文章编号:1004-0609(2010)S1-s0320-05

热加工方式对双合金结合界面组织与力学性能的影响

姚泽坤1,谭立军1,郭鸿镇1, 张建伟2,梁晓波2

(1. 西北工业大学 材料学院,西安710072;2. 北京钢铁研究总院,北京 100081)

摘 要:对比电子束焊接和线性摩檫焊接的Ti2AlNb/TC11双合金试样在焊接态与等温变形和热处理耦合作用后结合界面的组织与力学性能。结果表明:等温变形和热处理耦合作用可细化电子束焊接Ti2AlNb/TC11双合金结合界面的晶粒粒径,显著提高冲击韧性值约72%;等温变形和热处理耦合作用除可明显改变均匀线性摩擦焊接Ti2AlNb/TC11双合金结合界面的化学成分外,还可平缓地连续过渡为改变界面区域突变的显微组织,并大幅提高结合界面的抗拉强度和塑性。

关键词:双合金;等温变形;界面组织;力学性能

中图分类号:TG 146.4 文献标志码:A

Effect of hot working method on interfacial microstructures and mechanical properties of dual alloy

YAO Ze-kun1, TAN Li-jun1, GUO Hong-zhen1, ZHANG Jian-wei2, LIANG Xiao-bo2

(1. School of Materials and Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. Central Iron & Steel Research Institute, Beijing 100081, China)

Abstract: The interfacial microstructure and mechanical properties of Ti2AlNb/TC11 dual alloy jointed by electron beam weld and linear friction weld before and after near isothermal deformation and heat treatment were investigated. The results show that the grain size on interface of sample welded by the electron beam weld is refined obviously by near isothermal deformation and heat treatment couple. The chemical components at the interface of dual Ti2AlNb/T11 alloy are changed by isothermal deformation and heat couple treatment. The microstructure transform step by step through the weld line due to diffusion of element and re-construction of crystal lattice, the tensile strength and plasticity increase obviously after near isothermal deformation followed by solution and aging treatment.

Key words: dual alloy; isothermal deformation; interfacial microstructure; mechanical property

近年来,钛铝基金属间化合物在航空工业中显示出广阔的应用前景[1]。然而,其制品生产成本高,且加工条件苛刻[2],如果将其与常规钛合金进行连接制备某些构件,不仅能减少构件质量、降低生产成本,而且能发挥两种合金各自性能方面的优势[3]。因此,实现钛铝基金属间化合物与常规钛合金的连接,对于钛铝基金属间化合物的应用具有重要的意义。

目前,钛铝基金属间化合物/钛合金的焊接工艺主要集中于熔焊与固态焊。对于熔焊工艺,由于钛原子活性较高,焊缝金属易被氧化,国内外大多采用具有高能量密度分布的真空电子束焊接工艺对其进行连 接[4-7];在各种固态焊接工艺中,相对于钎焊与扩散焊等工艺,线性摩擦焊接工艺由于生产效率高、无需填充额外金属、焊合率高,且焊缝金属冶金缺陷较少,在钛铝基金属间化合物/钛合金的连接中显示出一定的优势[8-11]。本文作者在前期的研究中发现[12],电子束焊接的Ti2AlNb/TC11焊件接头具有较高的抗拉强度,但是焊缝组织脆性较高,线性摩擦焊接的Ti2AlNb/TC11接头抗拉强度较低。若对上述两种焊件进行热加工,使其焊缝显微组织细化,有望提高焊接接头的相关力学性能[13]。

本文作者对电子束焊接的和线性摩擦焊接的Ti2AlNb/TC11异种金属焊件进行热加工,试图了解热力耦合作用对不同方法焊接的结合界面显微组织与力学性能的影响规律,寻找进一步提高焊接接头力学性能的途径,为其实际应用提供理论依据和工艺参考。

1 实验

实验用Ti2AlNb合金名义成分为Ti-22Al-25Nb (摩尔分数,%),焊前在(α2+B2+O)三相区进行1 h的固溶处理;TC11合金焊前在950 ℃进行1 h固溶处理。

线性摩擦焊所用的试样尺寸分别为25 mm×40 mm× 37 mm (Ti2AlNb合金)和25 mm×40 mm×45 mm(TC11合金),其中25 mm×40 mm表面为待焊界面,焊前均用砂纸磨平并清洗干净。电子束焊接所用的两种合金试样尺寸均为25 mm×25 mm×37 mm,其中25 mm×25 mm表面为待焊界面,焊前所有试样表面均用丙酮溶液清洗干净。

将焊好的的试件按一定工艺条件进行横向压缩变形,即力的作用方向平行于焊接界面[14];采用的变形温度为980 ℃,应变速率为10-3 s-1,变形程度为40%,模具温度920 ℃。试样变形后进行(950 ℃, 1 h,AC(空冷))+(600 ℃, 4 h,AC)的热处理。

分别在焊态与热加工过的试样上沿垂直焊缝方向截取力学性能试样,按照HB5143—96进行拉伸性能测试,焊缝位于拉伸试样中心;按照HB5144—96进行冲击韧性测试,将焊缝置于U形缺口内(焊缝宽约1.2 mm, U形缺口宽2 mm)。采用光学电镜(OM)进行显微组织观察和扫描电镜(SEM)进行微观组织分析与断口形貌观察。

2 结果与分析

2.1 电子束焊结合界面的显微组织变化

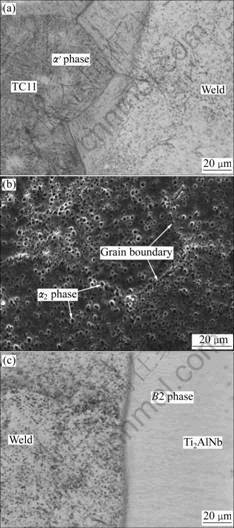

电子束焊接的Ti2AlNb/TC11接头焊态界面显微组织如图1所示。由图1可以看出,靠近焊缝的TC11合金侧热影响区的显微组织主要由针状马氏体α?相组成,其β晶粒在焊接过程中严重粗化(见图1(a));焊缝熔化区内β相稳定合金元素含量较高,熔池内的部分金属发生有序化,转变为B2相(见图1(b));Ti2AlNb合金侧热影响区为B2单相组织,晶界上无第二相析出(见图1(c))。但是,由于冷却速率较高,合金原子扩散程度有限,生成的O相数量也很有限,致使部分高温β相得以保留下来,与此同时,大量颗粒状α2相在晶内及晶界上析出,这些α2相的存在一方面增加焊缝组织的抗拉强度,另一方面使焊缝的脆性增大。

图1 焊态的Ti2AlNb/TC11接头界面的显微组织

Fig.1 Microstructures of interface of Ti2AlNb/TC11 joint: (a) Weld adjacent TC11 alloy side; (b) Weld; (c) Weld adjacent Ti2AlNb alloy side

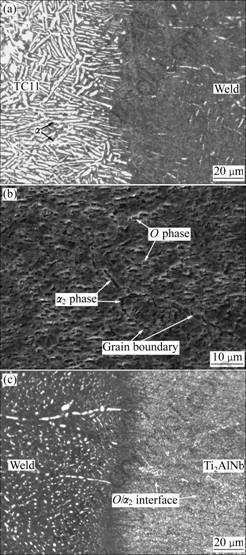

电子束焊接的Ti2AlNb/TC11试样进行等温变形和热处理后,结合界面的显微组织如图2所示。由图2(a)可以看出,TC11合金侧热影响区的显微组织为网篮状,条状α相随机分布在βt基体上,原始β晶界已完全消除,这主要是由于加热提供了内能,变形又提供了一定的晶格畸变能,促使不稳定的马氏体结构发生切变,使针状α′条切断,并进行了α′→α相的晶格重构,转变成晶体结构稳定的α相和β相,同时变形和扩散同步进行,使得原始β晶界α发生迁移、弯折或断裂所造成。焊缝熔化区在近等温变形和热处理后,显微组织为变形而少许伸长的O相和α2相颗粒弥散分布在B2相基体上,原始β晶界已基本破碎,但仍断续隐约可见(见图2(b))。这是由于在变形过程中,晶界及二次相周围会积累位错,当位错塞积到一定程度时,造成应力集中,局部能量升高,为了继续变形,那些位向关系不利于变形或者较厚的晶界处的位错塞积点就会生成新的晶核,那些利于变形位向关系的位错直接切过部分晶界移动,使原始β晶界α或α2破断。在Ti2AlNb合金侧热影响区(见图2(c)),晶界上及晶内均弥散分布着的细小O相和α2相,这是由于锻造温度相对于该合金而言较低,落入O相析出区,导致O相析出。对比图1(c)和2(c)可知,热影响区与焊接熔化区之间的痕迹已逐步淡化,这是某些合金元素扩散引起成分梯度减小、并逐步均匀所致。

图2 热加工后Ti2AlNb/TC11接头界面的显微组织

Fig.2 Microstructures of joint interface of Ti2AlNb/TC11 after hot working: (a) Weld adjacent TC11 alloy side; (b) Weld; (c) Weld adjacent Ti2AlNb alloy side

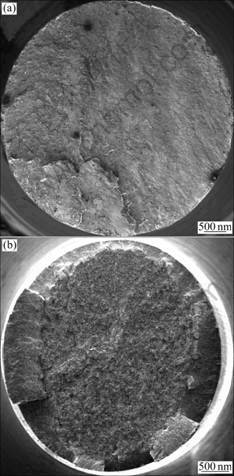

2.2 摩擦焊结合界面的显微组织变化

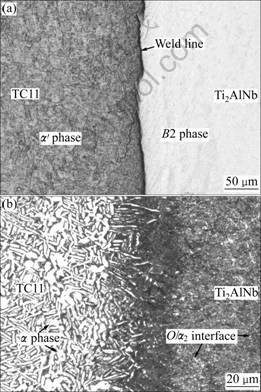

图3所示为线性摩擦焊接的Ti2AlNb/TC11试样热加工前后结合界面的显微组织。由图3(a)可以看出,TC11合金侧热影响区显微组织主要由小于15 μm的等轴β晶粒组成,在紧靠焊缝区前沿处有较长的屈曲波浪线。这是由于剧烈摩檫产生的热量过大,导致温度升高到α+β→β相转变温度以上,愈接近焊缝,温度愈高,造成β晶粒长大,在热量向基体传递的前沿,使得β晶界快速向此处迁移、连接,由于迁移阻力大小不等,所以造成波浪状曲线。在焊缝线上,TC11合金与Ti2AlNb合金发生相互镶嵌,这是由于两种合金的相关物理性能差别较大,如在相同温度下,Ti2AlNb合金的弹性模量高于TC11合金的,Ti2AlNb合金的流动应力也高于同等条件下TC11合金的,因此,在焊接过程中,两种合金的软化效果与塑性变形时间先后不一致。这种镶嵌现象在异种材料的线性摩擦焊接中较为常见[15]。在Ti2AlNb合金侧热影响区,可以见到大量平行于焊接界面的金属流线,这些流线在焊接前为O相或α2相,焊接过程中,O相和α2相发生变形,顺着金属流动方向被拉长。在焊接过程的最后阶段,因温度超过相转变点而转变成β相,随后的冷却又发生向B2相的有序化转变,并保持到室温。

图3 摩擦焊接的Ti2AlNb/TC11结合界面的显微组织

Fig.3 Microstructures of joint interface of Ti2AlNb/TC11 dual alloy welded by linear friction: (a) As-welded; (b) As- worked

近等温变形和热处理后,TC11合金侧热影响区显微组织为典型的双态组织(见图3(b)),只不过等轴α相含量偏少,愈靠近焊缝,α条愈薄愈细,这主要是由于近等温形变一方面使原始β晶界破碎,另一方面又有合金元素扩散和动态再结晶的作用,在热处理固溶期间,合金元素进一步扩散,α相发生溶解、界面晶格发生重构,合金元素愈深入Ti2AlNb基体,α相逐步减少、消失。在焊缝中心,存在一个宽约30 μm的显微组织“过渡区”,该区域内有一定量的α相和O相,且显微组织过渡平缓,这可能是在热加工过程中,焊态下的相互镶嵌金属及其周围的金属发生合金元素的剧烈扩散,甚至部分元素发生直接换位,进一步促进焊缝显微组织与合金元素的均匀化。Ti2AlNb合金侧热影响区显微组织为颗粒状或短棒状O相和α2相均匀分布在B2相基体上,与图2(c)对比可知,这些O相和α2相尺寸更细小,说明摩擦在焊接过程中,金属的剧烈流动有利于晶粒细化,其后的近等温变形和热处理有利于相粒子的进一步细化和合金元素的均匀化。

2.3 双合金热加工前后拉伸性能和断口形貌对比

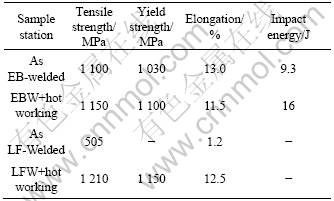

表1所列为不同焊接方法连接的双合金试样在不同状态下的室温力学性能,其对应的断口形貌如图4和5所示。从表1中可以看出,热加工后,电子束焊接(EBW)的Ti2AlNb/TC11试样拉伸强度只是略有提高,但焊缝冲击韧性提高幅度较大(达72%);不管是焊态还是热加工过的试样,拉伸时断裂均发生在TC11合金基体上,这是因为焊态的TC11合金侧为魏氏组织,塑性较低,而近等温变形和热处理后,TC11合金侧的显微组织尽管有所细化,但α相片条仍较粗、较长,裂纹容易沿相界面扩展所造成。鉴于冲击试样缺口设在结合界面处,在焊态下,脆性α2相在粗大的晶界上连续分布,增加了界面组织的脆性,导致室温冲击试样在焊缝内部发生沿晶开裂(图4(a));热加工后,由于焊缝组织中的晶界被破碎,晶粒内部的颗粒状α2相也发生了形变与晶格重构(部分转化为O相),并有所细化,晶界和晶内原子密排面方向差变小,室温冲击时,裂纹沿着晶内扩展并不断弯折(见图4(b)),焊缝组织中的基体塑性B2相得以发挥其吸收“冲击功”的能力,因此,其冲击韧性值得到较大提高。

线性摩擦焊接(LFW)的Ti2AlNb/TC11双合金试样,焊态的接头室温拉伸时沿着结合界面发生脆性断裂(见图5(a)),强度仅为505 MPa,这主要是由于连接界面未完全实现冶金结合。另一方面,焊件在高温下停留的时间短,合金元素几乎没有扩散,在垂直于焊缝的轴向化学成分存在突然的变化,紧挨焊缝的TC11合金侧热影响区的显微组织主要由针状马氏体α?相组成,而Ti2AlNb合金侧热影响区显微组织为B2单相组织,显微组织在焊缝上也是突然变化的。室温拉伸时,裂纹极易在α?/B2相界面上萌生并高速扩展,导致焊件发生脆性断裂。热加工后,合金元素得以充分扩散,成份变化已平缓地过渡,而焊缝组织也平缓连续过渡,由TC11合金侧热影响区的双态组织逐步向Ti2AlNb合金侧热影响区O+α2+B2三相均匀分布过渡(见图5(b)),过渡区内的各相细小弥散分布,使结合界面的强度超出了TC11合金侧热影响区的强度。以上实验结果说明,热力作用可以大幅度改善摩擦焊接的Ti2AlNb/ TC11双合金接头的显微组织,同时大大增强结合界面抗拉强度。

表1 不同状态下双合金试样的室温力学性能

Table 1 Room-temperature mechanical properties of LFW/ EBE joints before and after hot work

图4 电子束焊接的Ti2AlNb/TC11试样室温冲击断口形貌

Fig.4 Fractographs of impact specimens for EBW joints: (a) As-welded; (b) As-worked

图5 线性摩擦焊接Ti2AlNb/TC11试样室温拉伸断口形貌

Fig.5 Fractographs of tensile specimens for LFW joints: (a) As-welded; (b) As-worked

3 结论

1) 热力耦合作用能在一定程度上破碎电子束焊接的Ti2AlNb/TC11双合金焊缝熔化区的粗大晶界,同时使成分更加均匀,并和细化试样各部位显微组织,明显提高焊缝的冲击韧性值。

2) 等温变形和热处理的耦合作用可显著改变线性摩擦焊接的Ti2AlNb/TC11双合金结合界面的组织形态,使化学成分与显微组织逐步平缓过渡,大幅提高界面的室温抗拉强度和塑性。

REFERENCES

[1] JAMES C W, EDGAR A S. Progress in structural materials for aerospace systems [J]. Acta Mater, 2003, 51: 5775-5799.

[2] ALAIN L. Intermetallics: Why is it so difficult to introduce them in gas turbine engines [J]. Intermetallics, 2006, 14: 1123-1129.

[3] SUN Z, KARPPI R. The application of electron beam welding for the joining of dissimilar metals: An overview [J]. J Mater Process Technol, 1996, 59: 257-267.

[4] THREADGILL P L. The prospects for joining titanium aluminides [J]. Mater Sci Eng A, 1995, 192/193: 640-646.

[5] ZHANG H T, HE P, FENG J C, WU H Q. Interfacial microstructure and strength of the dissimilar joint Ti3Al/TC4 welded by the electron beam process [J]. Mater Sci Eng A, 2006, 425: 255-259.

[6] FENG J C, WU H Q, HE J S, ZHANG B G. Microstructure evolution of electron beam welded Ti3Al-Nb joint [J]. Mater Charact, 2005, 54: 99-105.

[7] QI Y L, DENG J, HONG Q, ZENG L Y. Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet [J]. Mater Sci Eng A, 2000, 280: 177-181.

[8] WANG Xiu-feng, MA Mo, LIU Xue-bin, WU Xue-qing, TAN Chao-gui, SHI Rong-kai, LIN Jiang-guo. Diffusion bonding of γ-TiAl alloy to Ti-6Al-4V alloy under hot pressure [J]. Trans Nonferrous Met Soc China, 2006, 16: 1059-1063.

[9] SHIUE R K, WU S K, CHEN Y T. Strong bonding of infrared brazed α2-Ti3Al and Ti-6Al-4V using Ti-Cu-Ni fillers [J]. Intermetallics, 2010, 18: 107-110.

[10] VAIRIS A, FROST M. High frequency linear friction welding of a titanium alloy [J]. Wear, 1998, 217: 117-131.

[11] VAIRIS A, FROST M. On the extrusion stage of linear friction welding of Ti6Al4V [J]. Mater Sci Eng A, 1999, 271: 477-484.

[12] TAN L J, YAO Z K, QIN C, GUO H Z, LI S Q. Linear friction and electron beam welded joints of Ti2AlNb/TC11 [J]. Advanced Materials Research, 2010, 97/101: 3895-3898.

[13] MOURER D P, RAYMOND E, GANESH S, HYZAK J. Dual alloy disk development [J]. Superalloys, 1996: 637-643.

[14] 高 峻, 姚泽坤, 梁新民, 刘莹莹,郭鸿镇. 热模锻造对Ti-24Al-15Nb-1.5Mo/TC4双合金界面连接强度与组织的影响[J]. 航空材料学报, 2008(2): 14-18.

GAO Jun, YAO Ze-kun, LIANG Xin-min, LIU Ying-ying, GUO Hong-zhen. Effect of hot-die forging on interfacial strength and microstructure at welded seam of Ti-24Al-15Nb-1.5Mo/TC4 dual alloys [J]. Journal of Aeronmautical Materials, 2008, 28(2): 14-18.

[15] BAESLACK III W A, BRODERICK T F, JUHAS M, FRASER H L. Characterization of solid-phase welds between Ti-6A1-2Sn- 4Zr-2Mo-0.1Si and Ti-13.5A1-21.5Nb titanium aluminide [J]. Mater Charact, 1994, 33: 357-367.

(编辑 李艳红)

通信作者:姚泽坤; 电话: 029-88493744; E-mail: yzekun@nwpu.edu.cn