DOI:10.19476/j.ysxb.1004.0609.2019.06.05

多道次固相合成AZ91D-Nd合金的组织演变规律及力学性能

王殿君,胡茂良,吉泽升,许红雨,王 晔

(哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040)

摘 要:采用多道次固相合成AZ91D镁合金屑和Mg-Nd中间合金屑,研究了固相合成过程中β-Mg17Al12相和中间合金屑的破碎机理及分散均匀性。结果表明:在多道次固相合成过程中,中间合金屑逐渐破碎,Nd元素溶入晶粒内部,形成固溶强化;以球团状颗粒在晶界处均匀分布,形成第二相粒子强化;粗大的β-Mg17Al12相被破碎,削弱了对基体的割裂影响;破碎的β-Mg17Al12相和中间合金颗粒促进了动态再结晶的发生,形成细晶强化,力学性能明显提高。AZ91D-Nd镁合金的抗拉强度达到323MPa,比铸态时提高了29.2%,伸长率达到7.2%,与铸态的相当。

关键词:固相合成;AZ91D;Mg-Nd中间合金;显微组织;力学性能

文章编号:1004-0609(2019)-06-1170-08 中图分类号:TG146 文献标志码:A

镁合金是目前工业应用中最轻的金属结构材料之一,广泛应用于航空、航天、汽车、3C等领域,被誉为“21世纪绿色工程结构材料”[1-3]。为了提高其性能,通常加入稀土元素Nd、Ce、Y等[4-6]。采用传统的熔炼方法制备稀土镁合金需要加覆盖剂和精炼剂或其他保护气氛,稀土元素在熔炼过程中产生烧损,名义上的加入量与实际测得的量不一致,同时加重对环境的污染。固相合成是一种新的镁合金制备技术,该方法是将镁合金铸锭和稀土中间合金铸锭车削成屑,混合均匀后通过冷压或热压再挤压的方式制备稀土镁合金。固相合成可以使稀土元素均匀分布,稀土颗粒与基体间的界面结合强度高、颗粒细小,基体晶粒细化,提高了镁合金的力学性能[7]。

国内外对AZ31、AZ61、AZ80、AZ91、ZM6等镁合金的固相再生研究的较多,通常只针对一种合金屑进行挤压。武淑艳等[8]采用固相合成工艺制备了AZ31镁合金,晶粒尺寸可以达到5~10 μm,室温抗拉强度和伸长率与铸锭挤压材料相当。朱瑶等[9]对AZ31B镁合金屑和Ce合金屑固相合成,随着挤压次数增加,抗拉强度和伸长率可以达到311MPa和9.83%。徐岩等[10]对AZ61镁合金在285 ℃下反复挤压,由于局部应变导致的动态再结晶,得到平均晶粒尺寸3.5 μm的细小晶粒。刘英等[11]采用间接热挤压方法回收AZ80镁合金废料,制备镁合金棒材室温抗拉强度为285 MPa,伸长率为6%,论证了热挤压屑是合成镁合金的一种可行方法。周霞等[12]基于SHPB实验挤压AZ91D镁合金,建立了应变速率相关的本构方程,认为应变速率在400~1000 s-1之间变化时,应变速率敏感性随应变速率增大而增大。胡茂良等[13]对AZ91D镁合金废料挤压,细化了晶粒,抗拉强度和伸长率随挤压温度升高而增加。文丽华等[14]对ZM6镁合金固相合成,合成试样在室温时的抗拉强度达到280 MPa,在250 ℃时的高温强度达到171.9 MPa。目前对于镁合金的固相合成主要集中在一种合金屑,由于两种合金屑制备过程及均匀化处理更为复杂,尤其是添加稀土中间合金屑,具有十分重要的实用价值,但相关研究很少。

本实验主要以铸造AZ91D镁合金为研究对象,采用固相合成的方法将Mg-Nd中间合金加入AZ91D镁合金中,讨论不同挤压道次对AZ91D-Nd镁合金微观组织演变的规律及对力学性能的影响。

1 实验

实验采用AZ91D铸锭和Mg-Nd中间合金铸锭为原始坯料,其化学成分如表1和表2所示。

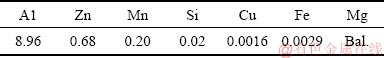

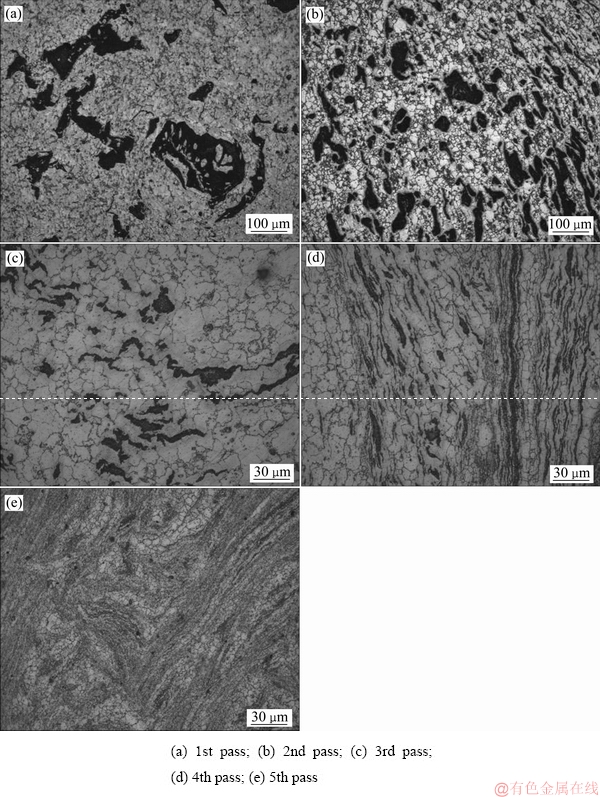

AZ91D镁合金含有较高的合金元素,其铸态组织由α-Mg固溶体和晶界处不连续网状分布的骨骼状β-Mg17Al12相组成[15]。β-Mg17Al12相硬度和脆性较大,其形貌、尺寸、数量和分布对合金的强度和塑性有很大的影响。在塑性变形过程中,沿晶界分布的粗大的β-Mg17Al12相易发生脆性断裂,降低合金的综合力学性能,显微组织如图1(a)所示。

表1 AZ91D镁合金的化学成分

Table 1 Chemical composition of AZ91D magnesium alloy (mass fraction, %)

表2 Mg-Nd中间合金的化学成分

Table 2 Chemical composition of Mg-Nd master alloy (mass fraction, %)

Mg-Nd中间合金是常用的稀土中间合金,其铸态组织由α-Mg固溶体和β-Mg41Nd5相组成,显微组织如图1(b)所示。

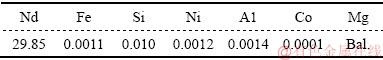

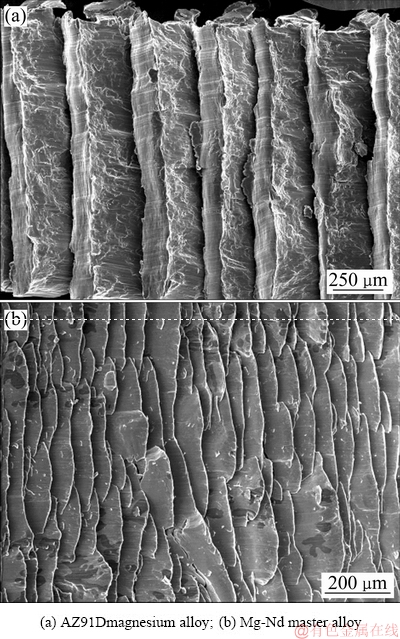

用CA6140型车床将2种铸锭分别车削成屑,AZ91D合金屑的表面形貌如图2(a)所示,Mg-Nd中间合金屑的表面形貌如图2(b)所示。

图1 合金的显微组织

Fig. 1 Microstructures of alloys

图2 合金屑的表面形貌

Fig. 2 Surface morphologies of alloy chips

从图2中可以看出,合金屑的表面有很多平行状的裂纹、毛刺等缺陷。这是由于在车削过程中,切削力使晶格产生了一定的畸变,组织产生大量的裂纹,体系内能提高,产生了大量的畸变能,结构缺陷增多,切屑存在一定的残余应力,切屑形成“鳞片状”结构。在随后的热挤压过程中,裂纹、毛刺等缺陷也会利于位错的攀移和滑移,有助于热挤压后塑性变形能力的提高。

加工的AZ91D屑的尺寸为(3.2~3.6) mm×(1.5~ 1.8) mm×(0.4~0.5) mm。加工的Mg-Nd中间合金屑的尺寸为(3.5~3.9) mm×(2.2~2.5) mm×(0.1~0.3) mm。

固相合成AZ91D-Nd镁合金的工艺流程如下:先将Mg-Nd中间合金屑按含Nd质量分数3%的比例与AZ91D镁合金屑在混料机上混合均匀,再利用冷压模具在300 MPa压力下冷压成锭坯,然后在热压模具内加热到400 ℃并保温30 min后热挤出直径为8 mm的棒材,挤压比为25:1。将热挤出的棒材去除表面杂质后再锯切成10~15 mm长的小段,再进行冷压和热挤,合成试样。

采用OLYMPUS-GX71-6230A型金相显微镜对试样进行金相组织观察,金相试样用0.5 g苦味酸、2 mL冰乙酸、1 mL蒸馏水和20 mL无水乙醇配制成的混合溶液腐蚀。采用WDW-10型微机控制电子万能试验机对试样进行室温力学性能测试,拉伸速率为1 mm/s。采用Quanta-200型扫描电子显微镜对试样进行能谱分析。采用Philips CM-12型透射电子显微镜对试样进行界面结构分析。

2 结果与讨论

2.1 光学显微组织分析

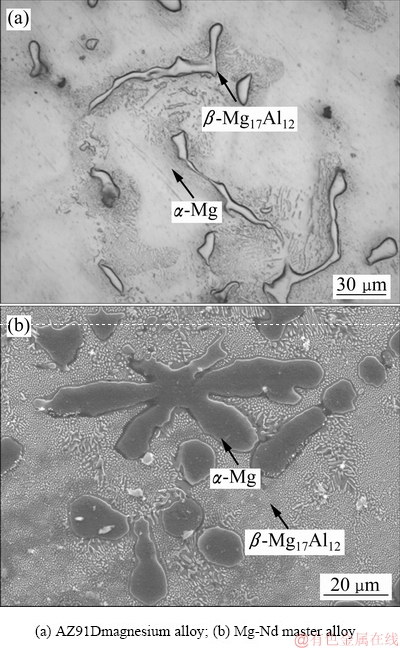

图3所示为不同道次固相合成后,试样横截面的光学显微组织。冷压过程中,切屑首先在原裂纹处破碎,屑与屑之间产生位移、变形、破碎、咬和,同时产生新的裂纹。从图3(a)中可以看出,经过第1道次热挤压后,中间合金屑沿裂纹破碎成多个小块,块的大小不等,20%~30%的中间合金屑已经破碎到50 μm左右,10%~20%的中间合金屑较大,仍保持原始的组织形态,呈梅花形的α-Mg相在屑内仍清晰可见,晶界处的β-Mg17Al12相保持较大尺寸。随着挤压道次的增加,中间合金屑和Mg17Al12相逐渐被破碎成小颗粒,并且随挤压流线分布在镁合金基体中。从图3(d)中可以看出,有中间合金颗粒分布的区域,晶粒细小;中间合金颗粒较少的区域,晶粒较大。在挤压过程中,中间合金颗粒作为第二相粒子有利于动态再结晶的发生。从图3(e)中可以看出,经过5道次的挤压后,镁合金基体中的大晶粒基本消失,粗大的中间合金屑已经完全破碎,动态再结晶的小晶粒与细小的第二相颗粒均匀分布。镁合金基体晶粒由20 μm左右减小到5 μm左右。随着挤压次数的增加,挤压流线变得紊乱、密集,这主要是由于晶粒通过自适应转动并调整滑移方向,形成弯曲的或波浪形的条纹。多次挤压变形后,沿着挤压方向发生塑性流动,最终被挤成纤维状。合金中破碎的中间合金屑和Mg17Al12相在塑性变形时随晶粒滑移、破碎的同时沿着挤压流线呈离散状分布,这些细密的挤压流线对提高力学性能起到积极作用。

由于镁合金滑移系少,层错能低,晶界扩散速率高,位错易塞积,热挤压时就可以很快达到再结晶所需要的高位错密度,在400 ℃温度下很容易发生动态再结晶。破碎的中间合金颗粒和Mg17Al12相周围存在局部大应变区,这些区域的位错密度非常高[16],晶格畸变加剧,这些位置是成为再结晶晶粒形核的理想位置。在光学显微镜下可以观察到镁合金基体粗大晶粒逐渐减少,再结晶晶粒逐渐增多,并且细小均匀分布。

图3 不同挤压道次下AZ91D-Nd合金横截面光学显微组织

Fig. 3 Optical microstructures of AZ91D-Nd alloy with different extrusion passes perpendicular to extrusion direction

2.2 扫描电镜组织特征分析

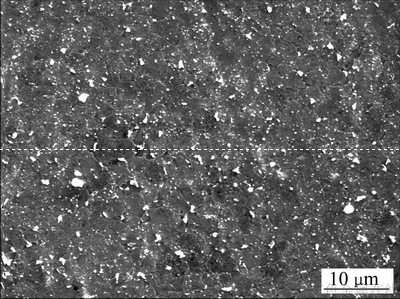

图4所示为经过5道次挤压后的AZ91D-Nd合金的SEM像。从图4中可以看出,大块的中间合金屑已经被充分的破碎成颗粒,随挤压流线均匀的分布到晶界上。由于发生动态再结晶,晶粒变得均匀、细小。在400 ℃以上,塑性变形的活化能接近镁合金的体积扩散能,导致大量的位错攀升[17],挤压热和摩擦热使合金中原子热振动及扩散速度增加,位错的滑移、攀移、交滑移以及位错节点脱锚比挤压次数低时更容易,使动态再结晶的形核增加[18]。中间合金颗粒破碎的程度增大,可以钉扎晶界,并阻碍热变形过程中的晶粒长大。经过5道次挤压后的镁合金主要由α-Mg相、Mg17A112相、Mg41Nd5相组成。

图5所示为固相合成AZ91D-Nd合金SEM形貌及EDS面扫描分析结果,图中越亮,元素含量越高。从图5中可以看出,Nd的均匀程度很高,晶界上有Nd元素,晶粒内部Nd元素均匀分布。这说明Nd元素已经固溶入晶粒内部,颗粒较大的中间合金在晶界处保留下来。稀土Nd具有晶粒细化、强化晶界的作用,溶入镁基体的Nd原子使基体产生晶格畸变,阻碍位错运动,强化基体。晶界强化可使位错运动的阻力增加,使位错运动限制在一定的范围内,使塑性变形均匀,裂纹扩展阻力增加,不利于裂纹扩展,使裂纹钝化或改变方向,表现为较高的伸长率。

图4 经5道次挤压后的AZ91D-Nd合金的SEM像

Fig. 4 SEM image of AZ91D-Ndalloy after 5th pass extrusion

图5 固相合成 AZ91D-Nd合金 SEM 形貌及EDS 面扫描分析结果

Fig. 5 SEM image of AZ91D-Nd alloy and EDS results of surface scan by prepared by solid phase synthesis

2.3 透射电镜组织特征分析

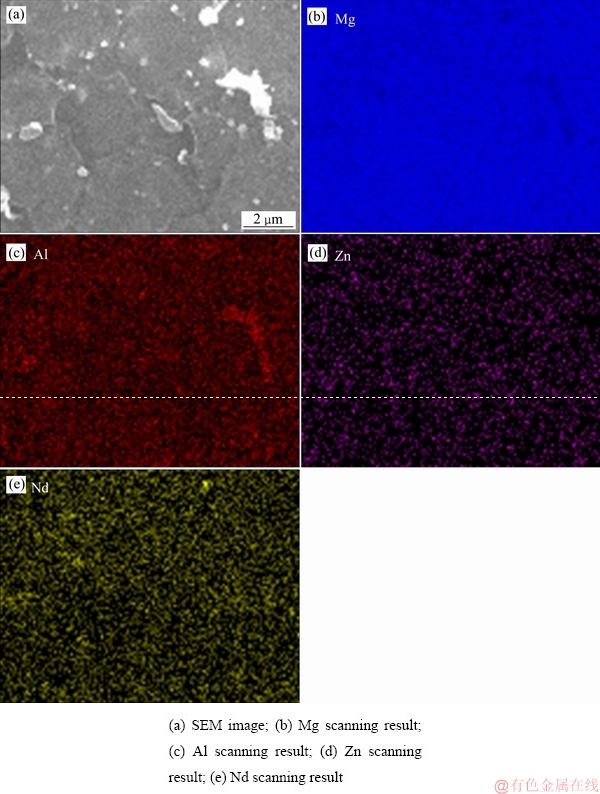

图6所示为经5道次挤压后AZ91D-Nd合金TEM像。从图6(a)中可以看出,在晶界处分布着尺寸均匀、细小的Mg-Nd中间合金颗粒,形状上主要以球团状为主。这种作为第二相的中间合金颗粒可以对晶界起到钉扎的作用,阻碍位错的运动,提高力学性能。从图6(b)中可以判断,点A处是含Nd的中间合金颗粒。从图6(c)中可以看到,中间合金颗粒与镁基体界面结合较好,没有发现裂纹,达到原子级结合。

图6 经5道次挤压后AZ91D-Nd合金TEM像

Fig. 6 TEM images of AZ91D-Nd alloy after 5th pass extrusion

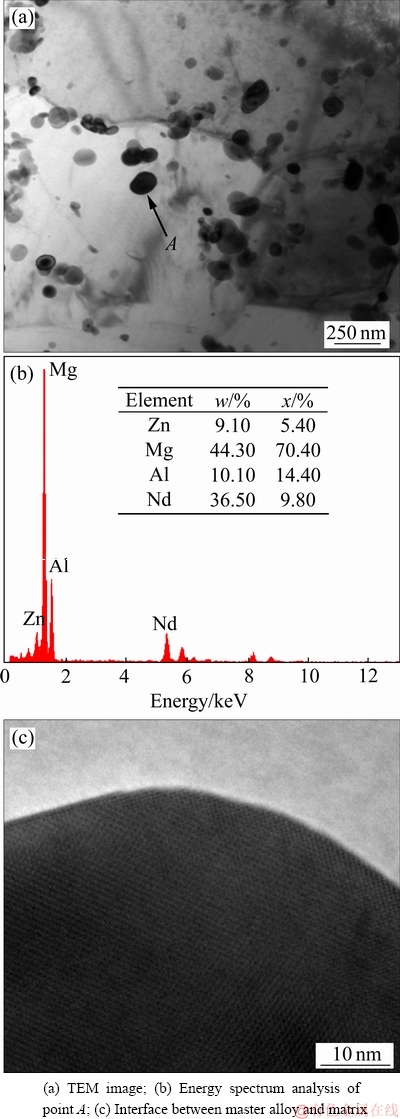

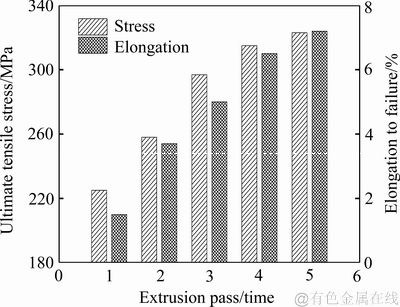

2.4 力学性能

图7所示为固相合成AZ91D-Nd合金的力学性能。经1次热挤压后,抗拉强度只有225 MPa,伸长率只有1.5%。这是由于中间合金屑较大,外形尖锐且内部有大量的裂纹,如图3(a)所示,在拉伸时会对基体造成割裂作用,应力首先在中间合金屑内部的裂纹及尖角处产生集中并生成裂纹,进而扩展发生断裂。另外,中间合金屑与基体结合的强度很低,界面处会有大量的裂纹和孔洞等缺陷存在,也易产生裂纹。随着挤压道次的增加,中间合金屑与基体结合的强度越来越高,中间合金屑逐渐被破碎成颗粒状并越来越均匀的分布到基体中。硬脆的Mg17Al12相被破碎,削弱了对基体的割裂影响。抗拉强度和伸长率都有大幅度增加。经5道次挤压后,抗拉强度达到323 MPa,伸长率达到7.2%。抗拉强度和伸长率相对于第4道次挤压后增加幅度变小。

图7 固相合成AZ91D-Nd合金力学性能

Fig. 7 Mechanical properties of AZ91D-Nd alloy prepared by solid phase synthesis

由于挤压热和摩擦热的影响,Nd元素和Mg17Al12相会扩散到晶粒内部,产生固溶强化和析出强化[19]。被充分破碎的中间合金颗粒和β-Mg17Al12相在挤出时作为第二相粒子存在,有效地阻碍了位错的移动和晶界的滑移,造成了位错的塞积,产生第二相粒子强化,提高了抗拉强度。挤压过程中,被破碎的中间合金颗粒优先在高位错密度处形核[20]。同时,细小的中间合金颗粒为再结晶提供形核的核心,还阻碍了再结晶晶粒的长大,使多次挤压后的晶粒变得非常细小。

Hall-petch公式[21]如式(1)所示。根据式(1)可知:晶粒越细小,强度越高,晶粒细小,有利于晶粒转动和晶界滑动,使材料塑性大大提高[21]。因此,细晶强化对镁合金力学性能的作用显著。

(1)

(1)

铸态AZ91D镁合金抗拉强度为250 MPa,伸长率为7%,经5道次固相合成后,抗拉强度达到323 MPa,比铸态时提高了29.2%,伸长率达到7.2%,与铸态时相当。固溶强化、析出强化、第二相强化和动态再结晶细晶强化的共同作用是固相合成AZ91D-Nd镁合金力学性能提高的主要强化机制。

3 结论

1) Mg-Nd中间合金屑经过5道次挤压后被破碎并均匀分布在基体中,形成固溶强化和第二相粒子强化,钉扎晶界,阻碍了晶界的运动,提高了塑性和强度。

2) 多道次挤压后的AZ91D-Nd镁合金发生了动态再结晶,晶粒越来越细小,产生细晶强化。中间合金颗粒分布多的区域,晶粒较细密。

3) 经过5道次挤压后,分布在晶界的硬脆、粗大的β-Mg17Al12相被挤碎,对基体的割裂作用减小。β-Mg17Al12相分布在晶界,可以起到第二相粒子的强化作用。

4) 随着挤压道次的增加,抗拉强度和塑性都得到提高,经5道次挤压后,抗拉强度达到323 MPa,伸长率达到7.2%。5道次挤压后的抗拉强度和伸长率增加幅度变小。

REFERENCES

[1] 郑留伟, 梁 伟, 赵子龙, 李亚娥, 王红霞, 王一德. 均匀化退火处理对AZ91镁合金轧制成形行为的影响[J].稀有金属材料与工程, 2016, 45(5): 1296-1301.

ZHENG Liu-wei, LIANG Wei, ZHAO Zi-long, LI Ya-e, WANG Hong-xia, WANG Yi-de. Effect of homogenizing annealing treatment on AZ91 magnesium alloy rolling deformation behavior[J]. Rare Metal Materials and Engineering, 2016, 45(5): 1296-1301.

[2] 石洪吉, 邓运来, 张 凯, 杨 柳, 陈明安. Nd含量对Mg-6Gd-2.5Y-0.5Zr合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2017, 27(9): 1785-1793.

SHI Hong-ji, DENG Yun-lai, ZHANG Kai, YANG Liu, CHEN Ming-an. Effects of Nd addition on microstructure and mechanical properties of Mg-6Gd-2.5Y-0.5Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1785-1793.

[3] 冯 艳, 陈 超, 彭超群, 王日初. 镁基复合材料的研究进展[J]. 中国有色金属学报, 2017, 27(12): 2385-2407.

FENG Yan, CHEN Chao, PENG Chao-qun, WANG Ri-chu. Research progress on magnesium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2385-2407.

[4] 刘志杰, 吴国华, 庞 松, 丁文杰. Mg-Nd系合金及Nd在镁合金中的应用与展望[J]. 铸造技术, 2012, 33(2): 151-154.

LIU Zhi-jie, WU Guo-hua, PANG Song, DING Wen-jiang. Mg-Nd alloy and application of Nd in magnesium alloys[J]. Foundry Technology, 2012, 33(2): 151-154.

[5] 王 军, 朱秀荣, 徐永东, 王 荣, 聂景江, 张立君. 稀土Ce和Y对AZ80镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(1): 25-35.

WANG Jun, ZHU Xiu-rong, XU Yong-dong, WANG Rong, NIE Jing-jiang, ZHANG Li-jun. Effectsofrare earthCe and Y on microstructure and mechanical properties of AZ80 Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 25-35.

[6] 郑伟超, 李双寿, 汤 彬, 曾大本. 稀土对AZ31B变形镁合金组织和力学性能的影响[J]. 中国有色金属学报, 2006, 16(2): 197-204.

ZHENG Wei-chao, LI Shuang-shou, TANG Bin, ZENG Da-ben. Effects of rare earth on microstructure and mechanical properties of AZ31B wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 197-204.

[7] 文丽华, 吉泽升, 宁慧燕, 毕凤阳, 胡茂良. 固相合成道次对ZM6-Ce镁合金组织和性能的影响[J]. 稀有金属材料与工程, 2015, 44(9): 2305-2309.

WEN Li-hua, JI Ze-sheng, NING hui-yan, BI Feng-yang, HU Mao-liang. Effect of extruding times on microstructure and mechanical properties of ZM6-Ce magnesium alloy[J]. Rare Metal Materials and Engineering, 2015, 44(9): 2305-2309.

[8] WU S Y, JI Z S, ZHANG T L. Microstructure and mechanical properties of AZ31B magnesium alloy recycled by solid-state process from different size chips[J]. Journal of Materials Processing Technology, 2009, 209: 5319-5324.

[9] ZHU Y, HU M L, WANG D J, XU H Y, WANG Y, JI Z S. Microstructure and mechanical properties of AZ31-Ce prepared by multipass solid-phase synthesis[J]. Materials Science and Technology, 2018, 34(7): 876-884.

[10] XU Yan, HU Lian-xi, SUN Yu, JIA Jian-bo, JIANG Ju-fu, MA Qing-guo.Microstructure and mechanical properties of AZ61 magnesium alloy prepared by repetitive upsetting- extrusion[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 381-388.

[11] LIU Ying, LI Yuan-yuan, ZHANG Da-tong, Ngai Tung-wai Leo, CHEN Wei-ping. Microstructure and properties ofAZ80 magnesium alloy prepared by hot extrusion fromrecycled machined chips[J]. Transactions of Nonferrous Metals Society of China, 2002, 12(5): 882-885.

[12] 周 霞, 赵昌美, 李 利, 黄宏军. 基于SHPB实验的挤压AZ91D镁合金动态力学行为数值模拟[J]. 中国有色金属学报, 2014, 24(8): 1969-1975.

ZHOU Xia, ZHAO Chang-mei, LI Li, HUANG Hong-jun. Numerical simulation of dynamic behavior of extruded AZ91D magnesium alloy based on SHPB experiment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 1969-1975.

[13] HU M L, JI Z S, CHEN X Y, WANG Q D. Microstructure and mechanical properties of AZ91D magnesium alloy recycled from scraps by hot-press/extrusion[J]. Journal of Harbin Institute of Technology (New Series), 2014, 21(1): 115 - 120.

[14] WEN L H, JI Z S, XIN M D. Microstructure and mechanical properties of ZM6 magnesium alloy produced by extrusion of machined chips[J]. Materials Science and Technology, 2009, 25(10): 1222-1226.

[15] 肖晓玲, 罗承萍, 聂建峰, MUDDLE B C. AZ91 Mg-Al合金中β-(Mg17Al12)析出相的形态及其晶体学特征[J]. 金属学报, 2001, 37(1): 1-7.

XIAO Xiao-ling, LUO Cheng-ping, NIE Jian-feng, MUDDLE B C. Morphology and crystallography of β-(Mg17Al12) precipitate in an AZ91 magnesium-aluminum alloy[J]. Acta Metallurgica Sinica, 2001, 37(1): 1-7.

[16] STYCZYNSKI A, HARTIG C, BOHLEN J, LETZIG D. Cold rolling textures in AZ31 wrought magnesium alloy[J]. Scripta Mater, 2004, 50(7): 943-947.

[17] HU Mao-liang, JI Ze-sheng, CHEN Xiao-yu, WANG Qu-dong, DING Wen-jiang. Solid-state recycling of AZ91D magnesium alloy chips[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): s68-s73.

[18] 蔡志伟, 陈拂晓, 郭俊卿. AZ41M镁合金动态再结晶临界条件[J]. 中国有色金属学报, 2015, 25(9): 2335-2341.

CAI Zhi-wei, CHEN Fu-xiao, GUO Jun-qing. Critical conditions of dynamic recrystallization for AZ41M magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2335-2341.

[19] 黄晓锋, 王渠东, 曾小勤, 朱艳萍, 卢 晨, 丁文江. 钕对Mg-5Al-1Si高温蠕变及组织性能的影响[J]. 中国稀土学报, 2004, 22(3): 361-364.

HUANG Xiao-feng, WANG Qu-dong, ZENG Xiao-qin, ZHU Yan-ping, LU Chen, DING Wen-jiang. Effect of neodymium on microstructure and high temperature creep properties of Mg-5Al-1Si magnesium alloy[J]. Journal of the Chinese Society of Rare Earths, 2004, 22(3): 361-364.

[20] YANG P, ZHAO Z D, REN X P. Microstructure, textures and deformation behaviors of fine-grained magnesium alloy AZ31[J]. Mater Sci Technol, 2005, 21(3): 331-337.

[21] ZHU Shao-zhen, LUO Tian-jiao, ZHANG Ting-an, LIU Yun-teng, YANG Yuan-sheng. Effects of extrusion and heat treatments on microstructure and mechanical properties of Mg-8Zn-1Al-0.5Cu-0.5Mn alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 73-81.

Microstructure evolution and mechanical properties of AZ91D-Nd alloy fabricated by multi-pass solid phase synthesis

WANG Dian-jun, HU Mao-liang, JI Ze-sheng, XU Hong-yu, WANG Ye

(School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China)

Abstract: AZ91D alloy chips and Mg-Nd master alloy chips were fabricated by multi-pass solid phase synthesis. The homogenization and breaking mechanism of β-Mg17Al12 phase and master alloy chips were analyzed. The results show that Mg-Nd master alloy chips are broken. Nd element dissolves inside the grain and solid solution strengthening is formed. The granular particles were distributed in the grain boundary, which produces the precipitation strengthening. The coarse β-Mg17Al12 phases, which deterioratesthe matrix, are broken. The broken β-Mg17Al12 phase and granular particles accelerate the dynamic recrystallization, refine the grain and improve the mechanical properties. The ultimate tensile strength of AZ91D-Nd alloy is 323 MPa, which is higher than that of as-cast AZ91D alloy. The elongation of AZ91D-Nd alloy is 7.2%, which is similar to that of as-castAZ91D alloy.

Key words: solid phase synthesis; AZ91D; Mg-Nd master alloy; microstructure; mechanical property

Foundation item: Projects(51404082, 51574100, 51704087) supported by the National Natural Science Foundation of China; Project(201510) supported by the Science Funds for the Young Innovative Talents of Harbin University of Science and Technology, China

Received date: 2018-05-02; Accepted date: 2018-07-04

Corresponding author: HU Mao-liang; Tel: +86-13936585119; E-mail: humaoliang@hrbust.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51404082,51574100,51704087);哈尔滨理工大学青年拔尖创新人才培养计划资助项目(201510)

收稿日期:2018-05-02;修订日期:2018-07-04

通信作者:胡茂良,教授,博士;电话:13936585119;E-mail:humaoliang@hrbust.edu.cn