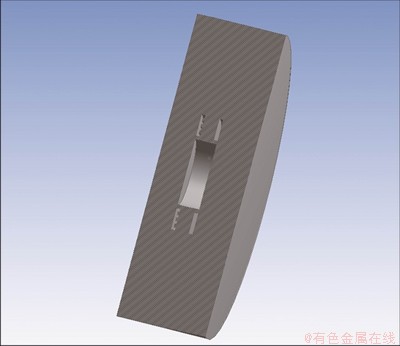

在数值计算中需要把对摩擦副流影响不大的细小结构去除,简化模型,达到减少网格划分的数量和降低计算时间的目的。在不影响计算精度的前提下,为提升网格划分质量,减小网格划分数量,忽略传动轴的花键齿、摩擦片内齿以及对偶钢片的外齿,建立的简化模型如图3所示。摩擦片参数如下:摩擦片内径为120 mm,外径为190 mm,基片厚度为1.5 mm,上衬片厚度为1 mm,下衬片厚度为1 mm。钢片内径为120 mm,外径为190 mm,厚度为3.5 mm。

图3 摩擦副模型图

Fig. 3 Figure of friction pair model

2.1 流场计算模型建立

将三维模型导入DM模块中,建立流场计算模型。摩擦副CFD计算模型如图4所示。

图4 摩擦副CFD计算模型

Fig. 4 CFD calculation model of friction pair

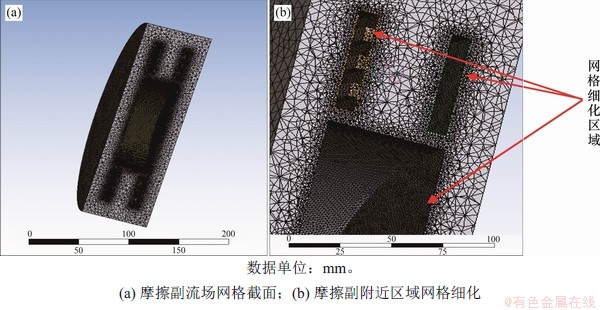

2.2 网格划分

对于复杂模型,非结构化四面体网格具有更强的适应性,能满足任意形状的复杂结构,因此,对流场计算模型划分非结构化网格[20],网格截面示意图如图5(a)所示。航空湿式离合器转速高,网格畸变大,影响流场的计算精度,且容易出现负体积。为了防止动网格计算时出现负体积,对摩擦片和对偶钢片附近区域进行网格局部细化,使之至少有两层网格,如图5(b)所示。此时,网格数量为230 160个,Skewness最大值为0.685 79,Skewness平均值为0.247 20。

2.3 边界条件

将网格模型导入fluent软件中设置仿真参数,其中边界条件与初始条件是控制方程有确定解的前提。通过CFD计算的问题都需要设定边界条件,边界条件的设定会影响求解结果的精确度,为尽可能还原中减运行过程的实际工作状况,对边界条件进行如下设置:1) 通过编写用户自定义文件(UDF)定义摩擦片的角速度边界;2) 通过编写用户自定义文件(UDF)定义对偶钢片的位移边界;3) 将出口处压力(pressure outlet)定义为0 Pa;4) 将进口处压力(pressure inlet)边界定义为2 kPa。

图5 摩擦副流场网格

Fig. 5 Friction pair flow field grid

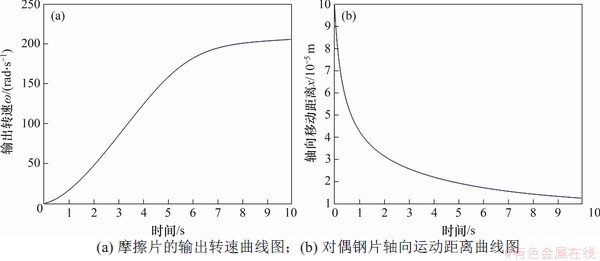

图6 数值仿真结果

Fig. 6 Numerical simulation results

2.4 公式拟合

数值仿真的摩擦片输出转速曲线和对偶钢片轴向运动距离曲线如图6所示,并根据此曲线进行公式拟合。在Matlab里基于P=polyflit(x,y,n)函数,编写判断程序以确定精度最高的拟合阶数,采用最小二乘法进行曲线拟合,拟合出摩擦片输出转速w(t)的计算公式以及钢片的轴向移动x(t)公式,分别作为速度边界条件和位移边界条件加载到Fluent中。经程序运行,得出当n=8时,精度最高。拟合的摩擦片输出转速公式w(t)和钢片的轴向移动距离公式x(t)如下:

(9)

(9)

(10)

(10)

2.5 动网格参数设置

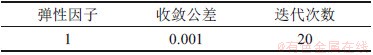

根据拟合的摩擦片输出转速公式和钢片轴向移动距离公式,通过编写UDF文件来定义摩擦片的速度边界条件以及钢片的位移边界条件。激活Dynamic Mesh选项,设置动网格参数,弹簧光顺法(Spring)的参数设置如表1所示,网格重构法考虑的因素主要为Local Cell,Local Face和Region Face,参数设置如表2所示。

表1 网格弹簧光顺参数设置

Table 1 Grid spring smooth parameter setting table

表2 网格重构参数设置

Table 2 Grid reconstruction parameter setting

3 摩擦副间流场仿真结果分析

3.1 摩擦副间油液流迹图分析

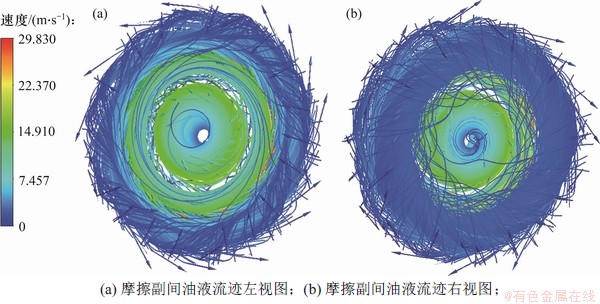

摩擦副具有速度特征的摩擦副油液流迹图能呈现油液在摩擦副中的流动情况,侧面表征润滑油在摩擦副间的润滑情况。选取接合时间为2.5 s时的摩擦副间油液流迹图,如图7所示。从图7中流线的箭头方向可以看出:在接合过程中,油液不断从摩擦副片间高速甩出,油液运动方向与转速方向一致,也有油液不断被搅动,再次进入摩擦副片间,润滑摩擦副。油液的流动轨迹无规律,润滑油均匀地分布在摩擦副间的各个地方,润滑效果好。

图7 t=2.5 s时具有速度特征的摩擦副间油液流迹图

Fig. 7 Flow diagram of oil flow between friction pairs with speed characteristics when t=2.5 s

3.2 不同接合时间下的油液速度云图分析

图8(a),(c)和(e)所示分别为接合时间t=2.5,3.8和5.0 s时,摩擦片的速度分布图。由图8(a),(c)和(e)可知:摩擦片由内往外,油液速度依次增大,摩擦片外径处油液的流速达到最大。且随着接合时间的增大,外径处油液的流速不停增大,依次为15.5,22.7和29.8 m/s(即t=5.0 s时,摩擦片的转速与钢片转速开始相等,此时接合完成)。由此可以看出,在摩擦副接合过程中,半径越大,油液流速越大,润滑油在油液离心力的作用下,高速排出。图8(b),(d)和(f)所示分别为接合时间t=2.5,3.8和5.0 s时对偶钢片的速度分布。因为钢片定转速运转,故图8(b),(d)和(f)中的速度分布完全一致。钢片外径处油液的流速最大,为29.8 m/s。摩擦片由内往外,油液速度依次增大。本模型的对偶钢片外径为190 mm,接合完成时的转速为314 rad/s,理论线速度为29.83 m/s,说明仿真结果准确。

图8 当t为2.5,3.8和5.0 s时摩擦片和对偶钢片速度分布图

Fig. 8 Velocity distribution diagram of friction plate and dual steel plate when t is 2.5, 3.8 and 5.0 s

摩擦副接合过程中,还包含了钢片的轴向运动,通过对摩擦副内部截面的云图进行分析,可以对接合过程中摩擦副内部的瞬态流场进行更直观、准确分析。图9(a),(c)和(e)所示分别为接合时间t=2.5,3.8和5.0 s时,在流场空间Y方向切面(Y=0 mm)上的润滑油速度云图。图9(b),(d)和(f)所示分别为其对应的局部放大速度云图。

图9 当t为2.5,3.8和5.0 s时Y截面的速度云图

Fig. 9 Velocity cloud of Y section when t is 2.5, 3.8 and 5.0 s

如图9(a),(c)和(e)所示,外流场区域流速较小,沿着摩擦片和对偶钢片的厚度方向(+z)的流速逐渐变大,其中蓝色区域是由于航空湿式离合器高速旋转,在摩擦副内部引起了涡流现象;对偶钢片输入转速大,其附近的油液流速大(黄色区域),对偶钢片上端周向油液速度高达29.8 m/s(红色区域),因为此处半径大,油液的切速度大,油液的离心力也大,油液可在离心力的作用下被高速甩出。由图9(b),(d)和(f)可知:摩擦片油槽处的流速相较于接合面大很多,说明本文仿真结果准确,油槽处油液的流速大,润滑油可在油槽处被快速甩出,润滑散热效果好;随着接合时间增大,油槽处油液的流速也增大。因为随着接合时间增大,摩擦片的转速在油膜剪切作用下越来越大,故油槽处的润滑油流速越来越大。

3.3 不同接合时间下的油液压力云图分析

图10所示分别为接合时间t=2.5,3.8和5.0 s时摩擦片和对偶钢片的油液压力云图。

图10 t为2.5,3.8和5.0 s时摩擦片和钢片的压力云图

Fig. 10 Pressure cloud diagram of friction plate and steel plate when t is 2.5, 3.8 and 5.0 s

由图10可知:摩擦副的压力分布呈现负压,因为航空湿式离合器高速旋转,在摩擦副内部引起了涡流现象,造成摩擦副周围流体压强小,故呈现负压。且随着接合时间增大,摩擦片和钢片的压力云图颜色逐渐趋于一致,表明压力分布越来越均匀,即摩擦副间润滑油分布越来越均匀,润滑效果好。

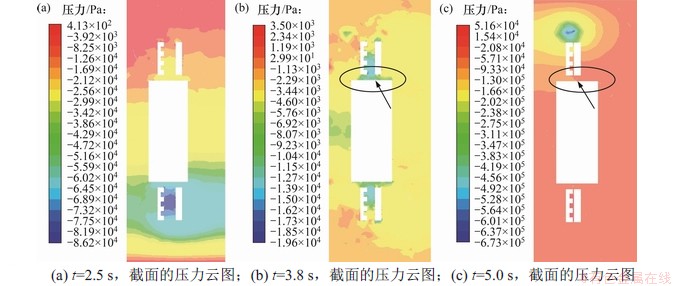

为了更好地反映接合过程中钢片轴向运动时接合面的油压分布情况,取在流场空间Y方向的截面(Y=0 mm)上的压力云图进行分析。图11所示分别为接合时间t=2.5,3.8和5.0 s时的油压分布云图。

图11 t=2.5,3.8和5.0 s时Y=0 mm截面的油液压力云图

Fig. 11 Oil pressure cloud of Y=0 mm section when t is 2.5, 3.8 and 5.0 s

由图11可知:随着接合时间增大,接合面间的油压也逐步增大。这是因为随着钢片的轴向运动,润滑油被不断排出摩擦副区间,摩擦副间的油液所受的油膜承载力越来越大。且随着接合时间增大,油液逐渐充满了模型区域,因此,油压分布越来越均匀,接合面间的油压几乎呈对称分布,表明润滑油分布均匀,润滑效果好。

4 结论

1) 在接合过程中,油液不断从摩擦副片间高速甩出,油液运动方向与转速方向一致,部分油液不断被搅动,再次进入摩擦副片间,润滑摩擦副,油液的流动轨迹无规律,润滑油均匀地分布在摩擦副间的各个地方,润滑效果好。

2) 摩擦副半径越大处,油液流速越大,润滑油在油液离心力的作用下,高速排出。

3) 在轴心润滑方式下,随着接合时间增大,润滑油被不断排出,摩擦副间的油液所受的油膜承载力越来越大,且油压分布越来越均匀,接合面的油压几乎呈对称分布,润滑效果好。

参考文献:

[1] CHO J, KATOPODES N, KAPAS N, et al. CFD modeling of squeeze film flow in wet clutch[C]// SAE Technical Paper Series 400 Commonwealth Drive. Warrendale, PA, United States: SAE International, 2011: 1-12.

[2] TAKAGI Y. Effect of two-phase flow on drag torque in a wet clutch[J]. Journal of Advanced Research in Physics, 2011, 2(2): 1-5.

[3] TERZI S, MANHARTSGRUBER B, MILANI M, et al. Optimization of the lubrication distribution in multi plate wet-clutches for HVT transmissions: an experimental-numerical approach[C]// SAE Technical Paper Series. 400 Commonwealth Drive, Warrendale, PA, United States: SAE International, 2018.

[4] ZHENG Xudong, XIE Fangwei, WU Diancheng, et al. CFD simulation of air effect on flow field characteristics of hydro-viscous clutch with constant speed difference[J]. Mechanics & Industry, 2018, 19(2): 1-10.

[5] PAHLOVY S, MAHMUD S F, KUBOTA M, et al. Multiphase drag modeling for prediction of the drag torque characteristics in disengaged wet clutches[J]. SAE International Journal of Commercial Vehicles, 2014, 7(2): 441-447.

[6] ZHANG Lin, WEI Chao, HU Jibin, et al. Influences of lubrication flow rates on critical speed of rub-impact at high circumferential velocities in no-load multi-plate wet clutch[J]. Tribology International, 2019, 140: 105847.

[7] 熊钊, 苑士华, 吴维, 等. 湿式离合器对偶片间油气两相流动的数值模拟[J]. 机械工程学报, 2016, 52(16): 117-123.

XIONG Zhao, YUAN Shihua, WU Wei, et al. Numerical Investigation of the Air-oil Two-phase Flow inside a Wet Clutch[J]. Journal of Mechanical Engineering, 2016, 52(16): 117-123.

[8] 冯珊珊. 车用液黏调速离合器流体传动特性分析[D]. 北京: 北京理工大学, 2015: 45-59.

FENG Shanshan. Study on flow transmission characteristics of hydro-viscous clutch in tracked vehicle[D]. Beijing: Beijing Institute of Technology, 2015: 45-59.

[9] 陈荣. 湿式离合器接合过程中液体流场特性的仿真研究[D]. 长春: 吉林大学, 2017: 25-34.

CHEN Rong. Simulation of fluid flow field characteristics in the engagement process of wet clutch[D]. Changchun: Jilin University, 2017: 25-34.

[10] 王小虎. 湿式离合器的离心轴供油冷却研究[D]. 成都: 西南交通大学, 2013: 7-13.

WANG Xiaohu. Study on centrifugal shaft oil cooling of the wet clutch[D]. Chengdu: Southwest Jiaotong University, 2013: 7-13.

[11] 王清. 湿式多片摩擦离合器多场耦合仿真及流场动态优化[D]. 重庆: 重庆大学, 2016: 7-21.

WANG Qing. Multi-field coupling simulation and oil way dynamic optimization of wet multi-plate friction clutch[D]. Chongqing: Chongqing University, 2016: 7-21.

[12] 童耀文. 基于空化效应的液粘离合器传递转矩特性研究[D]. 镇江: 江苏大学, 2017: 29-47.

TONG Yaowen. Transferred torque characteristics in hydro-viscous clutch based on cavitation effect[D]. Zhenjiang: Jiangsu University, 2017: 29-47.

[13] 郭广超, 邢作辉. 液黏调速离合器摩擦副间多相流CFD模拟[J]. 机械传动, 2018, 42(9): 72-74.

GUO Guangchao, XING Zuohui. CFD simulation of multi-phase flow inside the hydro-viscous speed regulating clutch[J]. Journal of Mechanical Transmission, 2018, 42(9): 72-74.

[14] 尹文超, 褚超美, 顾荣华, 等. 沟槽形态对冷却油流场影响的仿真分析[J]. 农业装备与车辆工程, 2019, 57(5): 25-27.

YIN Wenchao, CHU Chaomei, GU Ronghua, et al. Simulation analysis of influence of groove form on cooling oil flow field[J]. Agricultural Equipment & Vehicle Engineering, 2019, 57(5): 25-27.

[15] 鲍和云, 范永, 朱如鹏, 等. 齿轮箱浸油润滑流场及温度场仿真分析[J]. 中南大学学报(自然科学版), 2019, 50(8): 1840-1847.

BAO Heyun, FAN Yong, ZHU Rupeng, et al. Simulation analysis of flow field and temperature field of oil-immersion lubrication gearbox[J]. Journal of Central South University (Science and Technology), 2019, 50(8): 1840-1847.

[16] 章本照. 流体力学数值方法[M]. 北京:机械工业出版社, 2003: 116-181.

ZHANG Benzhao. Numerical method of fluid mechanics [M]. Beijing: China Machine Press, 2003: 116-181.

[17] Fluent Inc. Fluent 6.3 user’s guide[M]. Boca Raton, Florida, USA: Fluent Inc, 2006: 12-18-12-21.

[18] 张来平, 邓小刚, 张涵信. 动网格生成技术及非定常计算方法进展综述[J]. 力学进展, 2010, 40(4): 424-447.

ZHANG Laiping, DENG Xiaogang, ZHANG Hanxin. Reviews of moving grid generation techniques and numerical methods for unsteady flow[J]. Advances in Mechanics, 2010, 40(4): 424-447.

[19] 唐家鹏. FLUENT 14.0超级学习手册[M]. 北京: 人民邮电出版社, 2013: 402-412.

Tang Jiapeng. FLUENT 14.0 Super Learning Manual[M]. Beijing: People's Posts and Telecommunications Press, 2013: 402-412.

[20] 杜平安. 有限元网格划分的基本原则[J]. 机械设计与制造, 2000(1): 34-36.

DU Ping'an. Basic principles of finite element meshing[J]. Machinery Design & Manufacture, 2000(1): 34-36.

(编辑 杨幼平)

收稿日期: 2020 -06 -29; 修回日期: 2020 -08 -15

基金项目(Foundation item):国家自然科学基金资助项目(51975274);南京航空航天大学直升机传动技术重点实验室资金资助项目(HTL-A-19K03) (Project(51975274) supported by the National Natural Science Foundation of China; Project(HTL-A-19K03) supported by the National Key Laboratory of Science and Technology on Helicopter Transmission (Nanjing University of Aeronautics and Astronautics)

通信作者:鲍和云,副教授,从事机械传动、动力学及减振研究;E-mail: baoheyun@nuaa.edu.cn

引用格式: 谭武中. 航空湿式离合器接合过程中摩擦副间瞬态流场特性分析[J]. 中南大学学报(自然科学版), 2021, 52(4): 1138-1148.

Citation: BAO Heyun, XU Tongjing, TAN Wuzhong, et al. Analysis of transient flow field characteristics between friction pairs during engagement of aviation wet clutch[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1138-1148.